Lead paste composition of lead-acid battery anode

A lead-acid battery, positive lead paste technology, applied to battery electrodes, circuits, electrical components, etc., can solve the problems of poor charging acceptance, inability to solve the problem of battery over-discharge resistance, etc., and achieve the effect of high initial capacity and cycle life

Inactive Publication Date: 2014-10-15

钱松

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the lead paste formulations of lead-acid batteries used in domestic electric mopeds are different, and most of them are directly borrowed from the formulations of ordinary valve-regulated lead-acid batteries.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

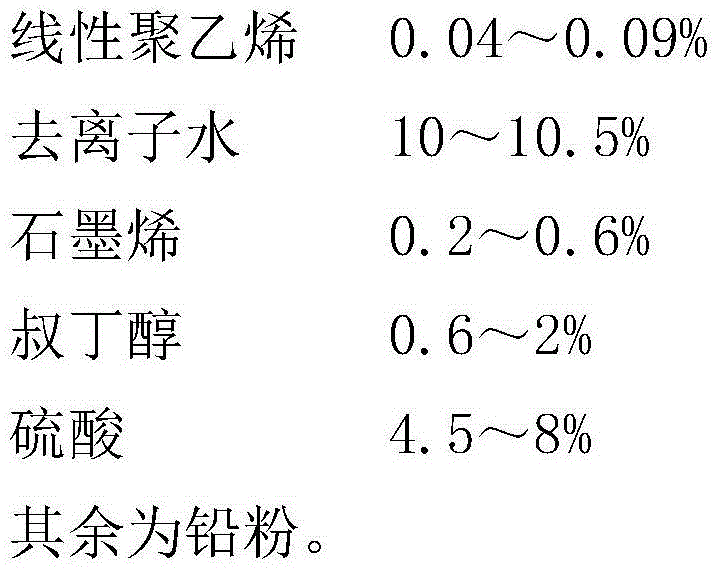

[0014] A lead-acid storage battery cathode lead paste composition, consisting of the following components by weight percentage,

[0015]

[0016]

Embodiment 2

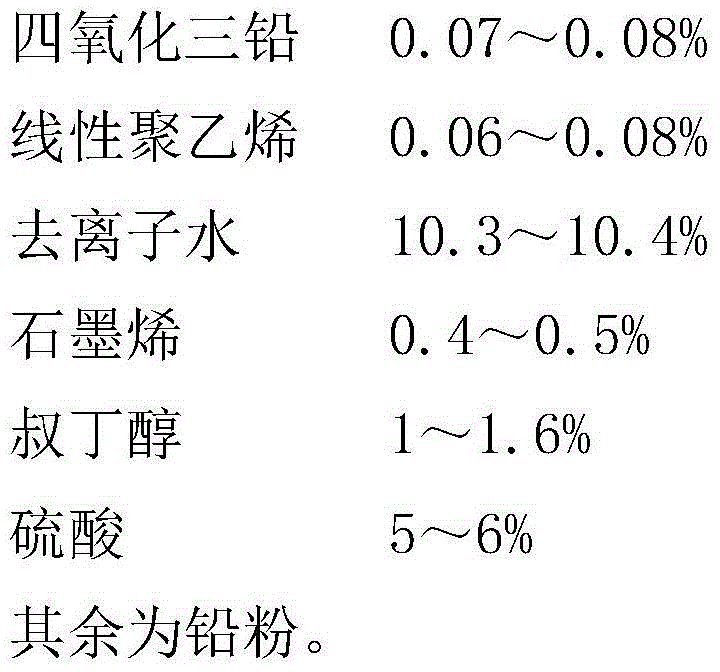

[0018] A lead-acid storage battery cathode lead paste composition, consisting of the following components by weight percentage,

[0019]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

A lead paste composition of a lead-acid battery anode relates to the technical field of a storage battery and is composed of following components based on weight percentage: 0.06-0.1 percent of tetroxide three lead, 0.04-0.09 percent of linear polyethylene, 10-10.5 percent of deionized water, 0.2-0.6 percent of grapheme, 0.6-2 percent of tertiary butanol, 4.5-8 percent of sulfuric acid and the balance of lead powder. Lead paste prepared according to a lead paste formula and a preparation method has high initial capacity and long cycle life after being prepared into the battery, and the over-discharging resistance performance and charging capability of the battery are far higher than standard requirement.

Description

technical field [0001] The invention relates to the technical field of storage batteries, in particular to a positive lead paste composition for lead-acid storage batteries. Background technique [0002] Lead-acid batteries have a history of 130 years. They have the advantages of reliable performance, mature production technology, and lower cost than nickel-metal hydride batteries and lithium batteries. The vast majority of current electric vehicles use sealed lead-acid batteries. The sealed lead-acid battery is to stack the positive and negative plates in the battery box, and the positive and negative plates are separated by insulating separators. When the electrolyte is charged into the battery box, the electrolyte and the positive and negative plates lead chemical reaction. When the battery is charged, the lead on the positive and negative plates that become lead sulfate releases the sulfuric acid component fixed in it into the electrolyte, and turns into lead and lead ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01M4/57H01M4/62

CPCH01M4/57H01M4/62Y02E60/10

Inventor 钱松

Owner 钱松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com