Method for synthesizing fire resistant clathrate multi-ring phosphoric acid ester for engineering plastic

A polycyclic phosphate, engineering plastics technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. The problem of plastic thermal deformation temperature drop, etc., to achieve the effect of easy quality assurance, low manufacturing cost and high temperature resistance

Inactive Publication Date: 2010-11-10

BEIJING INSTITUTE OF TECHNOLOGYGY

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In the process of researching and developing substitutes for brominated flame retardants, phosphorus and phosphorus-nitrogen flame retardants are the first to be favored and valued, and the most studied are halogen-free phosphates, but phosphoric acid esters that can be used for flame-retardant plastics Esters cannot meet the application requirements of plastics (especially high-grade downstream plastics) due to the following problems

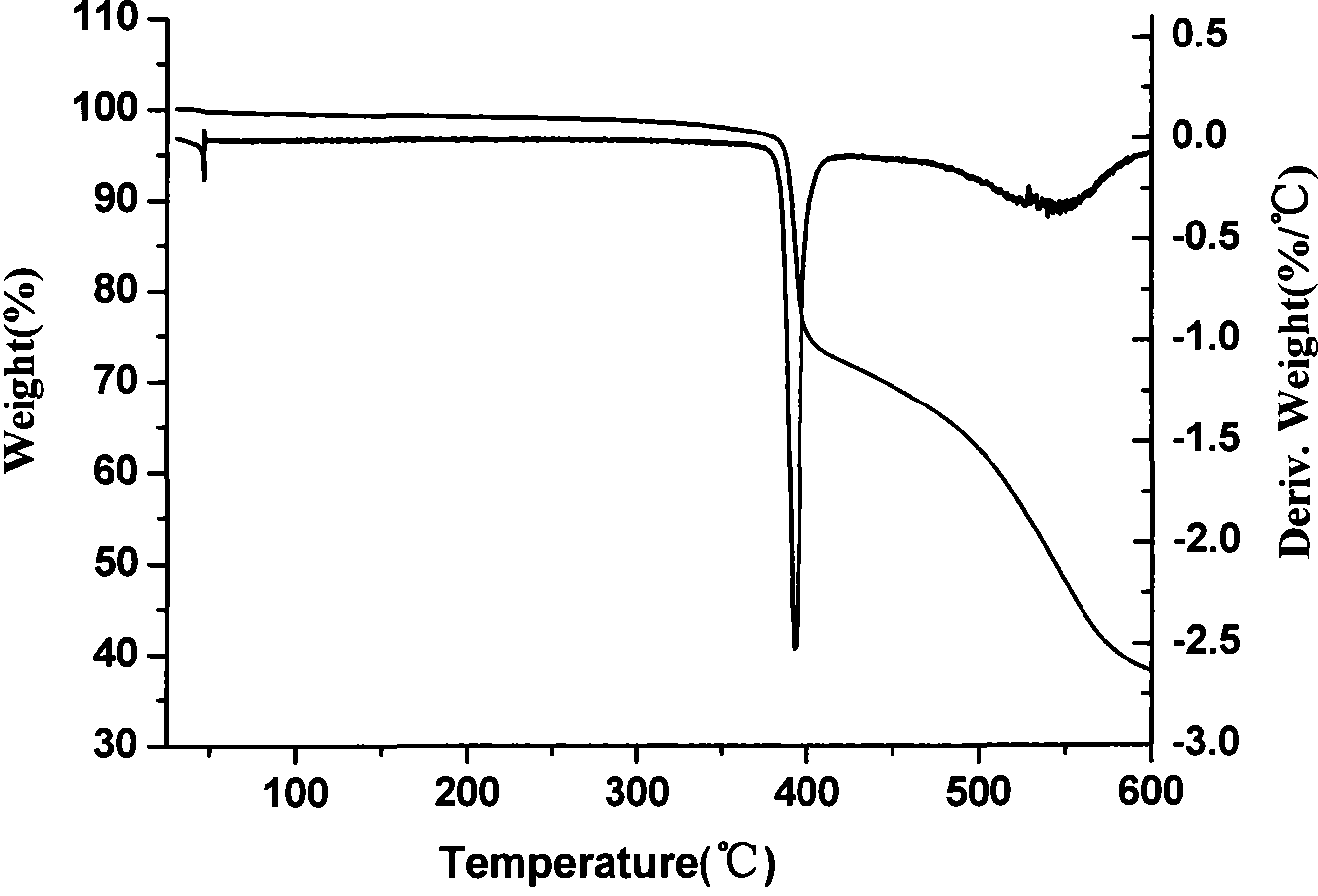

(1) Most of them have low heat resistance, and the initial decomposition temperature is mostly below 250°C, which cannot withstand the processing temperature of engineering plastics; (2) The phosphorus content is low, generally not exceeding 10%, so the flame retardant efficiency is limited; (3) ) are water-soluble and have low hydrolytic stability; (4) most of them have a large plasticizing effect, which reduces the heat distortion temperature of plastics; (5) there are currently some phosphate esters with high thermal stability, such as aromatic Bisphosphonates, but they are liquid, difficult to process, and have a significant plasticizing effect

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Login to View More

Abstract

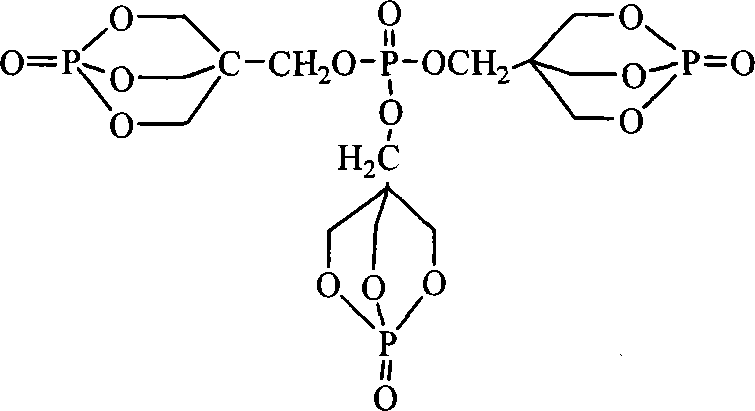

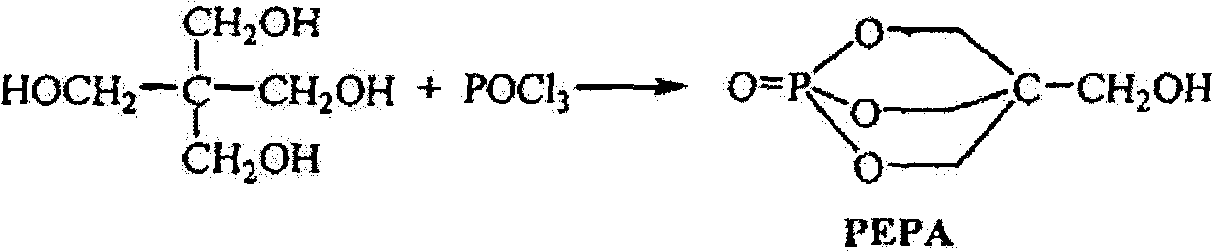

The invention relates to a synthesis method of engineer plastic high temperature resistant cage-type cyclic phosphate-3(1-oxo-1-phosphacyclopentene-2, 6, 7-trioxabicyclo [2, 2, 2] octane-4-methano) phosphate (abbreviated as trimer), wherein the trimer has symmetry cage-type cyclic structure (as below). The trimer has high temperature resistance (320DEG C) and phosphor content of 21.2%, which is not dissolved in water and is stable for hydrolysis. The trimer not contains halogen, affects little on flame retardant substrate and thermal deformation temperature. The synthesis materials are easilyaccessible. The invention has mild reaction conditions, low energy consumption, stable and controllable operation, while the yields in two steps both reach 90% at least, the hydrochloride generated in synthesis is completed absorbed, the generated some waste water can be treated biochemically to be discharged at standard, and the solvent can be circulated, to reduce environment pollution.

Description

A kind of synthetic method of high temperature resistant clathrate polycyclic phosphate for engineering plastics technical field The invention relates to the synthesis of a phosphate flame retardant, belonging to the field of chemical synthesis. Background technique Cage-type cyclic phosphate is a new type, high-efficiency, temperature-resistant flame retardant, which belongs to the additive type. It can be blended with high polymer base material through a twin-screw extruder to produce flame-retardant plastics, especially high-grade flame-retardant engineering plastics, which are widely used in the manufacture of high-tech electronics, precision machinery, aerospace, etc. Devices and components to ensure the safety of products, reduce and eliminate fire hazards. Scientific experiments and years of practical experience have proved that the use of flame-retardant materials (mainly flame-retardant plastics) is one of the most important strategic measures to improve the fire...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C07F9/6574C08K5/527

Inventor 欧育湘李昕房小敏赵毅

Owner BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com