Phosphorus-contained organic silicon resin fire retardant and preparation method thereof

A technology of silicone and flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

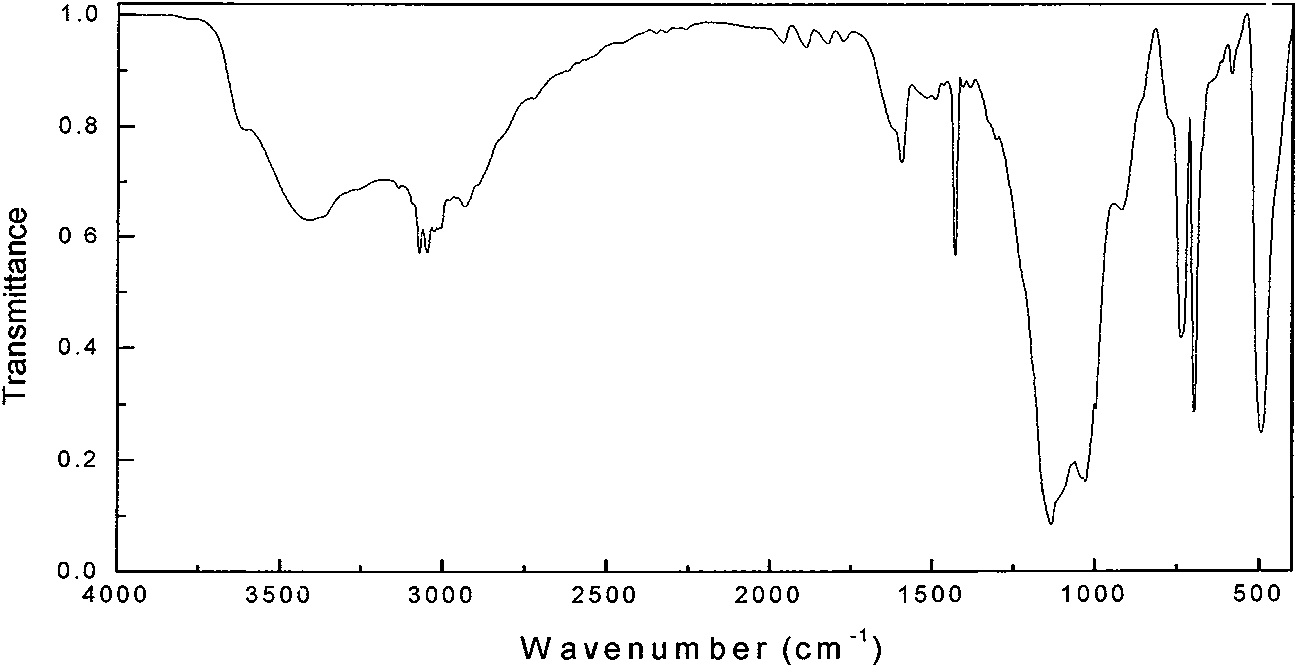

[0043] (a) A 500ml three-neck flask is equipped with a stirrer, a thermometer, and a spherical condenser, weighs 1.0 moles of pentaerythritol and 3.5 moles of phosphorus oxychloride, stirs and mixes, controls the reaction temperature at 20°C, and absorbs the gas in the reaction with an alkaline solution The product was reacted for 6 hours until no gas was released, and a precipitated substance was obtained from the reaction. Cool, filter, wash with chloroform solvent, remove unreacted substances, and dry under vacuum at 80°C to finally obtain a white solid powder which is chlorinated spirocyclic phosphate. attached figure 1 It is the infrared spectrum of chlorinated spirocyclic phosphate: 1308cm -1 It is the characteristic absorption peak of P=O, 1016cm -1 Stretching vibration absorption for P-O-C

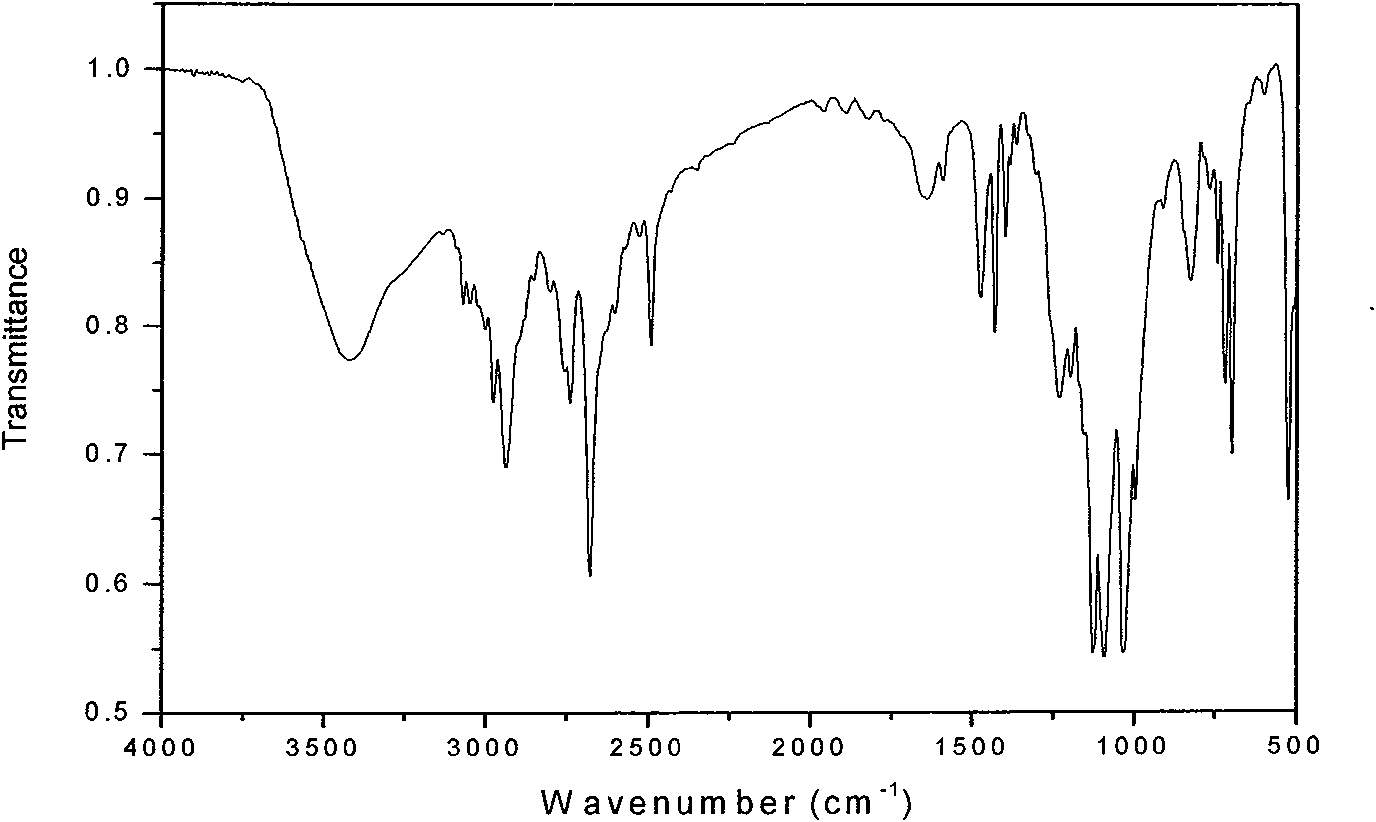

[0044] (b) Equip a 500ml four-necked flask with a stirrer, a thermometer, a spherical condenser and a 100ml constant pressure funnel, add 500mL of deionized water, and prepare t...

Embodiment 2

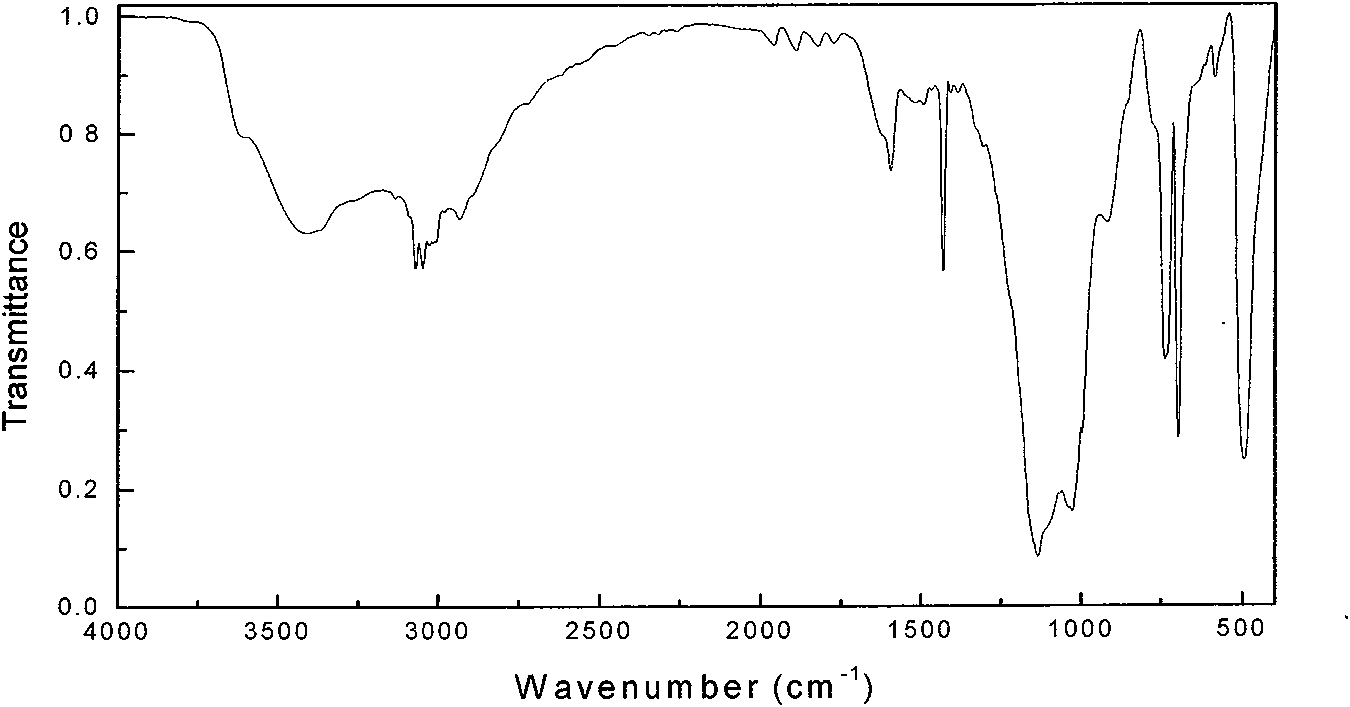

[0047] (a) Weigh 1.0 moles of polyol and 3.5 moles of phosphorus oxychloride, stir and mix, control the reaction temperature at 20°C, absorb the gas products in the reaction with alkaline solution, react for 6 hours, until no gas is released, and the reaction is precipitated substance. Cool, filter, wash with solvents such as chloroform, remove unreacted substances, and dry in vacuum to finally obtain a white solid powder which is chlorinated spirocyclic phosphate.

[0048] (b) A 500ml four-neck flask is equipped with a stirrer, a thermometer, a spherical condenser and a 100ml constant pressure funnel, and 250mL of deionized water is added to react the monomers aminopropylmethyldimethoxysilane and phenyltrimethoxysilane , dimethyldiethoxysilane, and methyltriethoxysilane were respectively added to the constant pressure funnel, the reaction temperature was controlled at 40°C, and the reaction monomer was added dropwise at an even speed. After the dropwise addition, continued hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com