Low-cost flame-retardant cable sheath material

A flame-retardant cable and sheath material technology, applied in the field of cable sheaths, can solve the problems of poor cold resistance and storage stability, and achieve the effects of improving oxidation resistance, improving tensile properties, and excellent aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

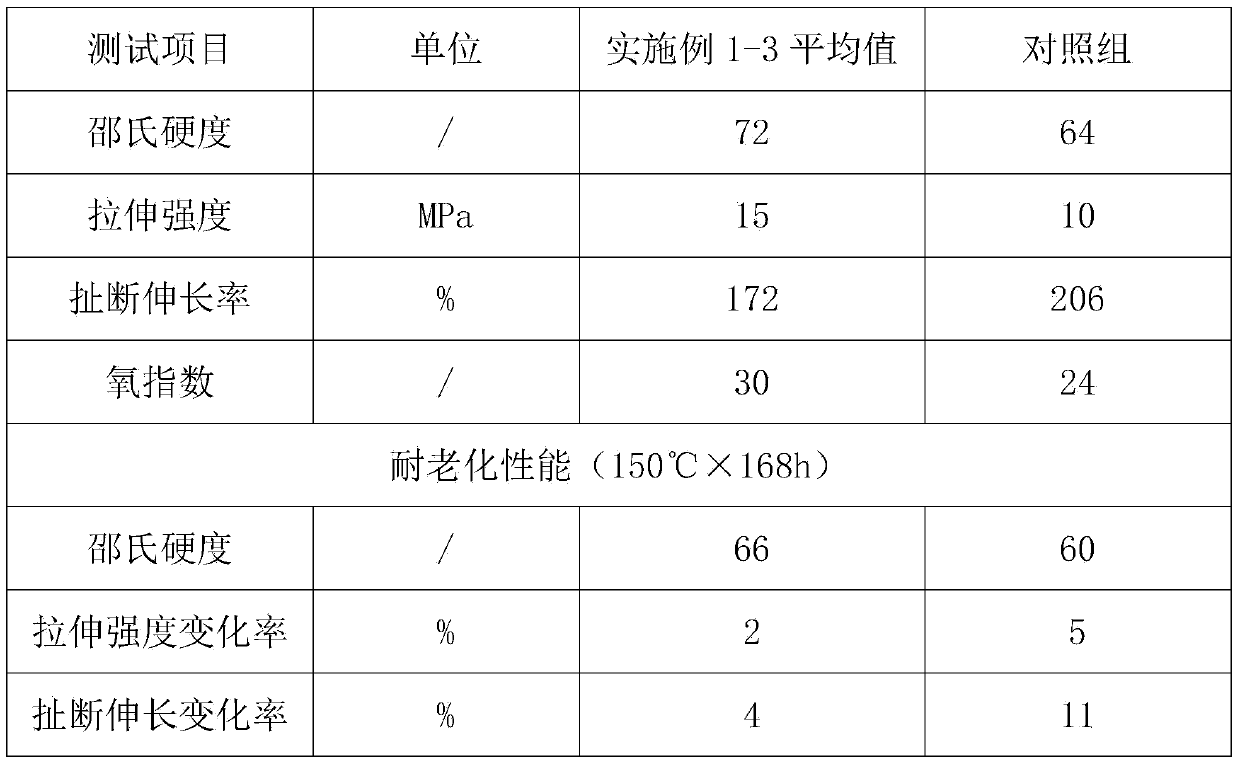

Examples

Embodiment 1

[0016] A low-cost flame-retardant cable sheath material proposed by the present invention, its raw materials include by weight: 10 parts of epichlorohydrin rubber, 30 parts of neoprene rubber, 0.7 parts of stearic acid, 15 parts of semi-reinforcing carbon black, zinc oxide 1.5 parts, 2.4 parts of ethylenethiourea, 5 parts of aluminum hydroxide, 10 parts of decabromodiphenyl ether, 1 part of dibenzothiazole disulfide, 0.35 parts of tetramethylthiuram disulfide, trimethylolpropane 0.15 part of methacrylate, 2.5 parts of antioxidant, described antioxidant is by weight percentage by 40% 2,6-di-tert-butyl-4 (dimethylaminomethyl) phenol, 40% part of antioxidant GS and 20% antioxidant 168;

[0017] During the preparation process, the epichlorohydrin rubber and neoprene rubber were masticated in an internal mixer for 3 minutes at a temperature of 68°C, then raised to 86°C for 2.5 minutes, and then raised to 92°C for 3 minutes to obtain a mixture. Base material: Put the mixed base mat...

Embodiment 2

[0019] A low-cost flame-retardant cable sheath material proposed by the present invention, its raw materials include by weight: 30 parts of epichlorohydrin rubber, 20 parts of neoprene rubber, 1.3 parts of stearic acid, 10 parts of semi-reinforcing carbon black, zinc oxide 3 parts, 1.5 parts of ethylene thiourea, 10 parts of aluminum hydroxide, 5 parts of decabromodiphenyl ether, 3 parts of dibenzothiazole disulfide, 0.2 parts of tetramethylthiuram disulfide, trimethylolpropane 0.3 part of methacrylic acid ester, 1 part of antioxidant, described antioxidant is made of 60% 2,6-di-tert-butyl-4 (dimethylaminomethyl) phenol, 20% part of antioxidant GS by weight percentage and 20% antioxidant 168;

[0020] During the preparation process, the epichlorohydrin rubber and neoprene rubber were masticated in an internal mixer for 2 minutes at a temperature of 70°C, then raised to 85°C for 3 minutes, and then raised to 92°C for 4 minutes to obtain a mixed base material; the mixed base ma...

Embodiment 3

[0022] A low-cost flame-retardant cable sheath material proposed by the present invention, its raw materials include by weight: 20 parts of epichlorohydrin rubber, 25 parts of neoprene rubber, 1 part of stearic acid, 12 parts of semi-reinforcing carbon black, zinc oxide 2 parts, 2 parts of ethylene thiourea, 10 parts of aluminum hydroxide, 10 parts of decabromodiphenyl ether, 2 parts of dibenzothiazole disulfide, 0.27 parts of tetramethylthiuram disulfide, trimethylolpropane 0.23 part of methacrylate, 2 parts of antioxidant, described antioxidant is by weight percent by 50% 2,6-di-tert-butyl-4 (dimethylaminomethyl) phenol, 30% part of antioxidant GS and 20% antioxidant 168;

[0023] During the preparation process, the epichlorohydrin rubber and neoprene rubber were masticated in an internal mixer for 4 minutes at a temperature of 65°C, then raised to 90°C for 1 minute, and then raised to 93°C for 2 minutes to obtain a mixed base material; put the mixed base material into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com