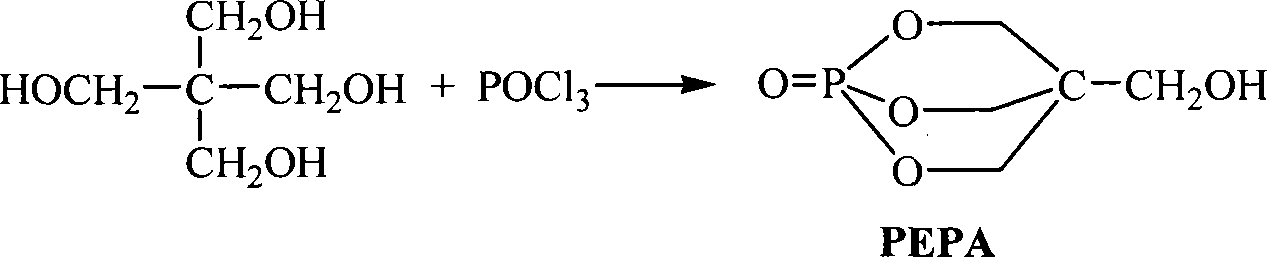

Method for synthesizing fire resistant clathrate multi-ring phosphoric acid ester for engineering plastic

A technology of engineering plastics and high temperature resistance, which is used in the synthesis of phosphate ester flame retardants, can solve the problems of not being able to withstand the processing temperature of engineering plastics, unable to meet the application requirements of plastics, and reducing the thermal deformation temperature of plastics. Low-cost, easy-to-absorb effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In a 500ml four-neck flask equipped with a thermometer, constant pressure dropping funnel, mechanical stirring, reflux condenser and drying tube, add 150ml of acetonitrile, 6g of catalyst anhydrous aluminum trichloride and 113g of PEPA in sequence, and heat the mixture to reflux under stirring. , Add dropwise 18.5ml of phosphorus oxychloride. After the dropwise addition, keep warm at 80-83°C and reflux for 12 hours until no hydrogen chloride gas is released. Cool to room temperature, filter, wash with water until the filtrate is neutral, dry and weigh. Yield 80.5%.

Embodiment 2

[0026] In a 500ml four-neck flask equipped with a thermometer, constant pressure dropping funnel, mechanical stirring, reflux condenser and drying tube, add 150ml of acetonitrile, 1.5g of ferric chloride and 110g of PEPA in sequence, and heat the mixture to reflux under stirring for 2.5h Add 18ml of phosphorus oxychloride dropwise. After the dropwise addition, keep warm at 80-83°C for reflux reaction for 11 hours (when almost no hydrogen chloride is absorbed, hydrogen chloride is distilled intermittently under a certain negative pressure). Cool to room temperature, filter, wash with boiling water until the filtrate is neutral, dry, and weigh. Yield 87.2%.

Embodiment 3

[0028] In a 500ml four-necked flask equipped with a thermometer, a constant pressure dropping funnel, mechanical stirring, a reflux condenser and a drying tube, add 150ml of acetonitrile, 3.5g of ferric chloride and 110g of PEPA in sequence, and heat the mixture to reflux under stirring. Add 18ml of phosphorus oxychloride dropwise, keep warm at 80-83°C for reflux reaction for 14h (when almost no hydrogen chloride is absorbed, hydrogen chloride is intermittently evaporated at a certain negative pressure). Cool to room temperature, filter, wash with boiling water until the filtrate is neutral, dry, and weigh. The yield is 90.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com