Closed stockyard

A closed, stock yard technology, applied in the directions of loading/unloading, transportation and packaging, storage devices, etc., can solve the problem of subsidence of underground corridors to deep underground positions, material yard adaptability, reduced selectivity, and inability to use materials. Pre-mixing and other problems to achieve the effect of saving materials, convenient construction and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

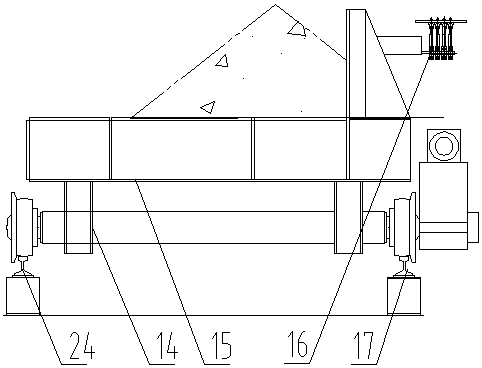

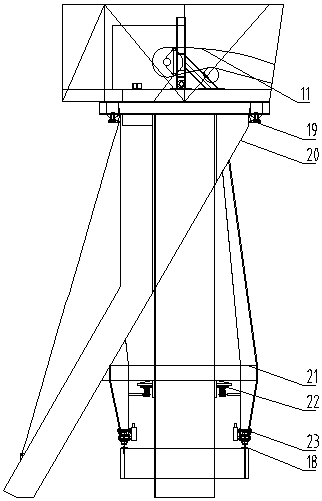

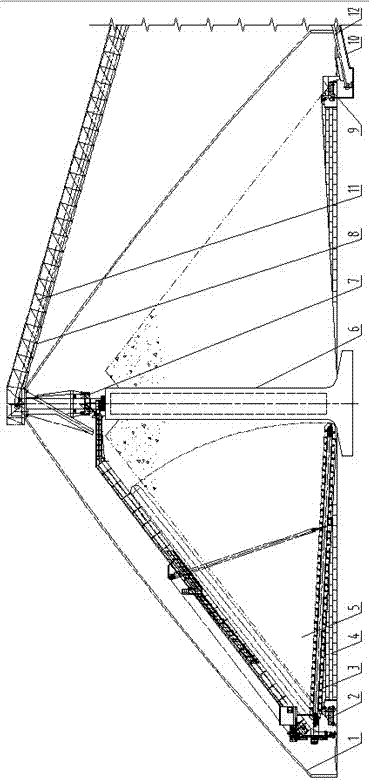

[0021] Such as figure 1 As shown in the closed stockyard, there is an annular wall around the closed stockyard, the conical dome 1 is connected to the top of the annular wall, the central column 6 is set at the center of the annular wall, and the closed stockyard is equipped with a material input system and a material input system. output system. The material input system includes a trestle 8 connected to the top of the central column 6, a feeding belt conveyor 11 arranged in the trestle 8, a stacking device 7 connected to the top of the central column 6, and the stacking device 7 accepts the feeding belt Type conveyor 11 incoming materials, and pile the incoming materials along the central column 6 into the material yard, after the material is stored in the material yard, the material is piled into a cone-like shape; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com