Process for synthesizing alpha, beta type lead dioxide and leadleaden oxide naon crystal

A lead dioxide, nanocrystalline technology, applied in lead dioxide, lead oxide, lead dan and other directions, to achieve the effect of less by-products, lower production costs, and solve environmental pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

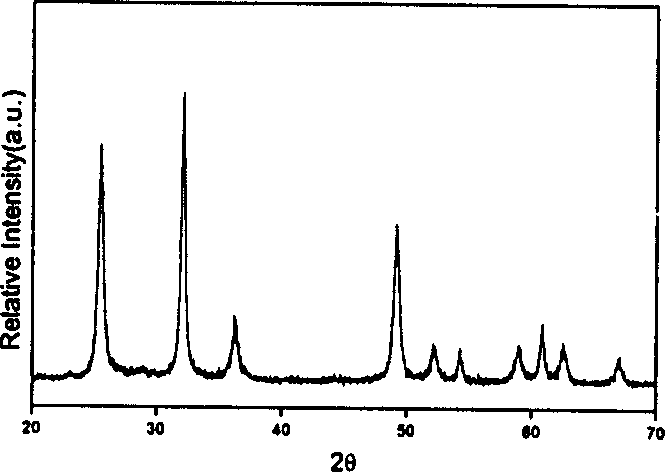

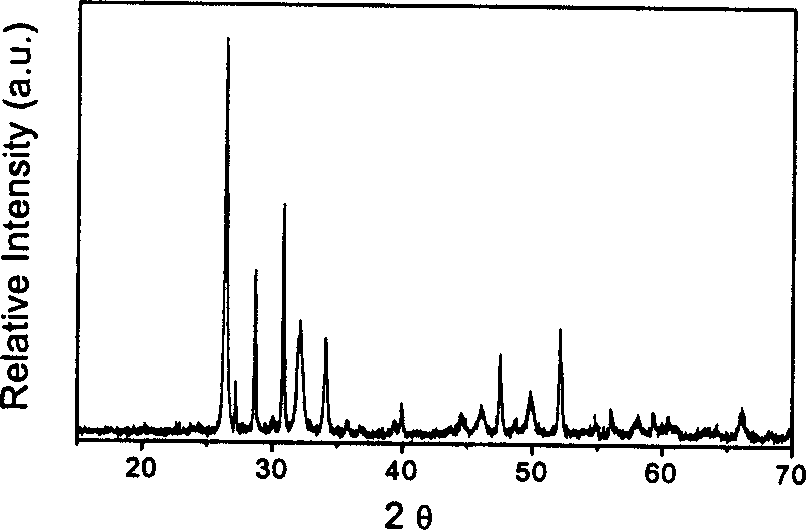

[0031] Weigh 5 g of analytically pure lead nitrate and dissolve it in 10 mL of water, add solid sodium hydroxide, adjust the pH of the solution to 9.0, add 50 mL of sodium hypochlorite solution (available chlorine content > 5.5%) after the solution is completely dissolved, and stir well. After reacting at 60 °C for 6 h, the obtained precipitate was filtered, washed and dried to obtain a brown powder. The filtrate used 0.01 mol·L -1 The potassium chromate solution was tested, and no yellow lead chromate precipitate was observed, indicating that the reaction was very complete. like figure 1 As shown, the product was identified as β-lead dioxide by X-ray powder diffraction; the morphology of β-lead dioxide nanocrystals was analyzed by transmission electron microscopy (TEM), from figure 2 It can be seen that the shape of the rod is rod-like, the diameter of the rod is between 10 and 20 nm, the length is 400 nm, and the aspect ratio is more than 20. The synthesized β-lead dioxid...

Embodiment 2

[0033] Weigh 3 g of analytically pure lead hydroxide in 10 mL of water, add sodium hydroxide solution with a concentration of 10%, adjust the pH of the solution to 13.0, add 40 mL of sodium hypochlorite solution (available chlorine content > 5.5%) after the solution is completely dissolved, and stir well. After reacting at 30°C for 24h, the obtained precipitate was filtered, washed and dried to obtain brown α-lead dioxide powder. The filtrate was 0.01mol·L -1 The potassium chromate solution was tested, and no yellow lead chromate precipitate was observed, indicating that the reaction was very complete. The obtained α-lead dioxide was pyrolyzed at 410° C. for 6 hours according to the method in Example 1 to prepare lead tetroxide nanocrystals.

Embodiment 3

[0035] Weigh 5g of analytically pure lead oxide into 10mL of water, add solid sodium hydroxide, adjust the pH of the solution to 10.0, add 50mL of sodium hypochlorite solution (available chlorine content> 5.5%) after the solution is completely dissolved, and stir well. After reacting at 120 °C for 2 h, the obtained precipitate was filtered, washed and dried to obtain brown β-lead dioxide powder. The filtrate was 0.01 mol·L -1 The potassium chromate solution was tested, and no yellow lead chromate precipitate was observed, indicating that the reaction was very complete. The obtained β-lead dioxide was pyrolyzed at 430° C. for 4 hours according to the method in Example 1 to prepare lead tetroxide nanocrystals.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com