Energy-saving device for preparing nano-scale lead tetraoxide (red lead)

A technology for the preparation of trilead tetroxide, which is applied in the direction of lead oxide, nanostructure manufacturing, nanotechnology, etc., can solve the problems of energy consumption, pollution, and poor product quality of coal furnaces, and achieve energy saving, pollution reduction, structural reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

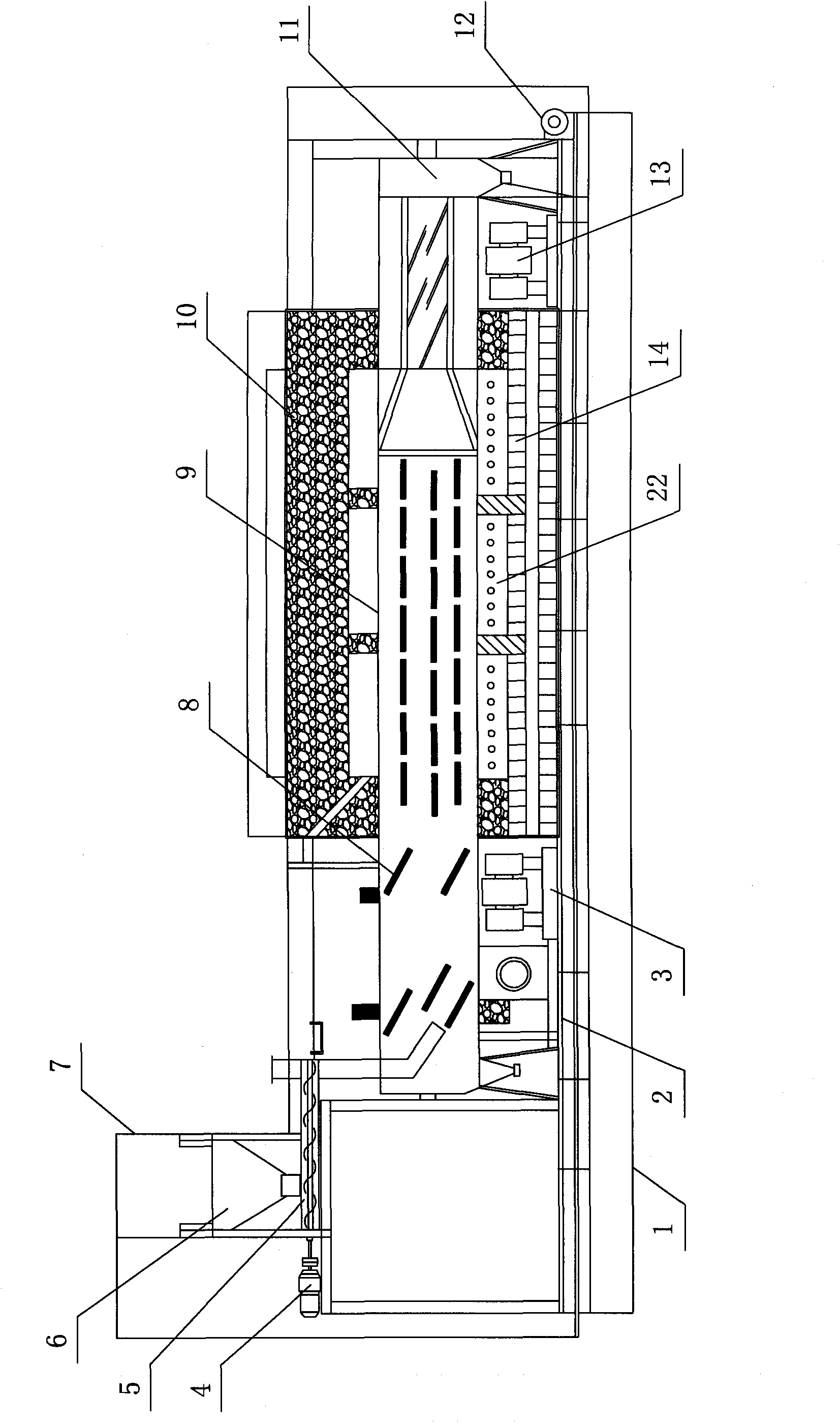

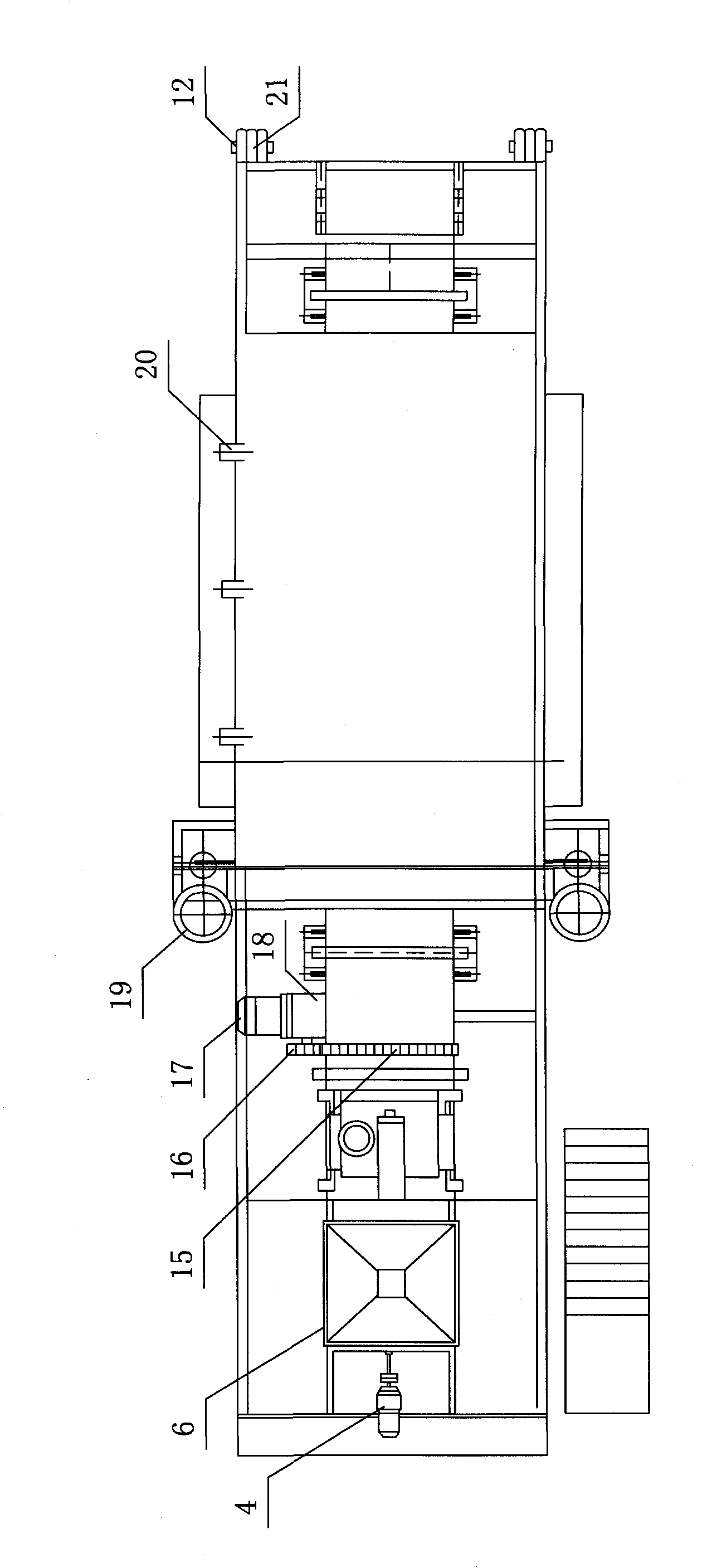

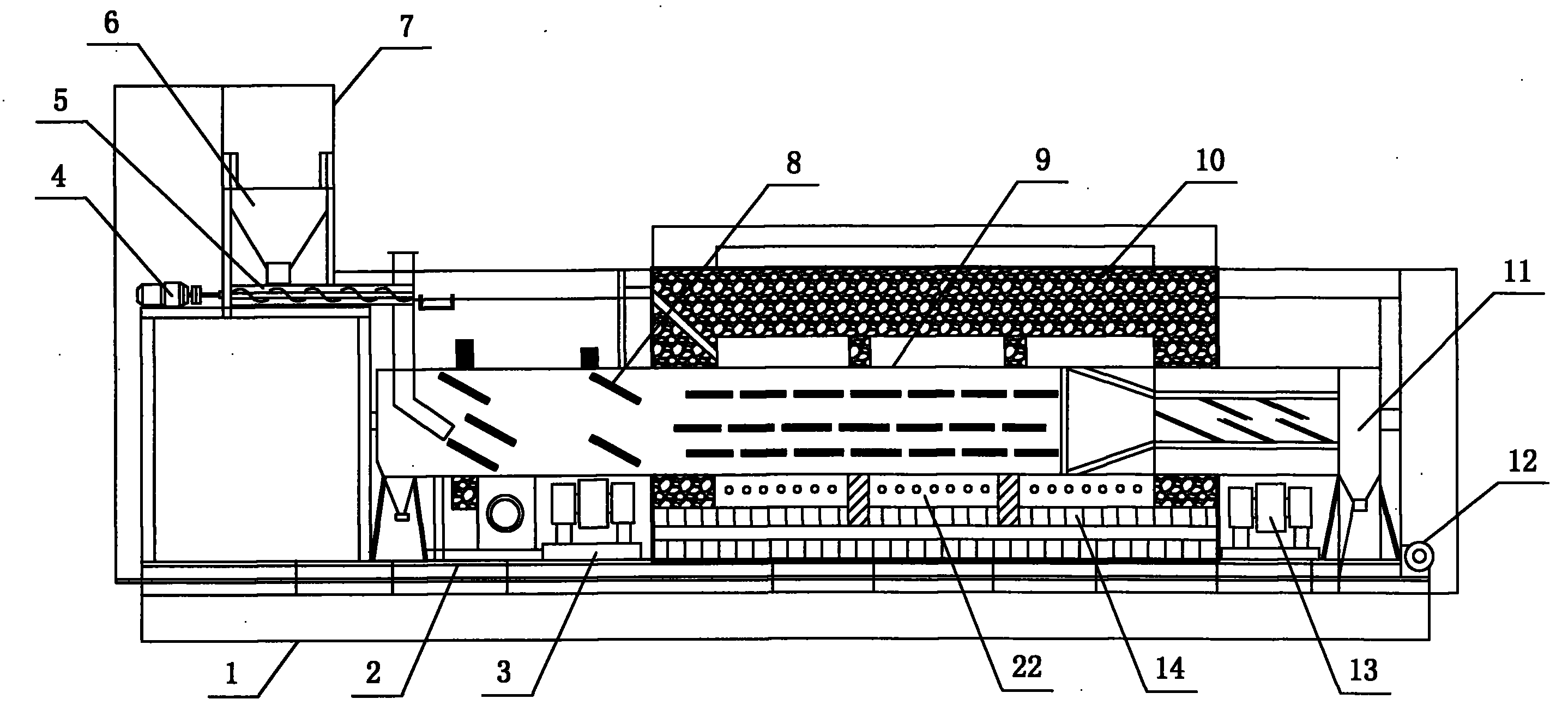

[0012] figure 1 , 2 The upper end of the base 1 shown in the figure is provided with a bracket 2, and the front and rear ends of the bracket are provided with two supporting roller frames 3, and two sets of supporting wheels 13 are installed on the supporting wheel frame, and the rotary kiln cylinder 9 is installed on the supporting rollers. The rear end of the bracket is provided with a hinge sleeve 12, the rear end of the rotary kiln cylinder is provided with a hinge pin 21, the inside wall of the rotary kiln cylinder is provided with a pusher rib 8, and the outside of the cylinder is provided with a heat preservation furnace body 10, A temperature measuring head 20 is arranged on the heat preservation furnace body, an insulation layer is arranged in the heat preservation furnace body, a heating furnace body 14 is arranged on the upper end of the support, an electric heating body 22 is arranged in the heating furnace body, and a Gear ring 15, motor 17 is housed on the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com