TiNi shape memory alloy and stainless steel instant liquid-phase diffusion welding connection method

A technology of memory alloy and instantaneous liquid phase, applied in welding equipment, welding/welding/cutting items, non-electric welding equipment, etc., to relieve welding stress, improve mechanical properties and shape memory performance, and high corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1) Cut the TiNi shape memory alloy and stainless steel 304 into rectangular strips of 30×10×2mm, and grind them step by step with sandpaper until the surface is smooth and metallic, then put them into acetone solvent for ultrasonic cleaning for 10 minutes, and wipe them to dry;

[0022] 2) Cut the Ag72Cu28Ti0 metal foil with a thickness of 20μm into a square of 10×10mm, put it in acetone solvent and ultrasonically clean it for 10min, wipe it clean and dry it;

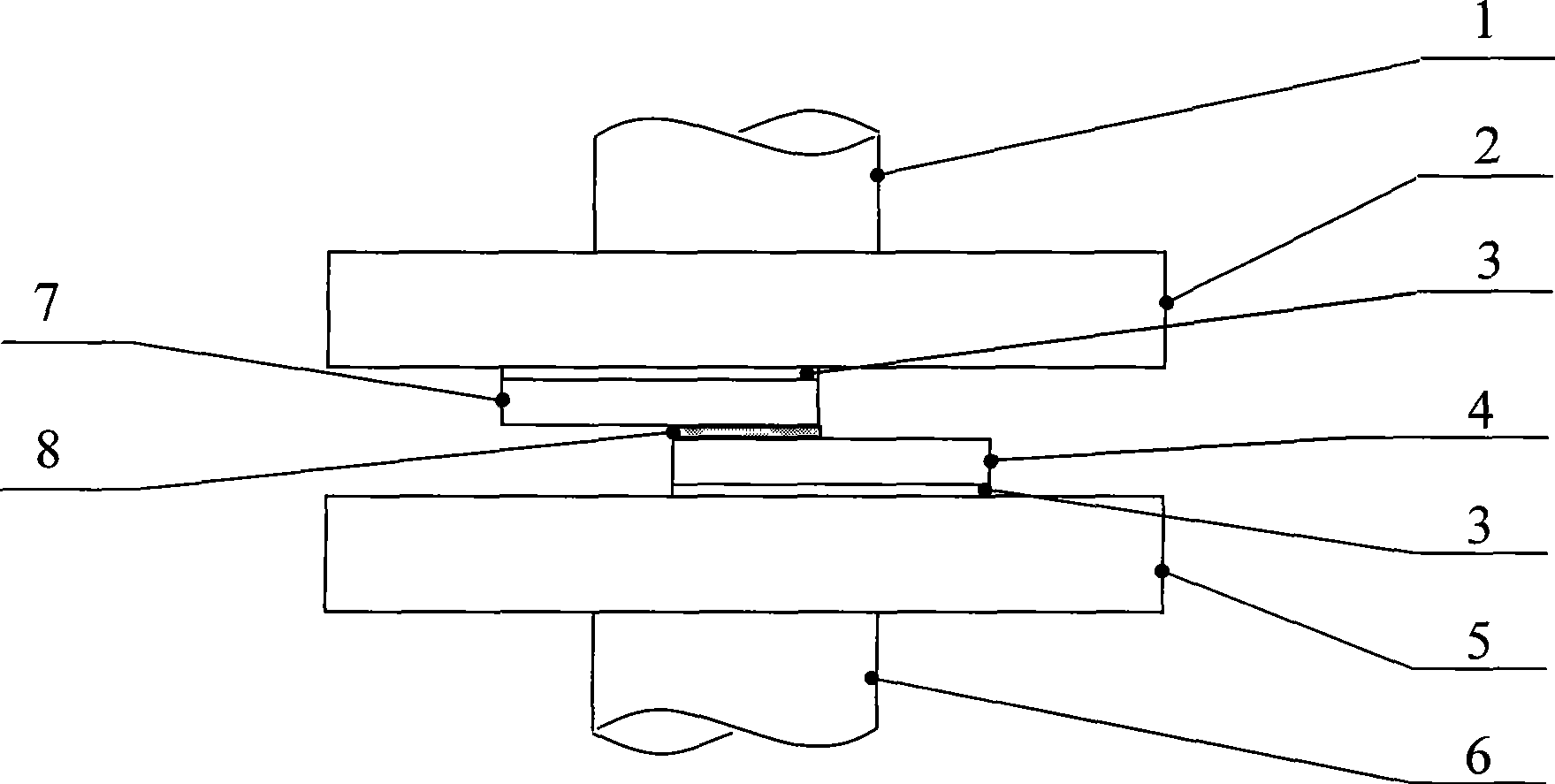

[0023] 3) Put the Ag72Cu28Ti0 metal foil between the TiNi shape memory alloy and stainless steel 304 to form a sandwich structure of TiNi shape memory alloy / Ag72Cu28Ti0 metal foil / stainless steel 304, and then fix it with a clamp (such as figure 1 shown), and placed in the vacuum chamber of the diffusion furnace, pre-coated solder resist on the contact surface of the welding fixture, TiNi shape memory alloy and stainless steel 304;

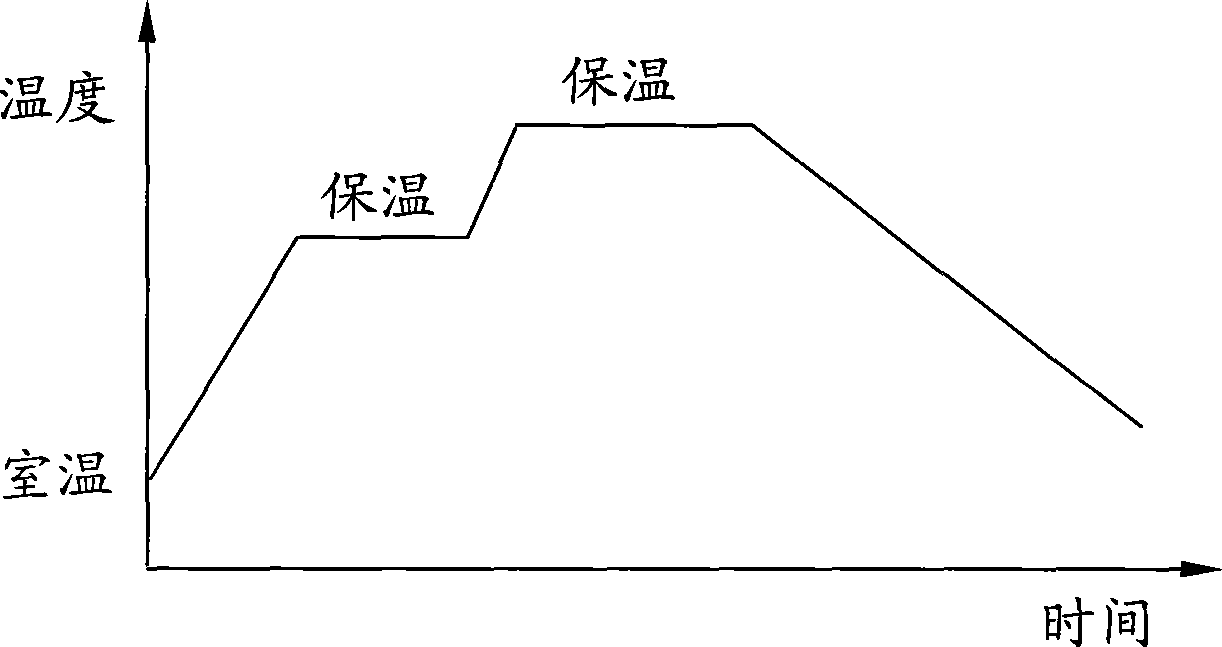

[0024] 4) Close the door of the vacuum chamber, apply a welding pressure of 0.05...

Embodiment 2

[0027] 1) Cut the TiNi shape memory alloy and stainless steel 304 into rectangular strips of 30×10×2mm, and grind them step by step with sandpaper until the surface is smooth and metallic, then put them into acetone solvent for ultrasonic cleaning for 10 minutes, and wipe them to dry;

[0028] 2) Cut the Ag62Cu27Ti11 metal foil with a thickness of 50 μm into a square of 10×10 mm, put it in acetone solvent and ultrasonically clean it for 10 minutes, wipe it and dry it;

[0029] 3) Place the Ag62Cu27Ti11 metal foil between the TiNi shape memory alloy and stainless steel 304 to form a sandwich structure of TiNi shape memory alloy / Ag62Cu27Ti11 metal foil / stainless steel 304, and fix it with a clamp (such as figure 1shown), and placed in the vacuum chamber of the diffusion furnace, pre-coated solder resist on the contact surface of the welding fixture, TiNi shape memory alloy and stainless steel 304;

[0030] 4) Close the door of the vacuum chamber, apply a welding pressure of 0.1M...

Embodiment 3

[0033] 1) Cut the TiNi shape memory alloy and stainless steel 304 into rectangular strips of 30×10×2mm, and grind them step by step with sandpaper until the surface is smooth and metallic, then put them into acetone solvent for ultrasonic cleaning for 10 minutes, and wipe them to dry;

[0034] 2) Cut the Ag67Cu20Ti13 metal foil with a thickness of 100 μm into a square of 10×10 mm, put it in acetone solvent and ultrasonically clean it for 10 minutes, wipe it and dry it;

[0035] 3) Place the Ag67Cu20Ti13 metal foil between the TiNi shape memory alloy and stainless steel 304 to form a sandwich structure of TiNi shape memory alloy / Ag67Cu20Ti13 metal foil / stainless steel 304, and fix it with a clamp (such as figure 1 shown), and placed in the vacuum chamber of the diffusion furnace, pre-coated solder resist on the contact surface of the welding fixture, TiNi shape memory alloy and stainless steel 304;

[0036] 4) Close the door of the vacuum chamber, apply a welding pressure of 2M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com