Patents

Literature

174 results about "Ethylene thiourea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ethylene thiourea (ETU) is an organosulfur compound with the formula C3H6N2S. It is an example of an N,N-disubstituted thiourea. It is a white solid. It is synthesized by treating ethylenediamine with carbon disulfide.

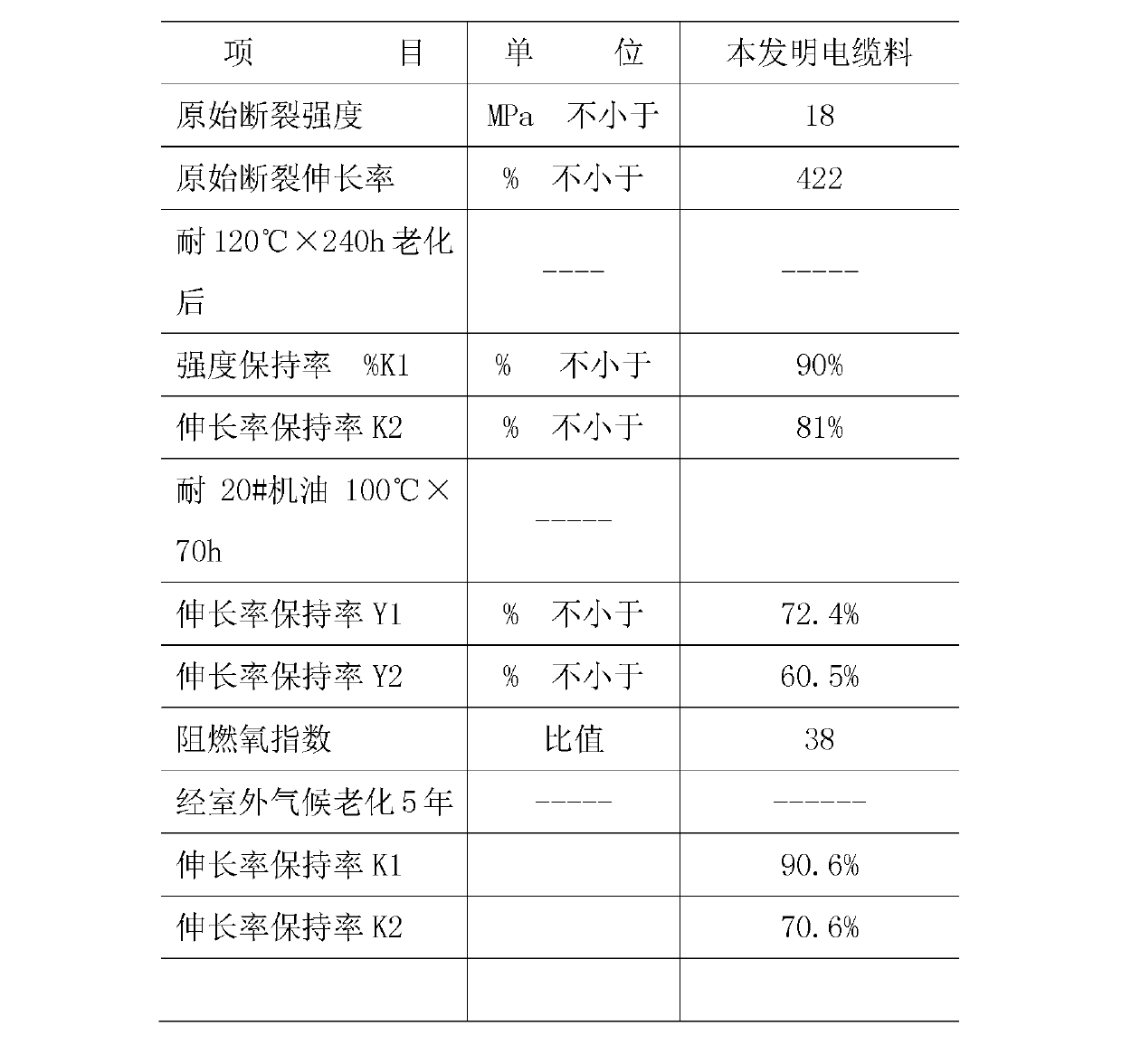

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

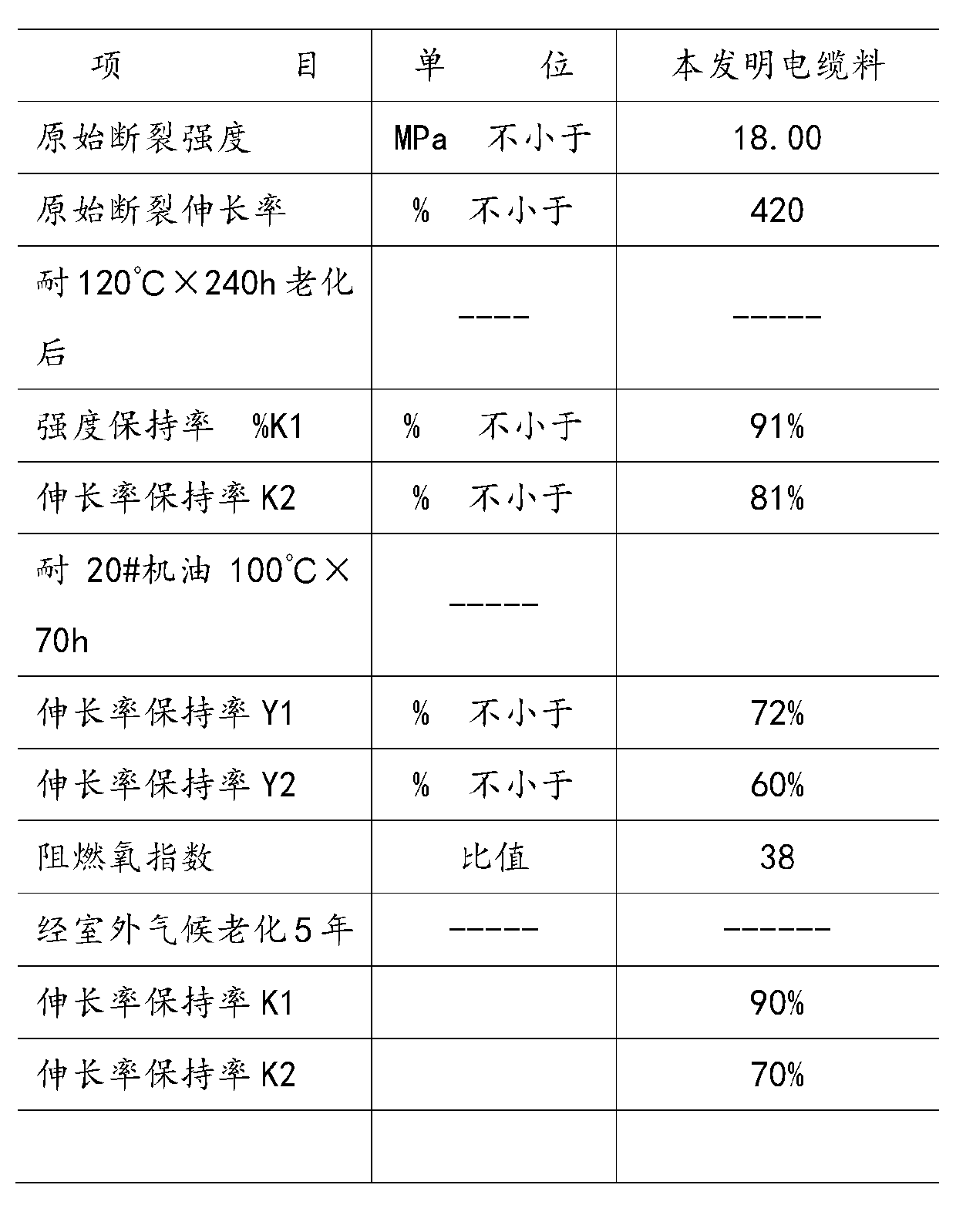

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

Stretch-proof cable sheath insulation material and preparation method thereof

InactiveCN102993518AGood physical propertiesDimensionally stableRubber insulatorsPlastic/resin/waxes insulatorsLead phosphateEthylene thiourea

The invention discloses a stretch-proof cable sheath insulation material and a preparation method thereof. The stretch-proof cable sheath insulation material comprises the following raw materials in parts by weight: 90-100 parts of neoprene CR121, 18-20 parts of chlorinated polyethylene, 15-25 parts of semi-reinforcing carbon black N774, 2-3 parts of magnesium oxide, 1-2 parts of ferrocene, 30-35 parts of mica powder, MB1-2 of antiager MB, 1-2 parts of 2-thiol group benzimidazole, 5-8 parts of dioctyl maleate, 1-2 parts of promoter DM1, 0.8-1 part of dibasic lead phosphate, 12 to 18 parts of nanometer silicon dioxide, 1-3 parts of 4, 4'- oxylbisbenzenesulfonyl hydrazide, 2-4 parts of antioxidant DSTP, 4-6 parts of glass powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony oxide and 4-6 parts of ethylene thiourea. The stretch-proof cable sheath insulation material prepared by the method has the advantages of excellent physical properties, stable size, low percentage of contraction and greatly increased tensile strength, tearing strength resistance and resilience force performance.

Owner:安徽文峰电子科技集团有限公司

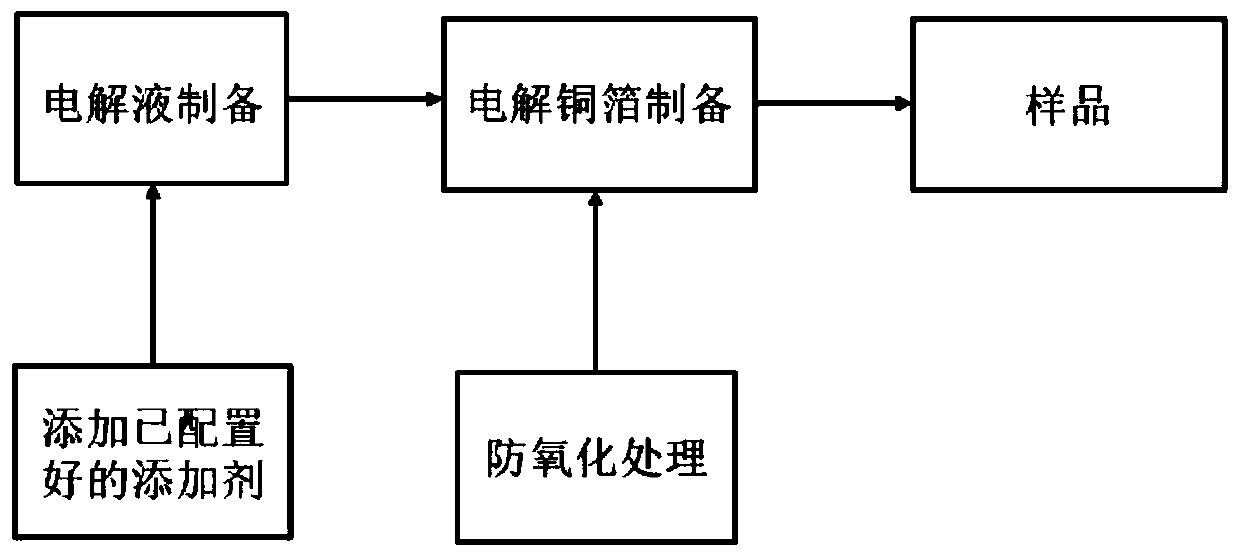

Mixed additive for electrolytic copper foil, preparation method for mixed additive, and method for preparing ultralow-profile electrolytic copper foil

InactiveCN102383148AImprove performanceImprove bending resistanceElectroforming processesSulfonateElectrolysis

The invention provides a mixed additive for an ultralow-profile (VLP) electrolytic copper foil. The invention is characterized in that: each liter of mixed additive comprises 0.3 to 2g of Arabic gum (AG), 1 to 2.5g of hydroxyethylcellulose (HEC), 0.5 to 1.6g of gelatin (Glue), 0.5 to 1.5g of sodium dithiodipropane sulfonate (SPS) and 0.01 to 0.1g of ethylene thiourea (N). In the 12-micron VLP copper foil produced by the mixed additive, the tensile strength at normal temperature (23 DEG C) is more than 380 MPa; the elongation percentage at normal temperature is more than 6 percent; the tensile strength at high temperature (180 DEG C) is more than 200 MPa; and the elongation percentage at high temperature is more than 8 percent. The roughness Rz of the crystal growth surface (M surface) is 1.5 to 2.5 mu m. The mixed additive is particularly applicable to a flexible printed circuit board (FPC) and a lithium ion battery.

Owner:SHANDONG JINBAO ELECTRONICS

Slag pot carrier cable sheath material and manufacturing method thereof

InactiveCN102344590AImprove mechanical propertiesHigh tensile strengthInsulated cablesInsulated conductorsHigh fractureSlag

The invention discloses a slag pot carrier cable sheath material and a manufacturing method thereof. The slag pot carrier cable sheath material comprises 23 parts of chloroprene rubber CR3221, 1.2 to 1.5 parts of zinc oxide, 1 to 1.5 parts of magnesium oxide, 0.1 to 0.3 parts of tetramethylthiuram disulfide (TMTD), 0.2 to 0.3 parts of ethylene thiourea (ETU), 1.0 to 1.3 parts of dioctyl sebacate (DOS), 0.45 to 0.6 parts of dioctyl phthalate (DOP), 0.1 to 0.15 parts of stearic acid (SA), 1.2 to 1.4 parts of microcrystalline paraffin, 0.9 to 1.2 parts of iso-octyl decyl adipate (ODA), 0.1 to 0.15 parts of N-(p-toluene-sulphonylamido-N'-phenylene diamine) (TPPD), 0.2 to 0.4 parts of 4,4-bis(alpha,alpha-dimethylbenzyl)diphenylamine (HS)-911, 5 to 8 parts of carbon black, 4.5 to 6 parts of semi-reinforced carbon black, 0.5 to 0.7 parts of vaseline, 8 to 10 parts of calcining potter's clay and 3 to 4 parts of calcium carbonate. The manufacturing method comprises the following steps of 1, mixing the chloroprene rubber CR3221 for 5 to 7 minutes, 2, adding the magnesium oxide as an active agent, the zinc oxide as an active agent, the microcrystalline paraffin, the SA, the calcium carbonate, the DOP, the carbon black, the DOS, the semi-reinforced carbon black and the vaseline into the mixture obtained by the step 1 to carry out mix for 9 to 11 minutes, 3, adding the calcining potter's clay, the ODA, the TPPD, the HS-911, the TMTD and the ETU into the mixture obtained by the step 2 to carry out mixing, wherein the TMTD and the ETU are added at the last 90 seconds, and 4, moving the mixture obtained by the step 3 to an open mill to carry out tabletting, turning eight triangular cornerites, and cutting into tablets. A cable sheath prepared from the slag pot carrier cable sheath material has the advantages of excellent mechanical properties, high tensile strength, high fracture elongation, aging resistance and oil resistance.

Owner:JIANGSU YUANYANG DONGZE CABLE

Flame-retardant type cable sheath insulation material and preparation method thereof

InactiveCN103012885ASo as not to damageGuarantee unimpededRubber insulatorsPlastic/resin/waxes insulatorsPolyesterEthylene thiourea

The invention discloses a flame-retardant type cable sheath insulation material and a preparation method thereof. The flame-retardant type cable sheath insulation material comprises the following raw materials in parts by weight: 94-102 parts of neoprene CR121, 16-21 parts of chlorinated polyethylene, 16-22 parts of semi-reinforcing carbon black N774, 2-4 parts of magnesium oxide, 1-2 parts of glass powder, 32-36 parts of mica powder, 1-2 parts of anti-aging agents MB, 1-2 parts of 2-thiol-group benzimidazole, 5-7 parts of polyamide wax micropowder, 1-2 parts of accelerants DM, 0.8-1 part of accelerants TMTD, 18-23 parts of kaolin, 1-3 parts of adipic acid propanediol polyester, 2-4 parts of zinc borate, 4-6 parts of talcum powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony trioxide, 4-6 parts of ethylene thiourea, 4-6 parts of ethylene bis stearamide, 0.7-0.9 part of di-n-octyltin bis(isooctyl thioglycollate) and 0.5-0.8 part of bis(P,P-bis-ethylhexyl diphosphato) ethanediolato titanate. The flame-retardant type cable sheath insulation material disclosed by the invention has characteristics superior to those of common rubber and flame-retardant rubber, namely, the flame-retardant type cable sheath insulation material disclosed by the invention has the property of common silicon rubber at normal temperature, and a rigid shell after is formed being ablated by high temperature flames so as to protect the burnt object not to be damaged.

Owner:安徽文峰电子科技集团有限公司

Curable composition

ActiveUS20160051450A1Excellent long-term storage stabilityModerate curabilityImpression capsDentistry preparationsThioureaMonomer

The present invention provides a novel curable composition in which a reaction is caused to occur between a hydroperoxide and a thiourea compound to initiate polymerization of a radical polymerizable monomer and which has excellent adhesive properties, moderate curability, and excellent long-term storage stability. The present invention relates to a curable composition (A) containing: a radical polymerizable monomer (a1) having no acidic group; a hydroperoxide compound (a2); and at least one cyclic thiourea compound (a3) selected from the group consisting of a substituted ethylenethiourea compound (a3-1), a substituted propylenethiourea compound (a3-2), and a substituted butylenethiourea compound (a3-3) each having a specific structure with a cyclic structure moiety into which a substituent is introduced.

Owner:KURARAY NORITAKE DENTAL

Environmental-friendly termite-resistant cable sheath insulating material and method for preparing same

InactiveCN102993521AMeet the use requirementsGood physical propertiesRubber insulatorsPlastic/resin/waxes insulatorsPolyesterEnvironmental resistance

The invention discloses an environmentally-friendly termite-resistant cable sheath insulating material and a preparation method thereof. The material is prepared from the following raw materials in parts by weight: 90-97 parts of chloroprene rubber (CR) 121, 15-21 parts of chlorinated polyethylene, 15-22 parts of semi-reinforcing purpose furnace black N774, 2-3 parts of magnesium oxide, 2-5 parts of glass powder, 30-35 parts of barite powder, 1-2 of anti-aging agent MB, 1-2 of N-(beta-aminoethyl)-gamma-3-aminopropyltrimethoxysilane, 0.9-1.4 of poly(1, 2-propylene glycol adipate, 5-77 parts of dioctyl maleate, 1-2 parts of accelerator DM, 0.8-1 part of dibasic lead phosphite, 12-18.4 parts of hydrotalcite, 1-3 parts of 4, 4'-oxybis(benzenesulfonyl hydrazide), 2-4 parts of antioxidant DSTP, 4-6 parts of glass powder, 0.8-1 part of zinc oxide, 2-3 parts of modified calcium carbonate, 5-6 parts of antimony oxide, 3-5 parts of ethylene thiourea and 0.8-1 part of modified bentonite. The produced environmentally-friendly termite-resistant cable sheath insulating material has excellent physical performance, stable dimensions and low shrinkage factor, and the tensile strength, tear resistance and elastic force performance of a product are all greatly improved.

Owner:安徽文峰电子科技集团有限公司

Electronic engraving printing gravure hard copper additive

The invention discloses an electronic engraving printing gravure hard copper additive which comprises a hardening agent and a gloss agent. The hardening agent is prepared from ethylene thiourea, polyethylene glycol, thiazoline-based dithio-propane sulfonate, a wetting agent, 98% sulfuric acid and purified water. The gloss agent is prepared from dithiobis-1-propanesulfonic acid disodium salt, phenyl disulfamate sodium sulfonate, acid copper leveling strong walking agent, acid copper middle-lower area walking agent, high-molecular polymer, sulfhydrazole, acid copper yellow dye, 98% sulfuric acid, 98% hydrochloric acid and purified water. The components and matching ratio are scientific and reasonable, water is added in batches, the components are sequentially added, the hardening agent and the gloss agent are prepared, the preparation process is simple, the additive is effectively used for electronic engraving printing gravure electroplating industry, and the prepared copper plating layer is large in hardness, good in smooth degree, good in flexibility and capable of being effectively stored for a long time.

Owner:三门峡毕昇制版科技股份有限公司

High-temperature resistant cable sheath insulation material and preparation method thereof

InactiveCN102993522AGood physical propertiesDimensionally stableRubber insulatorsPlastic/resin/waxes insulatorsPolyesterSodium Bentonite

The invention discloses a stretch-proof cable sheath insulation material and a preparation method thereof. The stretch-proof cable sheath insulation material comprises the following raw materials in parts by weight: 97-103 parts of neoprene CR121, 13-17 parts of SG-4 type PVC (Polyvinyl chloride) resin, 14-22 parts of semi-reinforcing carbon black N774, 2-3 parts of magnesium oxide, 1-2 parts of aluminic acid ester coupling agent, 30-33 parts of blanc fixe, 1-2 parts of antiager MB, 1-2 parts of 2-thiol group benzimidazole, 5-7 parts of polyamine wax micro powder, 1-2 parts of promoter DM1, 0.8-1 part of promoter TMTD, 14-18 parts of high wear resistance carbon black N330, 1.-1.2 parts of adipic acid propylene glycol polyester, 2-4 parts of zinc borate, 4-6 parts of glass powder, 0-8-1 part of zinc oxide, 2-3 parts of modified bentonite, 4-6 parts of ethylene thiourea, 2-3 parts of ammonium dihydrogen phosphate and 0.8-1 part of N-2-(amino ethyl group)-3-aminopropyl trimethoxy silane. The stretch-proof cable sheath insulation material prepared by the method has the advantages of excellent physical properties, stable size, low percentage of contraction and greatly increases tensile strength, tearing strength and resilience force performance and has the performances of common silicon rubber at the normal temperature and forms a hard shell after ablated in high-temperature fire to protect a burned objected from being damaged.

Owner:安徽文峰电子科技集团有限公司

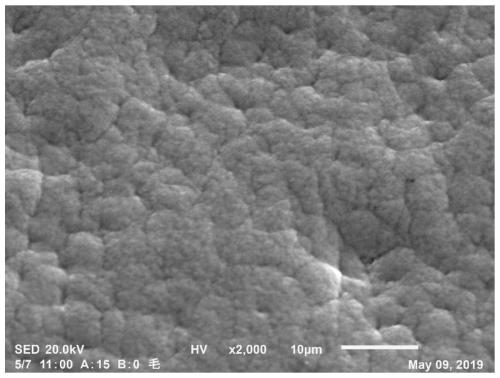

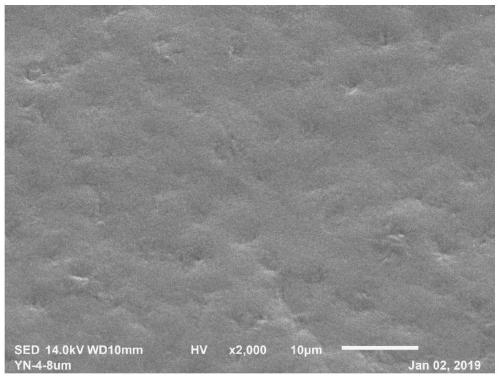

Composite additive for producing low-profile electrolytic copper foil and sedimentation process of composite additive

InactiveCN106521564AUniform crystal particlesSmall crystal particlesElectroforming processesSulfonateElectrolysis

The invention belongs to the technical field of electrolytic copper foil and particularly relates to a composite additive for producing low-profile electrolytic copper foil and a sedimentation process of the composite additive. The composite additive comprises four or more compounds of 3-sulfydryl propane sodium sulfonate, ethylene thiourea, small-molecule gelatin, sodium dodecyl sulfonate and hydroxyethyl cellulose. The copper foil made of the additive is high in tensile strength and elongation; grains at the rough-face side of the copper foil are refined; surface roughness is lowered, but certain peeling strength is still maintained; and the composite additive has great market prospect and economic value.

Owner:建滔(连州)铜箔有限公司

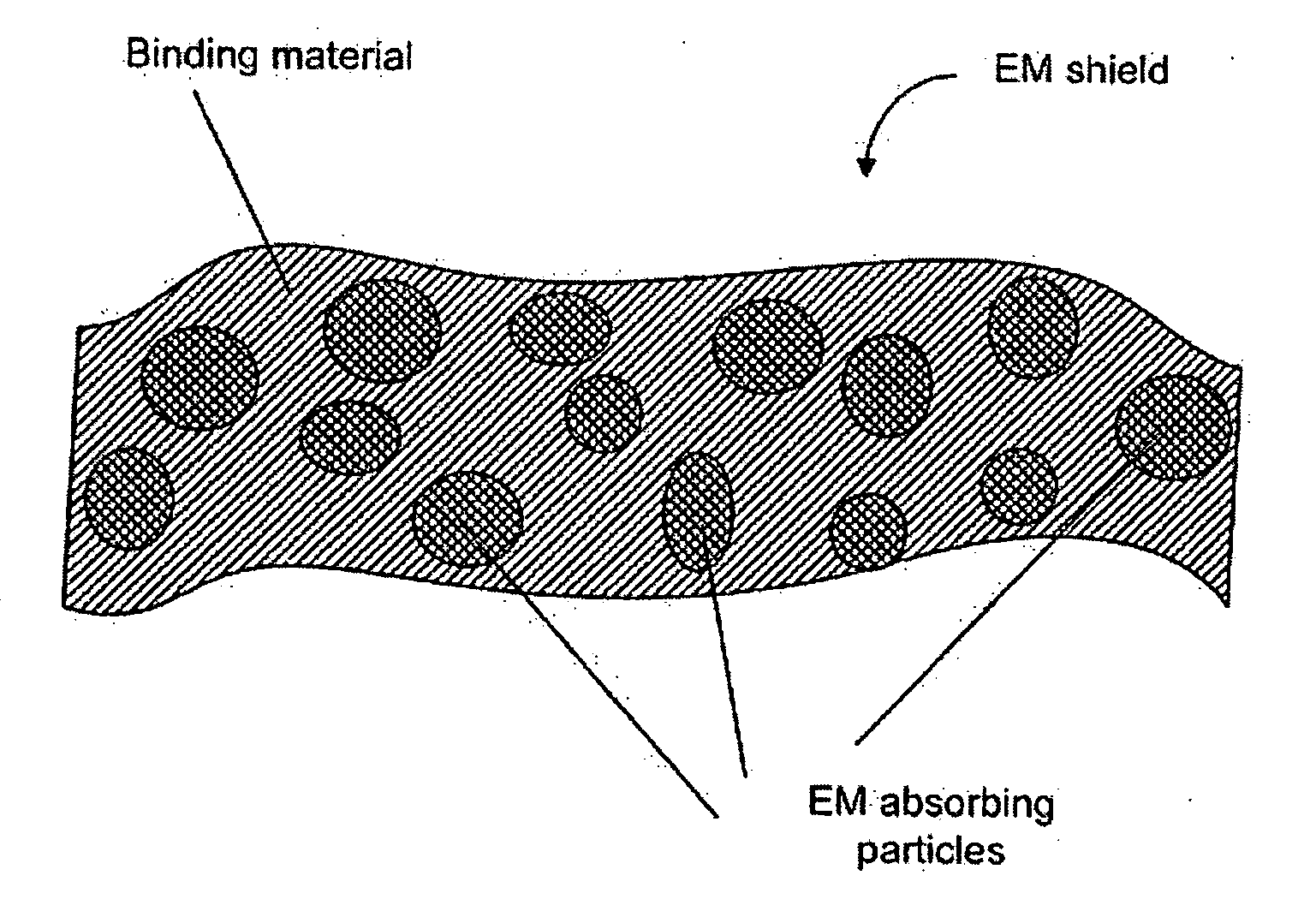

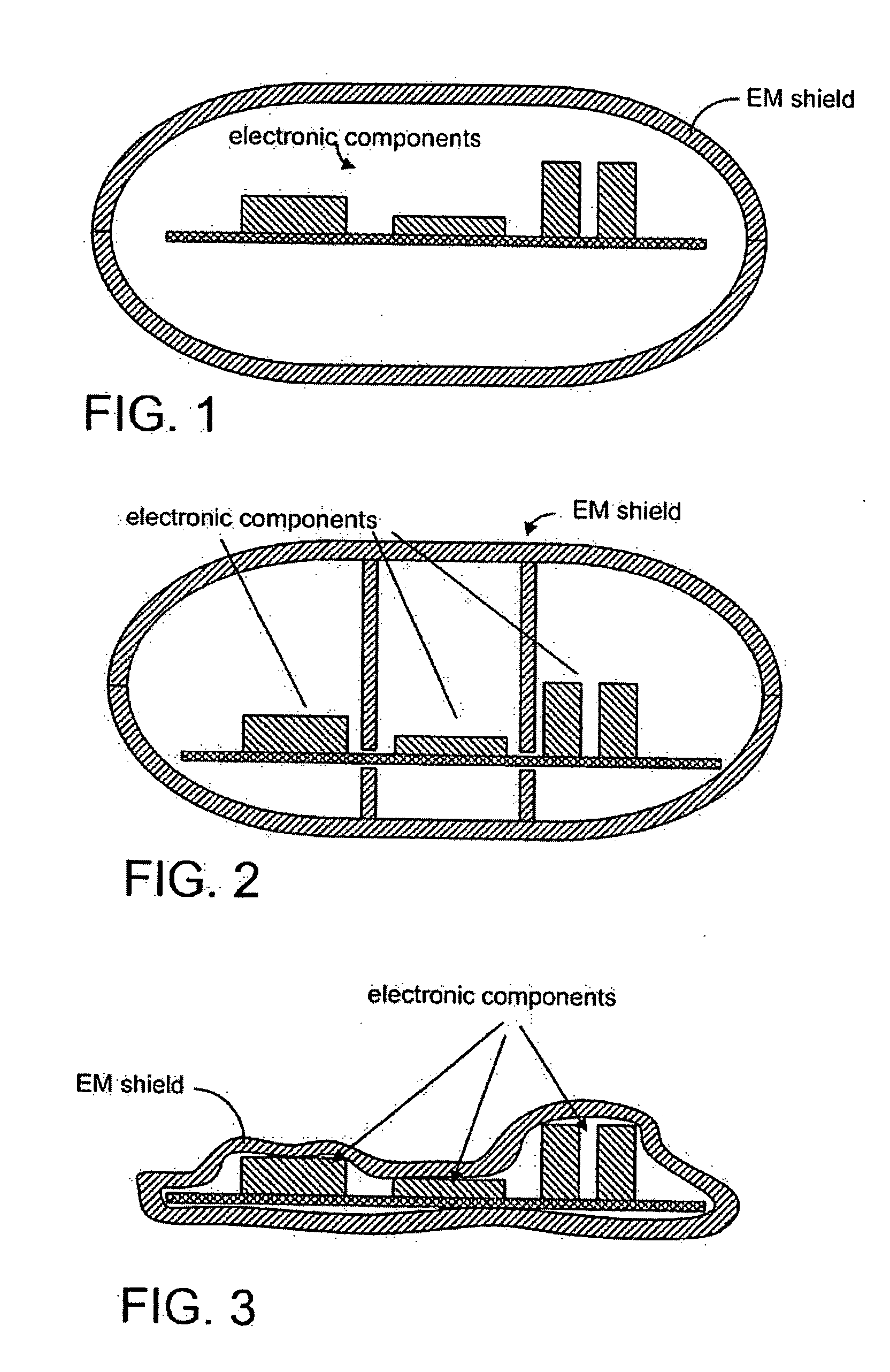

Shielding material for preventing from outleakage and penetration of electromagnetic waves

InactiveUS20050183871A1Effectively absorbs energy associated with electromagnetic waveReduce electromagnetic radiationMagnetic/electric field screeningRadiation-absorbing paintsEpoxyEthylene thiourea

An EM shielding material and an EM shielding contains a material composition comprising at least one EM absorbing element or compound in a discrete particle form and a binding compound to bind the discrete particles in a layer or paste. The discrete particles are made of one or more metals such as Fe, Ni, Cr and Mn or dielectric compounds having magnetic properties. The binding compounds can be selected from silicone, rubber, arcylonitrile butadiene styreneresin (ABS), polycarbonate (PC), epoxy, silica and polyurethane. The associated components can be selected from zinc oxide, magnesium oxide, ethylene thiourea, carbon black, and stearic acid. The material can also be used as the package material for the electronic components in an electronic product.

Owner:HOU PON WEI

High-performance urban rail cable sheathing material

InactiveCN103772764AIncrease in sizeReduce releaseInsulated cablesInsulated conductorsMicrocrystalline waxAcrylonitrile

The invention discloses a high-performance urban rail cable sheathing material. The high-performance urban rail cable sheathing material comprises main materials and auxiliary materials, wherein the main materials comprise butadiene-acrylonitrile rubber and chlorinated cis-butadiene rubber; the auxiliary materials comprise zinc oxide, an activating agent mercuric oxide, barium oxide, stearic acid, methylthiuram disulfide, an accelerator DTDM (4,4'-Dithiodimorpholine), ethylene thiourea, tribasic lead sulfate, dioctyl phthalate, microcrystalline wax, an anti-aging agent 4040, an anti-aging agent 4040NA, an anti-aging agent 445, high-wear-resisting carbon black, semi-enhanced carbon black, talcum powder, calcined pottery clay and calcium carbonate; the main materials are put into an open mill to be mixed uniformly and the mixing temperature is 40-52 DEG C; then the auxiliary materials are added to be mixed uniformly; the obtained mixed materials are put into a flat plate vulcanization machine to carry out vulcanization to obtain the high-performance urban rail cable sheathing material; the vulcanization temperature is 141-147 DEG C and the vulcanization time is 1-5 minutes. According to the high-performance urban rail cable sheathing material disclosed by the invention, the physical and mechanical properties are good, the combustion smoke is less and the flame retardant efficiency is good.

Owner:ANHUI HUALIAN CABLE GROUP

Fluororubber and epichlorophdrin rubber formulation

ActiveCN101081916AHigh electronegativityGood fuel resistanceSynthetic resin layered productsPolymer scienceLead(II,IV) oxide

The present invention is one kind of rubber pipe comprising one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber. The fluororubber consists of polyfluoroprene, thermal black N990, 2, 5-dimethyl-2, 5-dihexane, triallyl cyanourate and carnauba wax; and the chlorohydrin rubber consists of chlorohydrin rubber C, chlorohydrin rubber H, black N550, anti-ager NBC, processing aid R-300, stearic acid, plasticizer RS-107, red lead, ethylene thiourea NA-22, plasticizer W-305ELS and scorch retarder CTP-80. The rubber pipe with one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber has high heat resistance, high oil tolerance, high ozone tolerance and high fuel oil osmosis resistance.

Owner:TIANJIN PENGYI GRP CO LTD

Low-cost flame-retardant cable sheath material

Owner:ANHUI MENTOR CABLE GROUP

Two-acid yellow-fume-free polishing additive and polishing solution

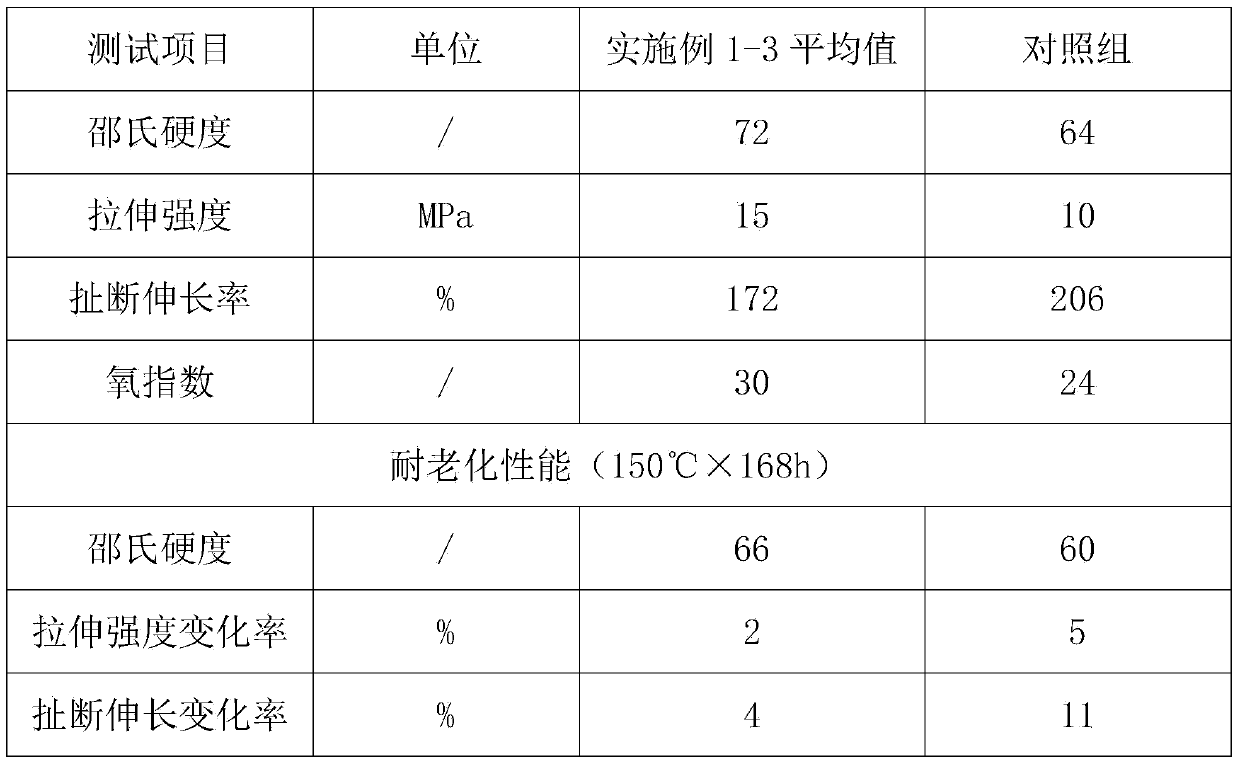

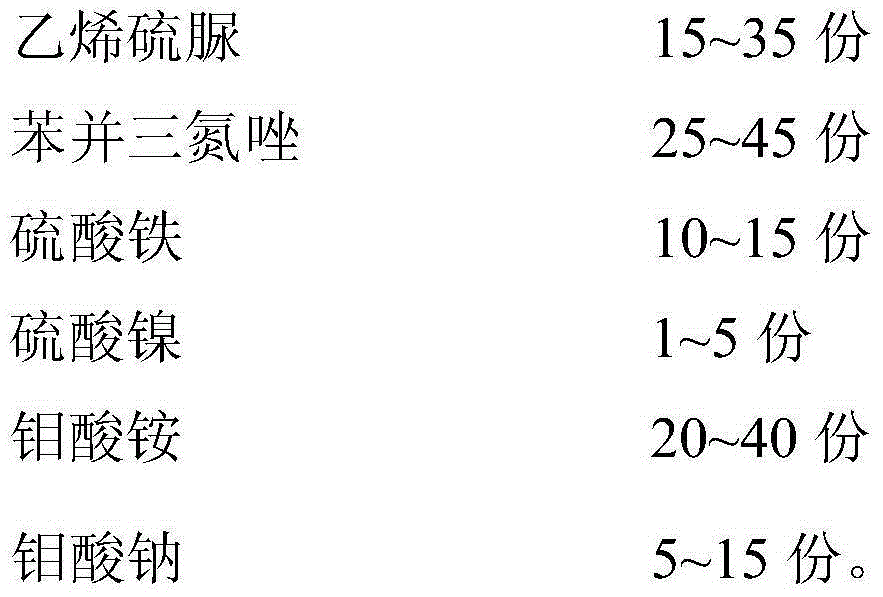

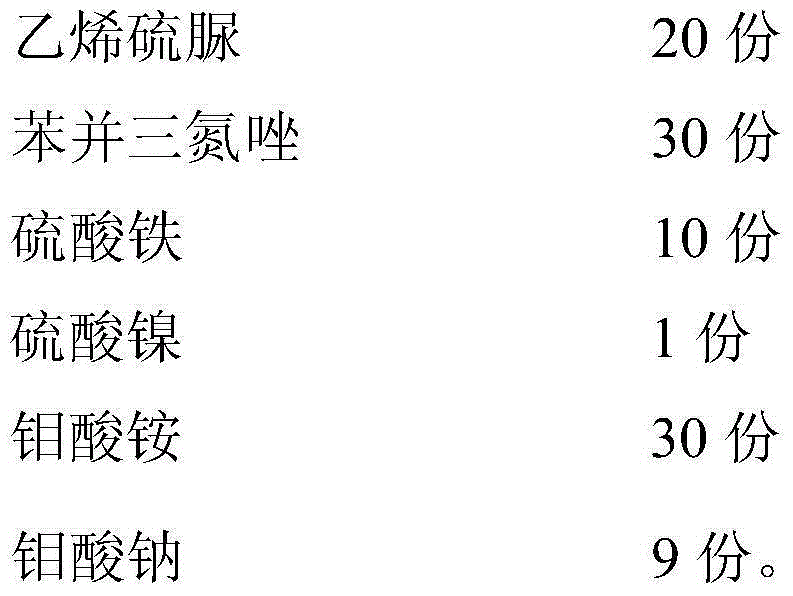

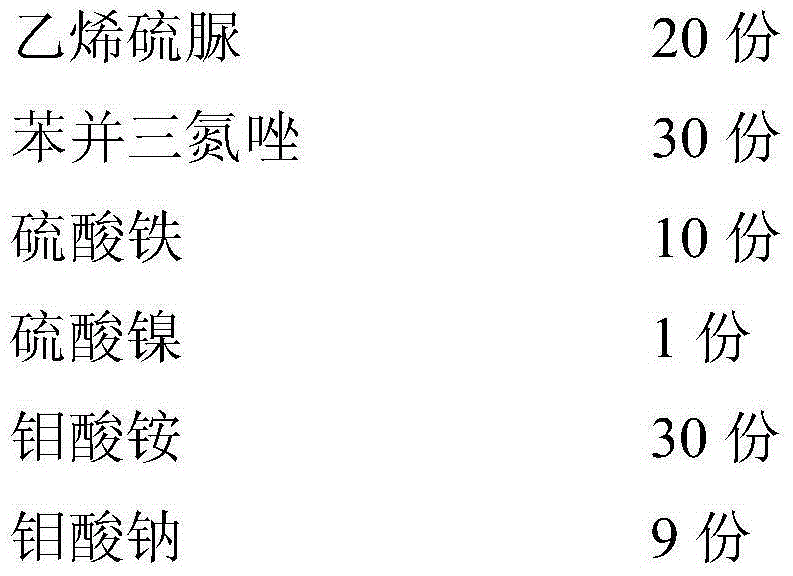

The invention discloses a two-acid yellow-fume-free polishing additive. The polishing additive comprises 15-35 parts of ethylene thiourea, 25-45 parts of benzotriazole, 10-15 parts of ferric sulfate, 1-5 parts of nickel sulfate, 20-40 parts of ammonium molybdate and 5-15 parts of sodium molybdate. By adopting a polishing process with the two-acid yellow-fume-free polishing additive, yellow fume of nitric oxide and other gaseous pollutants cannot be produced, and the components of the polishing additive are environmentally friendly; the surface glossiness of a polished product is more than 700 degrees, the glossiness is uniform, and the mirror effect is quite good; the requirement for the polishing temperature is low, little energy is consumed, energy is saved, and the environment is protected.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

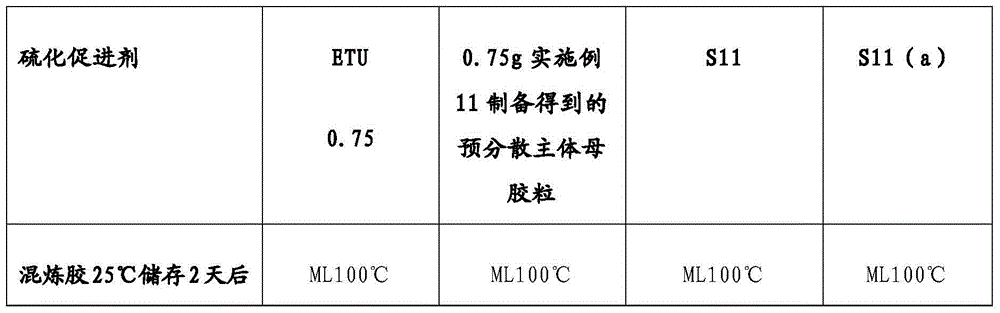

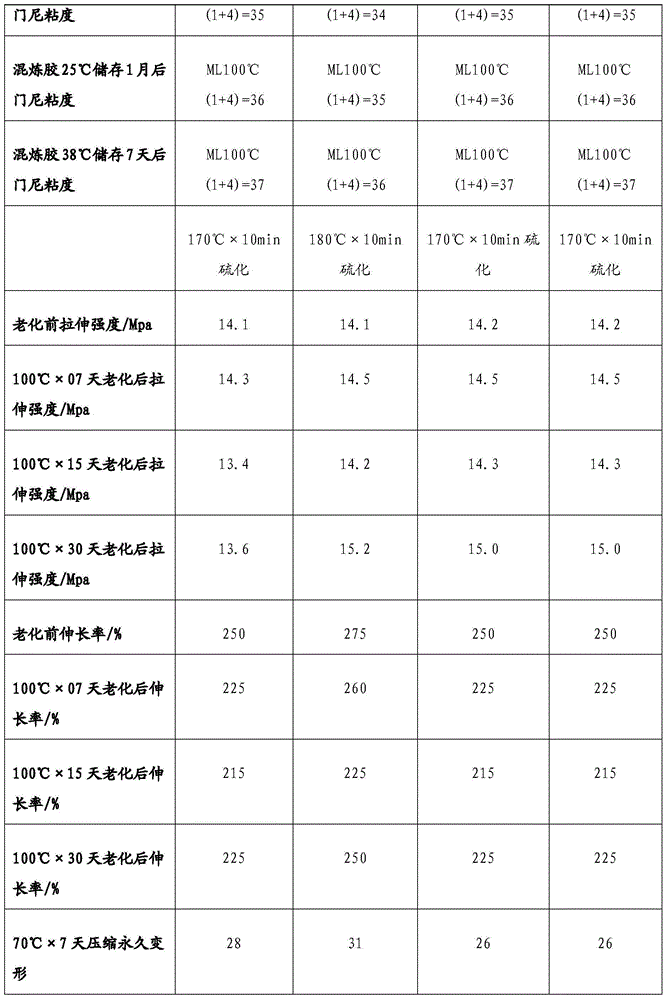

Vulcanization accelerator composition as well as preparation method and application thereof

InactiveCN104861319AAccelerated vulcanizationSolve environmental problemsPolymer scienceVulcanization

The invention discloses vulcanization accelerator composition. The vulcanization accelerator composition comprises pre-dispersion host master batch granules and pre-dispersion ligand master batch granules, wherein the pre-dispersion host master batch granules comprise 3-mythyl-2-thiazolidinone, the pre-dispersion ligand master batch granules comprise mixtures of organic amine compounds and benzimidazole compounds; each type of master batch granules further comprise rubber, stearic acid, pentaerythritol aliphatic ester, ethylene-vinyl acetate copolymer and / or ethylene-vinyl ester copolymer, rubber in liquid polar plasticizers and at least one other ingredient. Through cooperation of the two types of master batch granules, vulcanization of a chloroprene rubber system is synergistically accelerated, the vulcanization characteristic of the master batch granules is equivalent to that of ETU (ethylene thiourea), the processing property doesn't change, the comprehensive physical and mechanical properties are equivalent, the compression set performance of a product of the master batch granules is superior to that of ETU vulcanization accelerator products, and the product quality is improved.

Owner:范文杰 +2

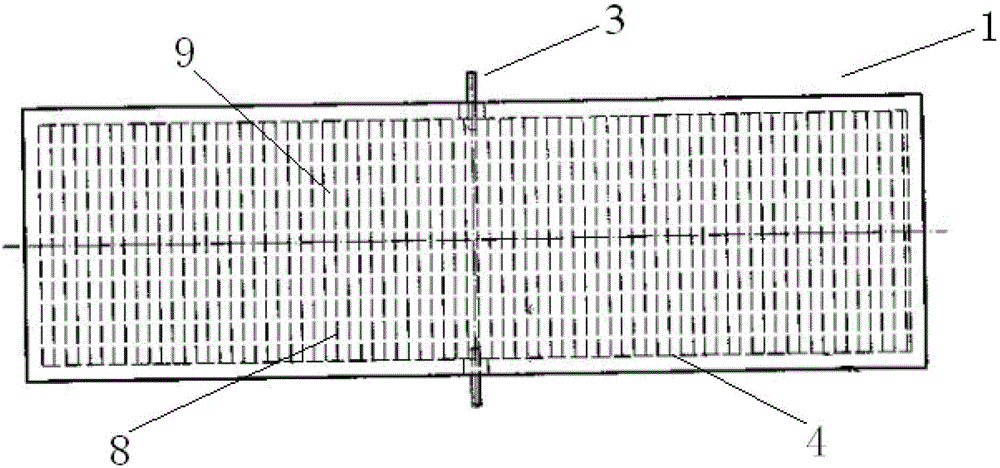

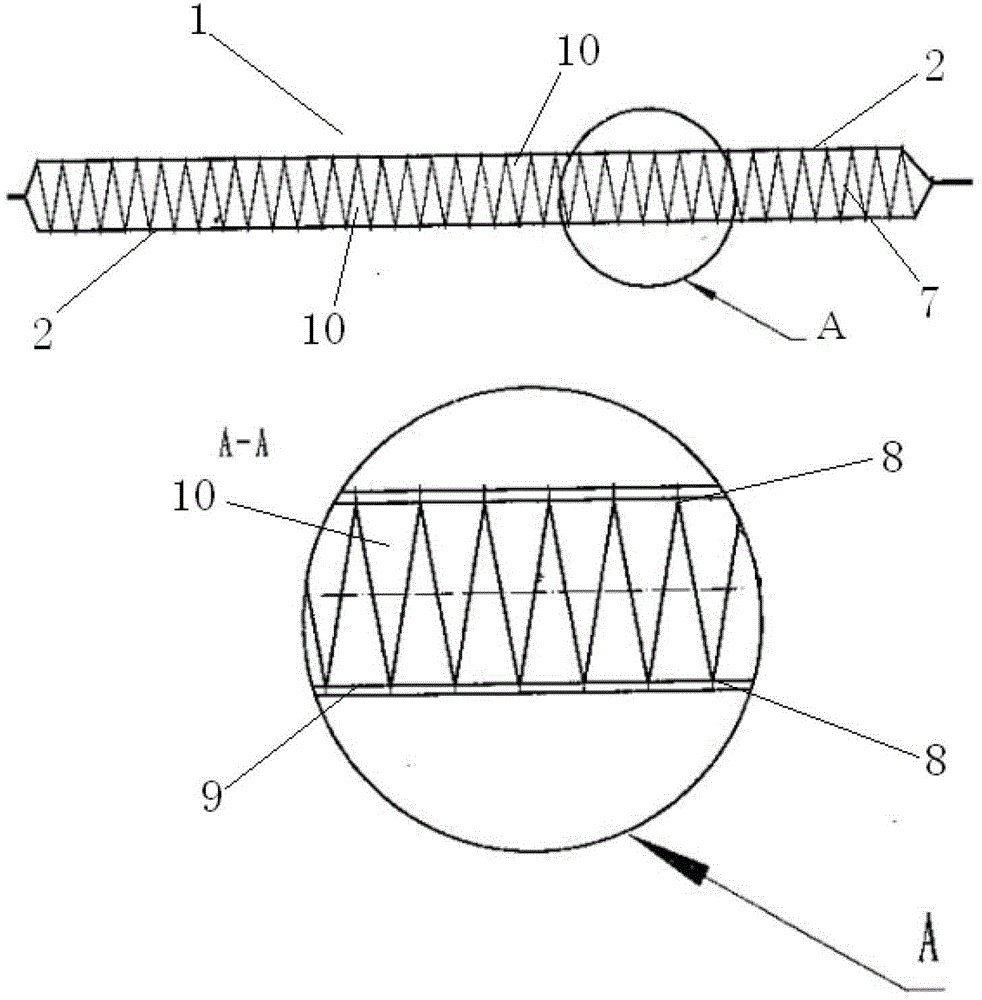

Pressurized gasbag of pipeline repair reinforcing layer as well as preparation method and application thereof

ActiveCN102978955APayload sharingImprove adhesionFibre treatmentSynthetic resin layered productsRubber materialAdhesive

The invention relates to a pressurized gasbag of a pipeline repair reinforcing layer as well as a preparation method and an application thereof. The gasbag is prepared from aramid fiber on which a rubber material is coated, wherein the rubber material comprises the following components in parts by weight: 80 to 100 parts of chloroprene adhesive, 2 to 8 parts of zinc oxide, 3 to 6 parts of magnesium oxide, 1 to 3 parts of stearic acid, 15 to 30 parts of carbon block, 5 to 15 parts of barium sulfate, 5 to 15 parts of transformer oil, 10 to 20 parts of o-dibutyl ester, and 0.2 to 0.8 part of ethylene thiourea (NA-22). By the steel pipeline repair reinforcing uniform pressure device and method developed by the invention, the repair construction problems of abhesion, demixing, hollowing and the like occuring after the pressurization-free construction process can be effectively solved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Weather-resistance and low-temperature-resistance chloroprene rubber adhesive

ActiveCN105238299AGood compatibilityGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesBenzoic acidPolymer science

The present invention discloses a weather-resistance and low-temperature-resistance chloroprene rubber adhesive, wherein the raw materials comprise a chloroprene rubber, a natural rubber, an alkyl benzoic acid resin, a phenolic resin, an epoxy resin, a terpene resins, a trans-1,4-polyisoprene rubber, active magnesium oxide, nanometer silicon dioxide, ethylene thiourea, zinc oxide, ethyl acetate, cyclohexane, acetone, propylene glycol, methyl cyclopentane, dimethyl carbonate, an anti-aging agent, cerium oxide, 3-aminopropyl trimethoxy silane, a silane coupling agent KH-560, and a plasticizer. The weather-resistance and low-temperature-resistance chloroprene rubber adhesive of the present invention has characteristics of high bonding strength, good low-temperature resistance, good weather resistance, and excellent storage stability.

Owner:安徽大松树脂有限公司

High-temperature resistant urban rail cable sheath material

InactiveCN103788579AExtended service lifeOptimize volumeRubber insulatorsPlastic/resin/waxes insulatorsEpoxyPolymer science

The invention discloses a high-temperature resistant urban rail cable sheath material, which comprises major ingredients and auxiliaries, wherein the major ingredients comprise epoxy resin, chloroprene rubber and natural rubber; the auxiliaries comprise zinc oxide, a ferric oxide activating agent, barium oxide, stearic acid, methylthiuram disulfide N,N-bi(epsilon-caprolactam)disulfide, ethylene thiourea, tribasic lead sulfate, dioctyl phthalate, microcrystalline wax, an anti-aging agent IPPD, octyl decyl adipate, an anti-aging agent 445, high-abrasion resistance carbon black, titanium dioxide, diatomaceous earth and calcium carbonate. A preparation method for the high-temperature resistant urban rail cable sheath material comprises the following steps of uniformly mixing the major ingredients at mixing temperature of 63 to 67 DEG C in an open mill, adding the auxiliaries and uniformly mixing; vulcanizing the obtained material mixture on a flat vulcanizing machine to obtain the high-temperature resistant urban rail cable sheath material, wherein the vulcanizing temperature is 145 to 148 DEG C, and the vulcanizing time is 2 to 4 minutes. The high-temperature resistant urban rail cable sheath material is flame-retardant, environment-friendly and long in service life.

Owner:ANHUI HUALIAN CABLE GROUP

Preparation method for modified polyacrylamide filtrate reducer for drilling fluid

InactiveCN105367710AImprove high temperature resistanceSmall filter lossDrilling compositionPolyvinyl butyralPhosphoric acid

The invention relates to a preparation method for a modified polyacrylamide filtrate reducer for drilling fluid, and belongs to the technical field of petroleum drilling oilfield chemistry high-molecular polymers. The preparation method comprises the following steps: adding acrylamide monomer, 1,3-butylene glycol diacrylate, ethylene thiourea, hydroxy-propyl acrylate, cardanol, trimethylol propyl triacrylate, maleic anhydride, polyvinyl butyral, a chain extender, water, a crosslinking agent, a surfactant and a catalyst into a reactor, uniformly mixing, adding the mixture into a phosphoric acid adjusting system to adjust the pH value to 4-6, feeding inert gas to remove dissolved oxygen in the reaction system; cooling the reaction system, adding an initiating agent, and warming up for polymerization reaction; taking out the obtained jelly reactant, and conducting granulation, stoving and smashing so as to obtain the modified polyacrylamide filtrate reducer. The provided modified polyacrylamide filtrate reducer has the advantages of being good in high-temperature resistance and small in filtrate reduction loss.

Owner:宋介珍

Cable sheath insulation material for coal mines and preparation method thereof

InactiveCN102993524AGood physical propertiesDimensionally stableRubber insulatorsPlastic/resin/waxes insulatorsPolyesterPolyvinyl chloride

The invention discloses a cable sheath insulation material for coal mines and a preparation method thereof. The cable sheath insulation material comprises the following raw materials in parts by weight: 95-105 parts of neoprene CR121, 15-20 parts of SG-3 type PVC (Polyvinyl chloride) resin, 15-25 parts of semi-reinforcing carbon black N774, 2-3 parts of ferrocene, 1-2 parts of N,N'- meta phenylene bis maleimide, 30-35 parts of blanc fixe, 1-2 parts of antiager MB, 1-2 parts of 2-thiol group benzimidazole, 5-8 parts of chlorinated paraffin, 1-2 parts of promoter DM1, 0.8-1 part of promoter TMTD, 15-25 parts of nanometer bauxite, 1-3 parts of adipic acid propylene glycol polyester, 1-3 parts of talcum powder, 0.3-0.5 part of acetyl triethyl citrate, 0.5-0.9 part of bis(P, P-bis-ethylhexyl diphosphato)ethanediolato titanate, 2-4 parts of zinc borate, 4-6 parts of epoxy butyl oleate, 0.8-1 part of zinc oxide, 2-3 parts of modified sepiolite and 4-6 parts of ethylene thiourea. The cable sheath insulation material for coal mines, prepared by the method, has the advantages of excellent physical properties, stable size, low percentage of contraction and greatly increasing of tensile strength, tearing strength and resilience force performance; and through reasonably collocation of raw materials in the formula, the mechanical property, anti-fatigue performance, oil resistance, ageing resistance and other performances of the produced insulation material are increased.

Owner:安徽文峰电子科技集团有限公司

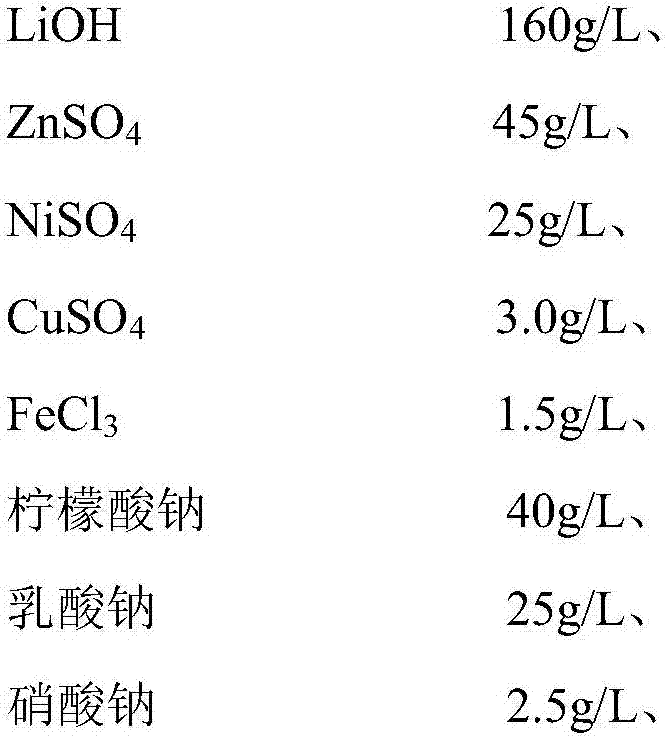

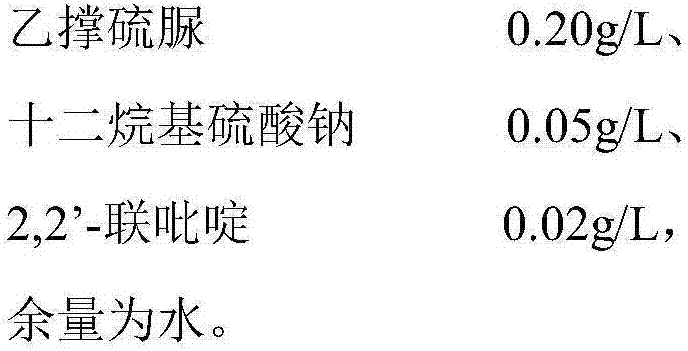

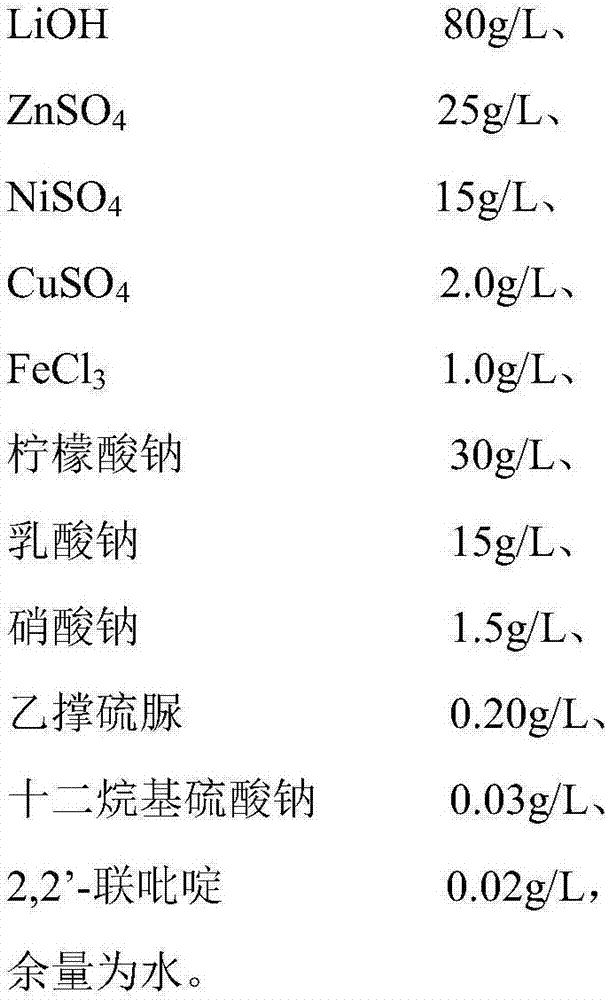

Non-cyanide zinc depositing agent for aluminum alloy and aluminum alloy zinc depositing method

The invention relates to a non-cyanide zinc depositing agent for an aluminum alloy and an aluminum alloy zinc depositing method. The non-cyanide zinc depositing agent comprises 60 to 180g / L of LiOH, 20 to 50g / L of ZnSO4, 10 to 30g / L of NiSO4, 0.5 to 5.0g / L of CuSO4, 0.5 to 2.0g / L of FeCl3, 20 to 50g / L of sodium citrate, 10 to 30g / L of sodium lactate, 1.0 to 3.0g / L of sodium nitrate, 0.10 to 0.30g / L of ethylene thiourea, 0.02 to 0.06g / L of lauryl sodium sulfate and 0.01 to 0.03g / L of 2,2'- dipyridyl. The non-cyanide zinc depositing agent is used for the aluminum alloy secondary zinc depositing technology, formed zinc grains are small and uniform, an obtained zinc immersion layer is thinner and more compact, the base body covering performance is good, corrosion resistance is higher, combination force between a base body and a coating is greatly improved, and meanwhile, a zinc immersion solution is stable in character and long in service life.

Owner:佛山市南博旺环保科技有限公司

Nitrile butadiene rubber gasket used for sealing high-pressure lubricating oil and preparation method thereof

The invention discloses a nitrile butadiene rubber gasket used for sealing high-pressure lubricating oil and a preparation method thereof. The nitrile butadiene rubber gasket is prepared from the following raw materials in parts by weight: 25-40 parts of carboxylated nitrile butadiene rubber, 16-27 parts of thermoplastic polyester elastomer, 12-23 parts of chlorohydrin rubber, 4-8 parts of C9 petroleum resin, 10-15 parts of white corundum micro powder, 1-2 parts of accelerator NS, 0.5-1 part of accelerator ZDBP, 5-10 parts of 1,2-polybutadiene, 2-3 parts of 1,1-di(tert-butylperoxy)cyclohexane, 1-2 parts of tetra-chloro-benzoquinone, 2-3 parts of ethylene thiourea, 3-5 parts of triallyl trimellitate, 1-2 parts of zinc stearate, 1-2 parts of anti-aging agent RD, 0.5-1 part of anti-aging agent TMDQ, 6-12 parts of diisononyl phthalate, 10-15 parts of tungsten disulfide and 6-12 parts of modifier. The nitrile butadiene rubber gasket has excellent comprehensive properties, and not only has higher mechanical strength but also has excellent pressure, oil, wear, impact and fatigue resistance.

Owner:ANHUI JINGYI GLASS MACHINERY

Curable composition, bonding method and assembly

ActiveUS20100068540A1Fast curingLow production costSynthetic resin layered productsLaminationAdhesiveThiourea

To provide a curable composition and an adhesive which exhibit a temporarily fixing effect very quickly and which are completely cured quickly at room temperature, and a bonding method.A curable composition comprising a component (A): a polymerizable acrylic liquid composition, a component (B): cumene hydroperoxide, a component (C): a reducing agent containing vanadium or copper or a reducing agent comprising ethylene thiourea, and a component (D): a basic compound having a primary, secondary or tertiary amine structure, and a bonding method using it.

Owner:DENKA CO LTD

Chloroprene rubber composition, and vulcanizate and molding thereof

To provide a chloroprene rubber composition providing good permanent compression set and excellent mechanical strength, a vulcanizate of the composition, and a molded article of the composition.A chloroprene rubber composition including a chloroprene rubber and a natural rubber in a total amount of 100 parts by mass, a copolymer of styrene and butadiene in an amount of 0.1 to 10 parts by mass, ethylene thiourea in an amount of 0.1 to 3.0 parts by mass, and dipentamethylenethiuram tetrasulfide in an amount of 0.1 to 3.0 parts by mass is vulcanized after or during molding of the composition to yield a vulcanized molding.

Owner:DENKA CO LTD

Preparation method of flame-retardant polyurethane foam material for automotive interior

InactiveCN105153392AImprove mechanical propertiesImprove flame retardant performancePolymer sciencePtru catalyst

The invention relates to a preparation method of a flame-retardant polyurethane foam material for an automotive interior, and belongs to the technical field of high polymer materials. The method comprises the step that by weight, 30-50 parts of oligomer polyhydric alcohols, 20-40 parts of polyisocyanates, 5-10 parts of brominated flame retardants, 5-15 parts of alumina sol, 3-6 parts of ethylene thiourea, 3-6 parts of N-Oleo sarcosine octadecyl amine, 3-5 parts of amine catalysts, 2-3 parts of organic tin catalysts, 2-4 parts of coupling agents, 5-10 parts of cross-linking agents, 1-5 parts of plasticizers, 1-5 parts of antioxidants and 90-130 parts of water are evenly mixed, then poured into a mold, heated, solidified and cooled. The flame-retardant polyurethane foam material for the automotive interior has the good mechanical performance, and the flame-retardant performance and the mechanical performance can be effectively improved by modifying the alumina sol and organic monomers.

Owner:刘应才

Ageing-resistant cable rubber

InactiveCN104817843AImprove antioxidant capacityStrong acid and alkali resistancePlastic/resin/waxes insulatorsPolymer scienceThiourea

Ageing-resistant cable rubber is produced from, by weight, 6-10 parts of ageing resister mercapto benzimidazole, 20-35 parts of butyl rubber, 3-8 parts of zinc diethyl dithiocarbamate, 15-25 parts of epichlorohydrin rubber, 6-8 parts of dioctyl phthalate, 7-13 parts of calcium carbonate, 5-8 parts of sulfur, 12-25 parts of chlorosulfonated polyethylene rubber, 2-3 parts of strengthening agent, 25-35 parts of silicone rubber, 4-6 parts of hydroxyl silicone oil, 5-7 parts of ethylene thiourea and 18-21 parts of 26-type nitrile butadiene rubber. The ageing-resistant cable rubber has the advantages of high resistance to oxidation, acid and alkali and higher ageing-resistant effect.

Owner:QINGDAO KANGTAIXIN ENVIRONMENTAL PROTECTION TECH

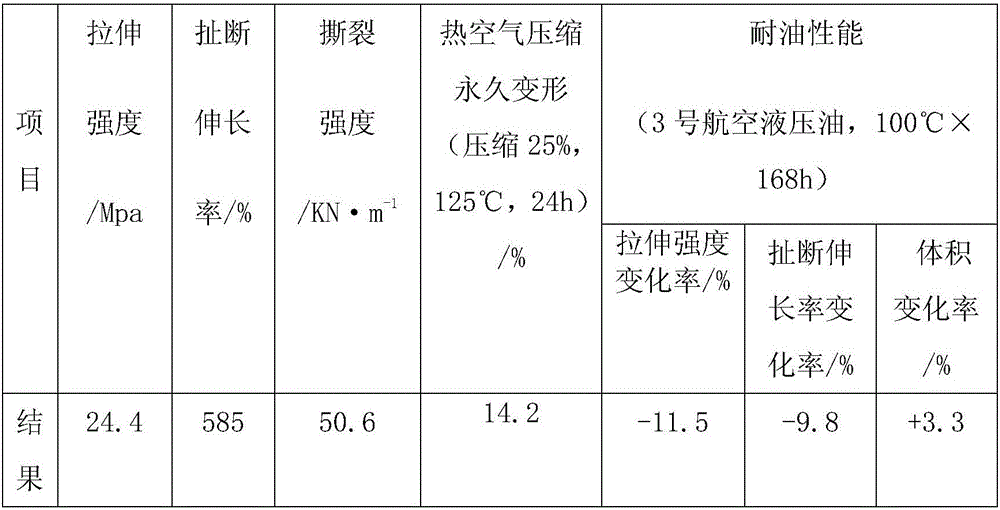

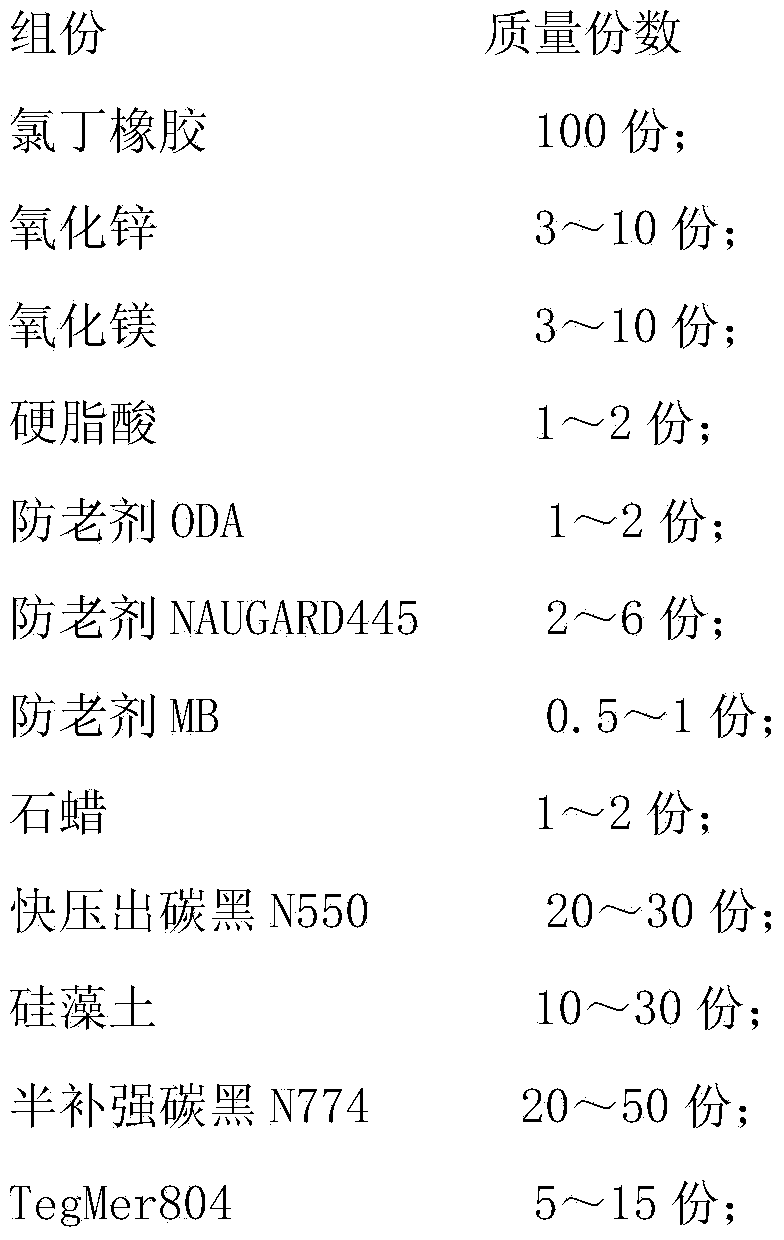

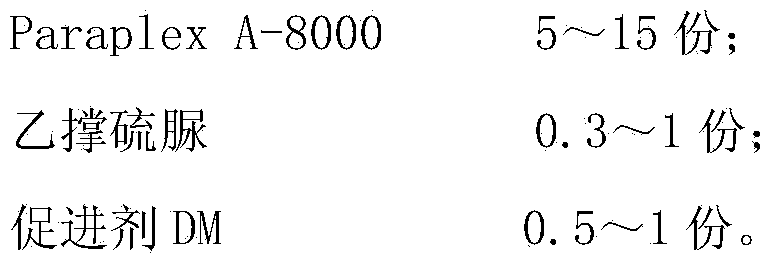

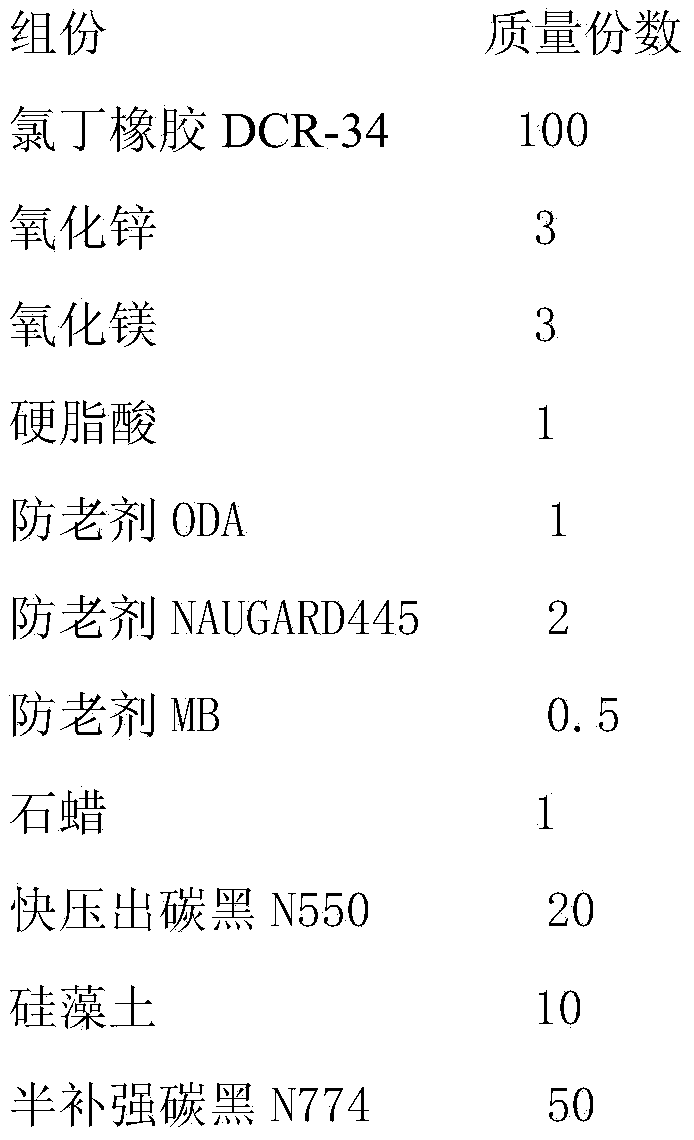

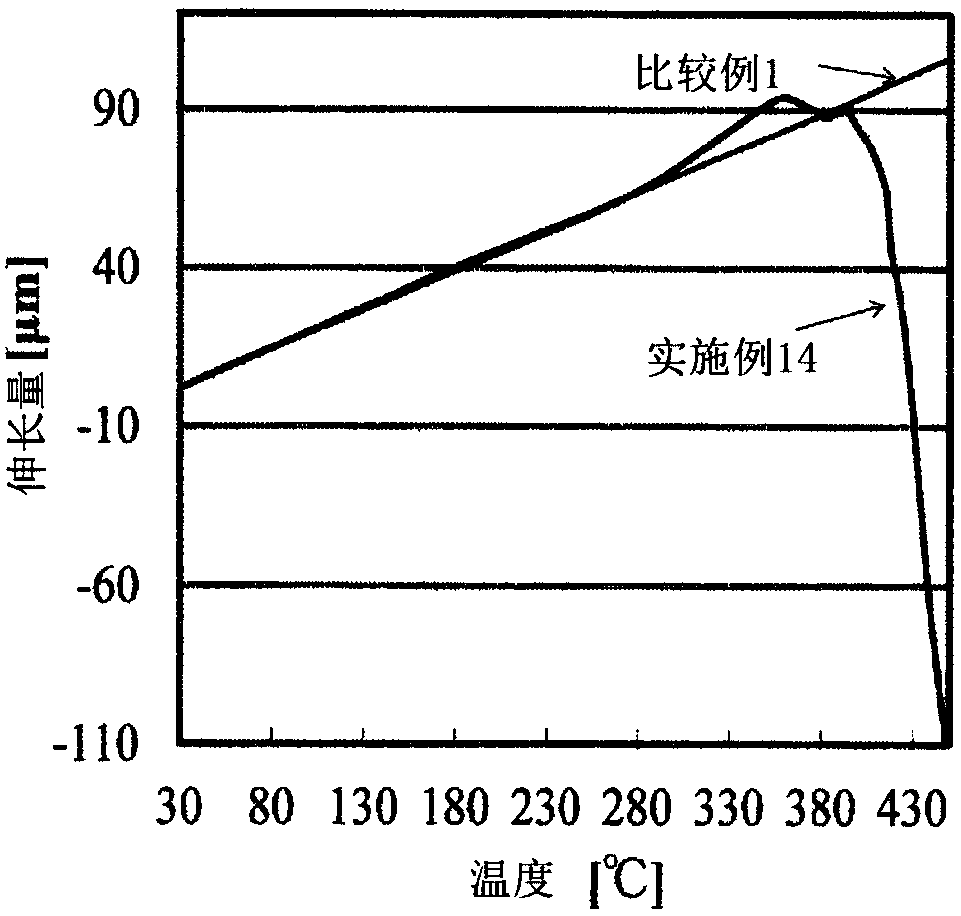

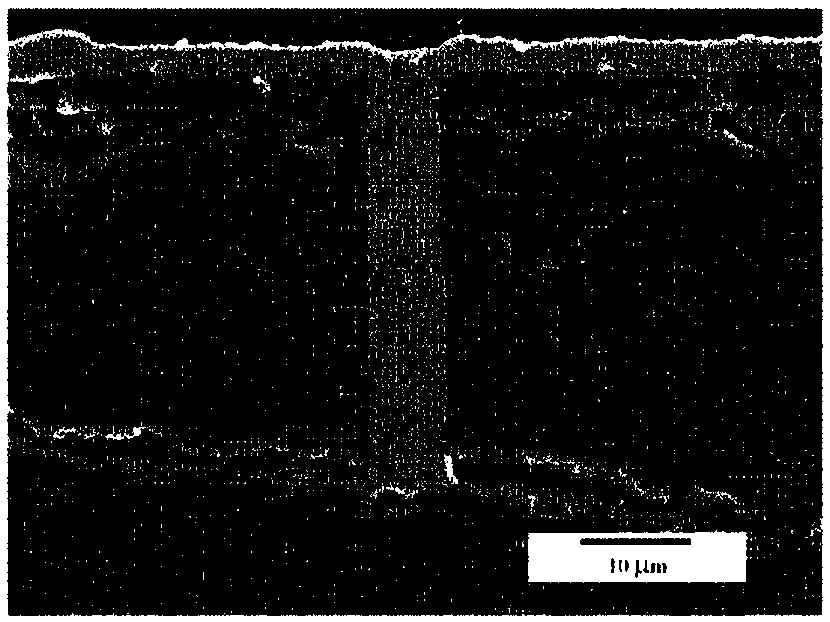

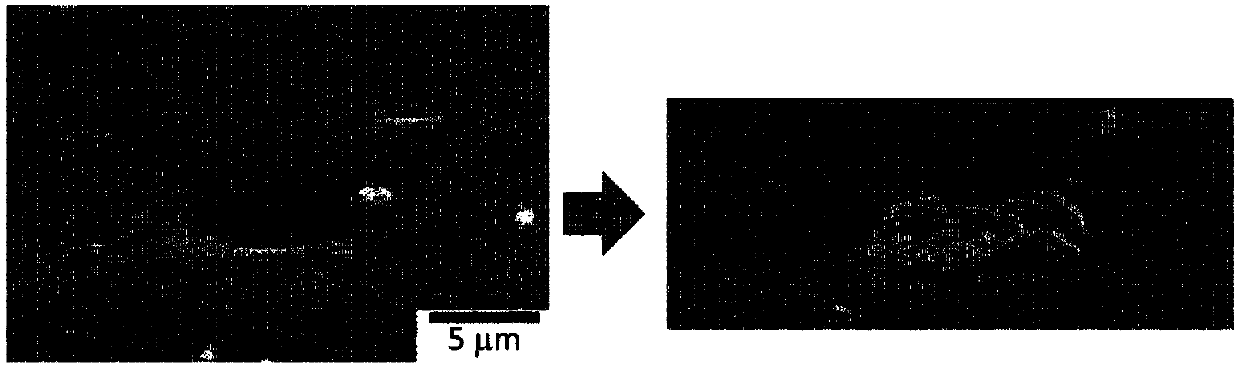

High temperature resistant and aging resistant chloroprene rubber composition

The invention provides a high temperature resistant and aging resistant chloroprene rubber composition. The high temperature resistant and aging resistant chloroprene rubber composition comprises the following components: chloroprene rubber, zinc oxide, magnesium oxide, stearic acid, an anti-aging agent ODA, an anti-aging agent NAUGARD445, an anti-aging agent MB, paraffin, fast extruding carbon black N550, diatomaceous earth, semi-reinforcing carbon black N774, TegMer804, Paraplex A-8000, ethylene thiourea and an accelerant DM. By virtue of contrastive analysis of chloroprene rubber formula experiment, the formula performance can fully meet the standard requirement, the hot air aging resistance is prior to that of the traditional chloroprene rubber formula, and good performances can be preserved under the hot air environment of 125 DEG C. Intercooler rubber tubes are produced by using the chloroprene rubber formula so as to ensure normal use in an automobile of a turbocharging system; the performances of chloroprene rubber products are improved, so that the service life of the automobile is ensured, and the cost of the turbocharging system is reduced.

Owner:TIANJIN PENGYI GRP CO LTD

Acidic copper plating solution, acidic copper plated product, and method for producing semiconductor device

InactiveCN107636205AAvoid pumpingRealize practicalitySemiconductor/solid-state device detailsSemiconductor/solid-state device manufacturingCopper platingEthylene thiourea

Owner:FINE FEATURE ELECTRODEPOSITION RES INST INC

Method and additive for preparing electrolytic copper foil for high temperature power battery with high elongation

ActiveCN110016697AGood room temperatureHigh temperature and high elongationElectroforming processesElectrolysisElectrical battery

The invention discloses a method and an additive for preparing an electrolytic copper foil for a high temperature power battery with high elongation. The method comprises the following steps: at first, heating and dissolving a high-purity copper wire to generate copper sulfate electrolyte; then, filtering the prepared copper sulfate electrolyte, filling the filtered copper sulfate electrolyte intoa head tank, adding the additive in the head tank, and carrying out electrolysis to generate the foil; and finally, treating the prepared copper foil through anti-oxidation liquid. The additive comprises a grain refiner, wherein the grain refiner is the aqueous solution of polyethyleneimine derivative, HP, polyethylene glycol and ethylene thiourea. According to the method, the tailor-made additive is added during the electrolytic copper foil preparing process, the prepared copper foil has high elongation at both room temperature and high temperature, the electrolytic copper foil can prevent the copper fol from cracking after the copper foil is coated with an active substance and is rolled by a roller and is in other flattening procedures; and during an overcharging characteristic test, the copper foil can bear the swelling stress caused by heating of overcharging and does not crack.

Owner:青海电子材料产业发展有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com