Cable sheath insulation material for coal mines and preparation method thereof

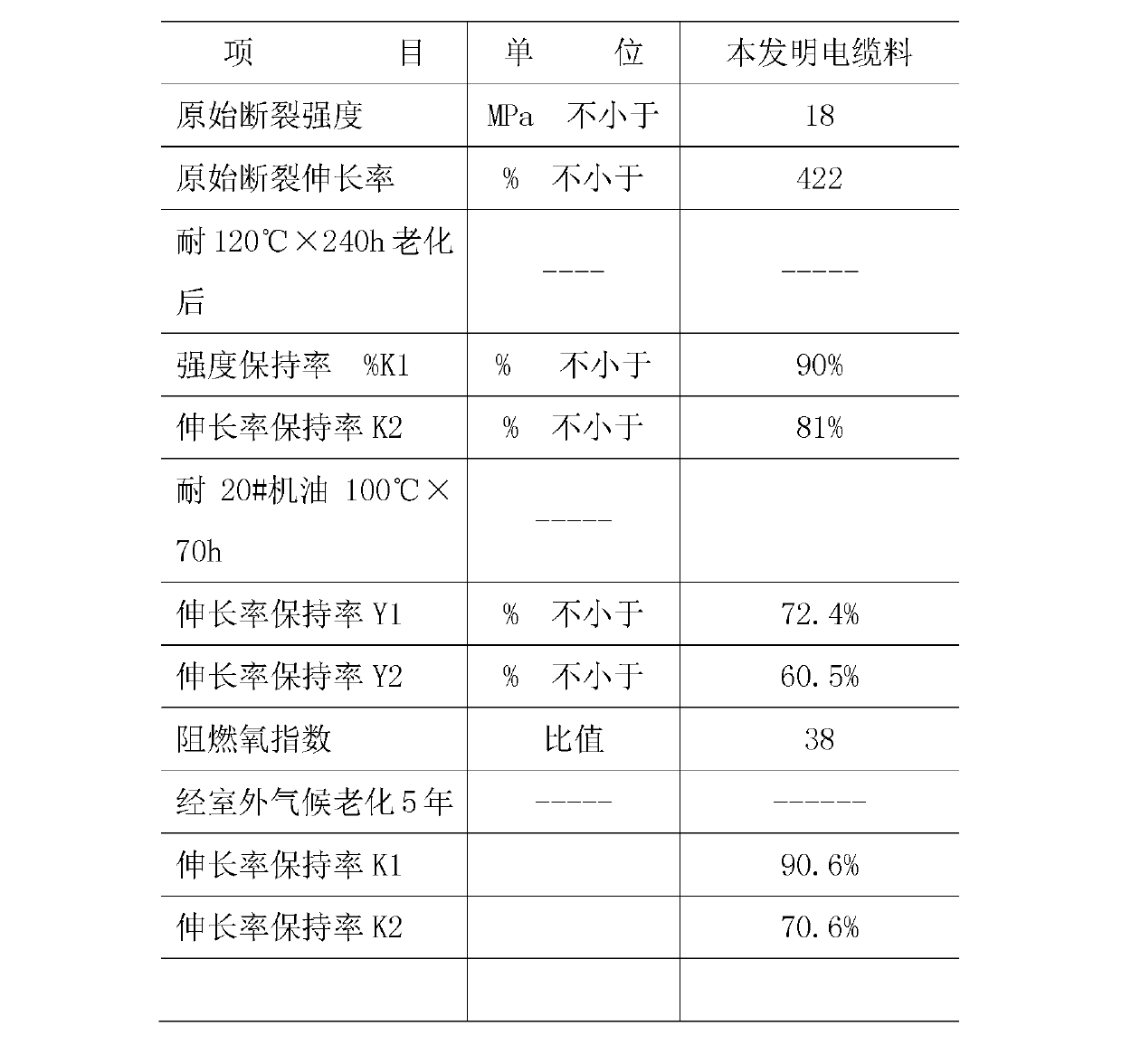

A cable sheathing and insulating material technology, applied in the direction of insulated conductors, insulated cables, rubber insulators, etc., can solve the problems of compatibility, low temperature resistance, compression set resistance, reduced thermal aging performance, low tear resistance, and water resistance. It can achieve the effect of high performance such as aging resistance, excellent physical properties and low shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A cable sheath insulating material for coal mines, which is composed of the following raw materials in parts by weight (kg):

[0017] Neoprene CR121 95, SG-3 type PVC resin 20, semi-reinforcing carbon black N774 25, ferrocene 2, N, N'-m-phenylene bismaleimide 2, barium sulfate powder 35, antioxidant MB2, 2-mercaptobenzimidazole 1-2, chlorinated paraffin 8, accelerator DM 2, accelerator TMTD 0.8, nano-bauxite 25, propylene glycol adipate polyester 3, talc powder 3, acetylcitric acid Triethyl ester 0.5, bis(dioctyloxypyrophosphate) ethylene titanate 0.9, zinc borate 4, epoxy butyl oleate 6, zinc oxide 0.8, modified sepiolite 2-3, ethylene Thiourea 6;

[0018] The preparation method of the modified sepiolite is as follows: soak the sepiolite in 1.2g / L potassium permanganate solution and 10% sodium hydroxide solution to remove impurities, then filter and wash to become neutral, and calcined at 450°C , 1 hour, grind into powder, then add 1-2% of the powder weight of quartz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com