Two-acid yellow-fume-free polishing additive and polishing solution

A technology without yellow smoke and additives, applied in the field of metal surface processing, can solve the problems of unevenness, large human injury, high energy consumption, etc., and achieve the effects of uniform gloss, good mirror effect and low temperature requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

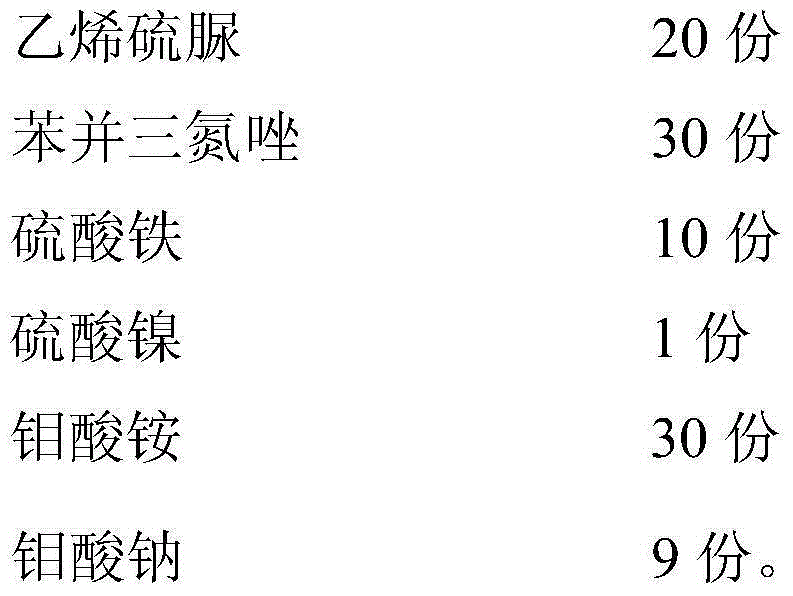

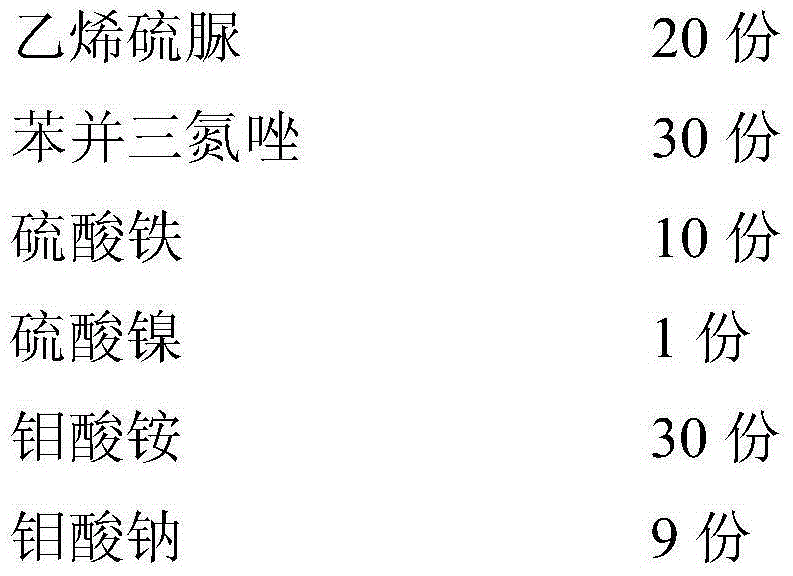

Embodiment 1

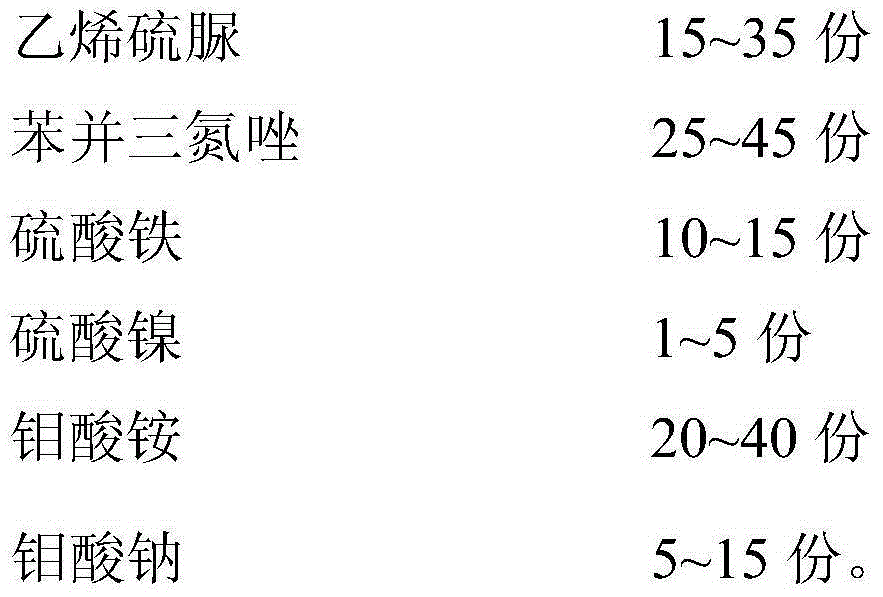

[0017] A two-acid non-yellow smoke polishing additive, its composition is calculated by weight, comprising:

[0018]

[0019] Among them, ethylene thiourea acts as a corrosion inhibitor in the polishing additive of the present invention, that is, it can be adsorbed on the metal surface, and on the one hand change the charge distribution and interface properties of the metal surface, stabilize the energy state of the metal surface, and reduce the corrosion rate. On the other hand, its non-polar group forms a protective film on the metal surface, which prevents the metal surface from being further oxidized and corroded, thus acting as a corrosion inhibitor. Benzotriazole also acts as a corrosion inhibitor in the polishing additive of the present invention. It combines with metal atoms through covalent bonds and coordination bonds to form an insoluble composite film on the metal surface, preventing metal ions from dissolving into water and slowing down the corrosion rate. . T...

Embodiment 2 to Embodiment 5

[0022] The composition and content of the two-acid no-yellow smoke polishing additive of embodiment 2 to embodiment 5 and the product gloss performance after polishing are as shown in table 1. In embodiment 2 to embodiment 5, the polishing liquid of the two-acid no-yellow smoke polishing additive The composition of the matching groove and the polishing process conditions are the same as those in Example 1.

[0023] Table 1 Composition content and polishing performance of two acid-free yellow smoke polishing additives

[0024]

[0025] The appearance of the two-acid non-yellow smoke polishing additive obtained by the invention is light yellow to red mixed solid powder; the bulk density at 25°C is in the range of 0.8-1.2g / mL. As can be seen from Table 1, the average gloss of the polished product obtained by using the two-acid yellow smoke-free polishing additive of the present invention is more than 700 degrees, the gloss is uniform, and the mirror effect is very good, especi...

Embodiment 6 to Embodiment 9

[0027] The composition and content of the matching tank of the two-acid no-yellow-smoke polishing solution and the gloss performance of the product after polishing are shown in Table 2, wherein the composition and content of the two-acid no-yellow smoke polishing additive used are the same as in Example 1, and the phosphoric acid used The concentration is 80-85%, the concentration of sulfuric acid is 95-98%, and the polishing process conditions are the same as those in Example 1.

[0028] Table 2 Composition content and polishing performance of two-acid non-yellow smoke polishing fluid

[0029]

[0030] As can be seen from Table 2, the average gloss of the polished product obtained by using the matching tank of the two-acid yellow smoke-free polishing solution of the present invention is more than 700 degrees, the gloss is uniform, and the mirror effect is very good, especially when the weight ratio of phosphoric acid / sulfuric acid When it is 7 / 3, the gloss is the best and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com