Method and additive for preparing electrolytic copper foil for high temperature power battery with high elongation

An electrolytic copper foil, high elongation technology, applied in the electrolysis process, electroforming, etc., can solve problems such as cracking or breaking of copper foil, reduction of battery capacity, and increase of contact resistance between copper foil and negative electrode carbon material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1, the additives used include grain refiners, the grain refiners are GISS (polyethyleneimine derivatives), HP (sodium alcohol thiopropane sulfonate), P (polyethylene glycol) , an aqueous solution of N (ethylene thiourea), wherein the GISS concentration in the aqueous solution is 0.9ml / l (between 0.7 and 1.0ml / l), the HP concentration is 17g / l, and the P concentration is 4g / l, The concentration of N is 1.7 g / l, Cl - The concentration is 25ppm (between 20 and 30ppm).

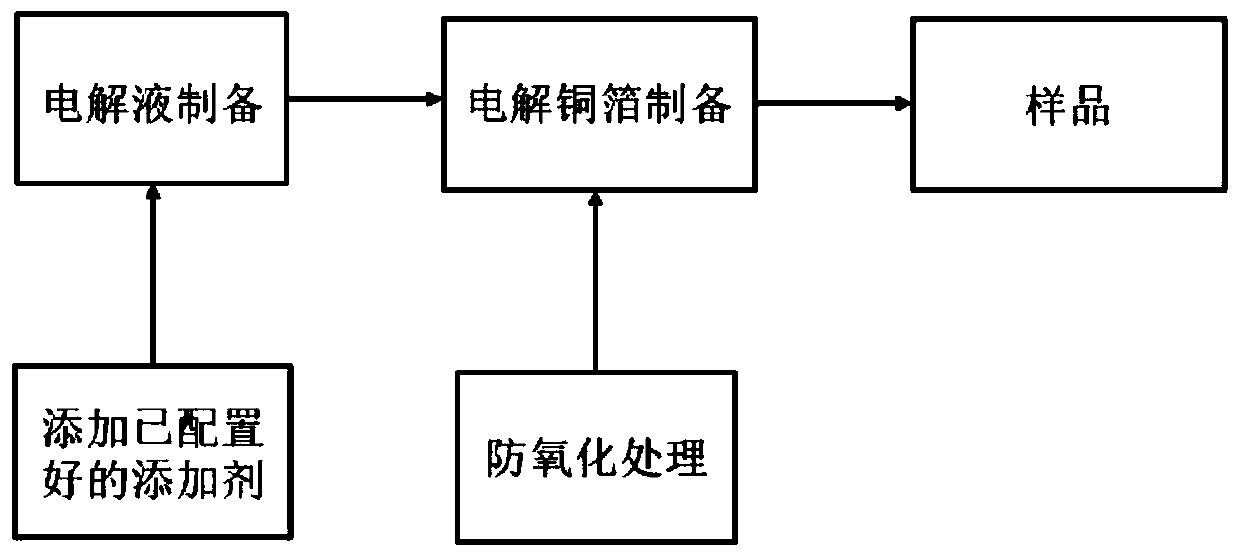

[0022] The specific preparation process includes the following steps:

[0023] (1) Electrolyte preparation: the high-purity copper wire with a purity of 99.95% is heated and dissolved in a copper-dissolving tank (sulfuric acid and hot water are added in the copper-dissolving tank and air is blown into it) to generate copper sulfate electrolyte;

[0024] (2) Preparation of electrolytic copper foil: the copper sulfate electrolyte obtained in step (1) is filtered through a diatomite filter, a bag fil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com