Rubber material of sealing component

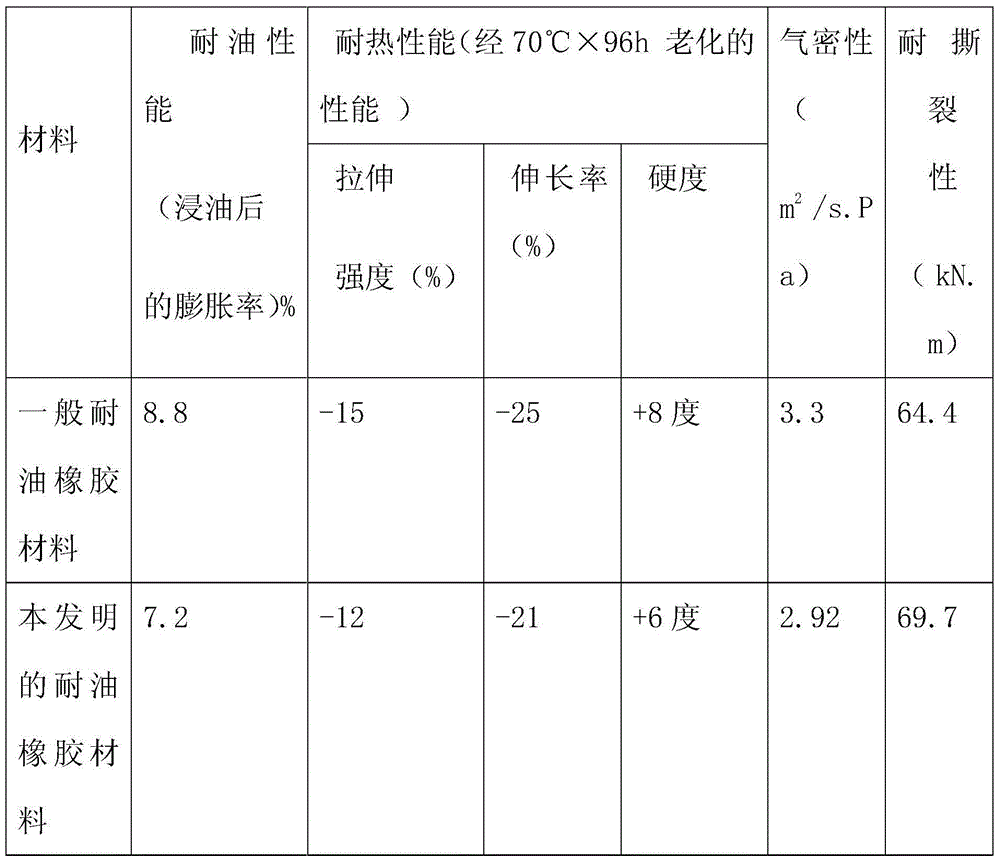

A technology for rubber materials and seals, which is applied in the compounding and preparation of rubber materials for seals, can solve the problems of high cost, inferiority, high price of hydrogenated nitrile rubber and chlorohydrin rubber, and achieve low cost, good oil resistance, good The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A kind of preparation method of rubber material, comprises the following steps:

[0021] The first step: Prepare A rubber material and B rubber material respectively

[0022] a) Preparation of rubber compound

[0023] (1) Mastication: Start the internal mixer, put the nitrile rubber N41 into the internal mixer for plastication, after 15-25 minutes of plastication (can be 20 minutes), when the temperature reaches 110-120°C (can be 120 ℃), start discharging, and stop to cool for 23-25 hours after discharging (can be 24 hours);

[0024] (2) Mixing: Add the above-mentioned cooled plasticized rubber into the internal mixer, then add zinc oxide, stearic acid, anti-aging agents, microcrystalline wax, and coumarone resin, and mix for 5-8 minutes ( After 6 minutes), add light calcium carbonate and continue mixing for 3-4 minutes (can be 3 minutes), then add carbon black N330 and N550 in two times for mixing, first add 2 / 3 carbon black and mix Refining for 2-3 minutes (can b...

Embodiment 1

[0033] The rubber material is mixed in equal proportions by two parts of rubber compound A and B, and the parts by weight of the raw materials composed of the two parts are:

[0034] A rubber material:

[0035] Nitrile rubber N41100, sulfur 0.5, zinc oxide 9, stearic acid 2, antioxidant RD1.5, antioxidant 4010NA1.5, microcrystalline wax 4, fast extrusion carbon black N55020, high wear-resistant carbon black N33066, dibutylene Ester DBP20, light calcium carbonate 24, coumarone resin 4.5, tetraethylthiuram disulfide 1.5, tetramethylthiuram disulfide 1.6, zinc diethyldithiocarbamate 1, N-oxygen di Ethylene-2-benzothiazole sulfenamide 0.8, anti-scorch agent CTP0.5;

[0036] B rubber material:

[0037] Monopoly homopolychlorohydrin rubber 89, co-polychlorohydrin rubber 18, zinc stearate 1, anti-aging agent RD2, gelatin T-780.8, rhine wax 1.5, fast extruded carbon black N55055, light calcium carbonate 15, two Butyl ester 6, trilead tetroxide 5, sulfur 0.5, accelerator Na-221.5. ...

Embodiment 2

[0039] The rubber material is mixed in equal proportions by two parts of rubber compound A and B, and the parts by weight of the raw materials composed of the two parts are:

[0040] A rubber material:

[0041] Nitrile rubber N41105 sulfur 0.3, zinc oxide 7, stearic acid 3, anti-aging agent RD2, anti-aging agent 4010NA2, microcrystalline wax 3, fast extrusion carbon black N55019, high wear-resistant carbon black N33068, dibutyl ester DBP18, light Calcium carbonate 22, coumarone resin 4.3, tetraethylthiuram disulfide 2, tetramethylthiuram disulfide 1.6, zinc diethyldithiocarbamate 1.6, N-oxydiethylene-2 - Benzothiazole sulfenamide 0.9, anti-scorch agent CTP0.3;

[0042] B rubber material:

[0043] Monopoly homopolychlorohydrin rubber 90, co-polychlorohydrin rubber 20, zinc stearate 1.5, anti-aging agent RD1, glue Yisu T-780.7, rhine wax 2, quick extruded carbon black N55058, light calcium carbonate 18, two Butyl ester DBP8, trilead tetraoxide 4, sulfur 0.6, accelerator Na-22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com