High-speed train alloy cast steel brake disc material and smelting process thereof

A technology of alloy cast steel and high-speed trains, applied in the field of metal materials, can solve the problems of non-wear-resistant brake friction surfaces, short service life, poor toughness, etc., and achieve less debris inclusions, low production costs, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

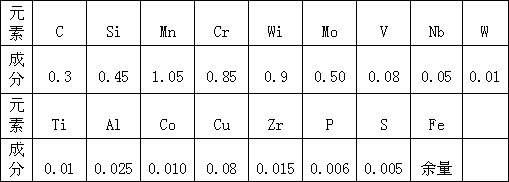

Embodiment 1

[0021] The molten steel is smelted in a 500Kg medium-frequency induction furnace, and the manufacturing process steps are as follows:

[0022] (1) Load high-quality steel ingots with a size of 70cm2, and add them in two times;

[0023] (2) Electric melting, allowing the use of the maximum power to melt the steel ingot. When the temperature of the molten steel rises to 1500-1520°C, add elements: carbon, ferromolybdenum, ferrochromium, nickel, zirconium, vanadium, and continue to heat up. With the melting of the steel ingot, Pound the charge at any time to avoid bridging, and add steel ingots for the second time;

[0024] (3) When the molten steel temperature rises to 1550-1560°C, add ferrosilicon;

[0025] (4) When the molten steel temperature rises to 1580-1590°C, add ferromanganese;

[0026] (5) Take samples for analysis, and adjust the chemical composition according to the analysis results;

[0027] (6) When the molten steel temperature rises to 1650-1670°C, stop the powe...

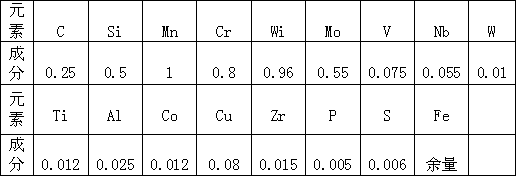

Embodiment 2

[0033] Melting molten steel with a 1000Kg intermediate frequency induction furnace, the manufacturing process steps are:

[0034] (1) Load high-quality steel ingots with a size larger than 80mm2, and add them in two times;

[0035] (2) Electric melting, allowing the use of the maximum power to melt the steel ingot. When the molten steel temperature rises to 1550-1560 ° C, add elements: carbon, ferromolybdenum, ferrochromium, nickel, zirconium, vanadium, and then continue to heat up, as the ingot melts , beat the charge at any time to avoid bridging, and add steel ingots for the second time;

[0036] (3) When the molten steel temperature rises to 1570-1580°C, add ferrosilicon;

[0037] (4) When the molten steel temperature rises to 1590-1600°C, add ferromanganese;

[0038] (5) Take samples for analysis, and adjust the chemical composition according to the analysis results;

[0039] (6) When the molten steel temperature rises to 1650-1660°C, stop the power supply, insert 0.5K...

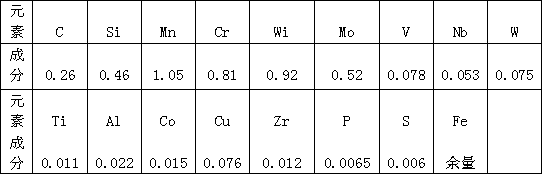

Embodiment 3

[0045] Using a 5000Kg intermediate frequency induction furnace to make molten steel, the manufacturing process steps are:

[0046] (1) Load high-quality steel ingots, the size of which is not greater than 120mm2, and add in two times;

[0047] (2) Electric melting, allowing the use of the maximum power to melt the steel ingot. When the molten steel temperature rises to 1540-1550 ° C, add elements: carbon, ferromolybdenum, ferrochromium, nickel, zirconium, vanadium, and then continue to heat up, as the ingot melts , beat the charge at any time to avoid bridging, and add steel ingots for the second time;

[0048] (3) When the molten steel temperature rises to 1560-1570°C, add ferrosilicon;

[0049] (4) When the molten steel temperature rises to 1580-1590°C, add ferromanganese;

[0050] (5) Take samples for analysis, and adjust the chemical composition according to the analysis results;

[0051] (6) When the molten steel temperature rises to 1640-1650°C, stop the power supply,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com