Non-cyanide zinc depositing agent for aluminum alloy and aluminum alloy zinc depositing method

A technology of aluminum alloy and zinc precipitation, which is applied in the field of aluminum alloy zinc precipitation and cyanide-free zinc precipitation agent for aluminum alloy, which can solve the problems of large loss of aluminum alloy matrix, strong corrosion of aqueous solution, coarse grains of zinc layer, etc., and achieve improvement Effects of binding force, stable concentration, and control of reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

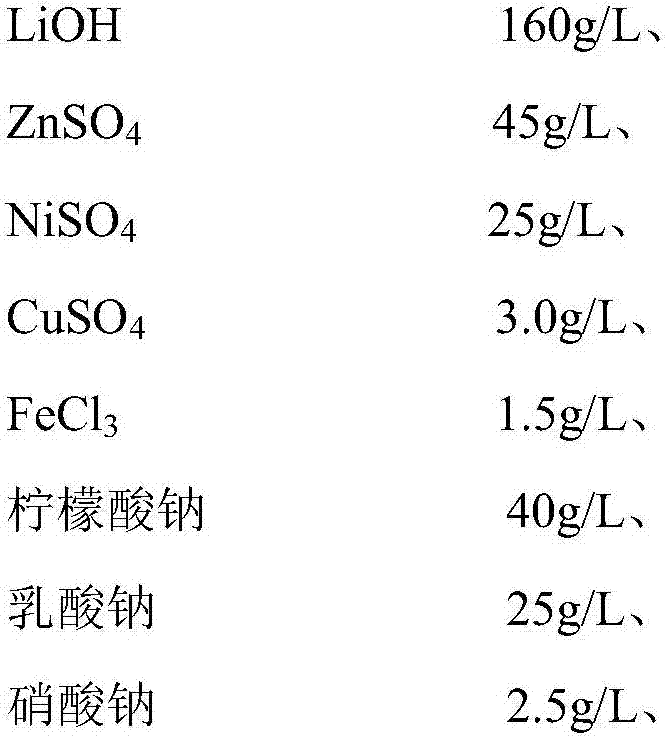

[0029] The cyanide-free zinc-precipitating agent for aluminum alloys of the present embodiment is composed of components with the following concentrations:

[0030]

[0031]

Embodiment 2

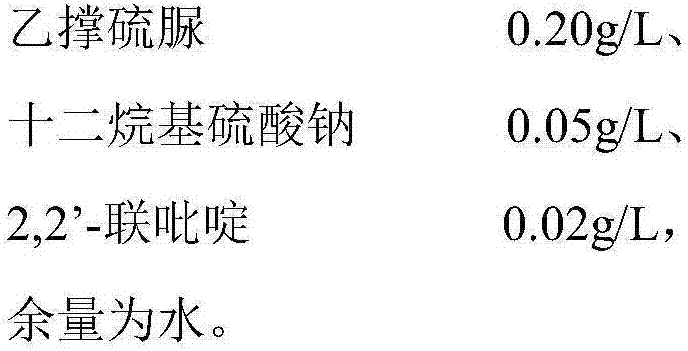

[0033] The cyanide-free zinc-precipitating agent for aluminum alloys of the present embodiment is composed of components with the following concentrations:

[0034]

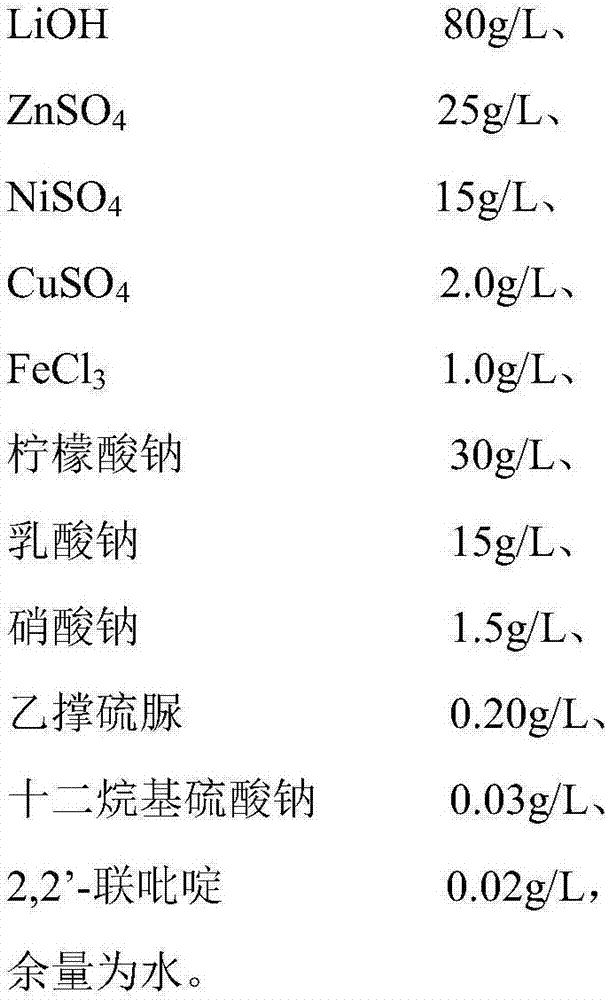

[0035] The composition of the cyanide-free zincating agents for aluminum alloys in Examples 3-10 is shown in Table 1.

[0036] The component composition of the aluminum alloy of table 1 embodiment 3-10 uses cyanide-free zinc precipitation agent (unit: g / L)

[0037]

[0038]

Embodiment 11

[0040] The aluminum alloy zinc-precipitating method of the present embodiment comprises the following steps:

[0041] 1) Degreasing, alkali etching and light treatment are carried out on the aluminum alloy substrate;

[0042] 2) Under room temperature conditions, the aluminum alloy substrate is subjected to a zinc-dipping treatment using the cyanide-free zinc-precipitating agent for the aluminum alloy of Example 1, and the zinc-dipping time is 60s;

[0043] 3) Under room temperature conditions, the aluminum alloy substrate is washed with water after nitric acid dezincification; the time for nitric acid dezincification is 30s;

[0044] 4) Under room temperature conditions, the aluminum alloy substrate was subjected to secondary zinc dipping treatment with the cyanide-free zincprecipitant for aluminum alloy of Example 2. The zinc dipping time was 30s, and then washed with water.

[0045] The aluminum alloy zinc-precipitating methods of Examples 12-15 are shown in Table 2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com