Preparation method of lithium ion battery electrode piece containing PTC coating layer

A lithium-ion battery and coating technology, which is applied in the direction of battery electrodes, batteries, secondary batteries, etc., can solve problems such as lithium-ion battery safety barriers, achieve battery volume energy density improvement, improve adhesion and compaction Density, reducing the effect of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

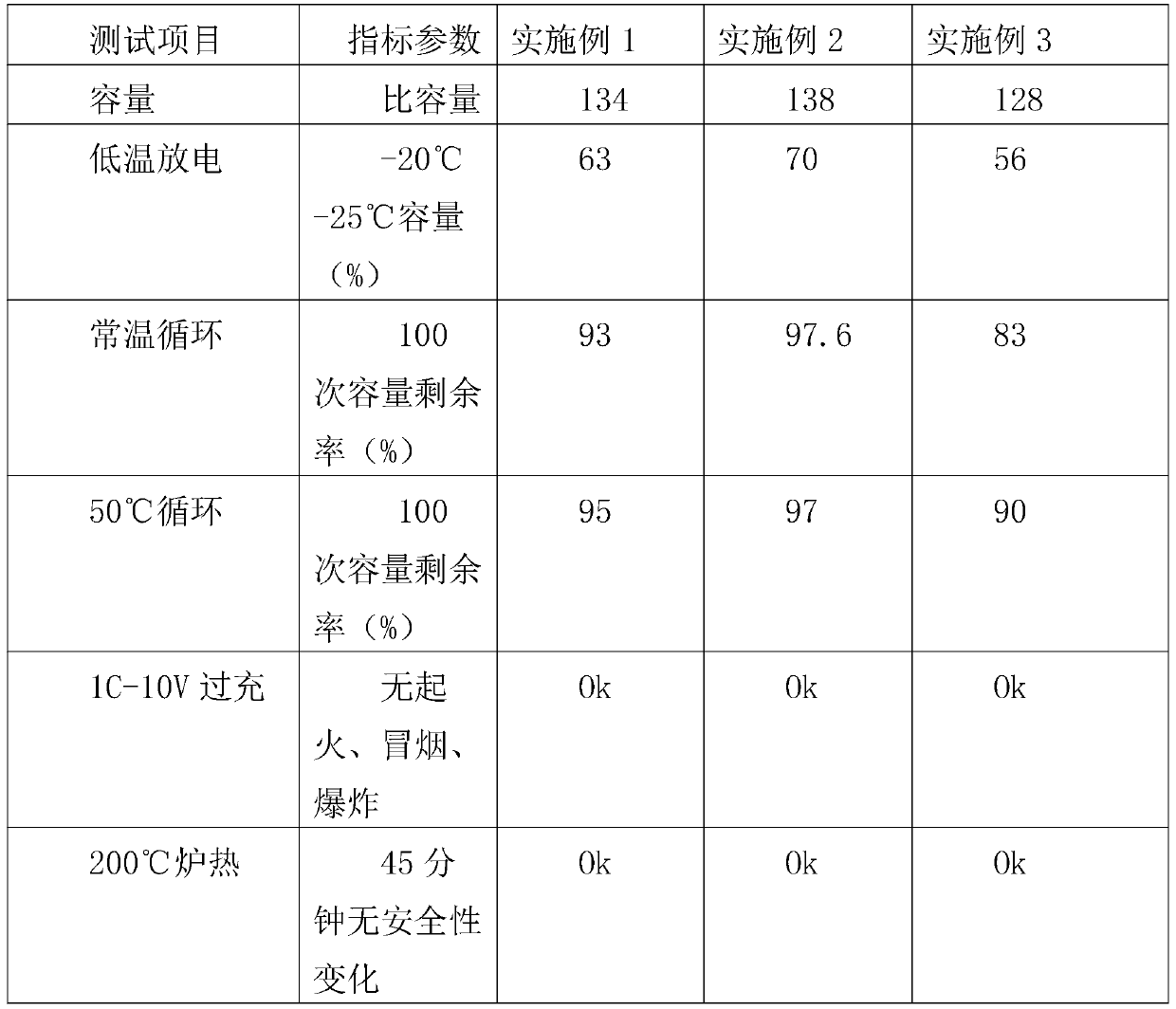

Embodiment 1

[0022] A kind of preparation method of the lithium-ion battery pole piece that the present invention proposes containing PTC coating comprises steps: the cathode active material of lithium-ion battery or negative electrode active material and conductive agent (conductive agent is conductive carbon black), bonding Agents (the ingredients on the market can be synthetic resins) are mixed in a weight ratio of 3:1:1, and the positive electrode slurry or negative electrode slurry is obtained after stirring, and the stirred slurry and sol are mixed in a weight ratio of 4:1, The mixed slurry is sprayed on the surface of the ceramic PTC coating by a spray coating machine. The raw materials of the ceramic PTC coating are 70 parts of barium titanate, 3 parts of titanium dioxide, 5 parts of tantalum pentoxide, 2 parts of lanthanum oxide, tetraoxide 3 parts of lead, 3 parts of calcium carbonate, 2 parts of manganese oxide, the raw materials are mixed with ionized water to prepare ceramic PT...

Embodiment 2

[0025] Further optimization on the basis of Example 1, the raw material of the ceramic PTC coating consists of 85 parts of barium titanate, 8 parts of titanium dioxide, 10 parts of tantalum pentoxide, 4 parts of lanthanum oxide, 3 parts of trilead tetraoxide, and 5 parts of calcium carbonate , composed of 4 parts of manganese oxide, mixed and stirred with the total weight ratio of ionic water at 1:1, after the stirring is completed and coated on the surface of the current collector, the heating rate is 200 ° C / hour, and the temperature is raised to 1250 ° C and then kept for 1 hour , the cooling rate is 250°C / hour, and the temperature is lowered to room temperature to prepare a ceramic PTC coating, and then all the slurry is sprayed on the ceramic PTC coating, and finally dried to form a battery pole piece.

Embodiment 3

[0027] Change on the basis of Example 1, the raw material of ceramic PTC coating consists of 85 parts of barium titanate, 8 parts of titanium dioxide, 3 parts of tantalum pentoxide, 3 parts of trilead oxide, 5 parts of calcium carbonate, and 4 parts of manganese oxide. , mixed with ionized water at a ratio of 1:1 to the total weight, and after the stirring is completed and coated on the surface of the current collector, the heating rate is 200°C / hour, and the temperature is kept at 1250°C for 1 hour, and the cooling rate is 250°C / hour, lower the temperature to normal temperature to obtain a ceramic PTC coating, then spray all the slurry on the ceramic PTC coating, and finally dry it to make a battery pole piece.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com