Negative electrode active material for lithium-ion secondary cell

A negative electrode active material, secondary battery technology, used in secondary batteries, battery electrodes, lithium batteries, etc., can solve the problems of rising internal resistance, low conductivity, particle breakage, etc., to suppress disintegration, improve initial capacity, The effect of reducing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

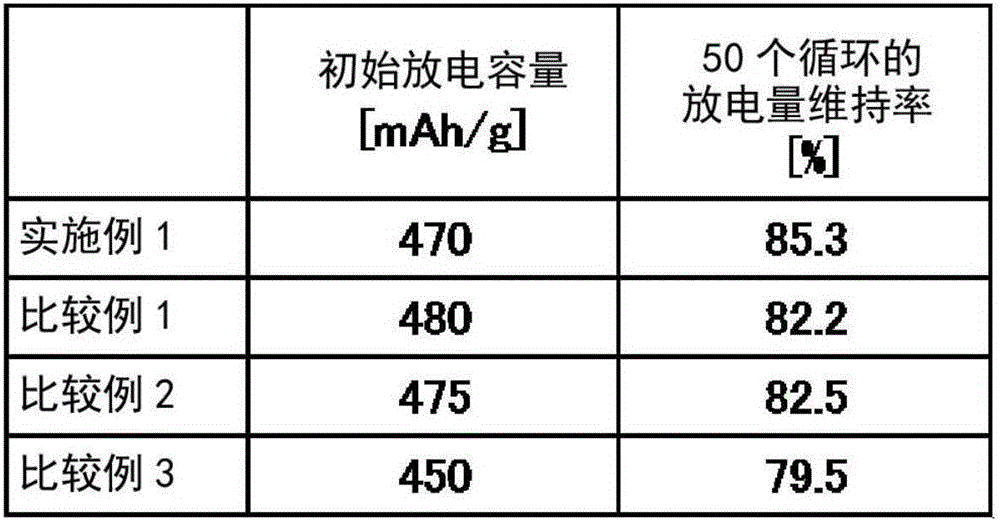

Embodiment 1

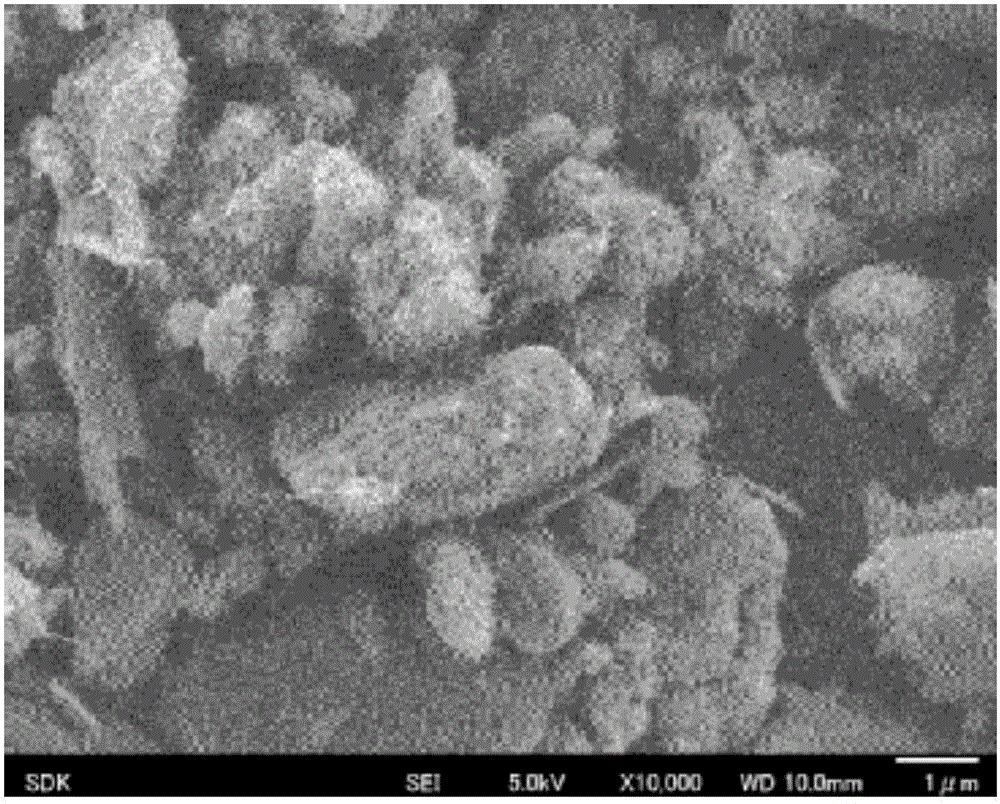

[0185] In such a way that the mass ratio of the carbonaceous carbon material (C) to the silicon-containing particles (b2) becomes 1 / 1, the silicon-containing particles (b2) and the carbon precursor (c) are used in a fiber mixer ( MX-X57) Mix for 1 minute. The mixture was placed on an alumina wafer boat, and heated to 250°C at a nitrogen flow rate of 300 ml / min and a temperature increase rate of 10°C / min in a horizontal calcination furnace for heat treatment. The heat-treated product was crushed with a fiber mixer in a nitrogen atmosphere for 1 minute to obtain a carbon precursor covering silicon-containing particles.

[0186] Next, the carbon precursor covering the silicon-containing particles and the carbon nanotubes (b1) were added to ethanol so that the mass ratio of the silicon-containing particles (b2) to the carbon nanotubes (b1) became 1 / 0.3. The homogenizer (UH-50 manufactured by SMT) was used for 60 minutes of dispersion and compounding treatment. The processed materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com