Self-strengthening high-zinc heat-resistant magnesium alloy

A magnesium alloy, heat-resistant technology, applied in the field of light metal materials, can solve the problems of insufficient high-temperature strength and poor plasticity of high-zinc-magnesium alloys, and achieve the effects of increasing room temperature and high temperature elongation, overcoming poor plasticity, and improving crystallographic morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

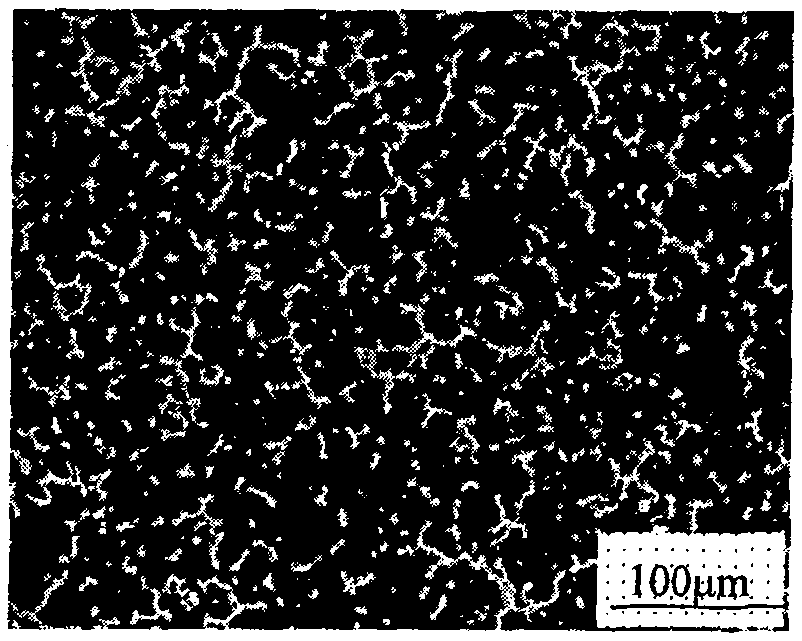

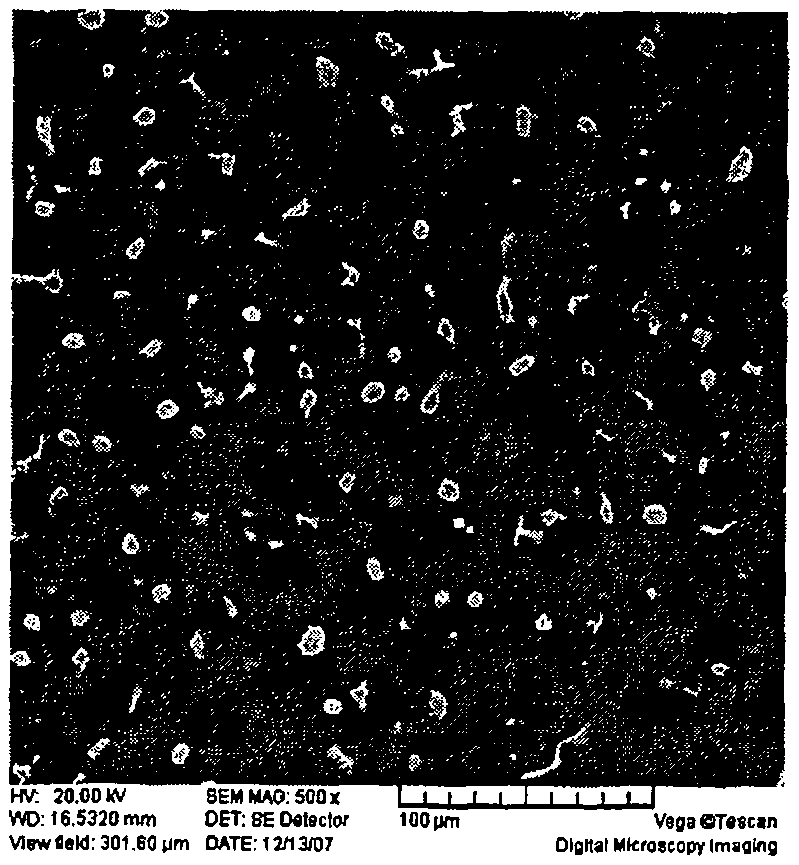

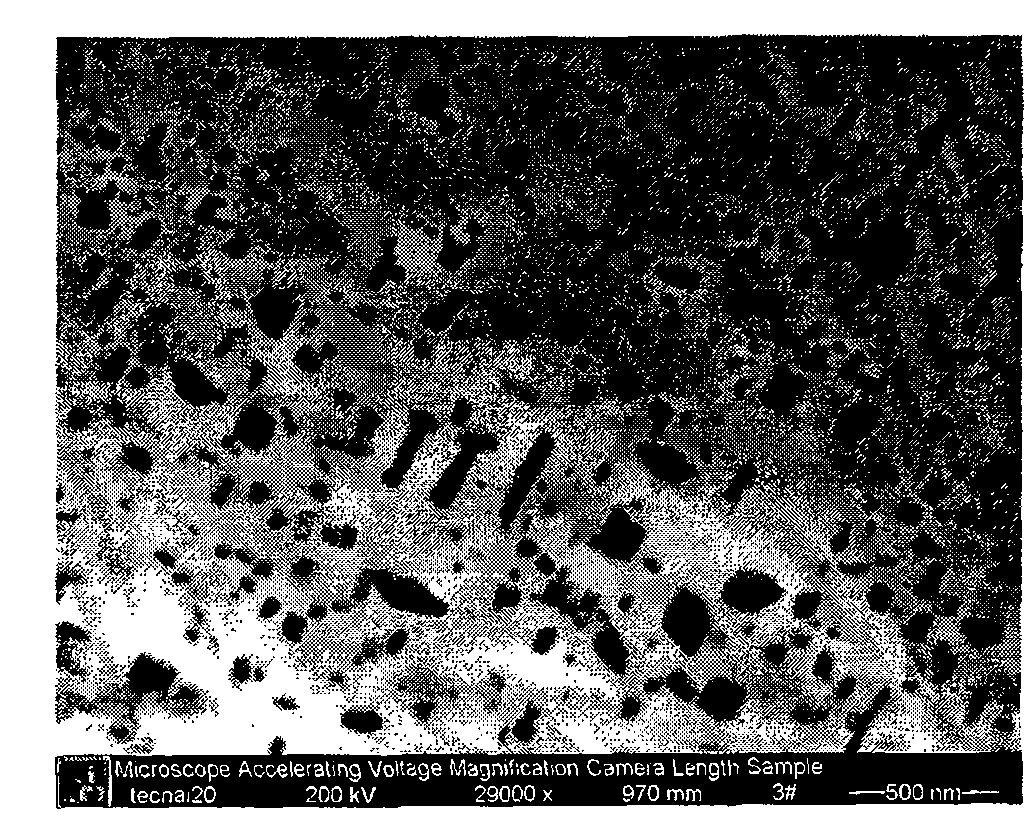

Image

Examples

Embodiment 1

[0014] Embodiment 1: A self-strengthening high-zinc heat-resistant magnesium alloy, the weight percentage of each composition in the magnesium alloy is zinc 10%, aluminum 4.0%, rare earth yttrium (containing Y25.4% yttrium-rich mixed rare earth) 0.4%, The remainder is magnesium and unavoidable impurities.

Embodiment 2

[0015] Embodiment 2: A self-strengthening high-zinc heat-resistant magnesium alloy, the weight percentage of each component in the magnesium alloy is 8% zinc, 3.4% aluminum, 0.4% rare earth erbium, and the rest is magnesium and unavoidable impurities.

Embodiment 3

[0016] Embodiment 3: A self-strengthening high-zinc heat-resistant magnesium alloy, the weight percentage of each component in the magnesium alloy is 7% of zinc, 3.0% of aluminum, 0.4% of rare earth erbium, and the rest is magnesium and unavoidable impurities.

[0017] The self-strengthening high-zinc and heat-resistant magnesium alloys of the present invention all use magnesium as a matrix and can be produced by the following preparation process: raw materials are magnesium ingots, pure zinc, pure aluminum and rare earth master alloys. Use resistance crucible furnace to melt, pass into SF 6 and CO 2 Mixed gas protection. During the smelting process, the magnesium ingot is first placed in the crucible, and after heating and melting, zinc block and aluminum block are added at the same time, and after complete melting, magnesium-erbium intermediate alloy or yttrium-rich rare earth magnesium alloy is added. After it is completely melted, heat the melt to 750°C, keep it warm for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com