Patents

Literature

63 results about "Lead(II,IV) oxide" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lead(II,IV) oxide, also called red lead is the inorganic compound with the formula Pb₃O₄. A bright red or orange solid, it is used as pigment, in the manufacture of batteries, lead glass, and rustproof primer paints. It is an example of a mixed valence compound, being composed of both Pb(II) and Pb(IV).

Method for recovering lead-containing raw material by using wet process

ActiveCN103526016AEnvironmentally Friendly Recycling MethodsEfficient recycling methodProcess efficiency improvementRecovery methodLead dioxide

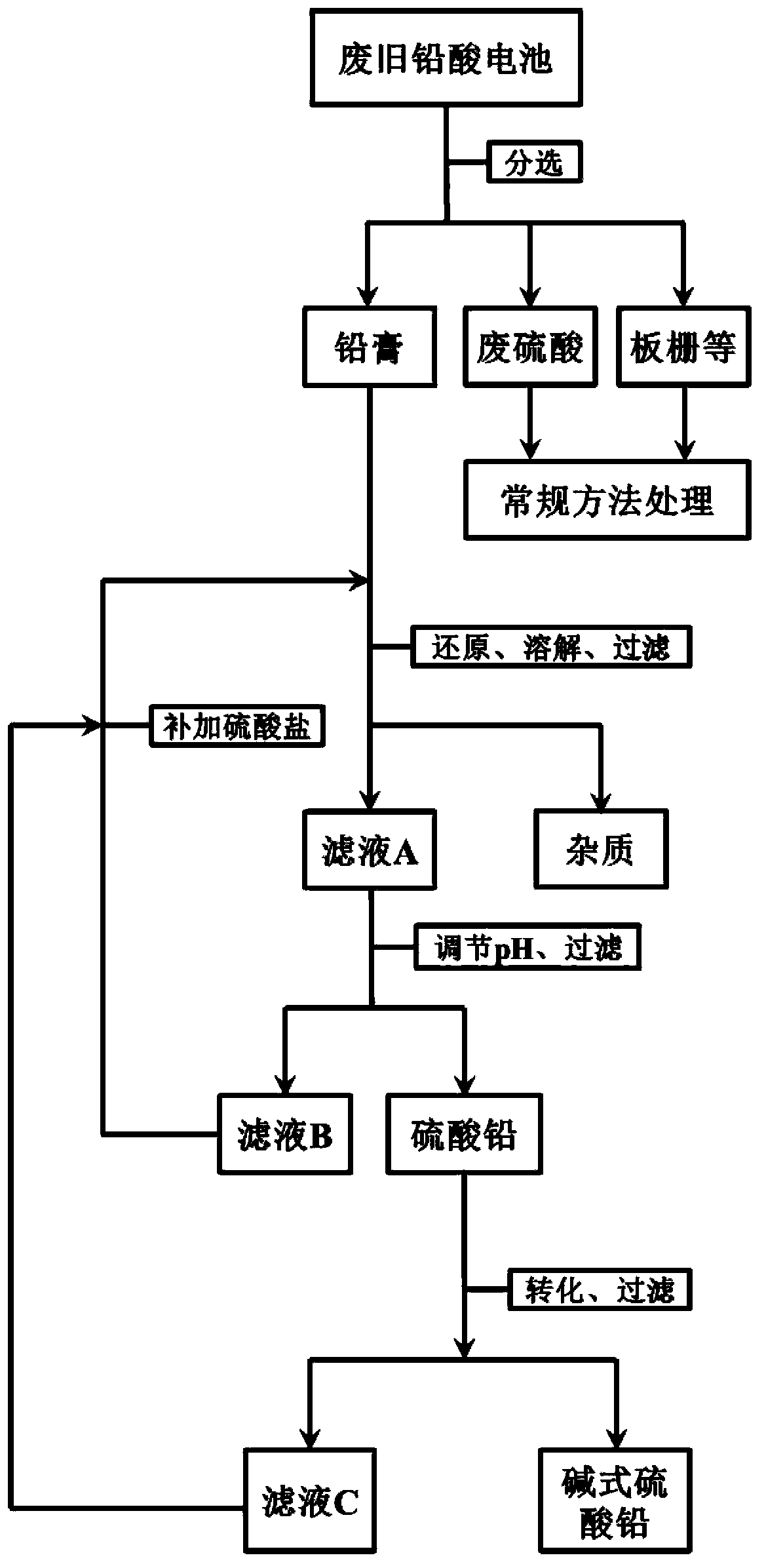

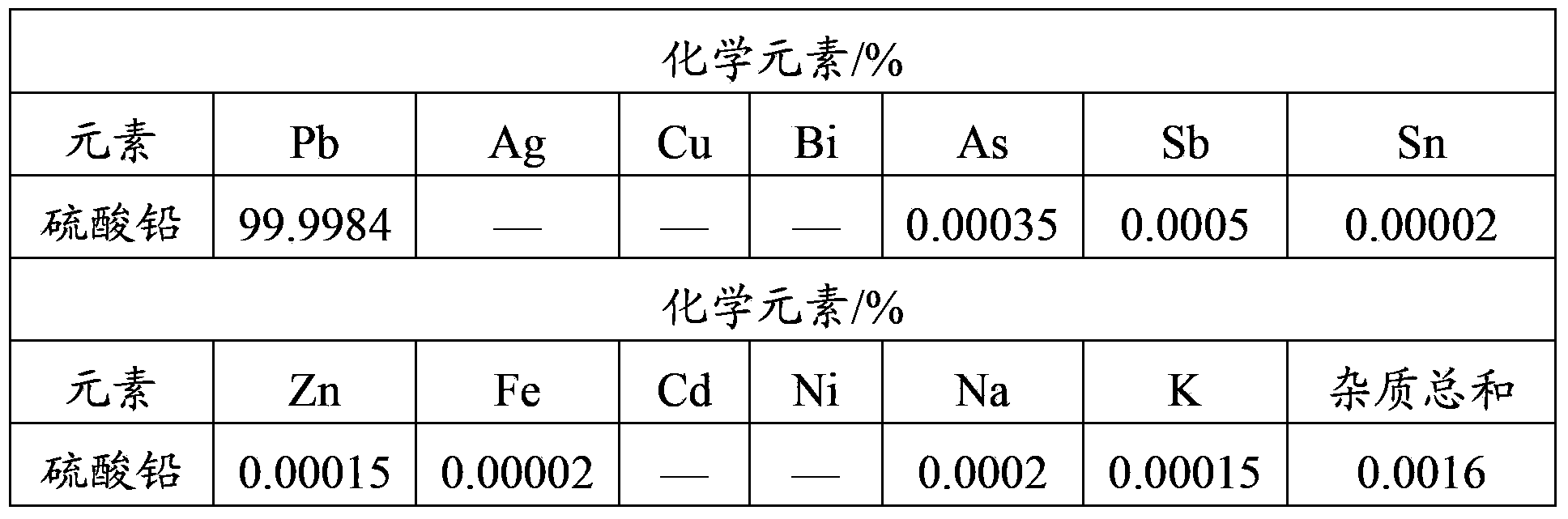

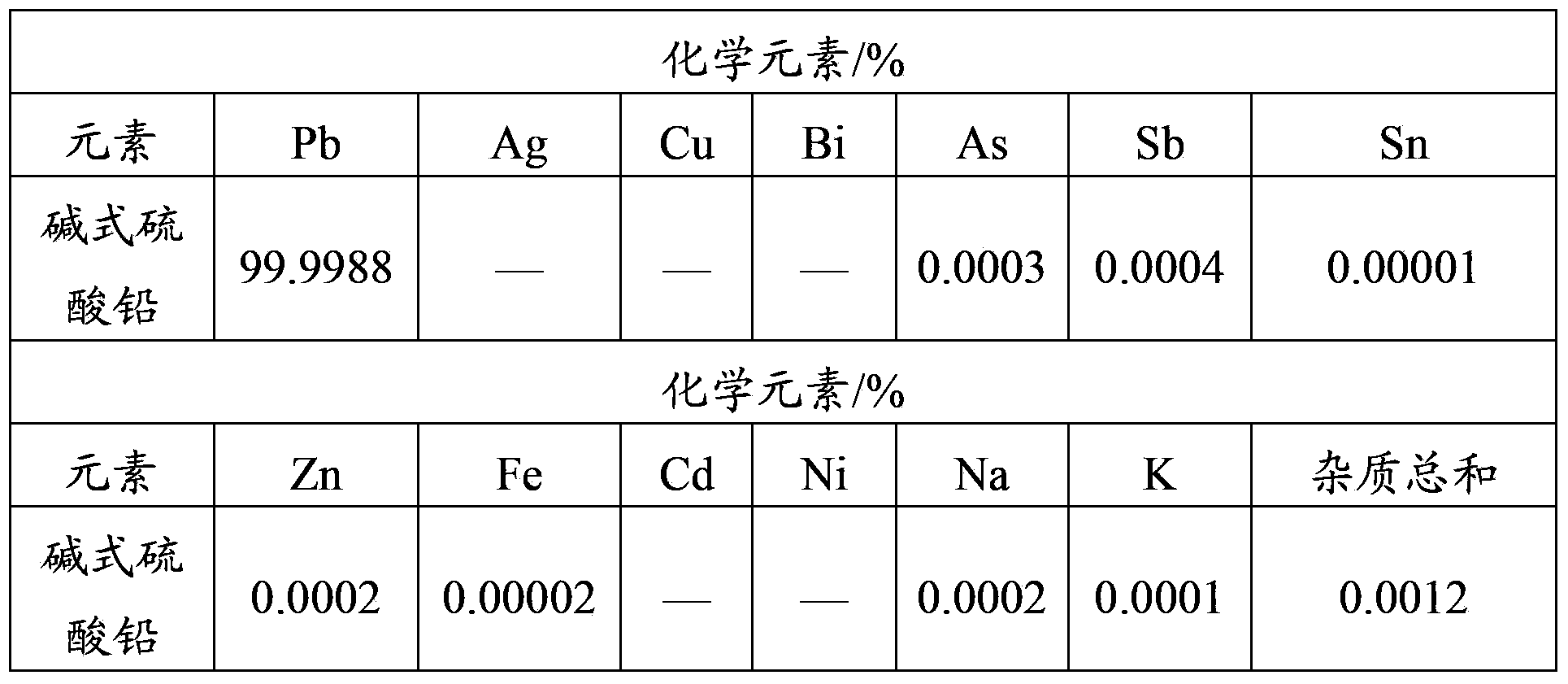

The invention discloses a method for recovering a lead-containing raw material by using a wet process. The method comprises the steps: (1) leaching the lead-containing raw material by using a solution, adding a reducing agent to reduce lead dioxide or lead orthoplumbate in the lead-containing raw material into a soluble lead salt, after a lead compound is completely dissolved, filtering the solution, and separating to obtain a filtrate A and an insoluble substance, wherein the solution contains sulfate, a complexing agent and a catalyst; (2) adjusting the pH value of the filtrate A, separating to obtain lead sulfate and a filtrate B, and returning the filtrate B to the step (1) after sulfate radicals are replenished and the pH value is adjusted; (3) directly using lead sulfate as battery materials or commodities, subjecting a sulfate-containing alkaline solution and lead sulfate to reaction, and separating to obtain basic lead sulfates and a filtrate C, wherein the basic lead sulfates include tribasic lead sulfate and tetrabasic lead sulfate. The method can be used for purifying the lead-containing raw material to form lead sulfate and basic lead sulfates directly used for producing lead-acid batteries, thereby being an environment-friendly wet-process recovery method.

Owner:北京中金瑞丰环保科技有限公司

Method for preparing lead tetraoxide from waste lead-acid batteries and application

ActiveCN103022593AOvercoming technical problems of polluting the environmentEasy to operateWaste accumulators reclaimingLead oxidesRecovery methodLead(II,IV) oxide

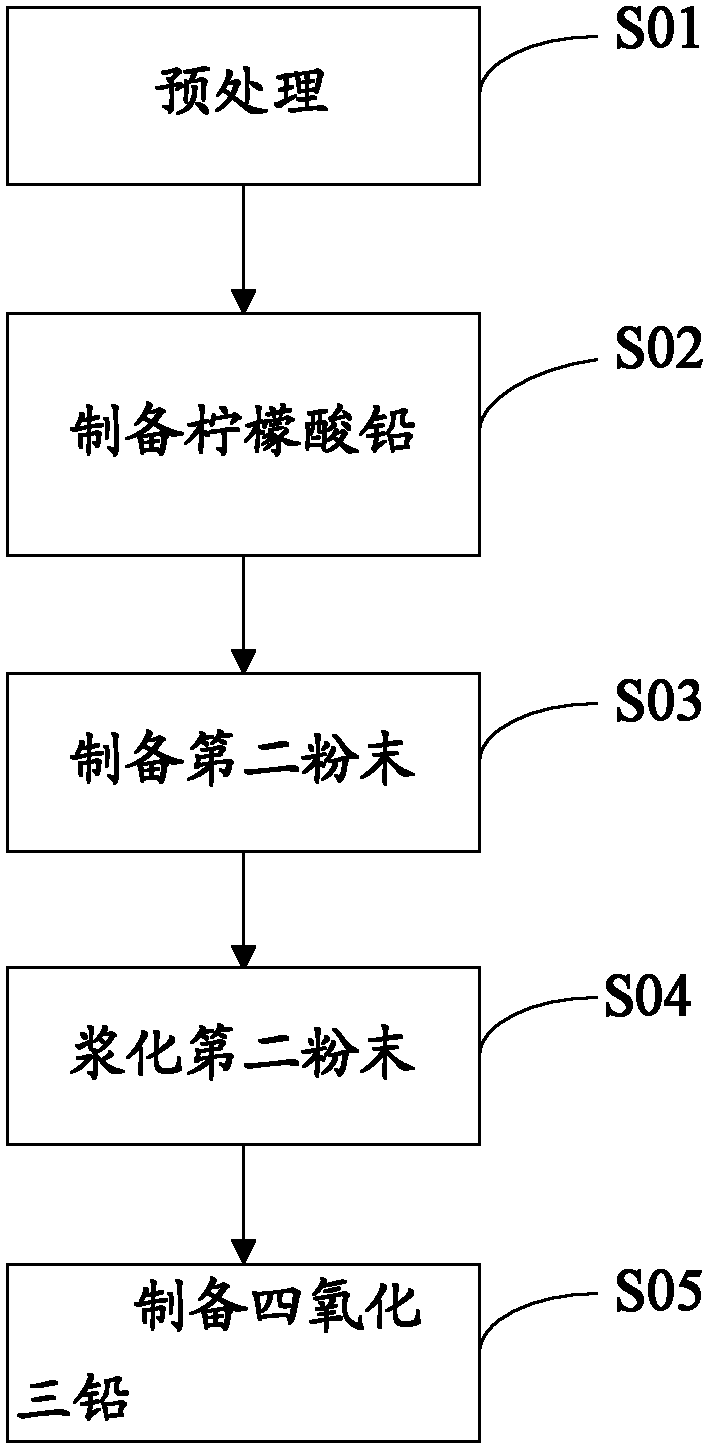

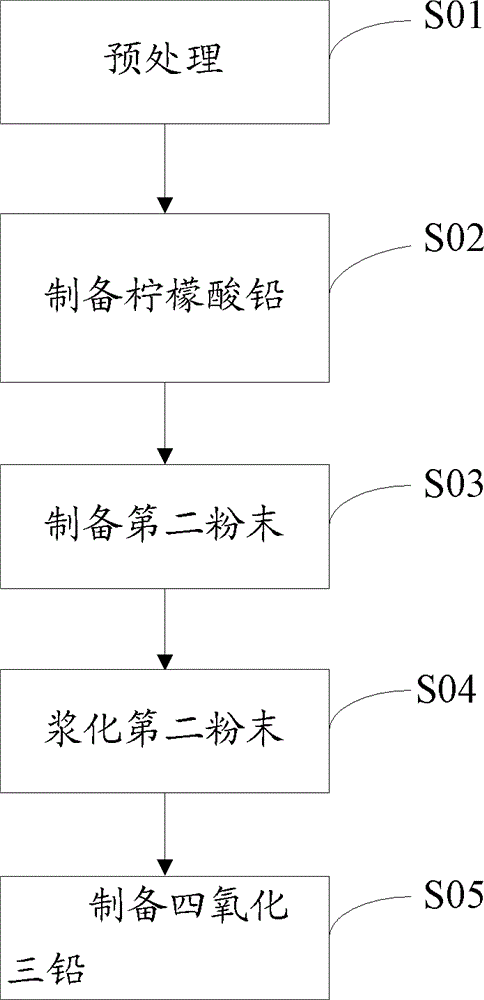

The invention is applicable to the field of waste battery recovery technologies and provides a method for preparing lead tetraoxide from waste lead-acid batteries. The method comprises the steps of carrying out pretreatment, preparing lead citrate, preparing second powder, pulping the second powder, preparing the lead tetraoxide, and the like. According to the method for preparing the lead tetraoxide from the waste lead-acid batteries, provided by the invention, lead sulfate and lead monoxide in lead plaster of the waste lead-acid batteries are converted into the lead citrate by using citric acid and alkali metal citrate, and then, the lead tetraoxide is prepared, so that the method has a significant economic benefit, and the technical problem of environment pollution caused by a waste lead-acid battery lead recovery method in the prior art is solved; and the method for preparing the lead tetraoxide from the waste lead-acid batteries is simple in operation, low in cost and high in economic benefit, thereby being very applicable to industrialized production.

Owner:SHENZHEN CENT POWER TECH

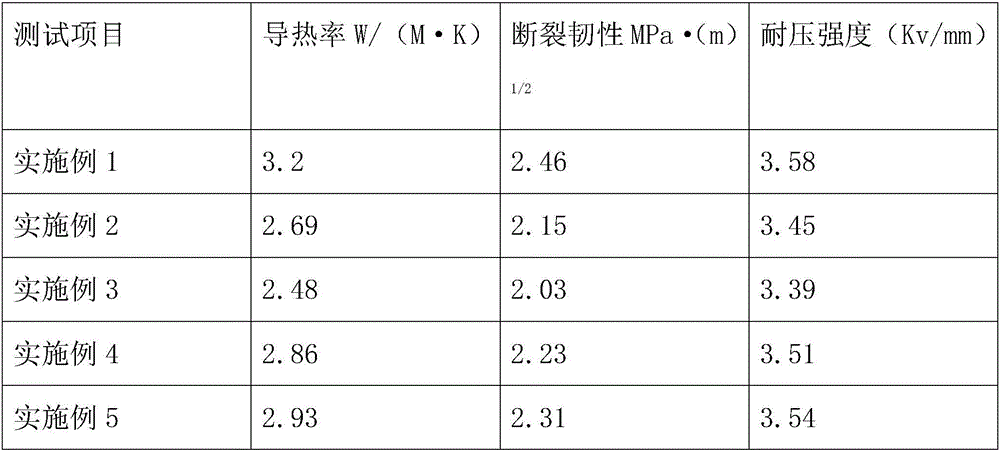

High temperature-resistant resistor ceramic composite material and preparation method thereof

InactiveCN106587990AHigh thermal conductivityImprove heat resistanceZirconium hydrideCeramic composite

The invention discloses a high temperature-resistant resistor ceramic composite material. The high temperature-resistant resistor ceramic composite material is prepared from barium titanate, zirconium dioxide, eucryptite, magnesium oxide, zirconium boride, hafnium diboride, lead zirconate, strontium carbonate, molybdenum disulfide, titania, yttrium oxide, calcium carbonate, thallium carbide, hafnium carbide, zirconium carbide, silicon nitride, zirconium oxide, polyvinyl alcohol, copper oxide, niobium pentoxide, tungsten trioxide, lead tetraoxide, alumina, silica and assistants. The invention also provides a preparation method of the high temperature-resistant resistor ceramic composite material. The high temperature-resistant resistor ceramic composite material has excellent high temperature resistance.

Owner:ANHUI RUIXIN AUTOMATION INSTR

Fluororubber and epichlorophdrin rubber formulation

ActiveCN101081916AHigh electronegativityGood fuel resistanceSynthetic resin layered productsPolymer scienceLead(II,IV) oxide

The present invention is one kind of rubber pipe comprising one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber. The fluororubber consists of polyfluoroprene, thermal black N990, 2, 5-dimethyl-2, 5-dihexane, triallyl cyanourate and carnauba wax; and the chlorohydrin rubber consists of chlorohydrin rubber C, chlorohydrin rubber H, black N550, anti-ager NBC, processing aid R-300, stearic acid, plasticizer RS-107, red lead, ethylene thiourea NA-22, plasticizer W-305ELS and scorch retarder CTP-80. The rubber pipe with one inner layer of fluororubber and one middle layer and one outer layer of chlorohydrin rubber has high heat resistance, high oil tolerance, high ozone tolerance and high fuel oil osmosis resistance.

Owner:TIANJIN PENGYI GRP CO LTD

Positive pole plate lead paste of lead storage battery, preparation method of lead paste and lead storage battery

ActiveCN107452947AEasy to apply and adhereImprove the ability to receive high-current chargingLead-acid accumulatorsCell electrodesFiberLEAD TETROXIDE

The invention relates to the technical field of a lead storage battery, in particular to positive pole plate lead paste of a lead storage battery, a preparation method of the lead paste and the lead storage battery employing the positive pole plate lead paste. The positive pole plate lead paste comprises the following substances based on parts by weight: 1,000 parts of lead powder, 2-5 parts of colloidal graphite, 0.1-2 parts of antimony oxide, 1-15 parts of tetrabasic lead sulfate, 20-50 parts of lead tetroxide, 0.1-2 parts of fiber, 60-100 parts of dilute sulphuric acid, 60-100 parts of pure water and 2-15 parts of processing powder. With the positive pole plate lead paste of the lead storage battery, provided by the invention, the corrosion of the lead paste on grid alloy is reduced, and the binding force between the lead paste and the grid alloy is improved; and by the addition of graphite in a relatively large proportion, the conductivity of the battery is greatly improved, and the large-current charging receiving capability of the battery is good.

Owner:JIESHOU HUAYU POWER SUPPLY

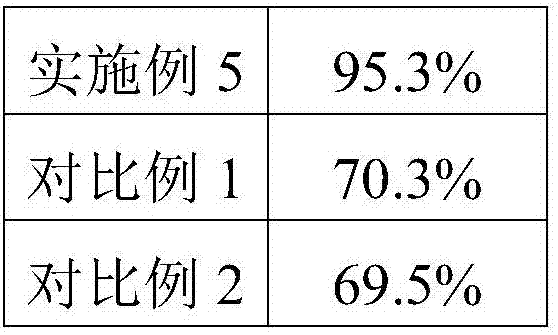

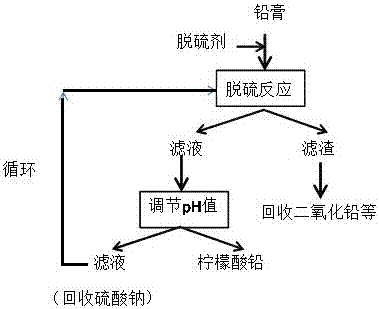

Method for preparing high-quality lead citrate by waste lead paste wet method

InactiveCN106929685AHigh recovery rateQuality improvementOrganic compound preparationSulfate/bisulfate preparationCITRATE ESTERFiltration

The invention discloses a method for preparing high-quality lead citrate by a waste lead paste wet method. The method comprises the following steps: lead paste is obtained from a positive plate and a negative plate of a waste lead accumulator; the lead paste is firstly mixed with solution containing sodium citrate to fully desulfurize for solid-liquid separation to obtain filtrate; citric acid is added in the filtrate to adjust pH of the filtrate; the filtrate is reacted with the citric acid for solid-liquid filtration and separation to obtain lead citrate; and the lead citrate is washed and dried to obtain high-quality lead citrate powder. The method prepare the lead citrate and lead tetraoxide by lead paste desulfurized products of waste lead, recovers sodium sulfate in desulfurizing solution, is low in energy consumption and simple in equipment, recovers lead resources in a classified manner, is high in quality of the lead citrate, and has the characteristics of good resource recovery effect and green and environment-friendly production process.

Owner:HENAN UNIV OF URBAN CONSTR

Method of quickly preparing red lead by utilizing intelligent oxygen supply device

ActiveCN103950971AShort oxidation timeIncrease production capacityRed leadLEAD TETROXIDELead(II,IV) oxide

The invention discloses a method of quickly preparing red lead by utilizing an intelligent oxygen supply device. The method comprises the following the steps: preparing red lead (lead tetroxide) by the intelligent oxygen supply device; compressing and storing pure oxygen gas prepared by oxygen preparation equipment in the intelligent oxygen supply device; adding air for diluting; controlling oxygen content to 35%-40% at a normal temperature under normal pressure by intelligent oxygen measuring equipment, wherein the intelligent oxygen measuring equipment intelligently switches on or switches off an air adding switch when the oxygen content is lower than or higher than 35%-40%; storing the diluted oxygen gas in a gas storage tank; heating the gas storage tank by a solar heating device or an electric heating device; controlling a temperature to 200 DEG C; and injecting the oxygen gas to a roasting bin and an oxidizing bin at a speed of 10L / m by an air feeder and an air guide tube. The device and the method disclosed by the invention can shorten oxidizing time, increase yield, save energy resource, lower consumption, save production cost and improve production efficiency.

Owner:JIESHOU CITY JUNMA IND & TRADE

Recycling process of waste battery lead

ActiveCN105925807ARealize repeated recyclingHigh purityPhotography auxillary processesWater/sewage treatment bu osmosis/dialysisElectrolysisLEAD TETROXIDE

The invention relates to the technical field of battery recycling equipment, in particular to a recycling process of waste battery lead. The recycling process is completed according to the following steps that a lead storage battery is mechanically cut off and broken and then is washed and screened at the same time by a rotary screen washing machine through an alkaline solution, plastic, waste electrolytes and lead bullion are screened out, and the waste electrolytes are conveyed to an ultrafiltration membrane processing system to be processed; lead carbonate is subjected to electromagnetic induction heating, sufficient oxygen is led in, the electromagnetic induction frequency ranges from 8 KHz to 60 KHz, the control temperature ranges from 330 DEG C to 460 DEG C, heat preservation is performed for 5 h to 6 h, and completely-oxidized lead tetroxide will be obtained; and in the electrolysis period, an electromagnetic induction magnetic field is applied at the bottom of an electrolytic tank, the magnetic induction intensity is 800 mT, and national standard number 1 lead is obtained. The recycling process has the beneficial effects that refining of the lead is achieved through a method that electrolysis is used in cooperation with electromagnetism, the purity of the lead is greatly improved, and repeated recycling of precious metal is also achieved; and the recycling process is simple, machining is easy, the recycling process is suitable for large-scale recycling, and therefore the recycling cost is reduced.

Owner:GUANGDONG NEW ENVIRONMENTAL PROTECTION TECH CO LTD +1

Preparing method of positive plate lead paste for power type lead acid storage battery

InactiveCN102723482AIncrease specific energyImprove discharge capacityCell electrodesFiberPower flow

A preparing method of positive plate lead paste for power type lead acid storage battery relates to lead acid storage batteries. At present, domestic lead acid storage batteries face difficulties of low specific energy and short service life in the prior art. The preparing method of the positive plate lead paste for the power type lead acid storage battery is characterized in that the formula of the positive plate lead paste is as follows: 100 kg lead powder, 0.10 to 0.12 kg short fiber, 30 to 50 kg red lead, 1 to 3 kg tin powder, 1.00 to 1.50 kg conductive graphite, 2.00 to 3.00 kg barium plumbate, 10000 to 1300 g deionized water, and 8200 to 7000 ml sulfuric acid with the concentration of 1.30 to 1.40 g / cm<3> (25 DEG C). The invention has the benefits that the preparing method of the positive plate lead paste for the power type lead acid storage battery has the advantages of high specific energy, strong heavy-current discharging capability and long circulating service life.

Owner:SHANDONG SACRED SUN POWER SOURCES

Equalizing fiche glue for aviation tyre and eualizing fiche

ActiveCN101200561ACorrection of static unbalance difference valueMeet static balance requirementsSpecial tyresAviationLead(II,IV) oxide

The present invention discloses a balanced film rubber and a balanced film of aviation tyre. The balanced film rubber is mixed and refined according to a certain proportion of natural rubber which is used as the main material, lead orthoplumbate, high-abrasion carbon black, pine tar, ketoamine type anti-aging agent, sulfur and sulfenamide type accelerator which are used as the main auxiliary materials; the balanced film rubber is used to manufacture the balanced film. The external layer of the balanced film rubber is coated with a thin layer of high-strength sizing material so as to manufacture the balanced film through prevulcanization. The balanced film rubber has the characteristics of large specific gravity and good adhesive performance with the sizing material on the surface of the internal cavity of the tyre. Static unbalanced sticking patch used for aviation tyre can repair the static disbalance of aviation tyre well, meet the static balance requirement of tyre and prolong the service life of tyre.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

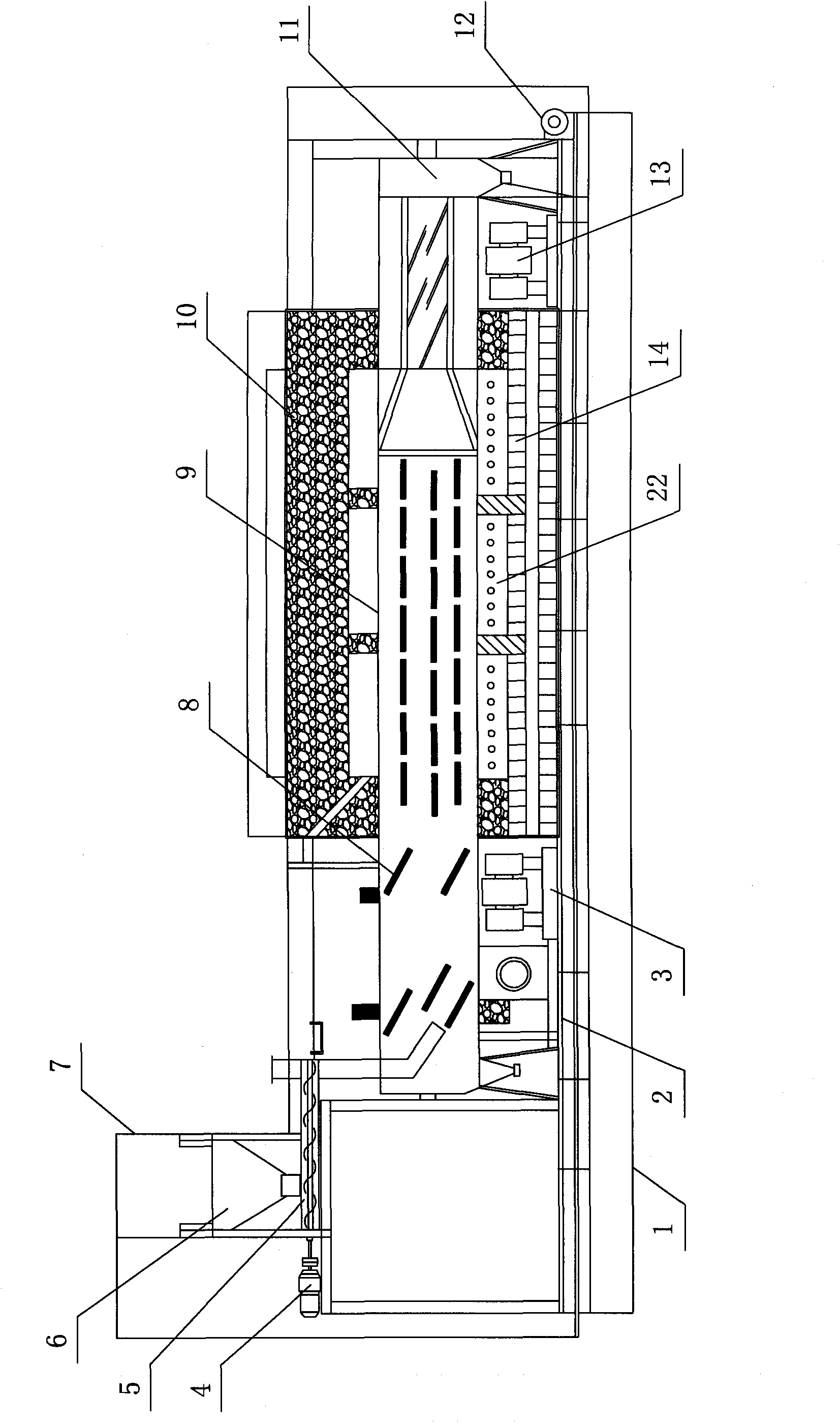

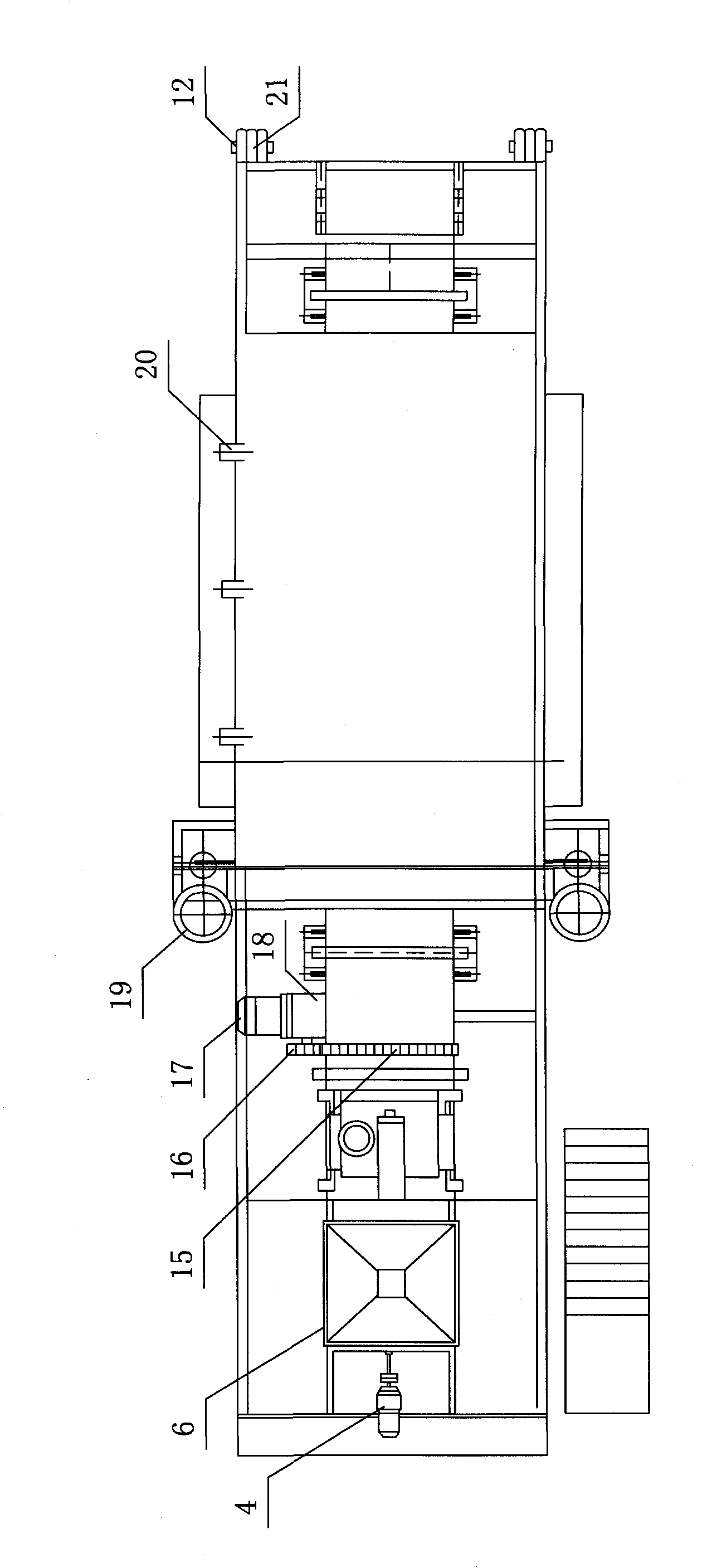

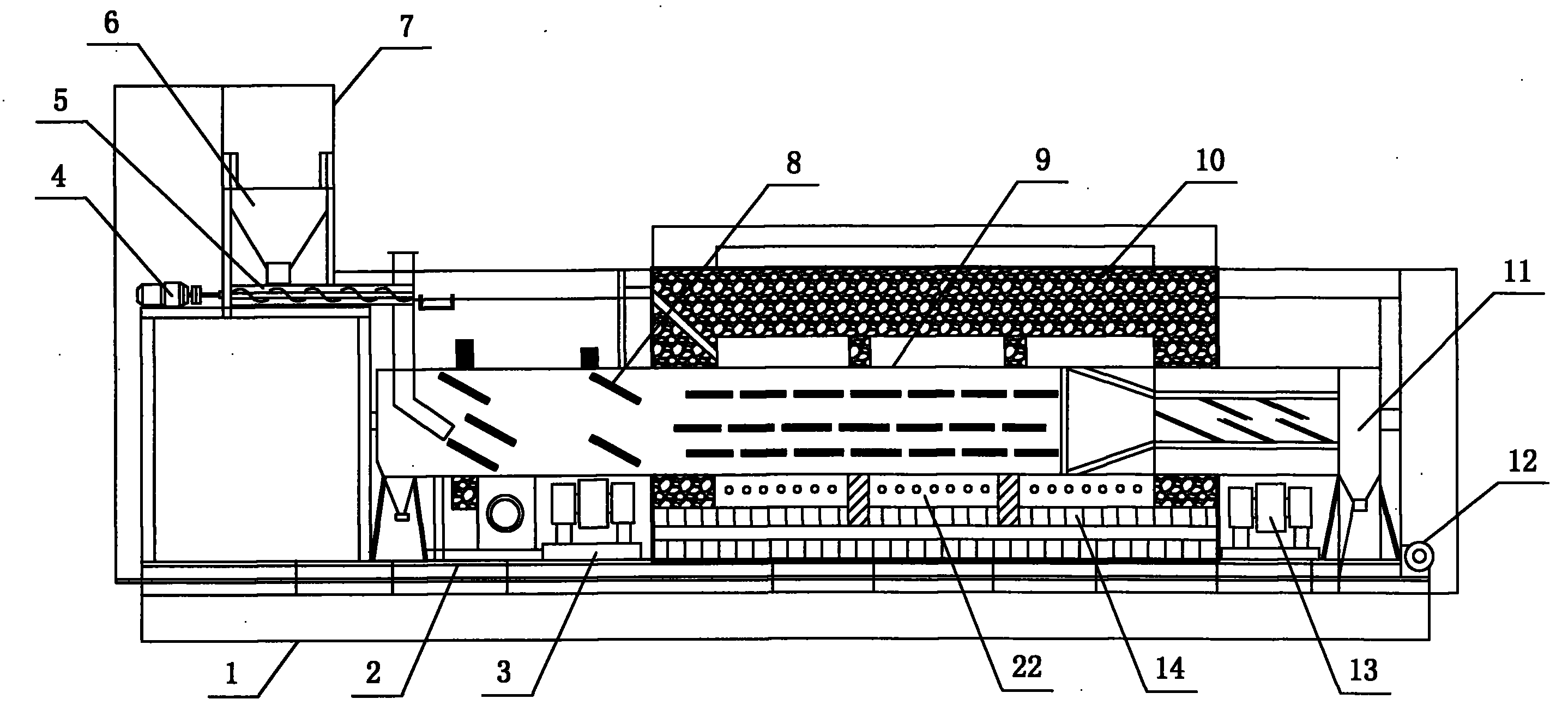

Energy-saving device for preparing nano-scale lead tetraoxide (red lead)

InactiveCN101780977AIngenious ideaReasonable structureNanostructure manufactureChemical industryLead(II,IV) oxideEngineering

The invention discloses an energy-saving device for preparing nano-scale lead tetraoxide (red lead). A bracket is arranged at the upper end of a pedestal; the bracket is provided with a front riding wheel and a rear riding wheel; a rotary kiln cylinder body is arranged on each riding wheel; a hinge sleeve is arranged at the rear end of the bracket; the rotary kiln cylinder body is connected to the bracket through a hinge pin; a material-pushing rib is arranged on the inside cylinder wall of the rotary kiln; an insulating furnace body is arranged on the outside of the rotary kiln; an insulating layer is arranged in the insulating furnace body; a heating furnace body is arranged at the upper end of the bracket; a gear ring is arranged on the circumference at the front end of the rotary kiln cylinder body; a motor is arranged on the right bracket of the gear ring; a reduction box is arranged in the motor; a hydraulic lift pump is arranged on the right bracket of the motor; a feed box is arrange at the left front end of the rotary kiln cylinder body; a discharging box is arranged at the rear end of the rotary kiln cylinder body; a feed hopper is arranged on the lower side of the feed box; a feed motor is arranged at the front end of the feed hopper; and a spiral stock pusher is arranged on the right side of the feed motor.

Owner:JIESHOU CITY JUNMA IND & TRADE

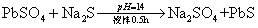

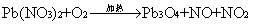

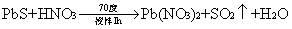

Method for converting lead sulfate into lead tetraoxide

The invention discloses a method for converting lead sulfate in a waste lead-acid storage battery into lead tetraoxide, comprising the following steps of: firstly, reacting the lead sulfate, excessive soluble sulfide salt and a small amount of ammonia water, and converting the lead sulfate into lead sulfide; then filtering out the lead sulfide, adding the lead sulfide into hot dilute nitric acid, and fully reacting; then steaming solution, continuously heating to be certain temperature, after reactants are decomposed completely, putting residues into a stirring ball mill for grinding, simultaneously, introducing oxygen-nitrogen mixed gas with certain oxygen content, and obtaining a final product, namely the lead tetraoxide. The method is simple and practical, high temperature is not needed, the energy consumption is low, the pollution is less, the prepared lead tetraoxide can be used as an active substance which is reused in a lead-acid storage battery.

Owner:双登天鹏冶金江苏有限公司

Formula of positive active material for lead-acid power battery and preparation method of positive active material

InactiveCN103000883AUnderestimated proportionHigh porosityCell electrodesPower batteryLead(II,IV) oxide

The invention discloses a formula of a positive active material for a lead-acid power battery. The formula is characterized in that sodium peroxide, lead tetraoxide and CMC (Carboxy Methylated Cellulose) are added. The invention also discloses a preparation method of the positive active material. The preparation method comprises the steps of: firstly, mixing and stirring lead powder, lead tetraoxide powder and sodium peroxide powder for 3-5min, then adding the CMC, stirring for 5-8min, adding deionized water, stirring for 8-10min, finally adding sulfuric acid with the specific gravity of 1.05g / cm<3>, stirring for 10-15min, coating a positive plate, and drying the coated positive plate for 4-6h in a drying room with the temperature of 60 DEG C and then performing assembly and battery formation processes.

Owner:江苏海宝电池科技有限公司

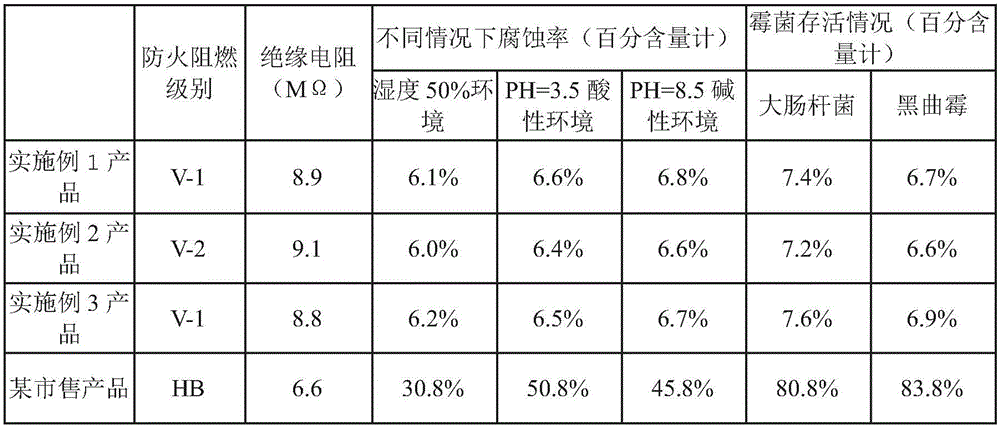

Printing ink for advertising art design wrapping paper

InactiveCN106167644AExcellent flame retardantGood acid and alkali resistanceInksChromium trioxidePolyester

The present invention relates to a printing ink for advertising art design wrapping paper, which is composed of the following components: polyester urethane resin, halogenated butyl rubber, fluorosilicone resin, amyl acetate, isobutyl triethoxysilane, cyclo Oxychloropropane, litsea cubeba oil, hydrogenated castor oil, borax powder, triethyltin chloride, eugenol, sodium dehydroacetate, artificial mica, molybdenum trioxide powder, chromium trioxide powder, gypsum powder, graphite powder , lead tetraoxide powder, barium titanate powder, niobium carbide powder, zinc hydroxystannate, hexabromocyclododecane, trichloroethyl phosphate, amidinourea phosphate, methyl benzotriazole, coconut oil Fatty acid diethanolamide, vinyl acetate, stearic acid amide, methyltriethoxysilane, diphenyl ether. The product of the invention has relatively superior flame retardancy, acid and alkali resistance, anti-mildew and antibacterial properties, and improves product performance.

Owner:孟根森

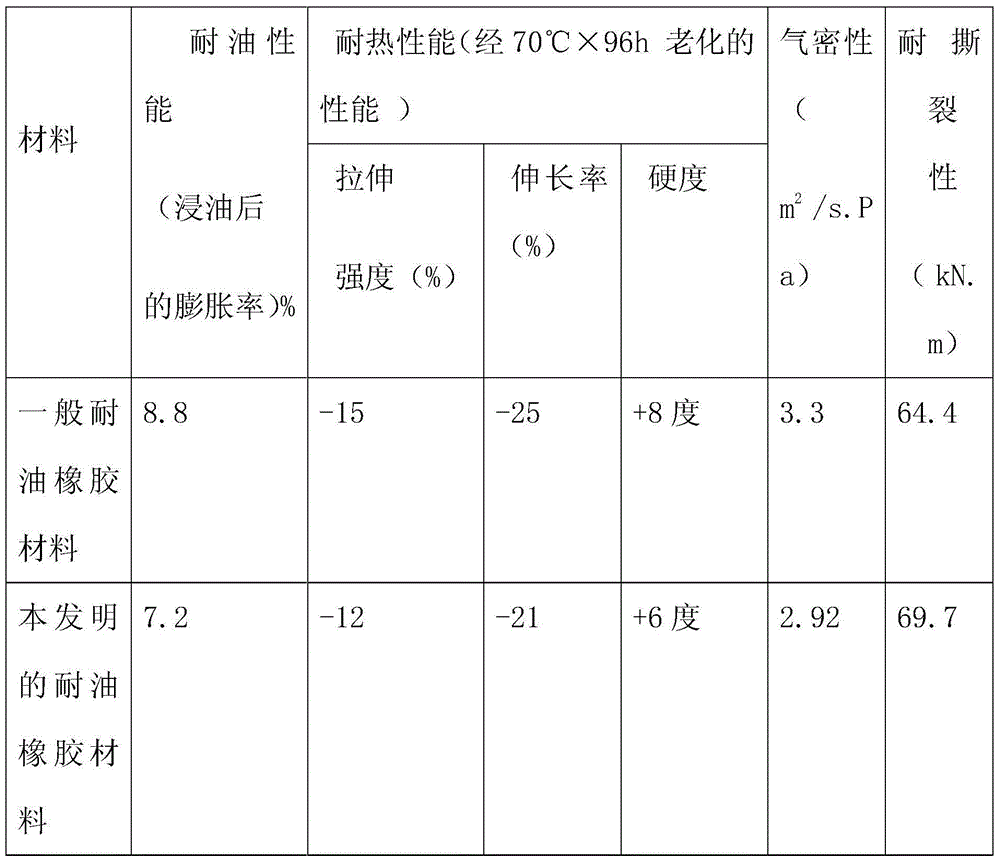

Rubber material of sealing component

The invention discloses a rubber material. The rubber material is prepared by mixing a rubber compound A and a rubber compound B in equal proportion, wherein the rubber compound A comprises butadiene-acrylonitrile rubber N41, sulfur, zinc oxide, stearic acid, an antiager RD, an antiager 4010NA, microcrystalline wax, fast extruding furnace black N550, high wear-resistant carbon black N330, dibutyl phthalate (DBP), light calcium carbonate, coumarone resin, tetraethylthiuram disulfide, tetramethyl thiuram disulfide, zinc diethyl dithiocarbamate, 2-benzothiazolyl-N-morpholinosulfide and an antiscorching agent CTP; the rubber compound B comprises unitary homopolymerization epichlorohydrin rubber, copolymerization chlorohydrine rubber, zinc stearate, an antiager RD, gum easy T-78, antilux 654, fast extruding furnace black N550, light calcium carbonate, dibutyl phthalate (DBP), lead tetraoxide, sulfur and a promoter Na-22. An oil-resistant sealing component (an oil cylinder sealing gasket) made of the rubber material disclosed by the invention has good oil resistance, heat resistance, gas tightness, flame retardance, tear resistance and low cost.

Owner:芜湖禾田汽车工业有限公司

Composite iron-titanium powder anti-rust paint

InactiveCN1405244ALow costNo environmental pollutionPigmenting treatmentAnti-corrosive paintsLead(II,IV) oxideTitanium powder

There is a kind of ferrotitanium compound powder antirust paint, it removes the red lead from the red lead antirust paint, the red lead is replaced by the ferrotitanium compound powder, its advantages are: it uses only 40% compound ferrotitanium powder to replace 50% red lead powder, its main technology includes reach or exceed red lead antirust paint, and the cost can be reduced about 1800 RMB / T. The product is innoxious and has no contamination to environment.

Owner:NAVAL UNIV OF ENG PLA

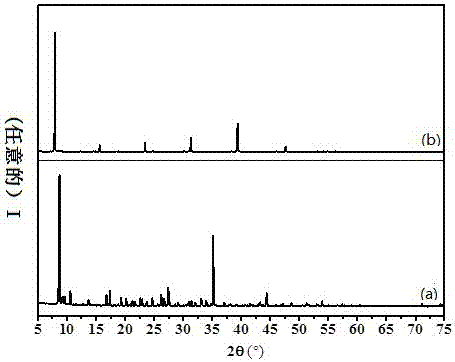

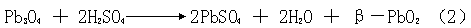

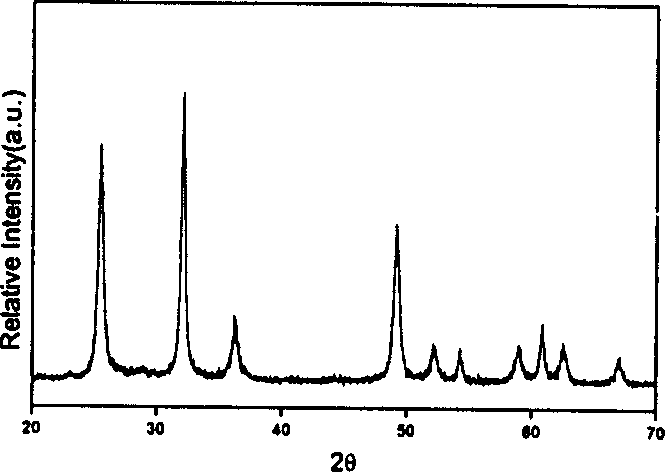

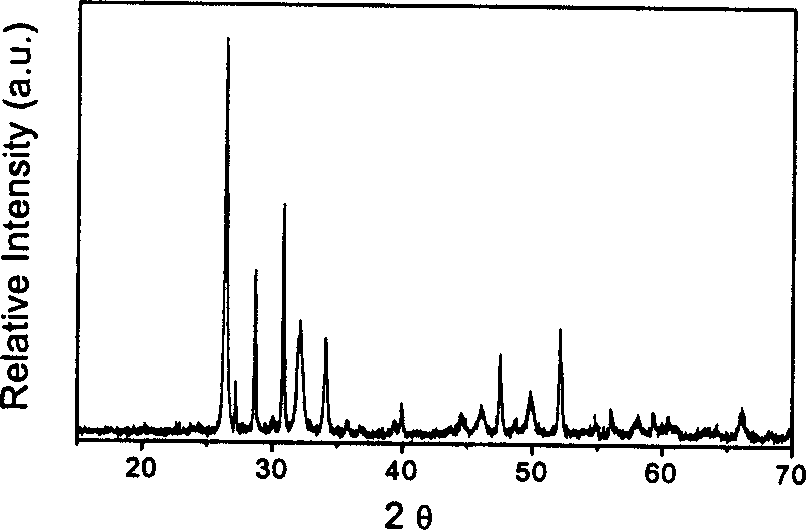

Process for synthesizing alpha, beta type lead dioxide and leadleaden oxide naon crystal

InactiveCN1171797CNo pollution in the processImprove pollutionLead dioxideRed leadCrystallographyLead dioxide

The method for synthesizing alpha and beta type lead dioxide nano crystal and lead tetraoxide nano crystal includes the following steps: adding lead salt or lead oxide into water to prepare solution, adding sodium hydroxide, regulating pH value of solutino to 9-14, making said solution produce liquid-phase reaction with oxidants of chlorine gas, etc., under the condition of 30-60 deg.C can obtain alpha type lead dioxide nano crystal, under the condition of 60-200 deg.C can obtain beta type lead dioxide nano crystal, then pyrolyzing the obtained lead dioxide nano crystal at 410-430 deg.C and can obtain lead tetraoxide nano crystal.

Owner:TSINGHUA UNIV

High-voltage DC electric wire cable insulation material and preparation process thereof

InactiveCN106065189AHigh tensile strengthLow rate of change in tensile strengthRubber insulatorsInsulated cablesCarbon fibersLead(II,IV) oxide

The invention discloses a high-voltage DC electric wire cable insulation material and a preparation process thereof. The insulation material is prepared from the raw materials of: methyl vinyl silicone rubber, organic silicone resin, terpene resin, polyvinylidene chloride, 3-hexyl substituted polythiophene, chlorinated polyethylene, nickel oxide, praseodymium oxide, carbon quantum dots, fumed silica, 2,2'-(1,2-ethylenedioxy)diethanethiol, asphalt-based carbon fibers, itaconic acid, calcium ricinoleate, [gamma] -mercaptopropyl triethoxysilane, an propylene-ethylene semi-crystalline copolymer, an ethylene-octylene copolymer, benzoin dimethyl ether, calcium hydroxide, trioctyl trimellitate, and Pb3O4. The insulation material is higher than 17 MPa in tensile strength, is 230% in break elongation, and is free of breakdown under a 120 kV DC voltage test for 15 min, has good anti-aging property and long service life after the DC voltage test, and is very suitable for being widely applied as a high-voltage DC electric wire cable insulation material.

Owner:潘明华

Extenal use ointment for restoring period of knocks and falls

An exterior-applied plaster for the recovery stage of bone fracture and injury is prepared from vegetable oil, Pb3O4 and 8 Chinese medicinal materials including Chinese and root and bark, prunella spike, senecio, frankincense, myrrh, etc. in a certain proportion.

Owner:董裕国

Antirust coating for tire type container crane

InactiveCN102234471AReasonable formulaImprove work performanceAnti-corrosive paintsLEAD TETROXIDELead(II,IV) oxide

The invention discloses an antirust coating for a tire type container crane. The antirust coating consists of graphite, phenolic resin varnish, antirust oil, methylbenzene, iron oxide red, titanium dioxide, organic bentonite, magnesium oxide and lead tetroxide. The antirust coating has the advantages of reasonable formula and good working effect.

Owner:陈建斌

Method for preparing linear thermistor slurry with negative temperature coefficient

The invention discloses a method for preparing linear thermistor slurry with negative temperature coefficient, which comprises the following steps: 1) burdening barium carbonate and lead tetraoxide according to mole ratio of 1: 0.34-0.4, performing high-speed ball-milling mixing, drying and sieving, insulating for 8-12 hours at 750-850 DEG C to obtain a reactant, performing ball milling on the reactant for standby; 2) burdening barium carbonate and bismuth trioxide according to mol ratio of 1: 0.5-0.53, then performing high-speed ball-milling mixing, drying and sieving, insulating for 8-12 hours at 700-850 DEG C to obtain a reactant, performing ball milling on the reactant for standby; and 3)uniformly mixing the material obtained in the last two steps according to mass ratio of 1: 0.05-0.8, and then adding a certain amount of organic carrier for rolling to obtain a slurry. According to the invention, the linear NTC thick membrane slurry used for screen printing can be developed, and a slurry formula with high resistance temperature coefficient (TCR) and low sheet resistance can be obtained, TCR can reach -1000--7000ppm / DEG C, the sheet resistance scope is 5 omega / squre-4K omega / square, and the a technical scheme provided by the invention has good expansibility.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

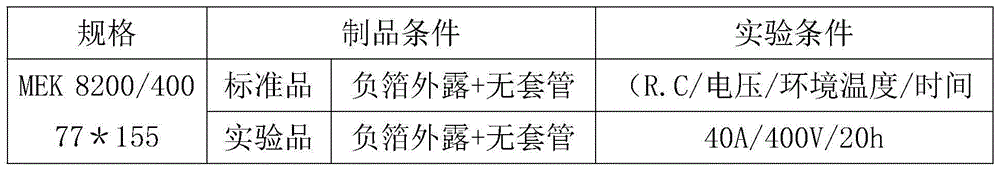

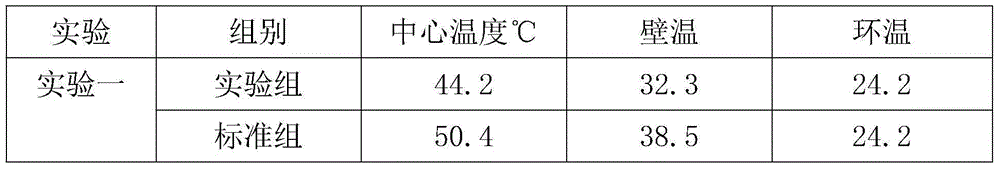

Electrolytic capacitor casing heat radiating coating containing graphene material

An electrolytic capacitor casing heat radiating coating containing a graphene material is characterized by comprising the following components by weight: 30 parts of macroporous adsorption resin, 10 parts of silicon carbide, 5 parts of non crystal quartz particles, 2 parts of potassium feldspar, 5 parts of tert-butyl alcohol, 10 parts of graphene, 2 parts of boron fiber, 2 parts of carbon fiber, 2 parts of potassium tungstate, 5 parts of pigment, 50 parts of deionized water, 2 parts of lead tetraoxide, 3 parts of rare earth, 2 parts of chloroplatinic acid, 5 parts of modified corn starch and 0.5 part of cobalt selenide. According to the invention, the graphene mixed coating coats on the electrolytic capacitor shell to effectively achieve the heat radiation effect; the experimental data shows that the coating on the electrolytic capacitor shell can effectively guide the internal temperature of electrolytic capacitor increased by working to the shell and convert heat into infrared radiation wave. In addition to the enhancement of the service life of the electrolytic capacitor, the coating also can keep the work voltage of the electrolytic capacitor at a steady state.

Owner:TONGLING XINTAI ELECTRIC APP & CAPACITOR

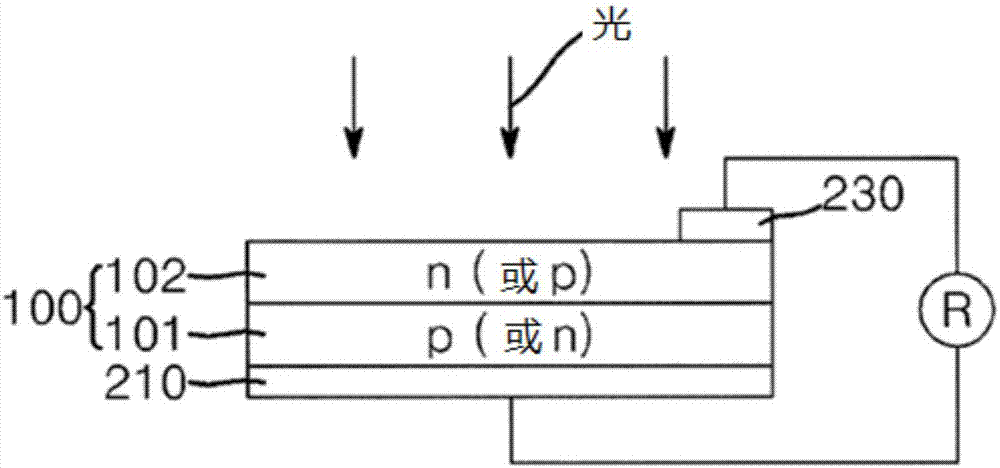

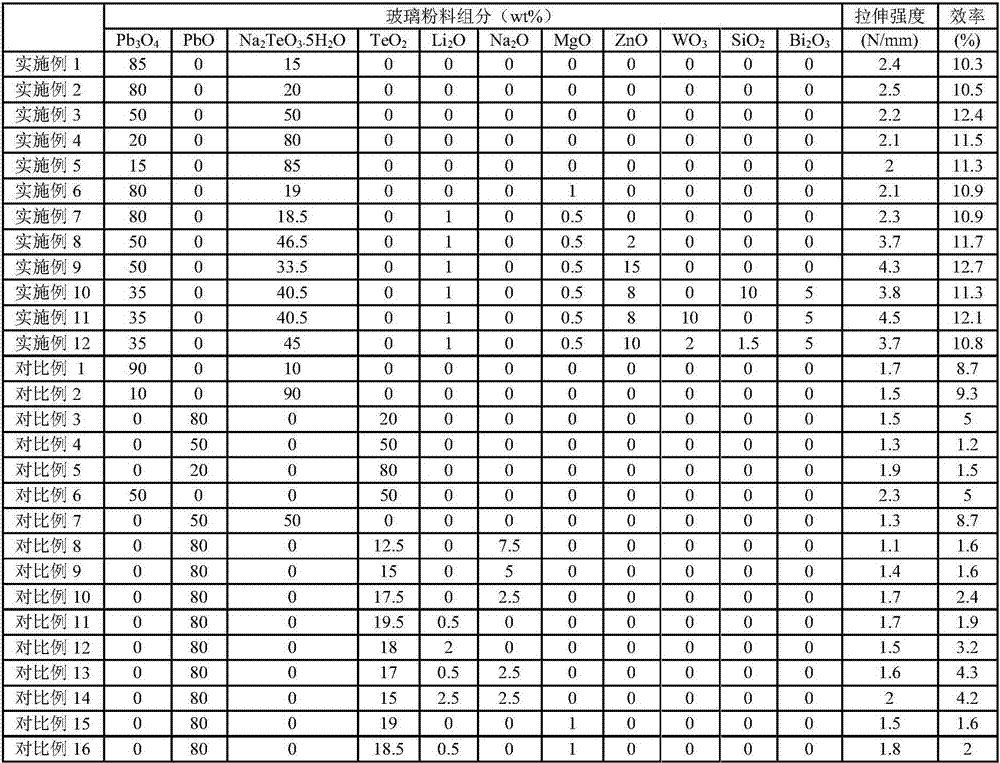

Glass powder for preparing solar cell electrode, as well as paste composition, solar cell electrode and solar cell including same

ActiveCN107879635AFacilitated liquid phase sinteringStable contact resistanceNon-conductive material with dispersed conductive materialPhotovoltaic energy generationLead(II,IV) oxideSolar cell

The invention discloses glass powder for preparing a solar cell electrode, as well as a paste composition, a solar cell electrode and a solar cell including same. The glass powder comprises sodium tellurite pentahydrate and lead tetraoxide. The glass powder has a relatively high eutectic point due to lead tetraoxide-sodium tellurite, and can provide a certain space to control of the reactivity between the glass powder and silicon nitride; the composite compound Na element in Na2TeO3 can form an Ag-Na anionic complex, and can be used for promoting liquid-phase sintering of Ag particles in the sintering process. Therefore, the lead tetraoxide-sodium tellurite composition can provide stable reactivity with silicon nitride, and enables a solar cell to have excellent and stable contact resistance. The solar cell electrode prepared by applying the paste composition has excellent adhesive strength, and enables series resistor (Rs) to be minimized, so that high conversion efficiency can be provided.

Owner:DK ELECTRONICS MATERIALS INC

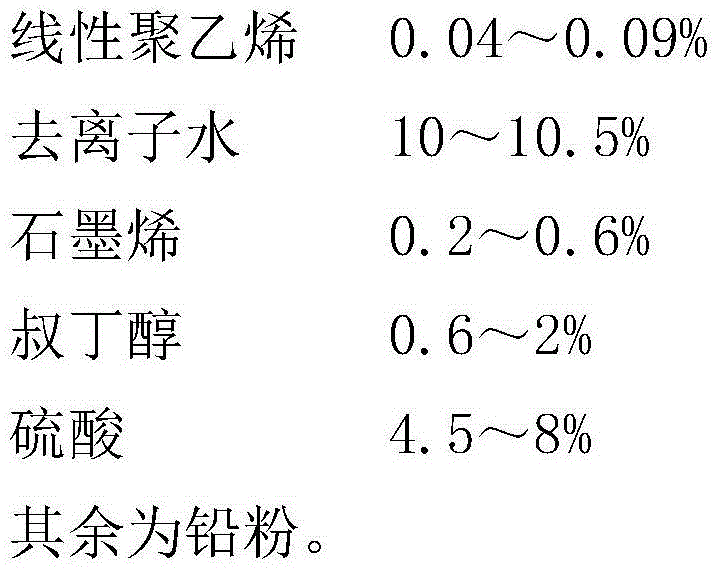

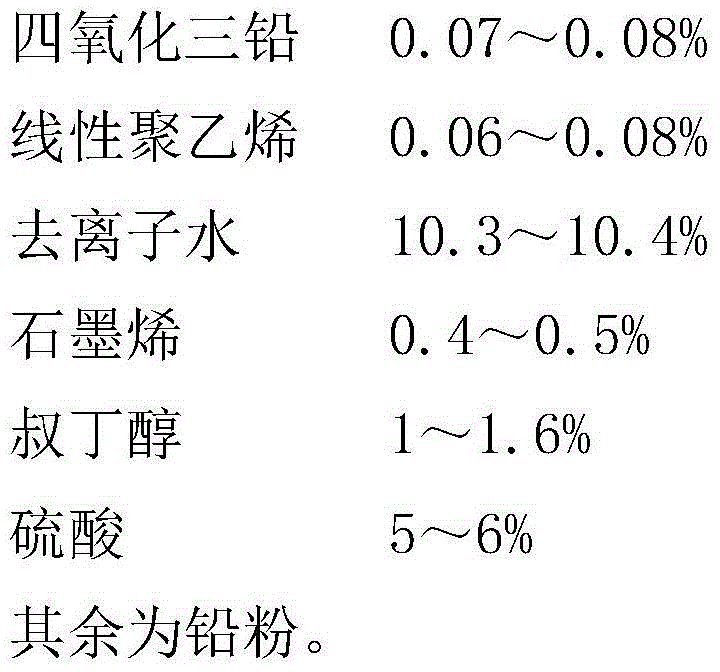

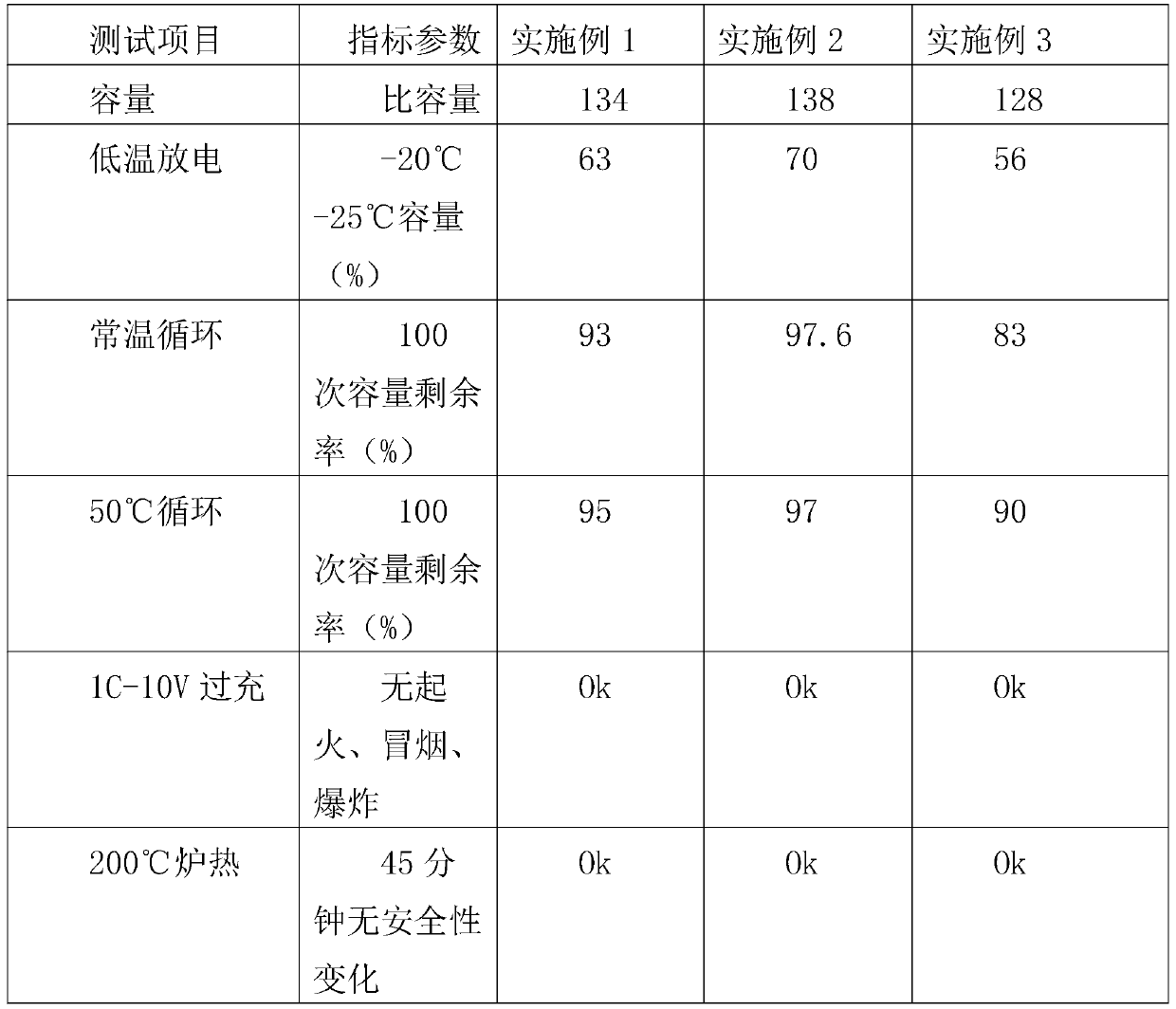

Lead paste composition of lead-acid battery anode

InactiveCN104103827AHigh initial capacityImprove cycle lifeCell electrodesLead(II,IV) oxideMaterials science

A lead paste composition of a lead-acid battery anode relates to the technical field of a storage battery and is composed of following components based on weight percentage: 0.06-0.1 percent of tetroxide three lead, 0.04-0.09 percent of linear polyethylene, 10-10.5 percent of deionized water, 0.2-0.6 percent of grapheme, 0.6-2 percent of tertiary butanol, 4.5-8 percent of sulfuric acid and the balance of lead powder. Lead paste prepared according to a lead paste formula and a preparation method has high initial capacity and long cycle life after being prepared into the battery, and the over-discharging resistance performance and charging capability of the battery are far higher than standard requirement.

Owner:钱松

Preparation method of lithium ion battery electrode piece containing PTC coating layer

ActiveCN110380006APlay the role of overheating protectionReduced speed of temperature transferCell electrodesSecondary cellsBarium titanateLead(II,IV) oxide

The invention discloses a preparation method of a lithium ion battery electrode piece containing a PTC coating layer. The method is characterized in that the method comprises the following steps: mixing a positive active material or a negative active material of the lithium ion battery with a conductive agent and a binder according to a certain ratio; performing stirring to obtain positive electrode slurry or negative electrode slurry; mixing the stirred slurry with sol; before the mixed slurry is coated on a current collector, performing the pre-coating of ceramic PTC coating slurry; performing drying to prepare a battery electrode piece after coating is completed, wherein the ceramic PTC coating layer is composed of barium titanate, titanium dioxide, tantalum pentoxide, lanthanum oxide,lead tetraoxide, calcium carbonate and manganese oxide. According to the invention, a heating source is made by using the temperature resistance characteristic, and can also play a role in overheatingprotection of the battery as a heating element.

Owner:江西力能新能源科技有限公司

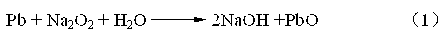

Part lead semi-annular jade pendant for high-voltage insulation and ray shielding and manufacturing method

The invention discloses a part lead yoke for high-voltage insulation and ray shielding and a manufacturing method thereof. The composition mainly includes trilead tetroxide and epoxy resin. Beneficial effects of the present invention: the lead trioxide contained in the part lead has X-ray shielding properties similar to that of lead; at the same time, different from lead in physical properties, trilead tetroxide is an insulating material and can be used in the field of high-voltage insulation . The lead jumbo is formed by heating and curing after vacuum infusion, and the structure is flexible. The lead jumbo can tightly wrap the X-ray tube, making the structure easy to install and fix, meeting the requirements of miniaturization, light weight and safety of the X-ray source equipment.

Owner:苏州镭瑞机电科技有限公司

Piezoelectric ceramic composition and manufacturing method of piezoelectric ceramic

InactiveCN102603295AImprove performanceLower sintering temperatureConversion factorLead(II,IV) oxide

The invention relates to a piezoelectric material, and particularly to a piezoelectric ceramic composition and a manufacturing method of the piezoelectric ceramic. The piezoelectric ceramic composition comprises lead tetraoxide, zirconium dioxide and titanium dioxide and is characterized by also comprising antimony trioxide, wherein the content of antimony trioxide is 0.5-2% the weight sum of lead tetraoxide, zirconium dioxide and titanium dioxide. The invention also provides a method for manufacturing the piezoelectric ceramic. Test results show that the piezoelectric ceramic manufactured from the piezoelectric ceramic composition has excellent piezoelectric performances, the dielectric constant is not less than 6000, the piezoelectric constant D33 is not less than 600, and the electromechanical energy conversion factor is not less than 65%; and furthermore, the sintering temperature is 100-200 DEG C lower than that of the piezoelectric material free of antimony trioxide and lithium carbonate.

Owner:JIANGSU YILONG NEW ENERGY TECH DEV

Method for preparing lead tetraoxide from waste lead-acid batteries and application

ActiveCN103022593BOvercoming technical problems of polluting the environmentEasy to operateWaste accumulators reclaimingLead oxidesRecovery methodCITRATE ESTER

The invention is applicable to the field of waste battery recovery technologies and provides a method for preparing lead tetraoxide from waste lead-acid batteries. The method comprises the steps of carrying out pretreatment, preparing lead citrate, preparing second powder, pulping the second powder, preparing the lead tetraoxide, and the like. According to the method for preparing the lead tetraoxide from the waste lead-acid batteries, provided by the invention, lead sulfate and lead monoxide in lead plaster of the waste lead-acid batteries are converted into the lead citrate by using citric acid and alkali metal citrate, and then, the lead tetraoxide is prepared, so that the method has a significant economic benefit, and the technical problem of environment pollution caused by a waste lead-acid battery lead recovery method in the prior art is solved; and the method for preparing the lead tetraoxide from the waste lead-acid batteries is simple in operation, low in cost and high in economic benefit, thereby being very applicable to industrialized production.

Owner:SHENZHEN CENT POWER TECH

Lead tetraoxide oxidation technology

ActiveCN106517317AFully oxidizedSolve the problem of adding an appropriate amount of ammonium nitrate as a catalystRed leadEnergy inputLead(II,IV) oxideEngineering

The invention relates to a lead tetraoxide oxidation technology which comprises the following steps: 1) preheating air; 2) blowing the preheated air into an oxidizing furnace; 3) performing three-section temperature control on the oxidizing furnace, wherein the temperature of the oxidizing furnace from top to bottom is divided into the first section of temperature controlled at 450-510 DEG C, the second section of temperature controlled at 420-460 DEG C and the third section of temperature controlled at 380-420 DEG C; 4) putting the material into the oxidizing furnace from top to bottom and performing oxidizing reaction; 5) storing the oxidized material after fully reacting in a hearth of the oxidizing furnace into a storage silo and cooling; 6) reducing the temperature of the oxidized material in the storage silo to 60 DEG C or below and then taking out from the storage silo. According to the invention, the purpose of quickly preparing red lead can be achieved, the yield is increased, the resource is saved, the cost is saved and the production efficiency is increased.

Owner:湖南省水口山共建新材料有限公司

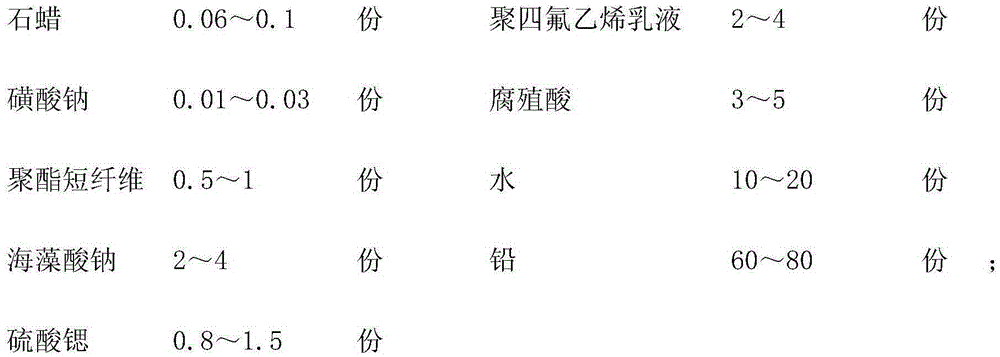

Cathode, anode and electrolyte formula for solar power generation storage battery and preparation method of cathode, anode and electrolyte formula

InactiveCN106711405AStrong deep discharge abilityStrong ability to withstand overchargeFinal product manufacturePV power plantsPolyesterLead(II,IV) oxide

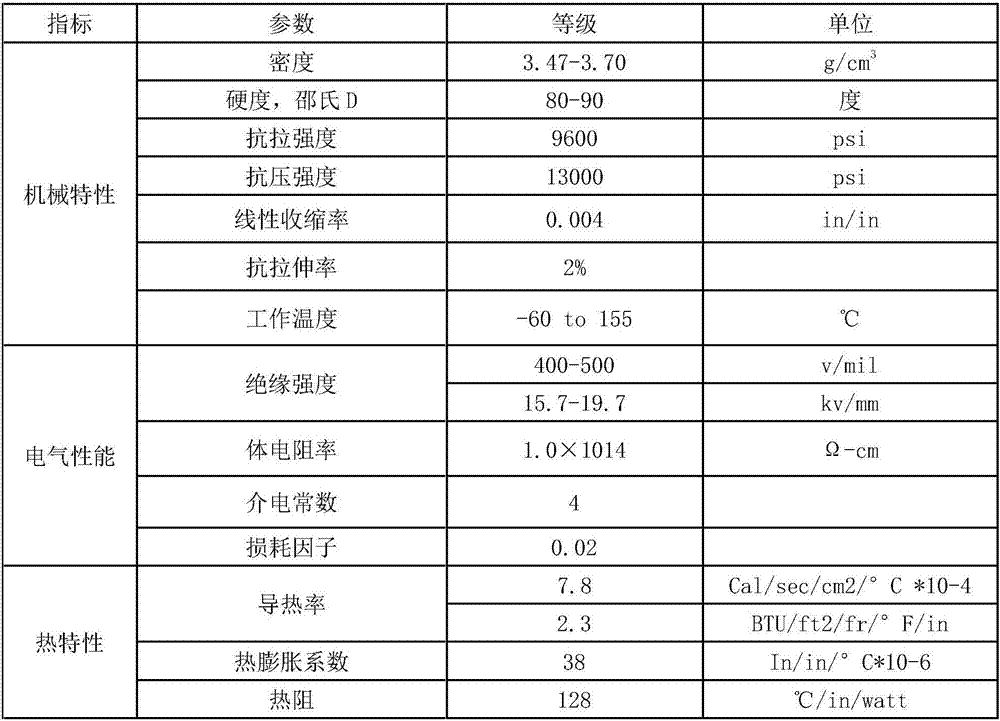

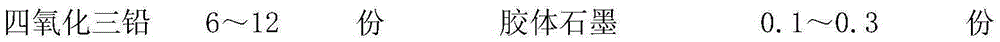

The invention relates to a cathode, anode and electrolyte formula for a solar power generation storage battery. Cathode materials are lead tetroxide, sulfuric acid, polyester staple fiber, carbon fiber, calcium phosphate, colloidal graphite, a polyaniline nanosolution, silica emulsion and lead; anode materials are paraffin, sodium sulfonate, polyester staple fiber, sodium alginate, strontium sulfate, polytetrafluoroethylene emulsion, humic acid, water and lead; electrolyte raw materials are sulfuric acid, ammonium sulfate, magnesium sulfate, sodium carboxymethylcellulose, sodium tetraborate, stannous sulfate, polyvinyl alcohol and water; by matching the cathode raw materials, the anode raw materials and the electrolyte raw materials, the cathode, anode and electrolyte formula has the characteristics of high deep discharge capacity, high overcharge resistance and long cycle life; the deep discharge capacity is improved by 4 percent, the overcharge resistance is improved by 5 percent, and the cycle life is prolonged by 10 percent.

Owner:天津杰士达电源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com