Magnesium alloy and smelting and heat treatment processes thereof

A magnesium alloy and process technology, applied in the field of magnesium-calcium-zinc alloy and its smelting and heat treatment process, can solve the problems of poor mechanical properties, poor strength and mechanical properties of pure magnesium, and achieve improved mechanical properties, improved casting performance, and liquid The effect of phase temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Prepare to make magnesium alloy I. In this experiment, magnesium ingots are used as the main component (see Table 1-1), and metal calcium and metal zinc are alloy elements. , to prepare magnesium-calcium-zinc alloy, the experimental materials, weight and drugs used are shown in Table 1-2, and the main equipment used in this experiment is listed in Table 1-3.

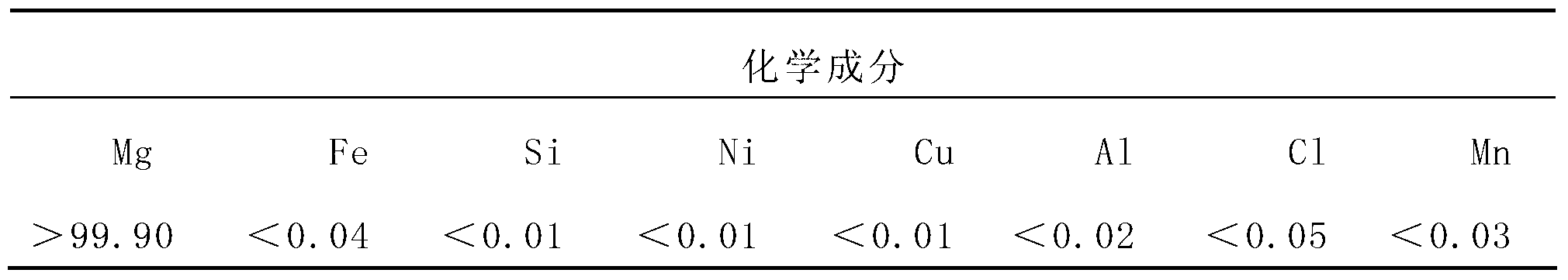

[0043] Table 1-1 Composition of pure magnesium ingot

[0044]

[0045] Table 1-2 Experimental materials, weight and drugs

[0046]

[0047] Table 1-3 Experimental instruments and equipment

[0048]

[0049] Melting process steps:

[0050] (1) Divide the magnesium ingot into small pieces, remove the impurities and scale on the surface of the magnesium ingot, and weigh the metal zinc and metal calcium separately for use;

[0051] (2) Clean up the equipment used and try to avoid mixing impurities during the smelting process;

[0052] (3) Before melting, preheat the graphite crucible and mold to 280-290°C...

Embodiment 2

[0065] Prepare to make magnesium alloy II. In this experiment, magnesium ingot is used as the main component (see Table 1-1), and metal calcium and metal zinc are alloy elements. , to prepare magnesium-calcium-zinc alloy, the experimental materials, weight and drugs used are shown in Table 1-5, and the main equipment used in this experiment is listed in Table 1-3.

[0066] Table 1-5 Experimental materials, weight and drugs

[0067]

[0068] The smelting process and heat treatment process steps are the same as in Example 1.

[0069] Experimental design The composition of magnesium alloy II is 98% magnesium, 1.0% calcium, 2% zinc, and other <0.01%. Although there is protective gas (argon and sulfur hexafluoride) during the melting process, the molten magnesium will also melt to varying degrees. At the same time, Ca and Zn elements have a certain loss, so the actual composition of the prepared alloy is not completely consistent with the design composition.

[0070] During th...

Embodiment 3

[0074] Using the magnesium alloy prepared in Example 1 or 2 as a material, a medical biodegradable airway stent can be made, which can be applied to children with congenital or acquired airway stenosis.

[0075] At present, the treatment methods for tracheal stenosis are mainly surgery or intratracheal stenting. There are many surgical complications, such as subcutaneous emphysema, infection, hemorrhage, pneumothorax, tracheoesophageal fistula, etc., which are not the first choice for treatment. The existing airway stent has a very prominent shortcoming: regardless of whether the treatment succeeds or fails, the stent needs to be taken out again. This will further increase the risk of related adverse complications, especially the progress of the treatment of airway stenosis in infants and young children is greatly restricted.

[0076] However, the above disadvantages can be avoided by using the biodegradable airway stent of the present invention, because the above-mentioned m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com