Patents

Literature

209results about "Lead oxides" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

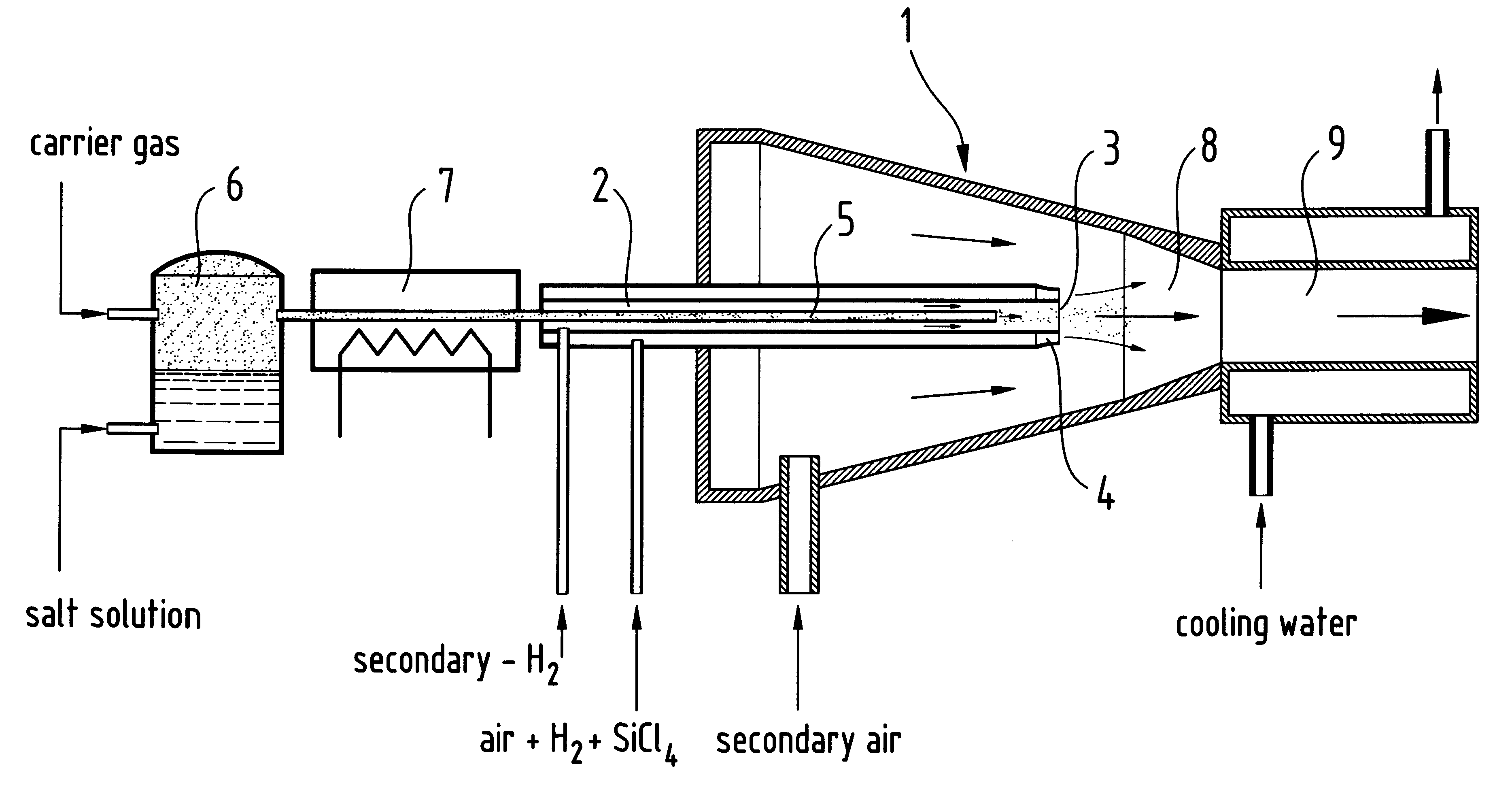

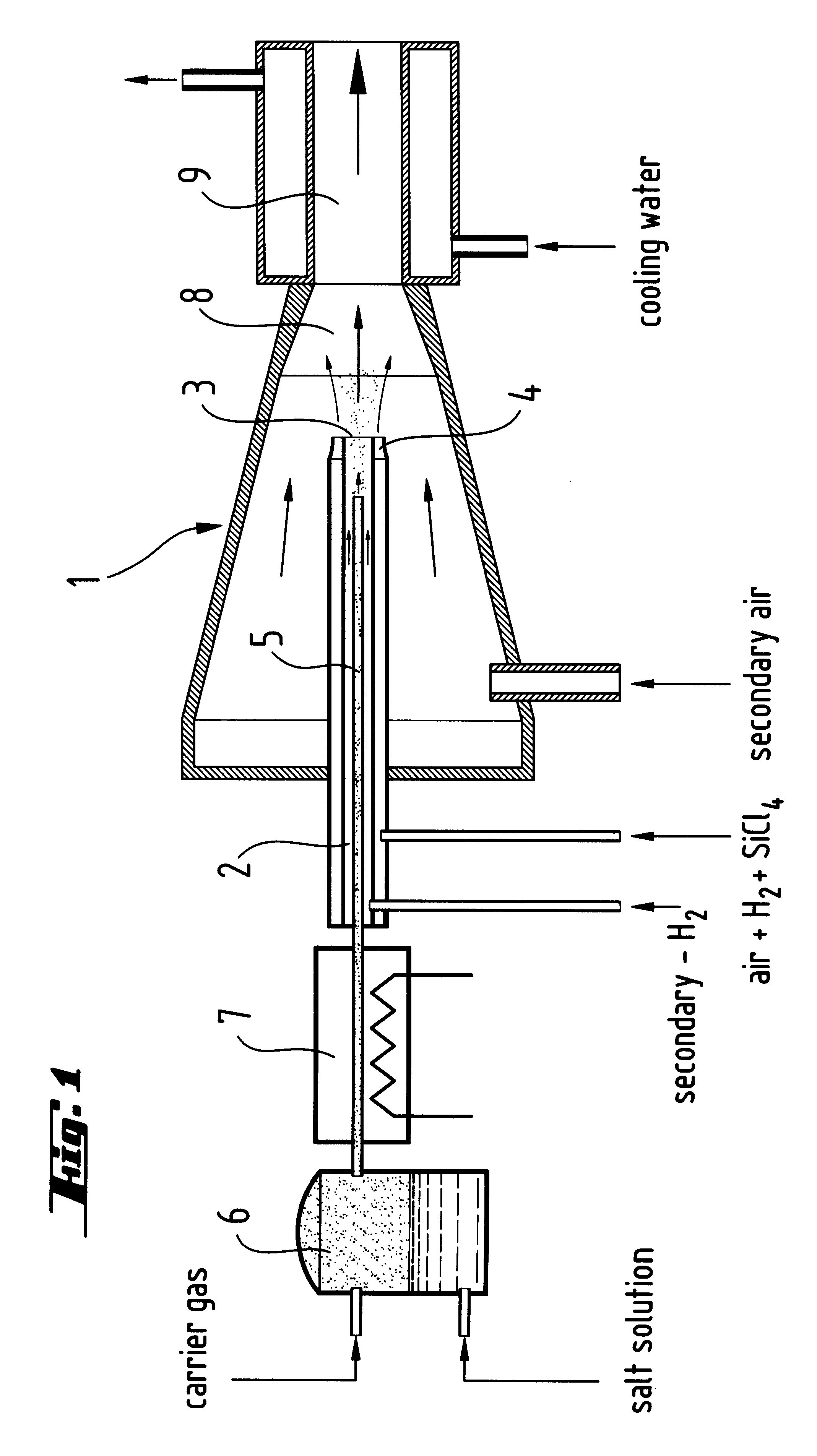

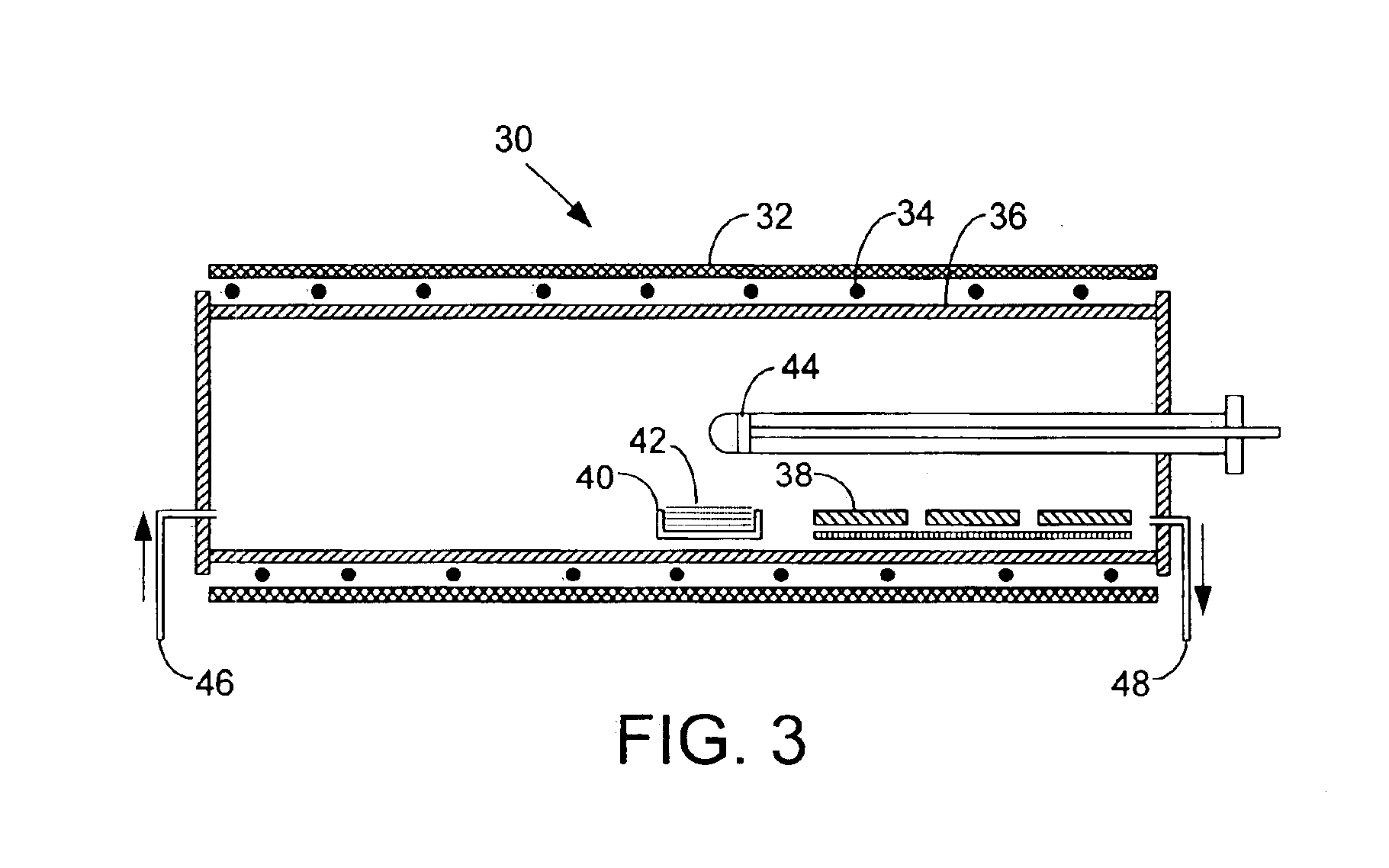

Doped, pyrogenically prepared oxides

InactiveUS6328944B1Germanium dioxidePipe protection by thermal insulationDoped oxideAqueous solution

Doped, pyrogenically prepared oxides of metals and / or non-metals which are doped with one or more doping components in an amount of 0.00001 to 20 wt. %. The doping component may be a metal and / or non-metal or an oxide and / or a salt of a metal and / or a non-metal. The BET surface area of the doped oxide may be between 5 and 600 m2 / g. The doped pyrogenically prepared oxides of metals and / or non-metals are prepared by adding an aerosol which contains an aqueous solution of a metal and / or non-metal to the gas mixture during the flame hydrolysis of vaporizable compounds of metals and / or non-metals.

Owner:EVONIK DEGUSSA GMBH

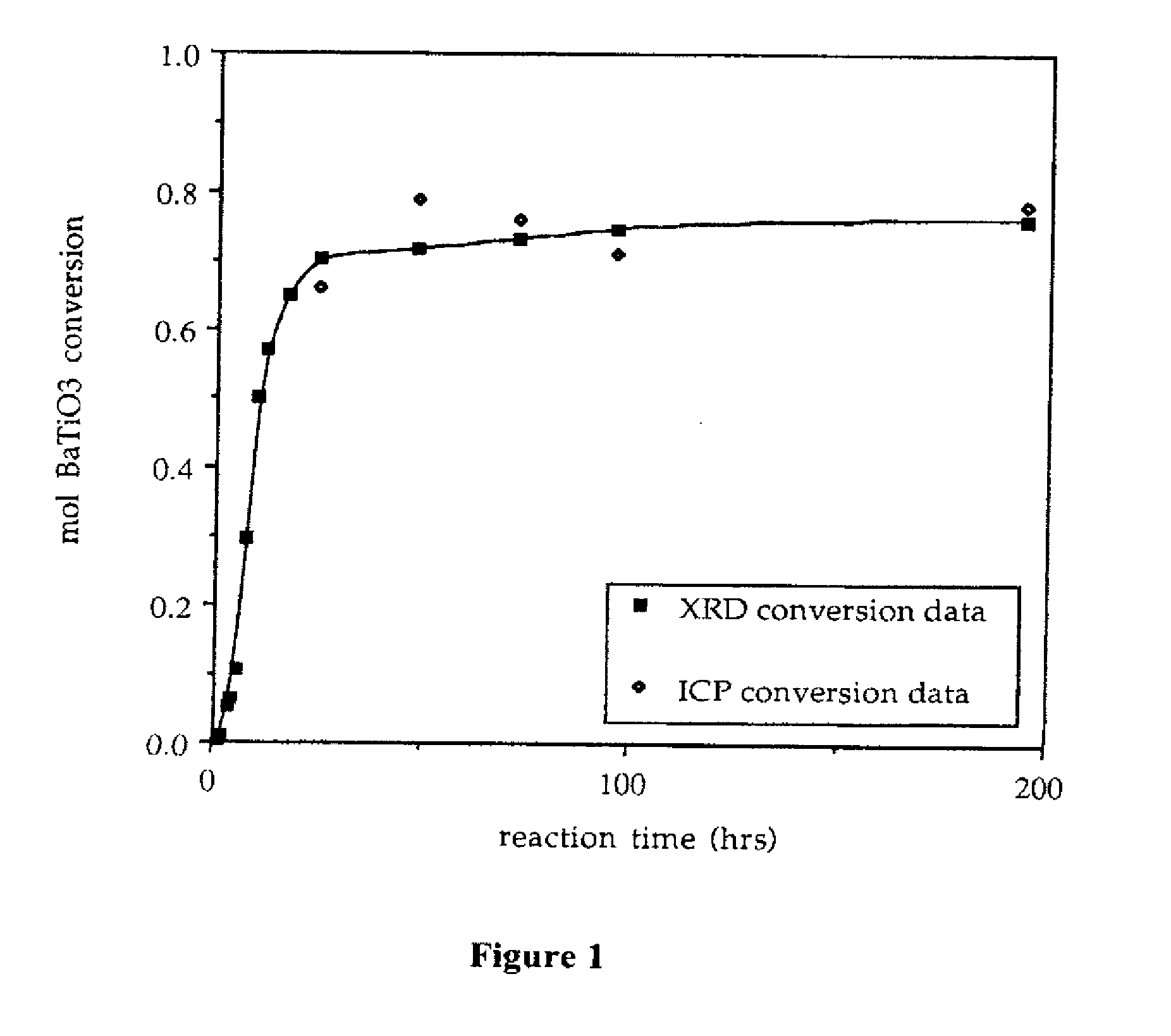

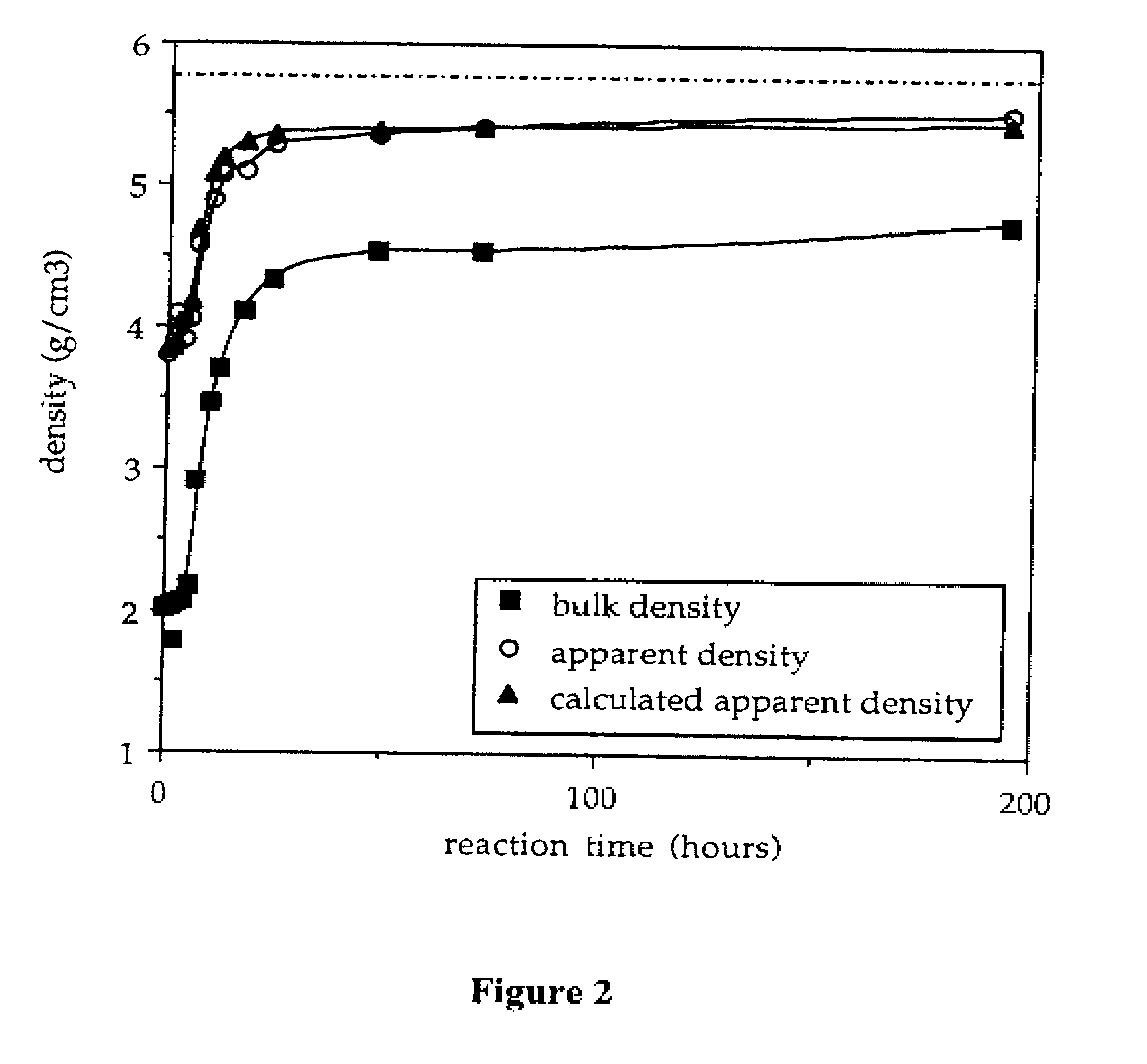

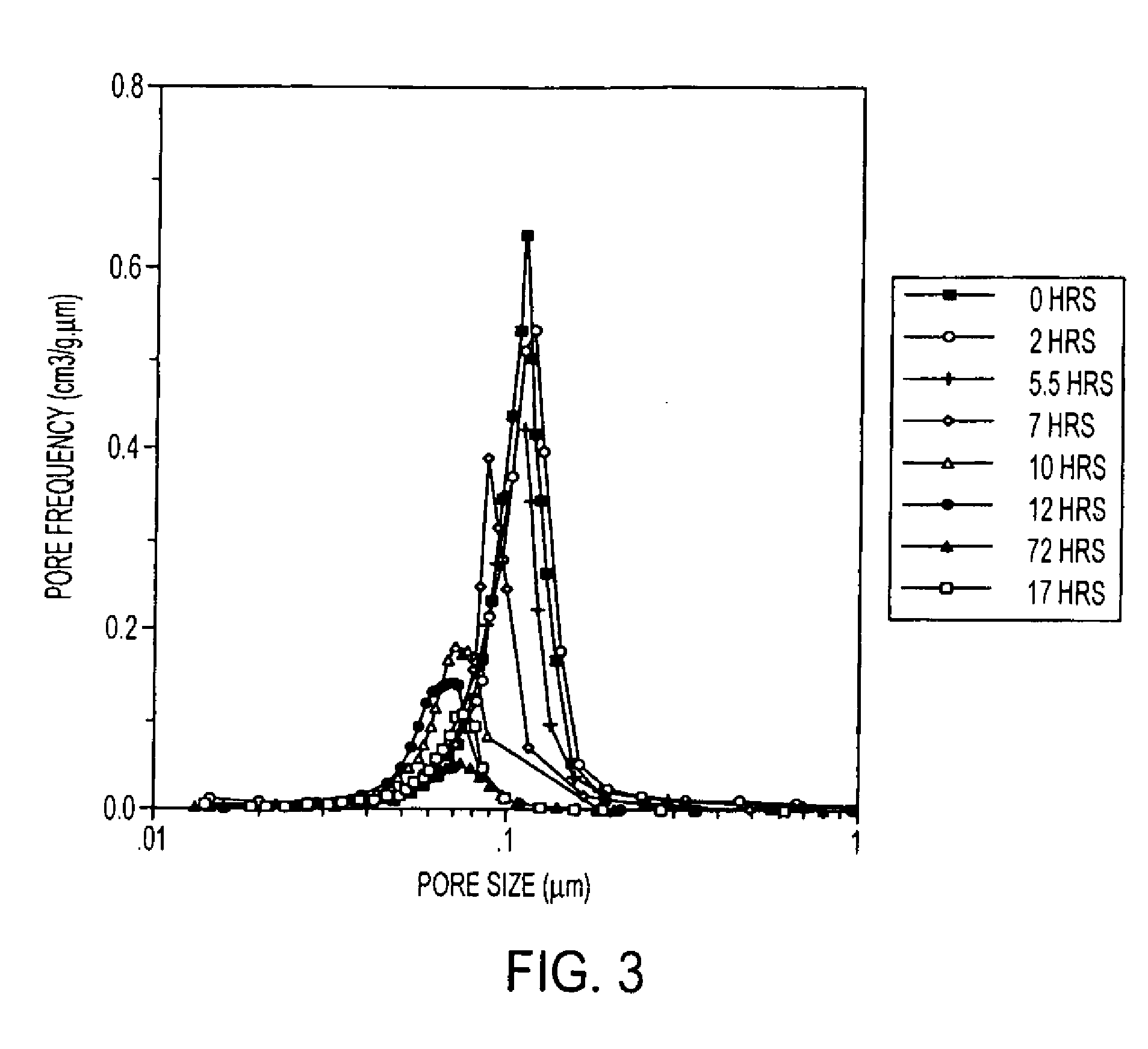

Method of hydrothermal liquid phase sintering of ceramic materials and products derived therefrom

Provided here is a method of producing a monolithic body from a porous matrix, comprising: (i) providing a porous matrix having interstitial spaces and comprising at least a first reactant; (ii) contacting the porous matrix with an infiltrating medium that carries at least a second reactant; (iii) allowing the infiltrating medium to infiltrate at least a portion of the interstitial spaces of the porous matrix under conditions that promote a reaction between the at least first reactant and the at least second reactant to provide at least a first product; and (iv) allowing the at least first product to form and fill at least a portion of the interstitial spaces of the porous matrix, thereby producing a monolithic body, wherein the monolithic body does not comprise barium titanate.

Owner:RUTGERS THE STATE UNIV

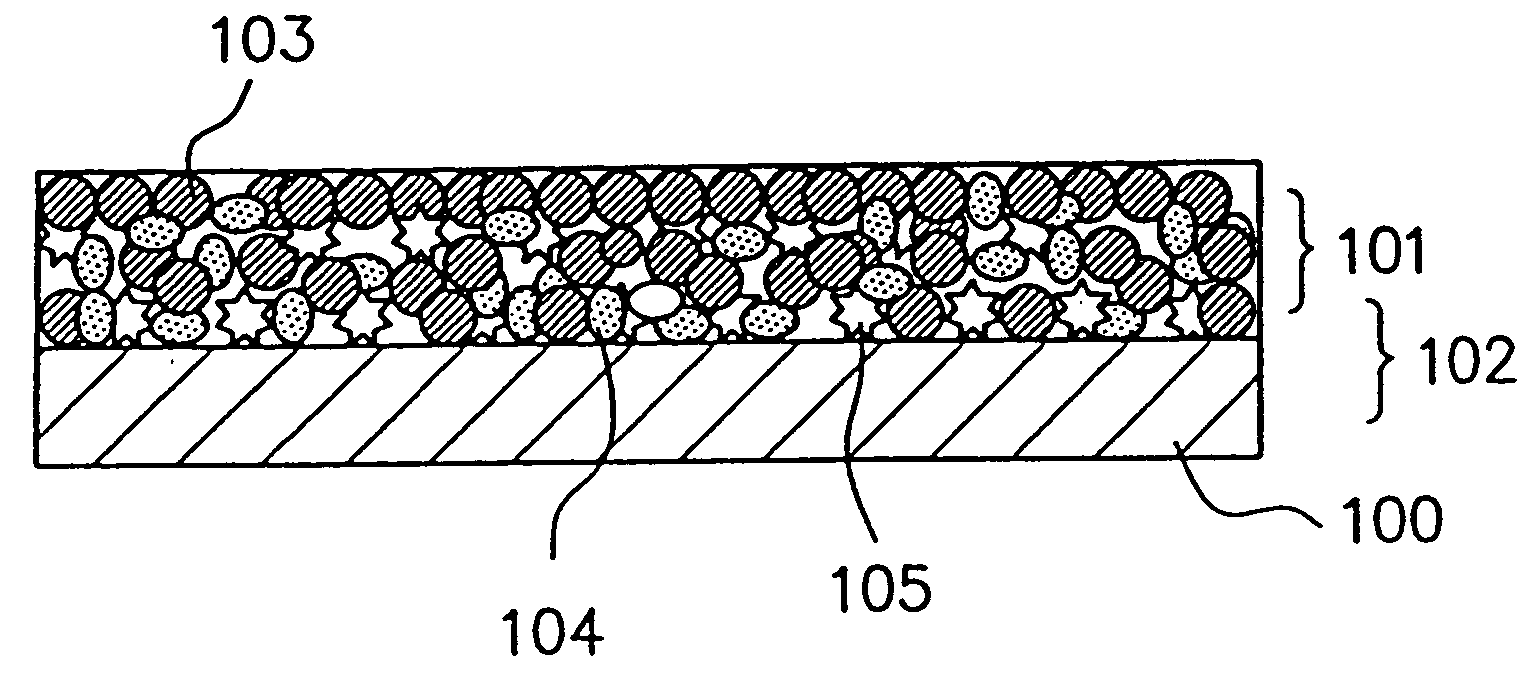

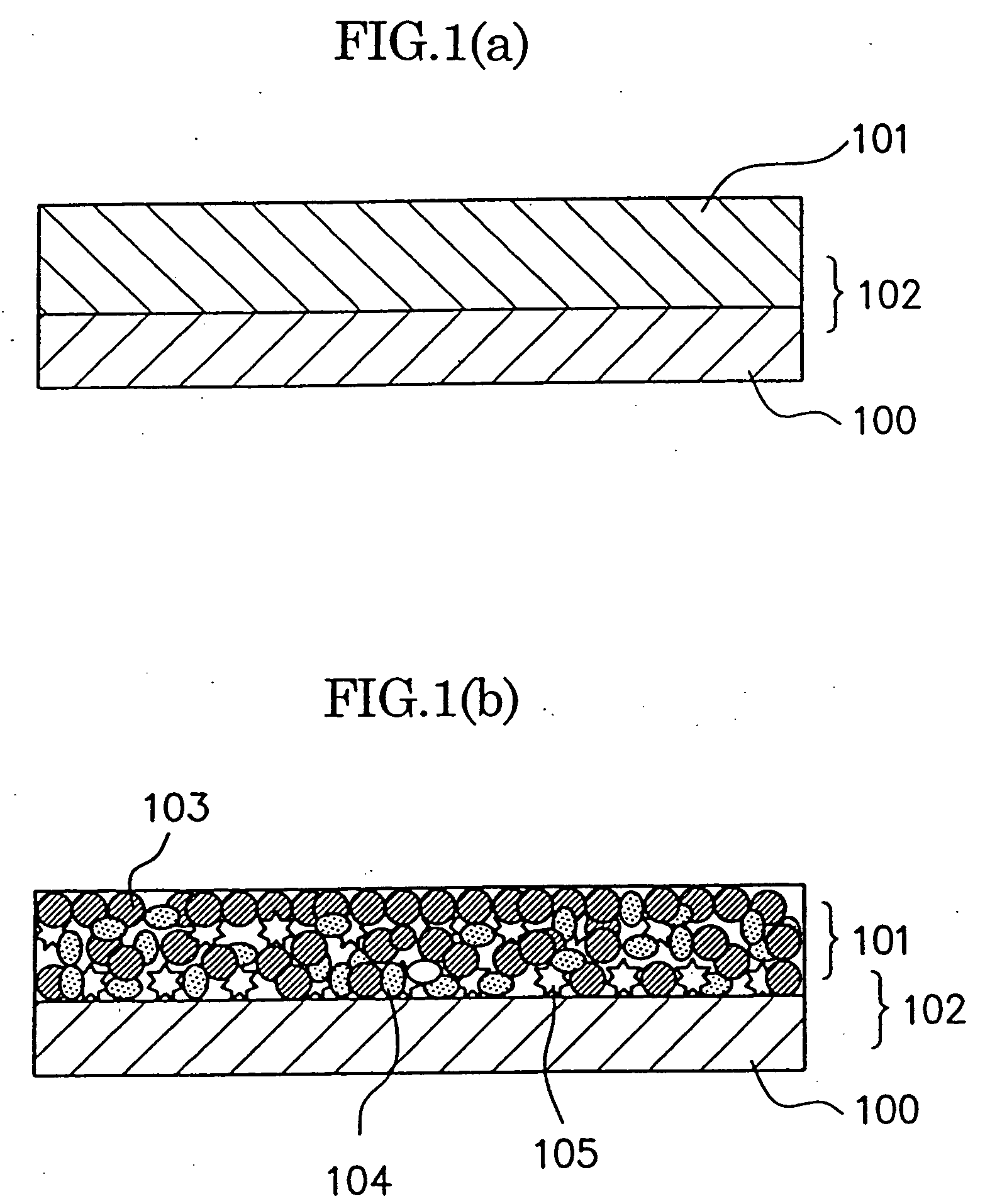

Process of making hydrophobic metal oxide nanoparticles

InactiveUS7081234B1Uniform coatingSulfur compoundsCopper oxides/halidesMetal oxide nanoparticlesTransport layer

A process of treating metal oxide nanoparticles that includes mixing metal oxide nanoparticles, a solvent, and a surface treatment agent that is preferably a silane or siloxane is described. The treated metal oxide nanoparticles are rendered hydrophobic by the surface treatment agent being surface attached thereto, and are preferably dispersed in a hydrophobic aromatic polymer binder of a charge transport layer of a photoreceptor, whereby π—π interactions can be formed between the organic moieties on the surface of the nanoparticles and the aromatic components of the binder polymer to achieve a stable dispersion of the nanoparticles in the polymer that is substantially free of large sized agglomerations.

Owner:XEROX CORP

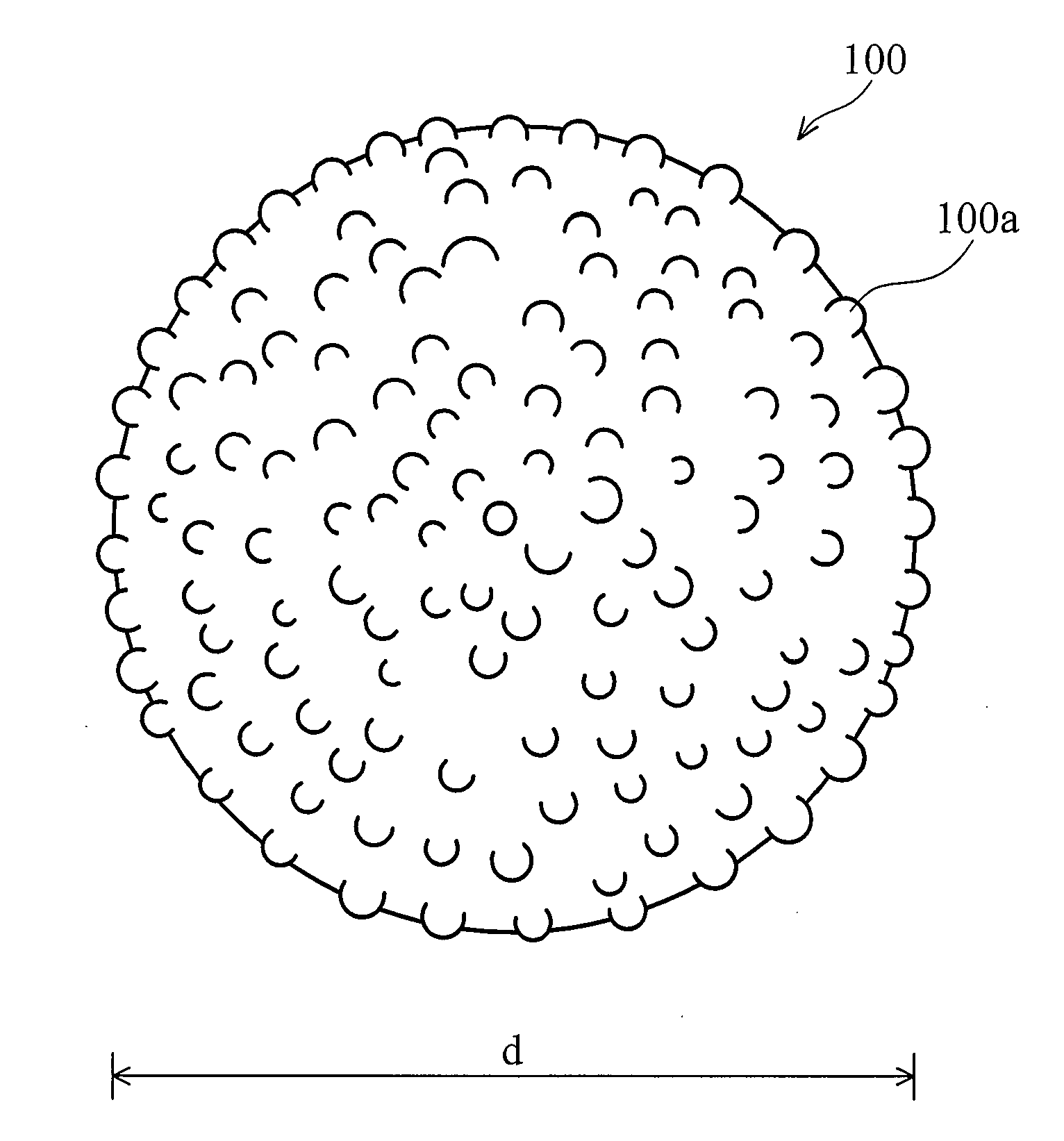

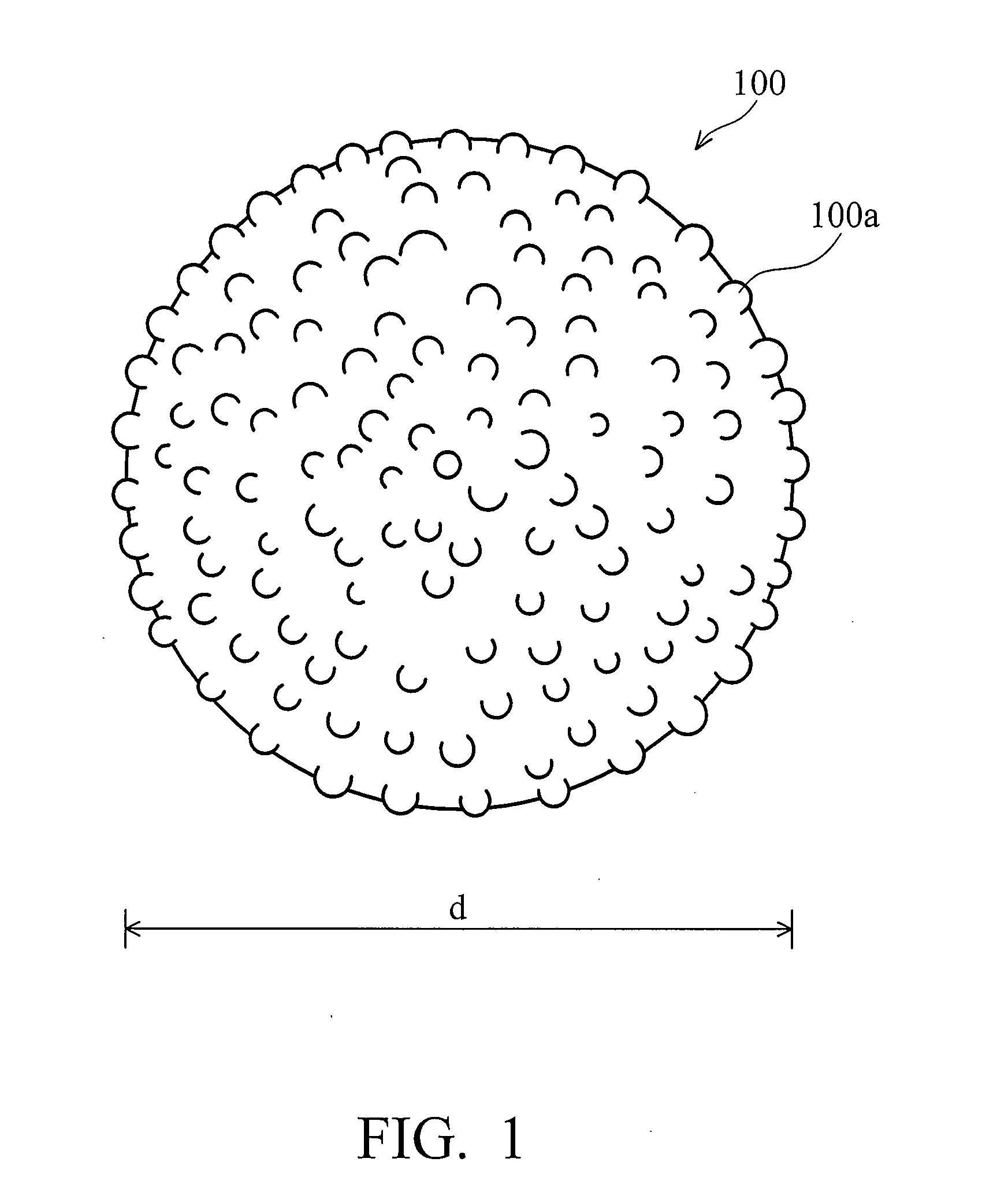

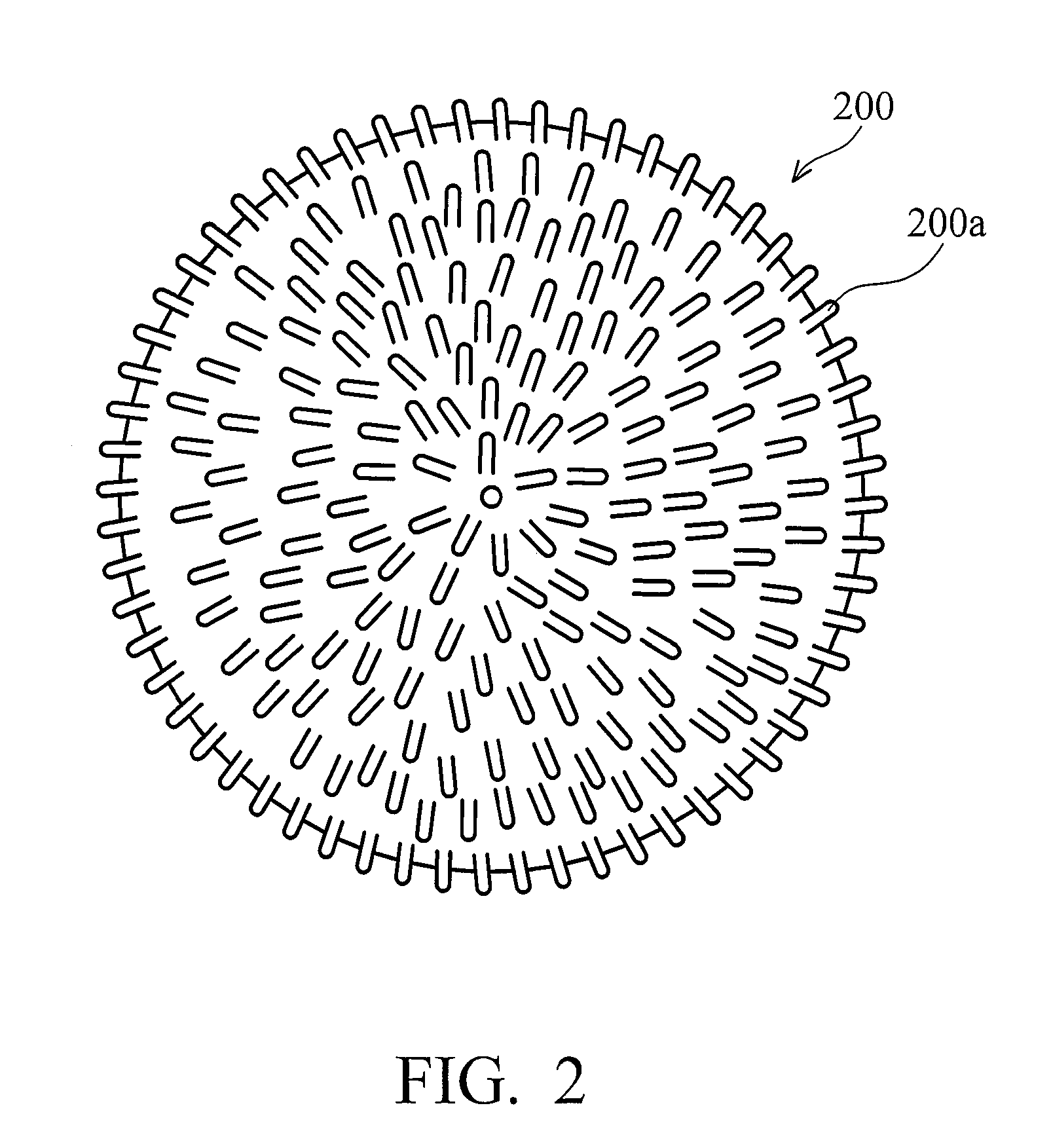

Superhydrophobic and self-cleaning powders and fabrication method thereof

The invention discloses nano / micron binary structured powders for superhydrophobic, self-cleaning applications. The powders are featured by micron-scale diameter and nano-scale surface roughness. In one embodiment, the average diameter is about 1-25 μm, and the average roughness Ra is about 3-100 nm. The nano / micron binary structured powders may be made of silica, metal oxide, or combinations thereof.

Owner:IND TECH RES INST

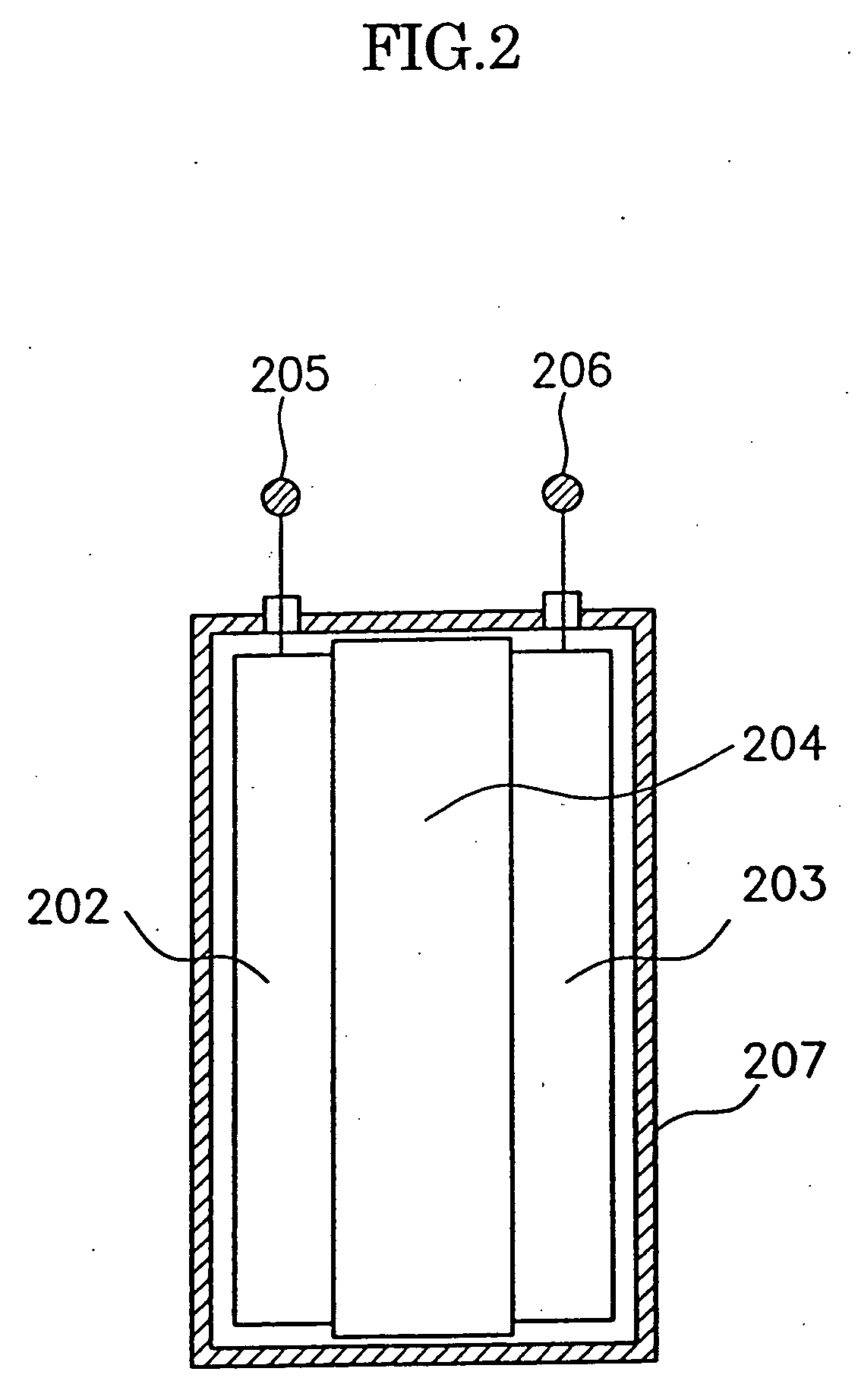

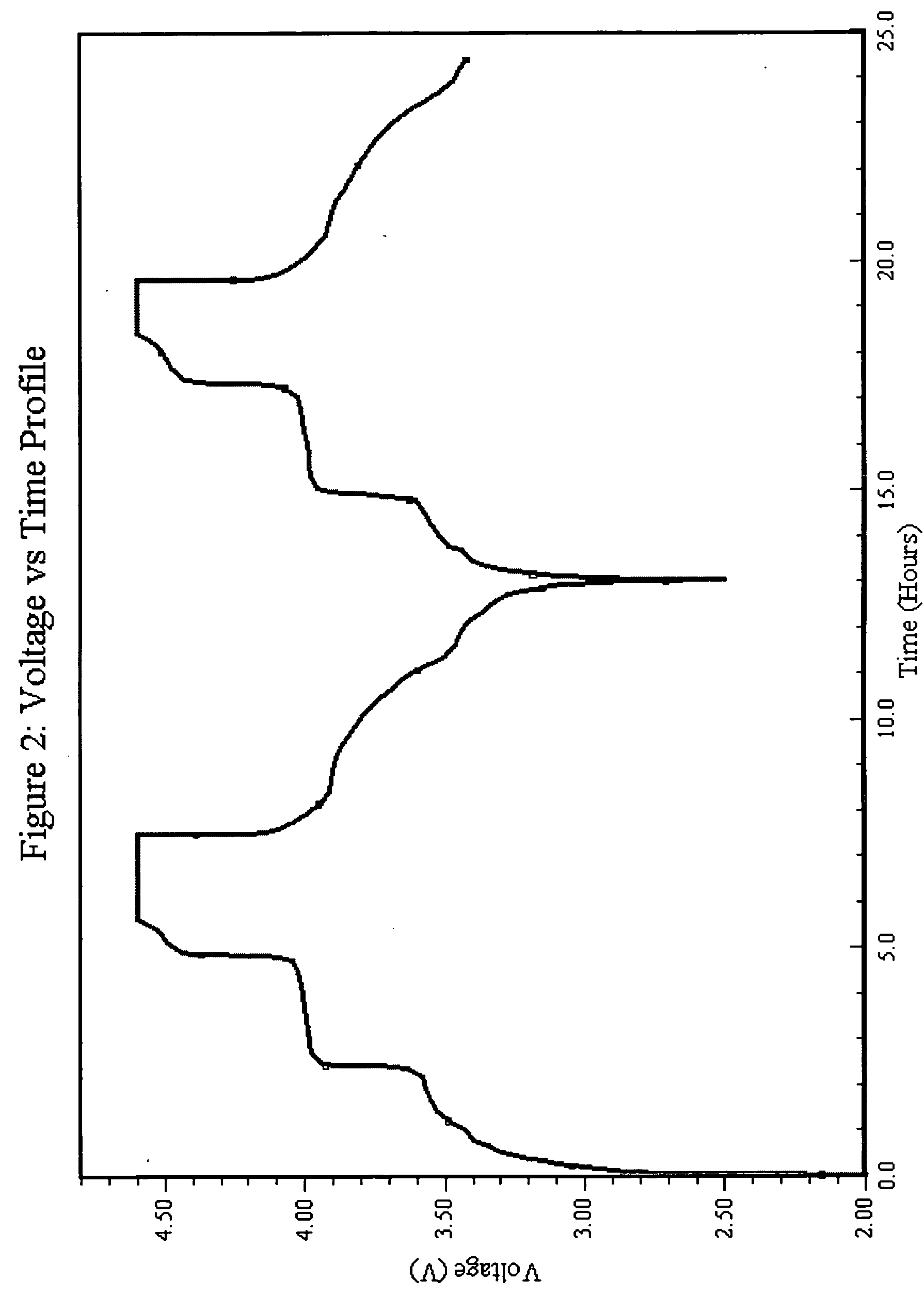

Electrode material for anode of rechargeable lithium battery, electrode structural body using said electrode material, rechargeable lithium battery using said electrode structural body, process for producing said electrode structural body, and process for producing said rechargeable lithium battery

InactiveUS20050175901A1Prolonged discharging cycle lifeLarge capacityNitrogen compoundsSelenium/tellurium compundsElectrochemical responseParticulates

An electrode material for an anode of a rechargeable lithium battery, containing a particulate comprising an amorphous Sn.A.X alloy with a substantially non-stoichiometric ratio composition. For said formula Sn.A.X, A indicates at least one kind of an element selected from a group consisting of transition metal elements, X indicates at least one kind of an element selected from a group consisting of O, F, N, Mg, Ba, Sr, Ca, La, Ce, Si, Ge, C, P, B, Pb, Bi, Sb, Al, Ga, In, Tl, Zn, Be, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, Lu, As, Se, Te, Li and S, where the element X is not always necessary to be contained. The content of the constituent element Sn of the amorphous Sn.A.X alloy is Sn / (Sn+A+X)=20 to 80 atomic %. An electrode structural body for a rechargeable lithium battery, comprising said electrode material for an anode and a collector comprising a material incapable of being alloyed with lithium in electrochemical reaction, and a rechargeable lithium battery having an anode comprising said electrode structural body.

Owner:CANON KK

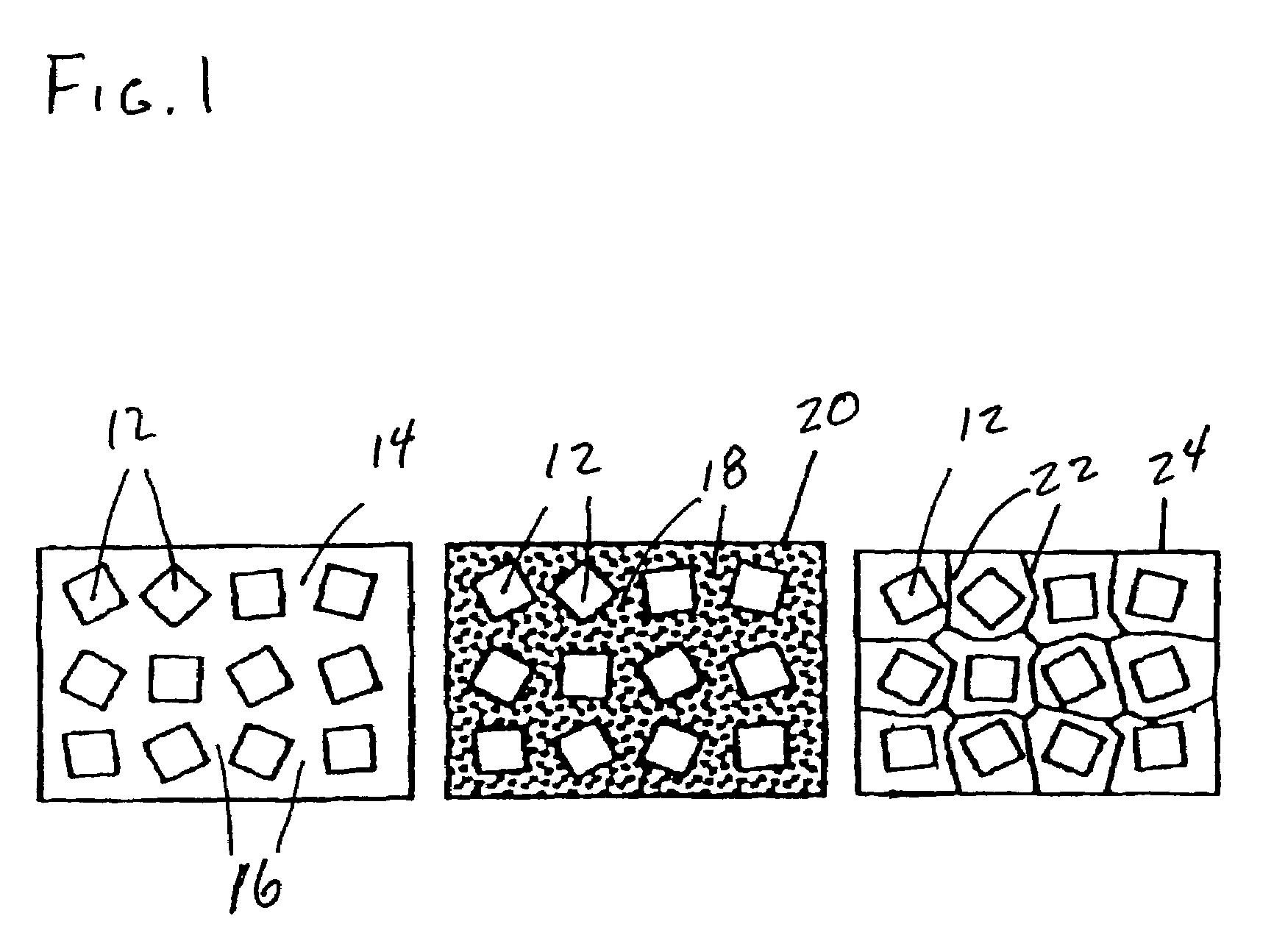

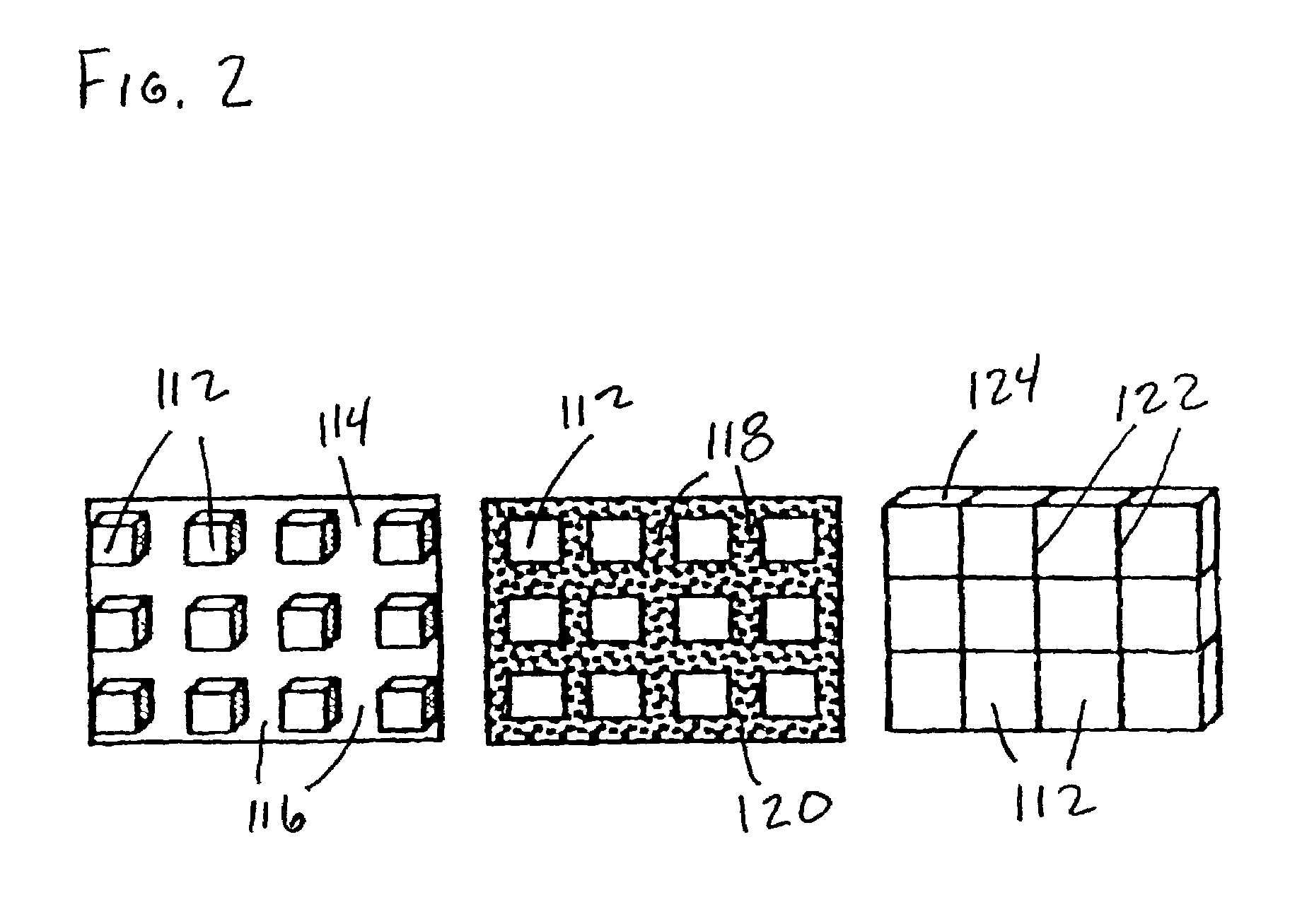

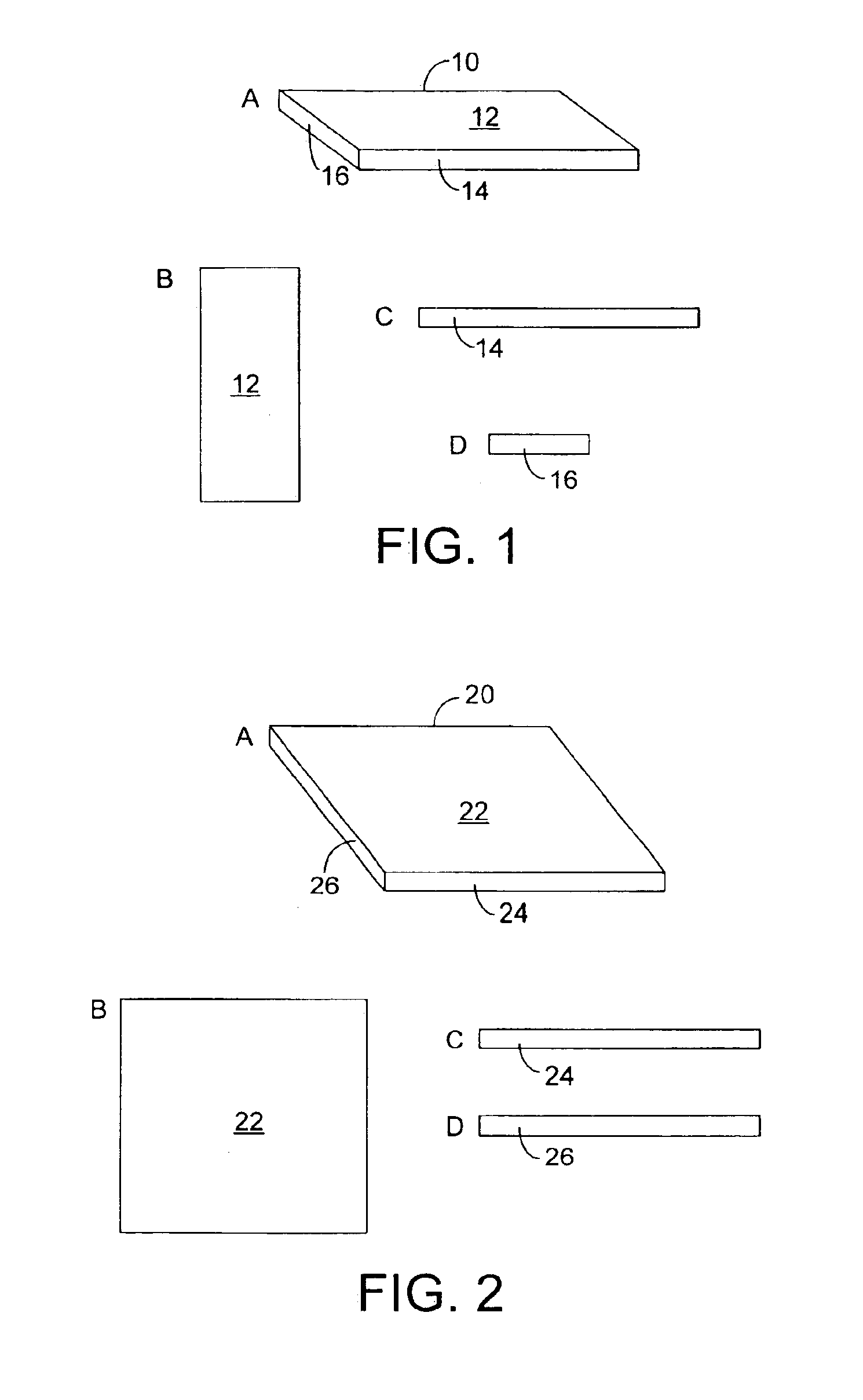

Single-crystal-like materials

InactiveUS7022303B2Improve fracture toughnessReadily apparentMagnesium fluoridesCalcium/strontium/barium fluoridesMetallurgySingle crystal

Polycrystalline materials of macroscopic size exhibiting Single-Crystal-Like properties are formed from a plurality of Single-Crystal Particles, having Self-Aligning morphologies and optionally ling morphology, bonded together and aligned along at least one, and up to three, crystallographic directions.

Owner:RUTGERS THE STATE UNIV

Methods of Making Binary Metal Oxide Nanostructures and Methods of Controlling Morphology of Same

ActiveUS20100278720A1Reduce crystallinityControl dimensionalityCopper oxides/halidesManganese oxides/hydroxidesPorous membraneNanostructure

The present invention includes a method of producing a crystalline metal oxide nanostructure. The method comprises providing a metal salt solution and providing a basic solution; placing a porous membrane between the metal salt solution and the basic solution, wherein metal cations of the metal salt solution and hydroxide ions of the basic solution react, thereby producing a crystalline metal oxide nanostructure.

Owner:WONG STANISLAUS S +1

Ultrafine lead oxide prepared by using waste lead plaster and preparation method thereof

InactiveCN103374657AReduce energy consumptionSimple ingredientsReclaiming serviceable partsLead oxidesFiltrationTwo step

The invention discloses an ultrafine lead oxide prepared by using a waste lead plaster and a preparation method thereof. The preparation method comprises the following steps of: carrying out desulphurization process by mixing the waste lead plaster with an aqueous solution containing a composite desulfurizer for reaction; carrying out filtration to remove the desulphurization filtering solution to obtain the desulfurated lead plaster (filter residue); carrying out a leaching and crystal transformation process by adding a citric acid solution and a reducing agent into the desulfurated lead plaster obtained in the process, and carrying out filtration, washing, and drying to obtain the lead citrate after the desulfurated lead plaster reacts with the citric acid solution; carrying out a roasting process by roasting the lead citrate to obtain the ultrafine lead oxide. According to the preparation method disclosed by the invention, the ultrafine lead oxide is prepared from the waste lead storage lead plaster; a two-step leaching process is adopted; the filtering solution is simple in ingredient and can be recycled; a side product is recycled from the desulphurization solution. The preparation method disclosed by the invention is low in energy consumption, simple in equipment, high in lead recycling rate, and high in ultrafine lead product quality, and has the characteristics of good resource recycling effect, environmentally-friendly and pollution-free production process, and capability of clean production.

Owner:湖北金洋冶金股份有限公司 +1

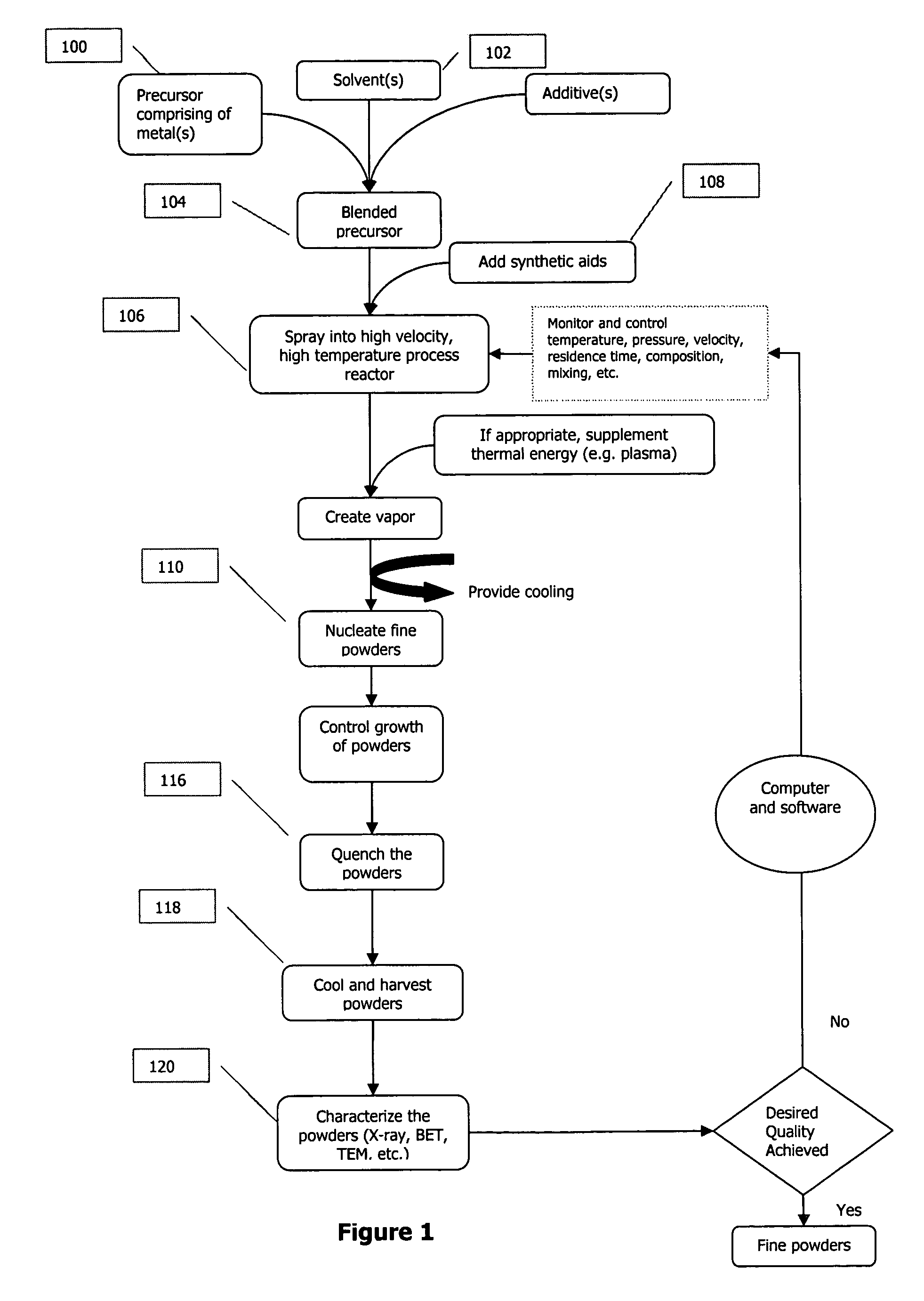

Titanium comprising nanoparticles and related nanotechnology

ActiveUS7232556B2Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

Titanium comprising nanoparticles and related nanotechnology

ActiveUS20050191492A1Increase volumeLow cost productionNitrogen compoundsGermanium dioxideNanoparticleTitanium metal

Owner:PPG IND OHIO INC

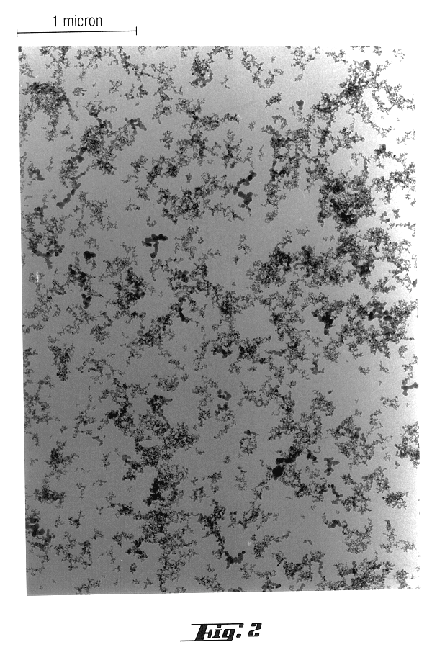

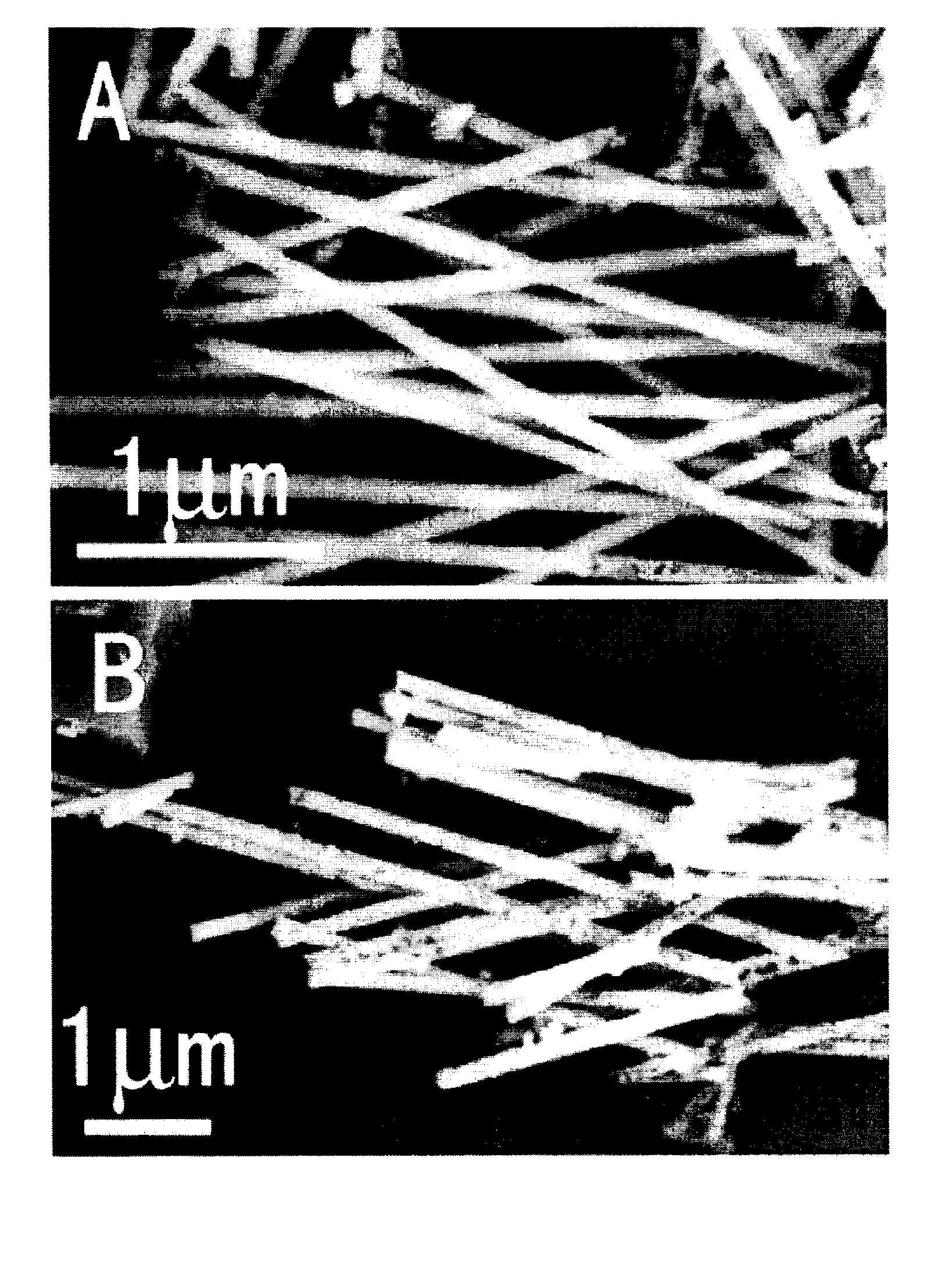

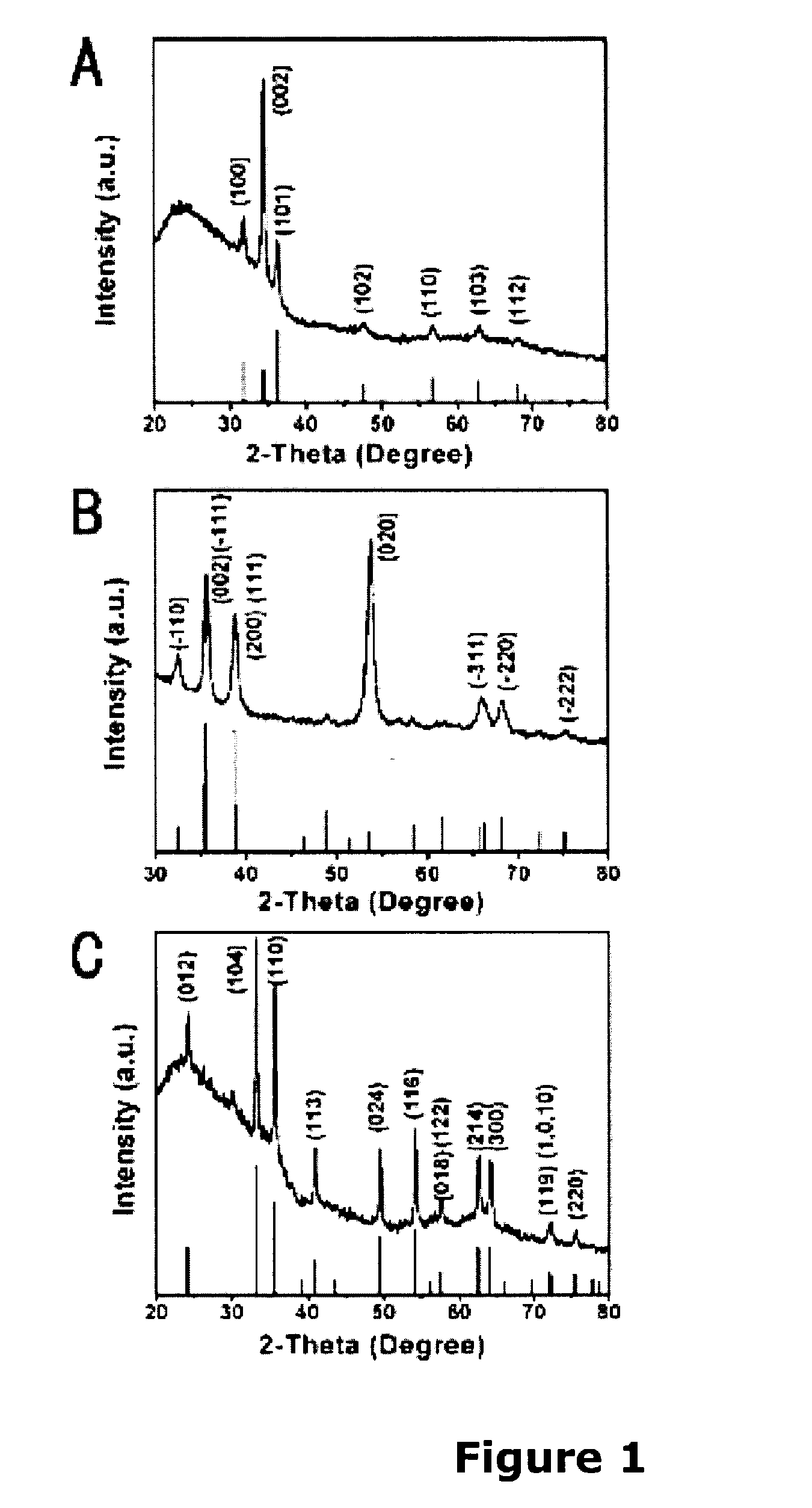

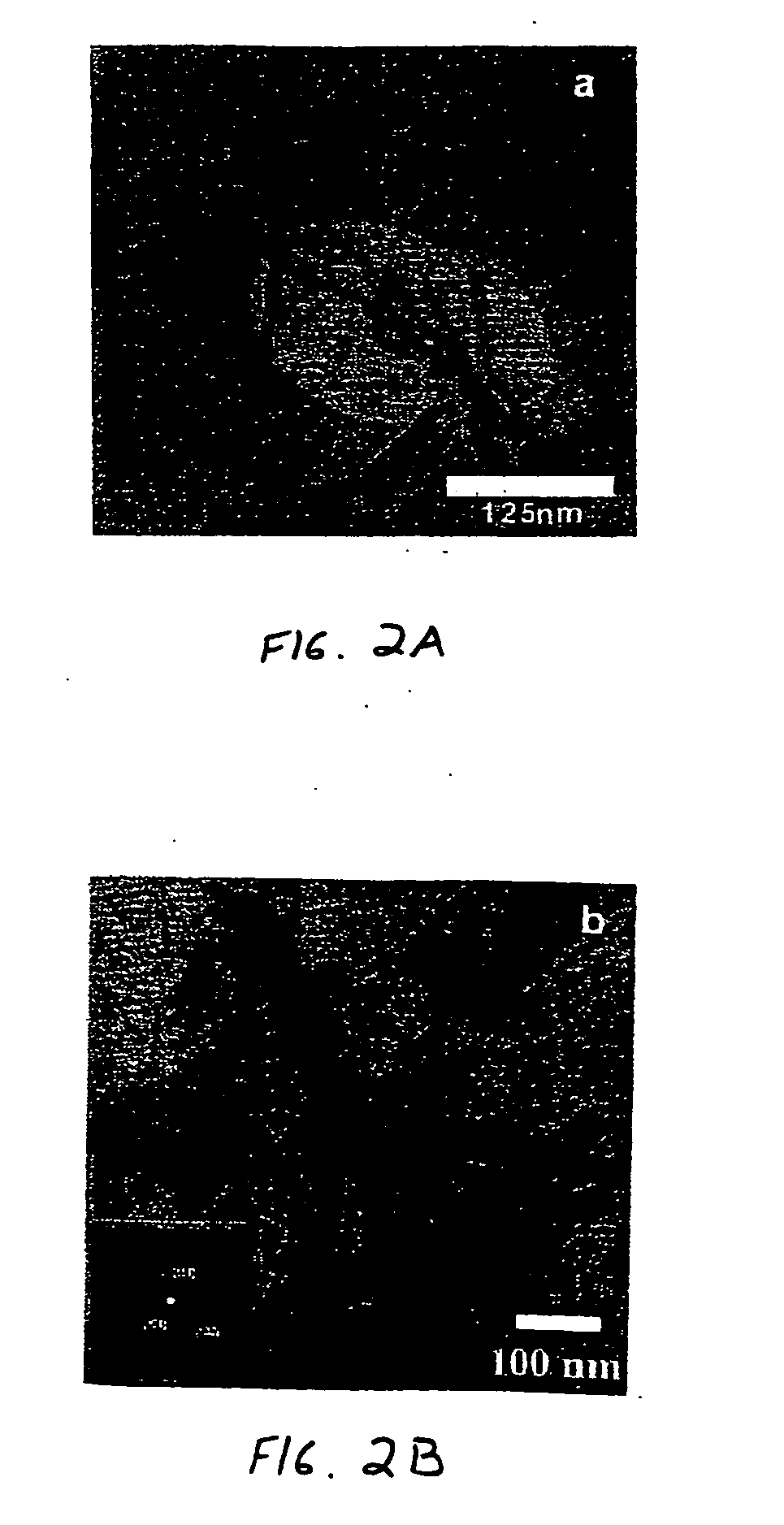

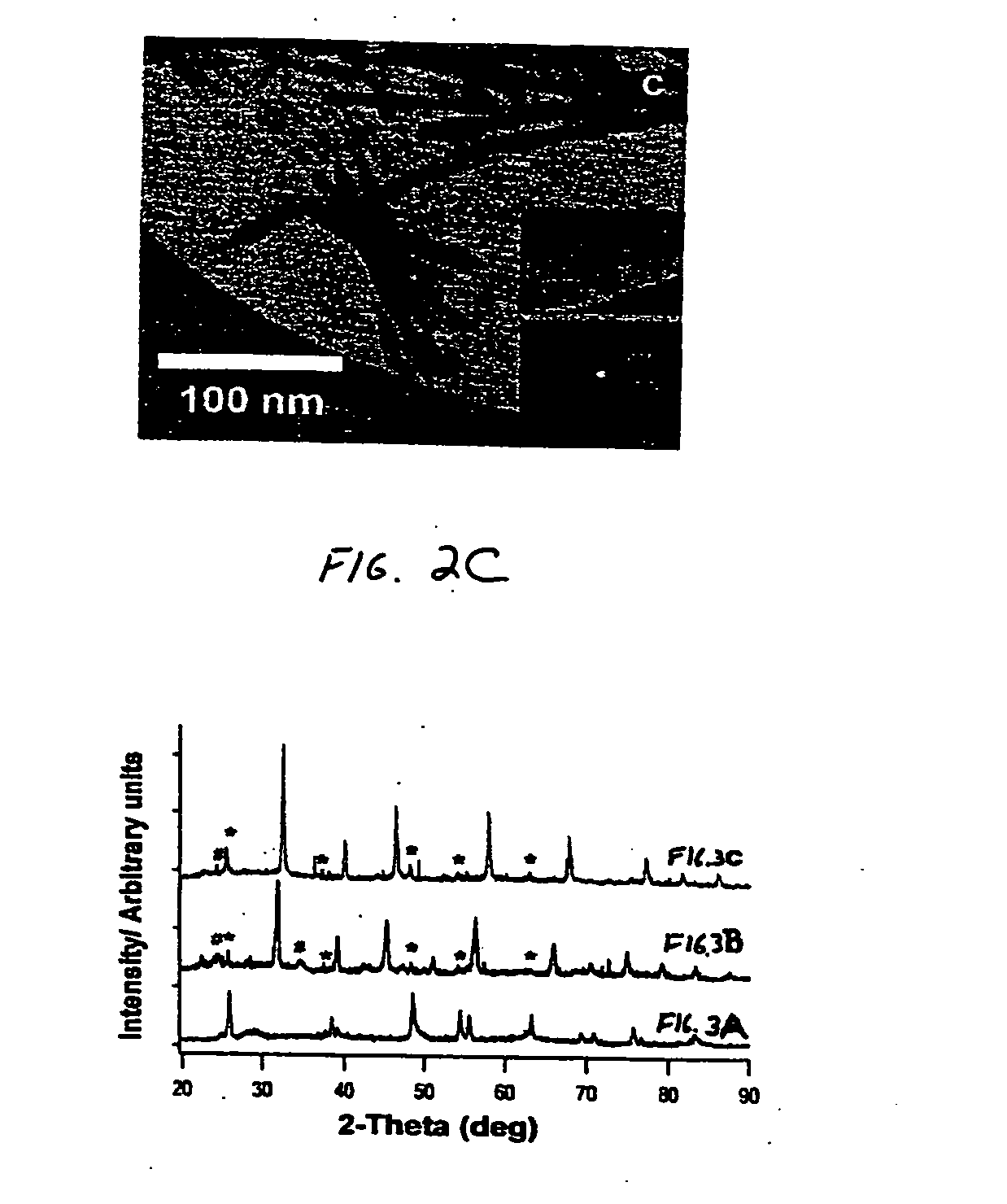

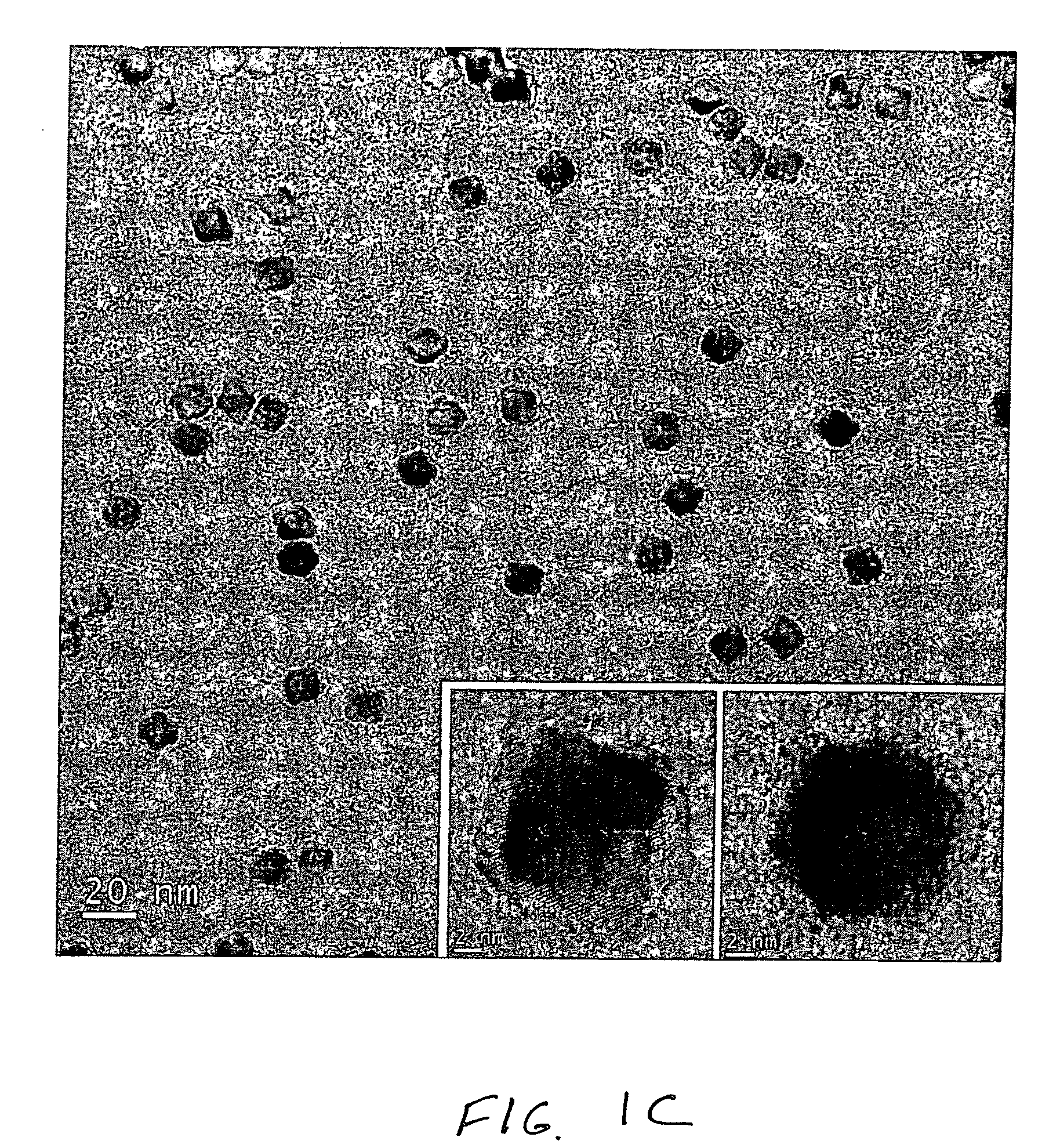

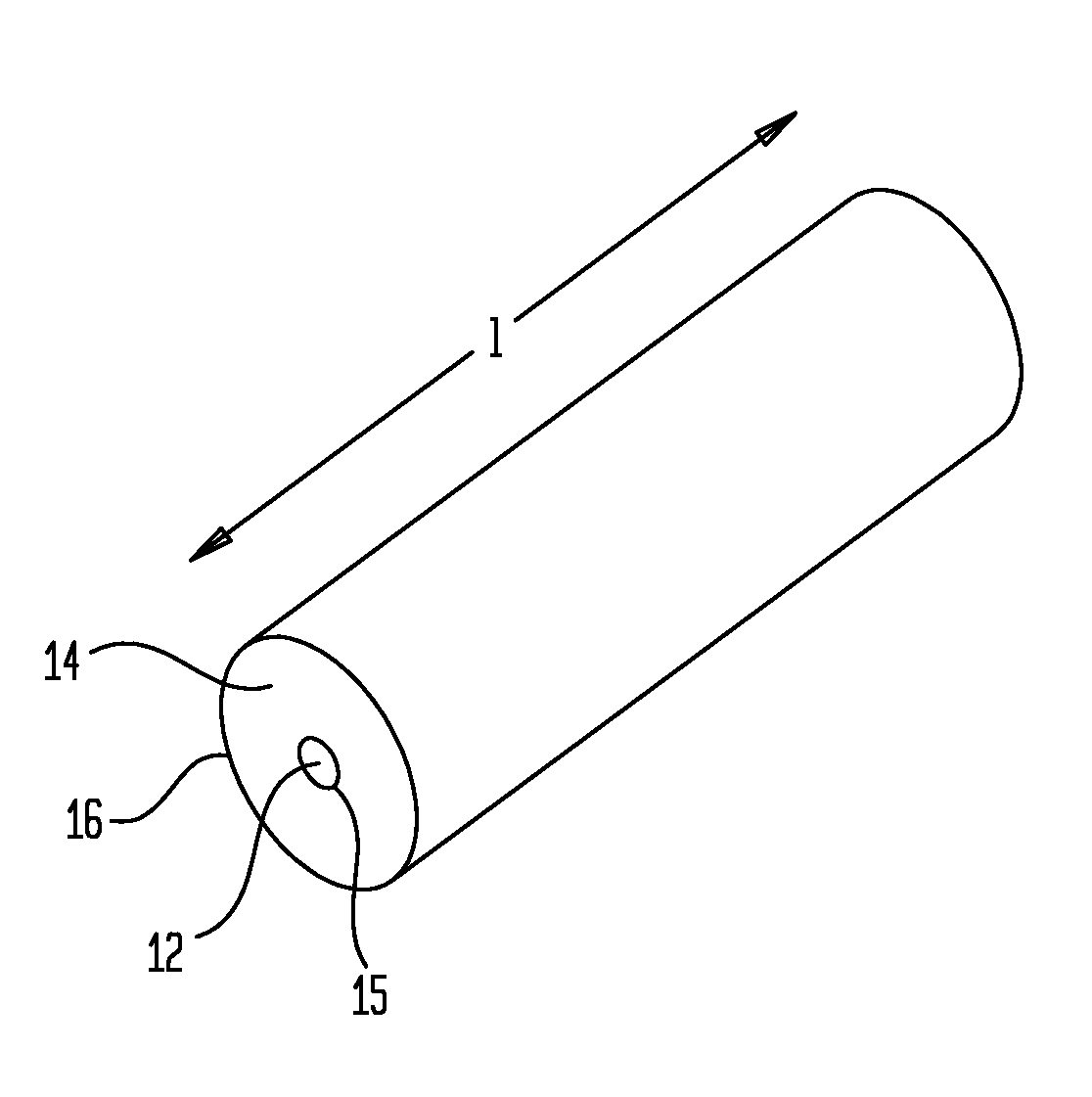

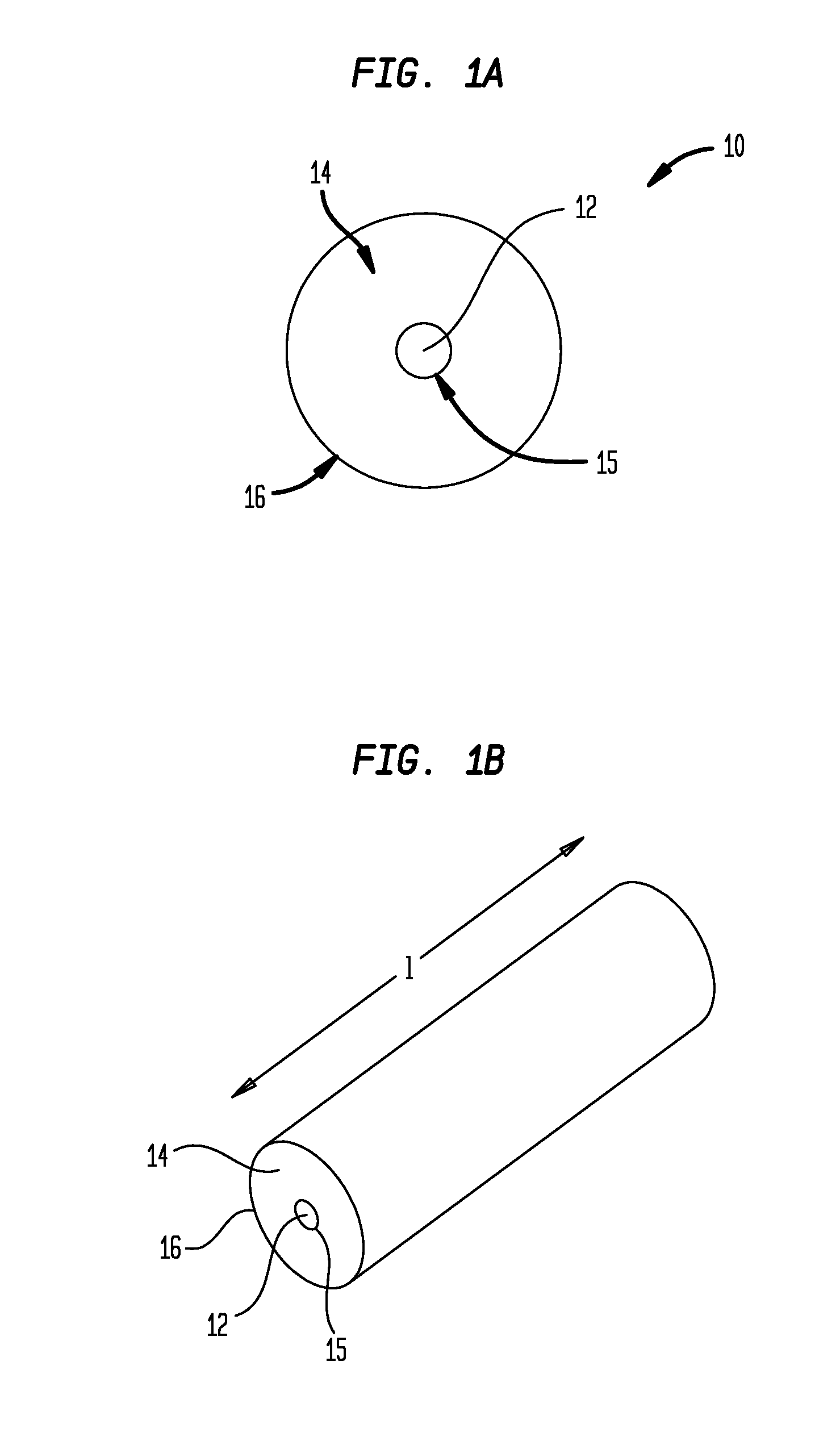

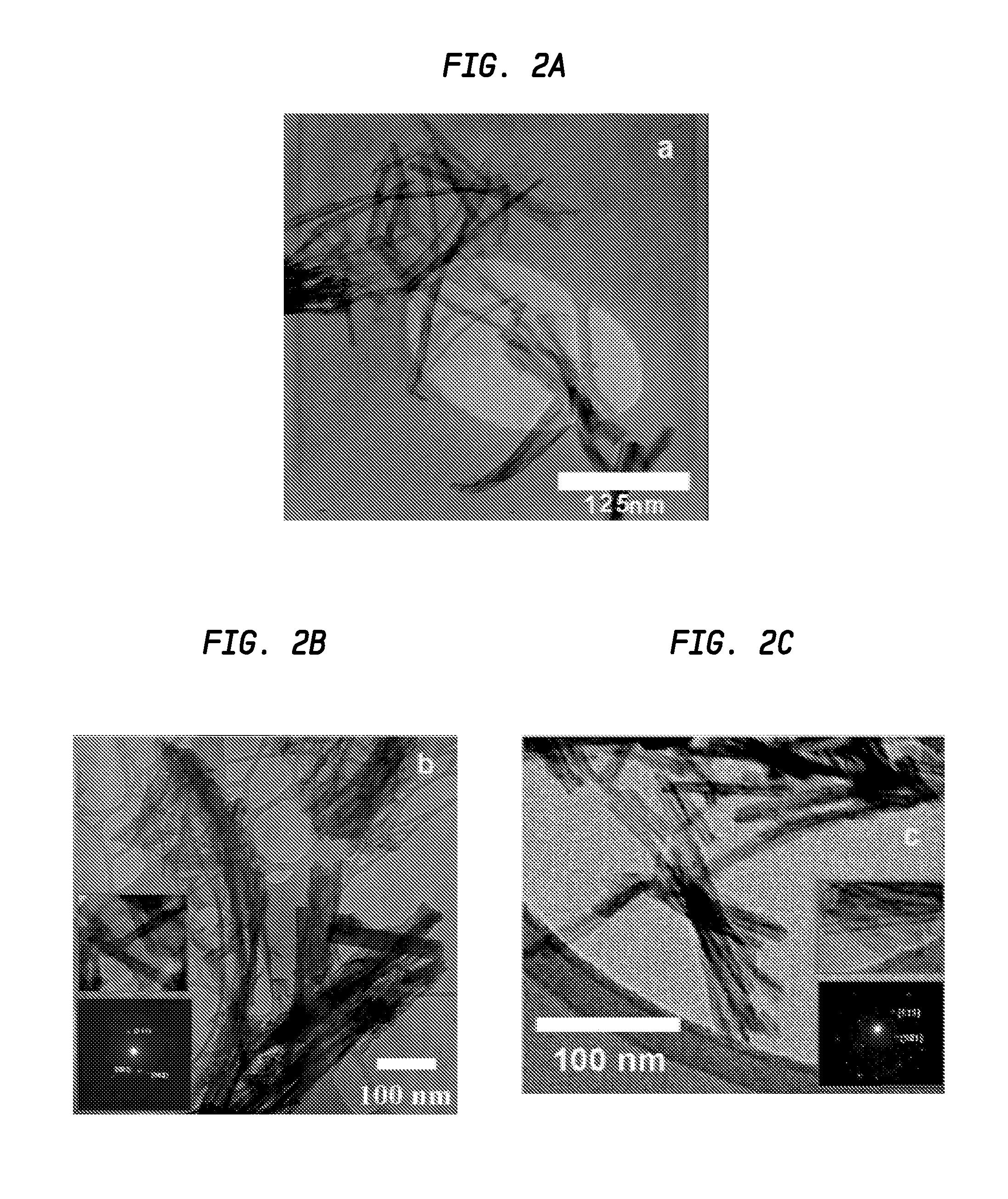

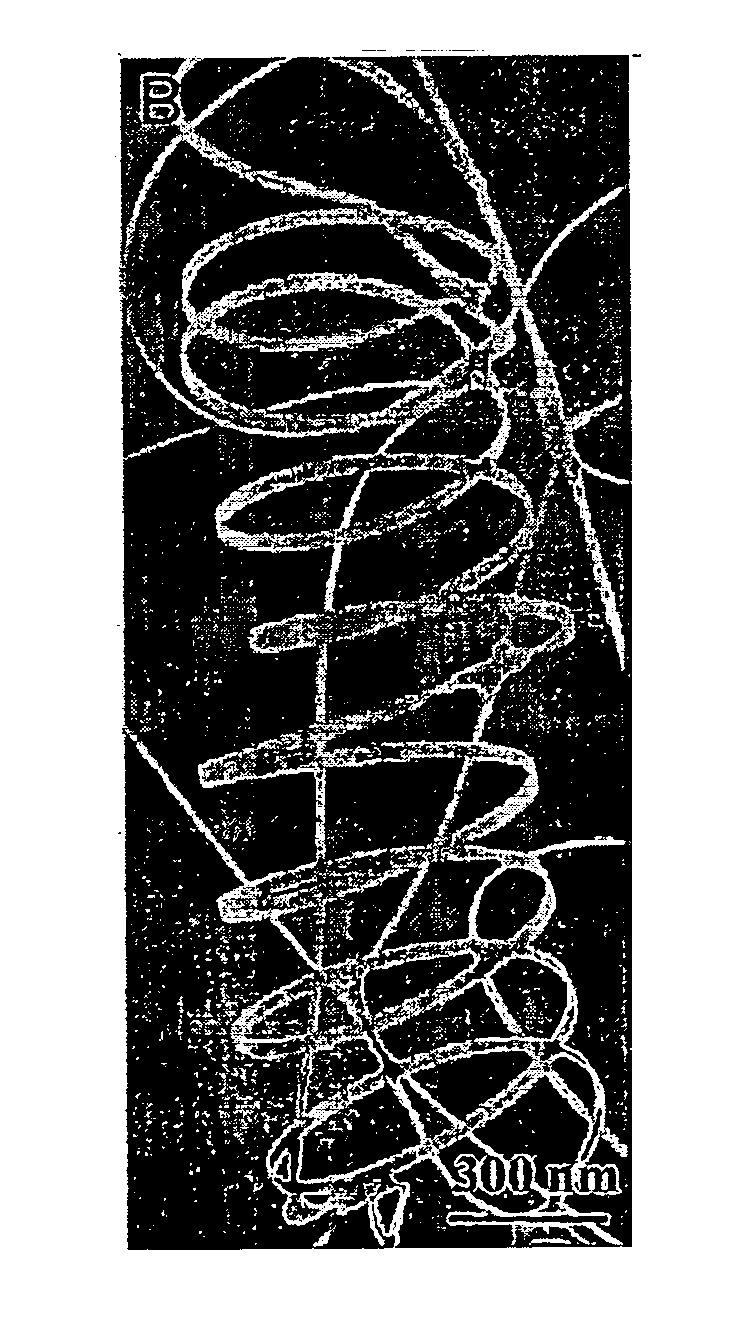

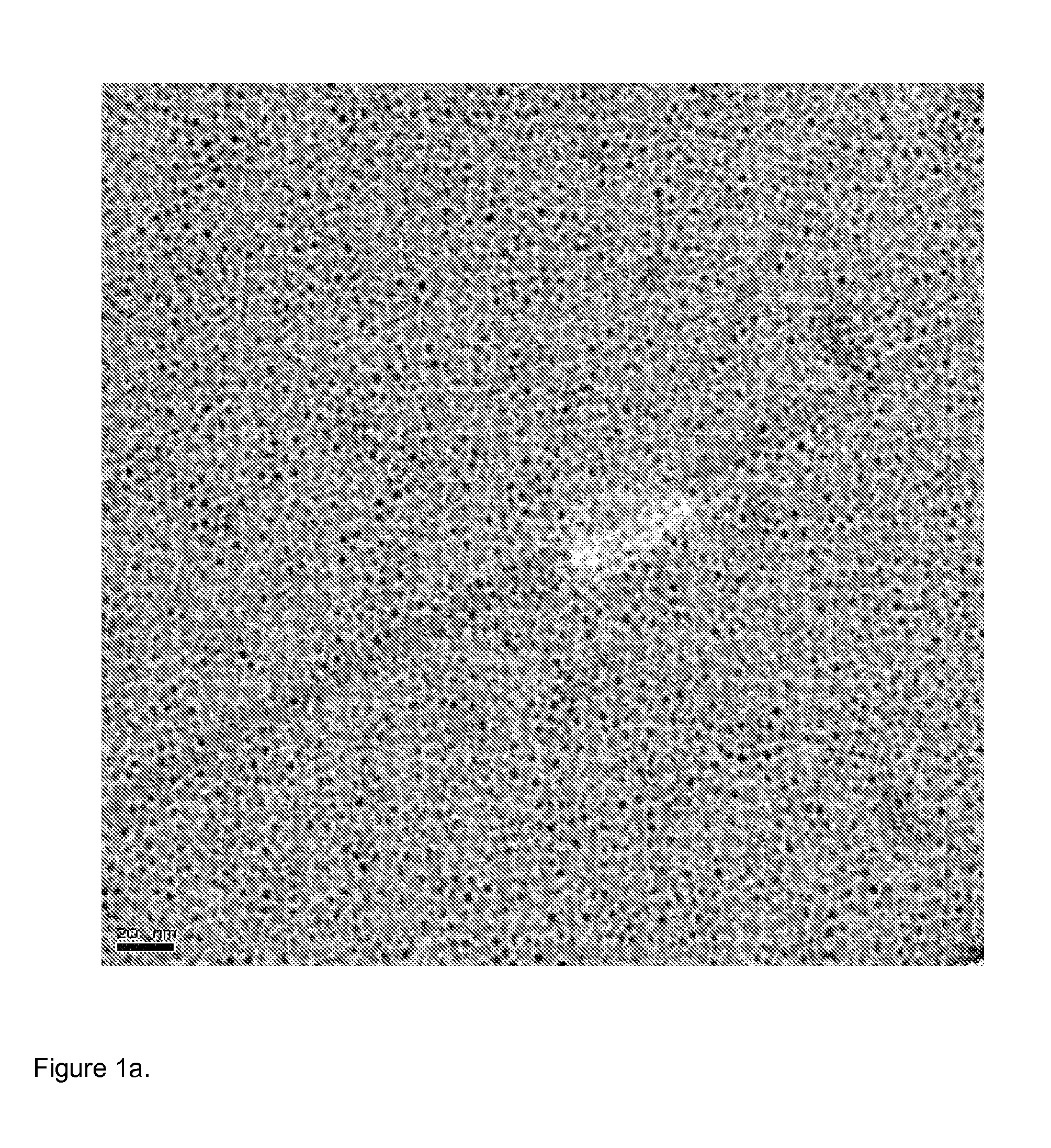

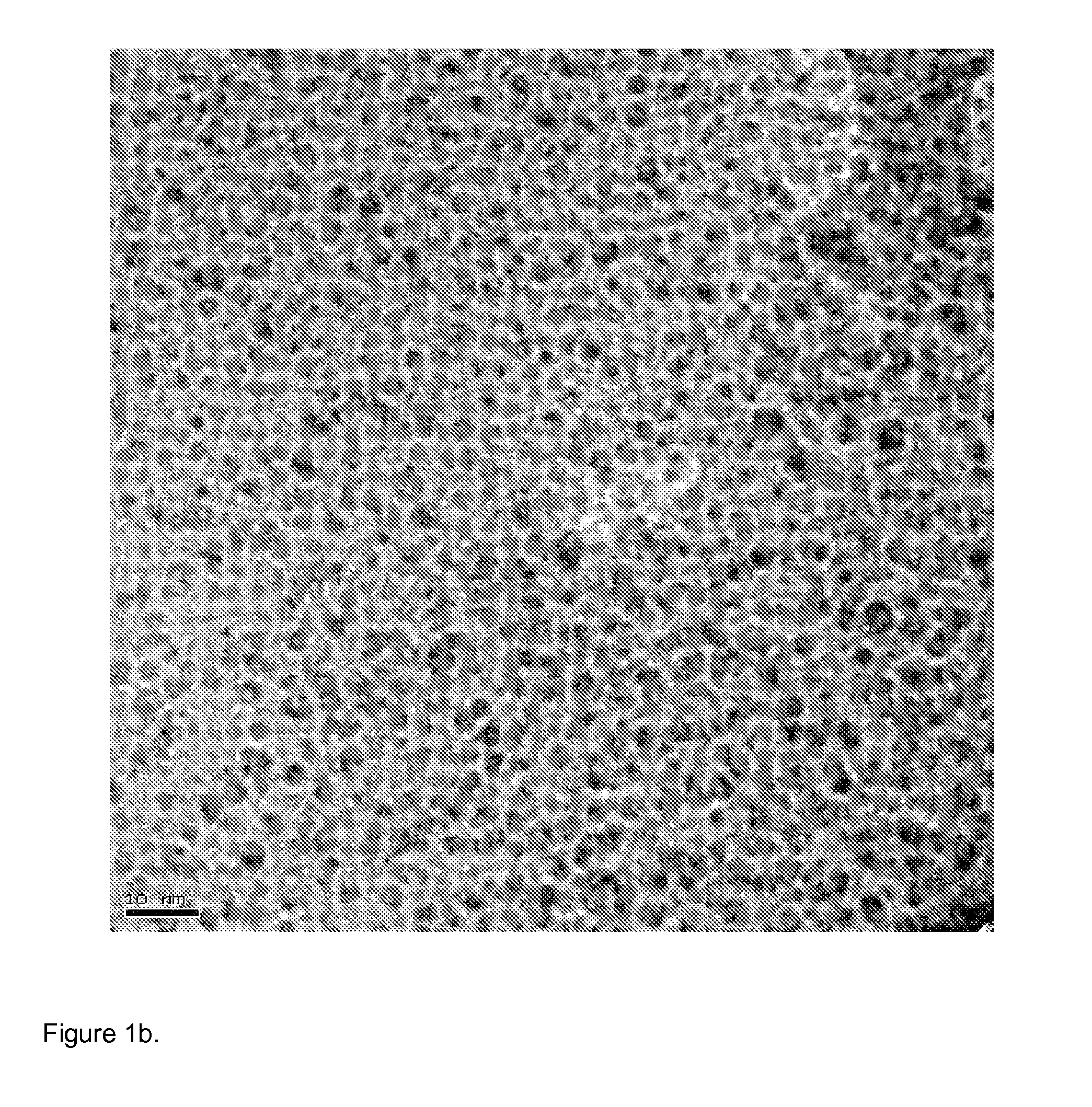

Hydrothermal synthesis of perovskite nanotubes

ActiveUS20050036939A1Reduce the amount requiredThe instrumentation is simpleDigital storageGermanium dioxideStrontium titanateBarium titanate

A low-temperature hydrothermal reaction is provided to generate crystalline perovskite nanotubes such as barium titanate (BaTiO3) and strontium titanate (SrTiO3) that have an outer diameter from about 1 nm to about 500 nm and a length from about 10 nm to about 10 micron. The low-temperature hydrothermal reaction includes the use of a metal oxide nanotube structural template, i.e., precursor. These titanate nanotubes have been characterized by means of X-ray diffraction and transmission electron microscopy, coupled with energy dispersive X-ray analysis and selected area electron diffraction (SAED).

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

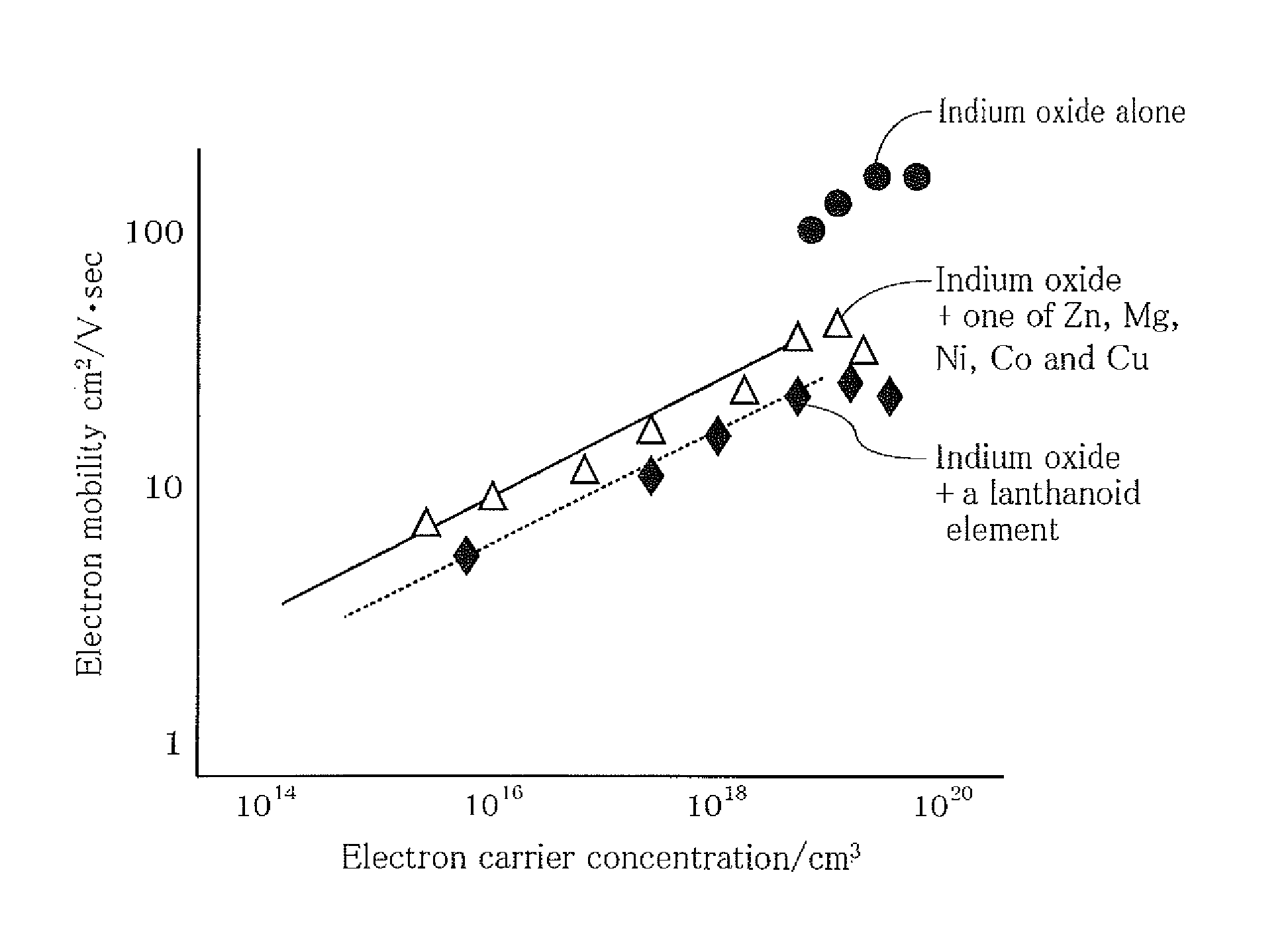

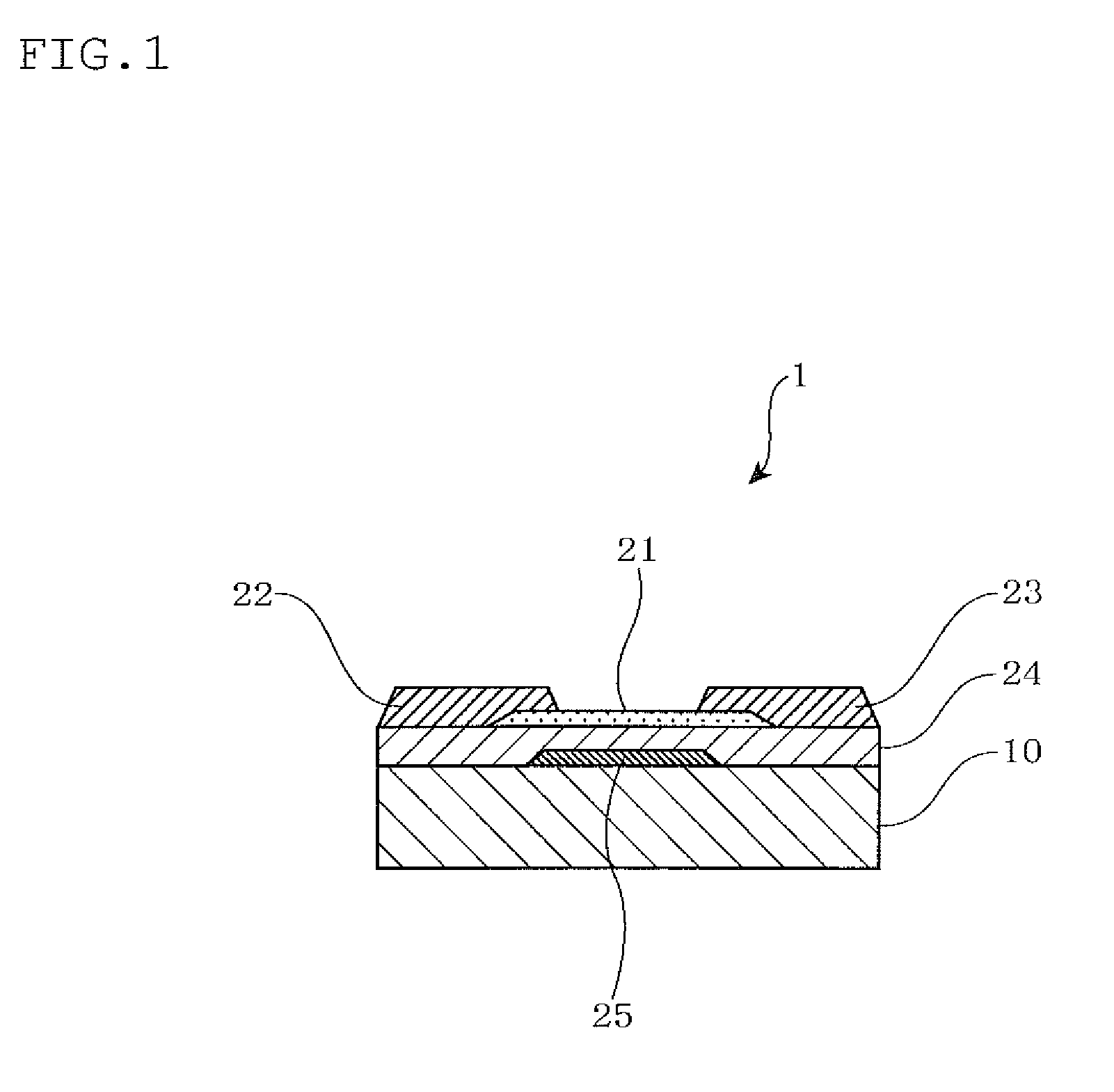

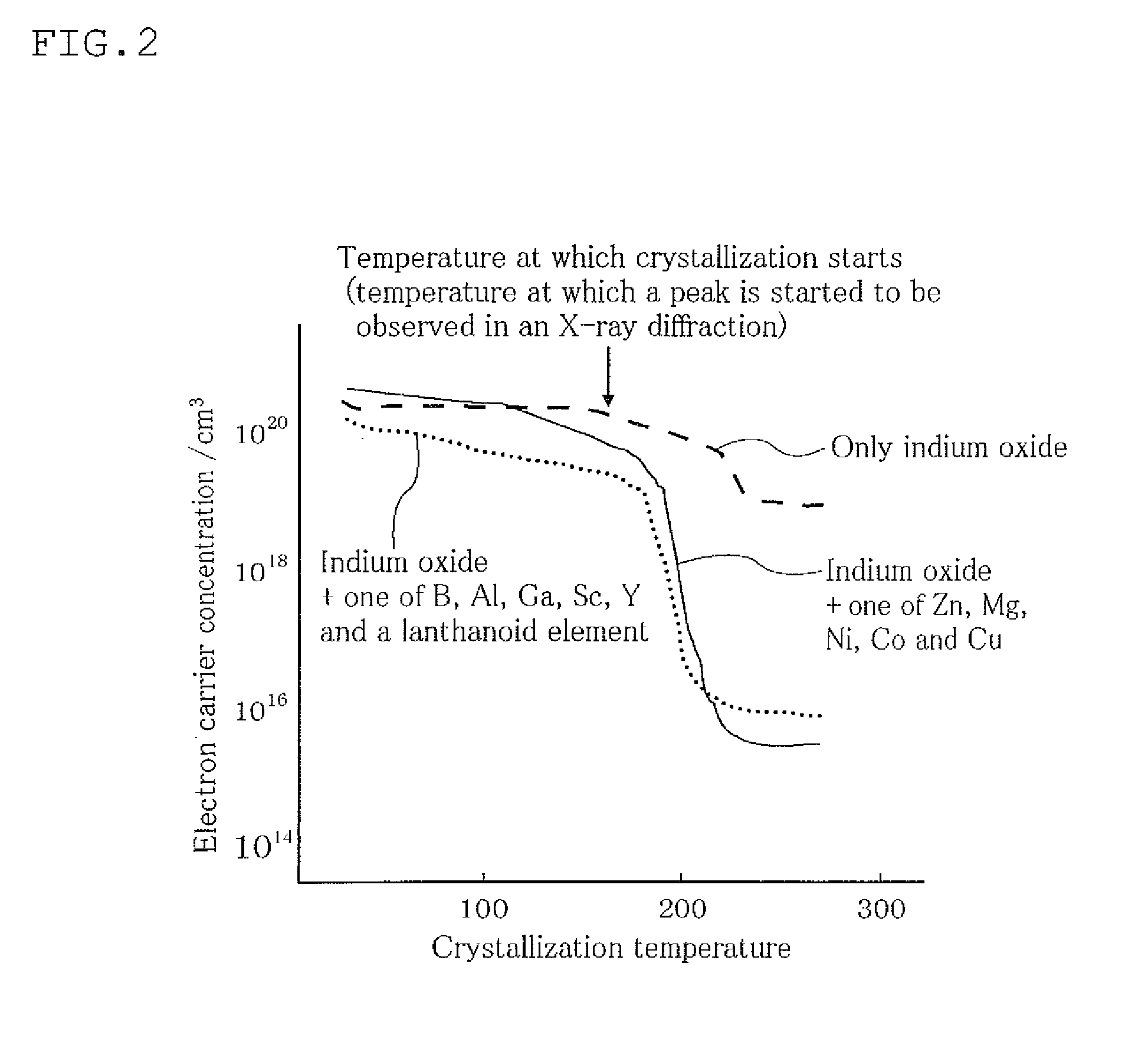

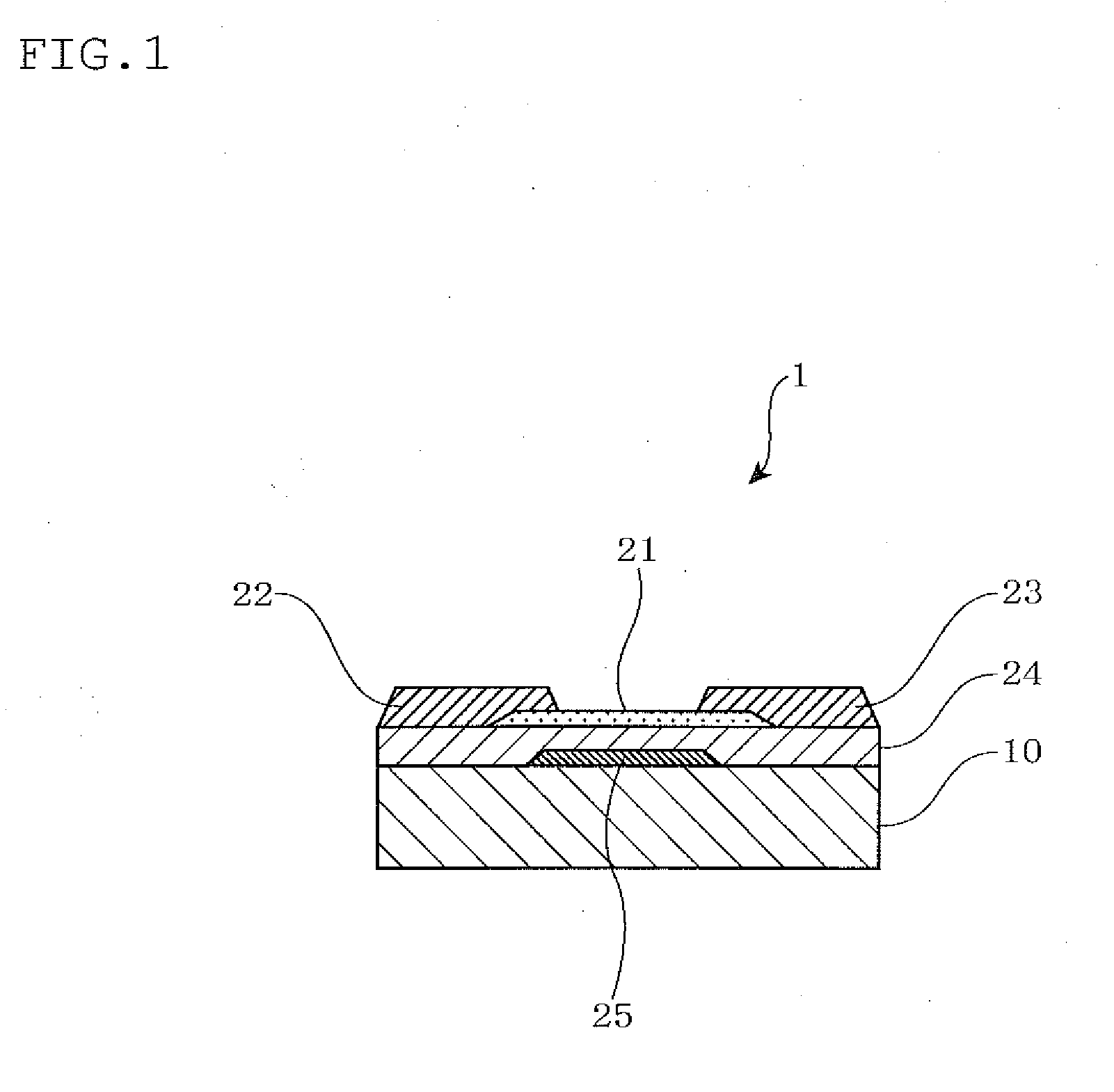

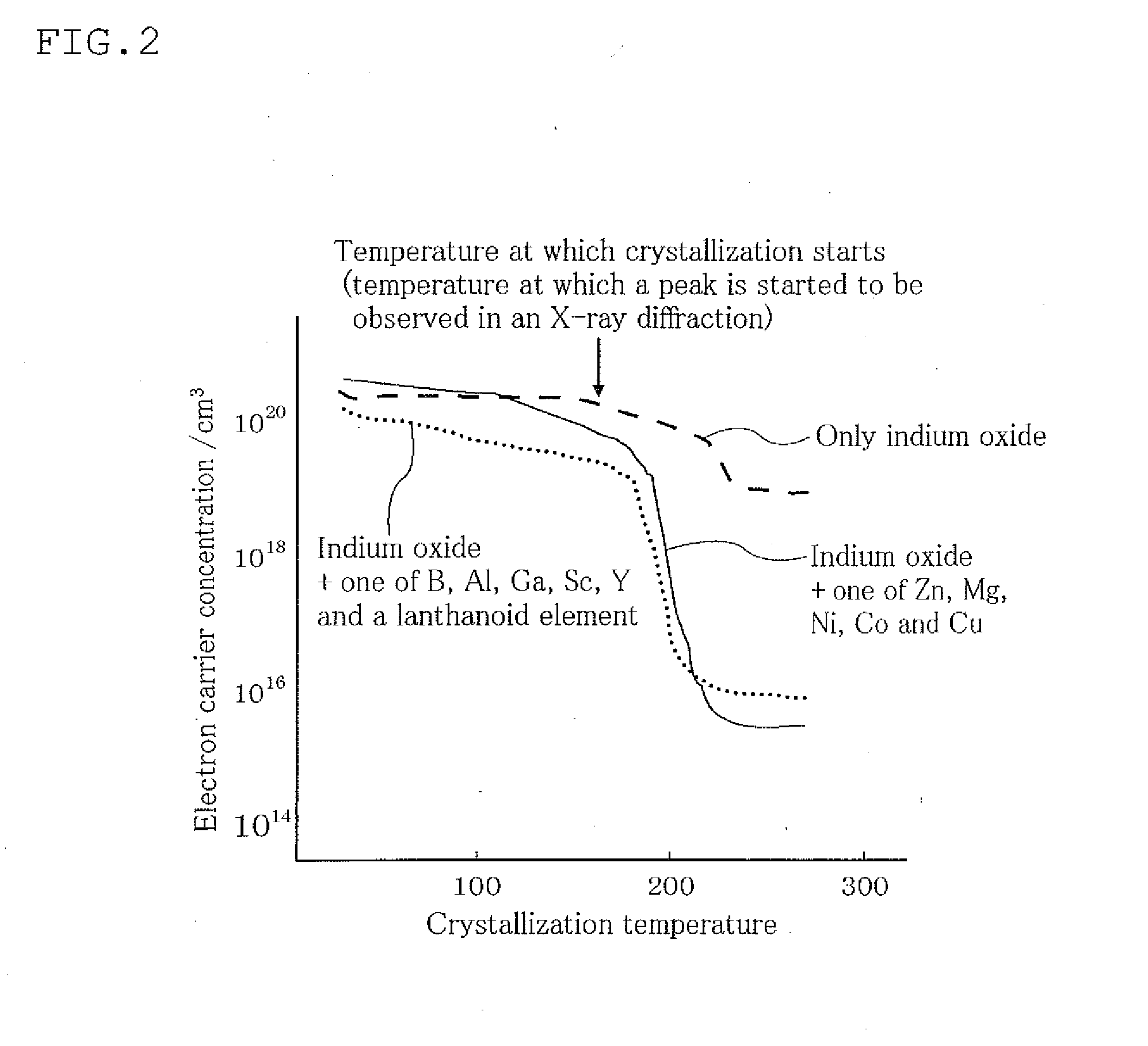

Sputtering target, oxide semiconductor film and semiconductor device

A sputtering target including an oxide sintered body, the oxide sintered body containing indium (In) and at least one element selected from gadolinium (Gd), dysprosium (Dy), holmium (Ho), erbium (Er) and ytterbium (Yb), and the oxide sintered body substantially being of a bixbyite structure.

Owner:IDEMITSU KOSAN CO LTD

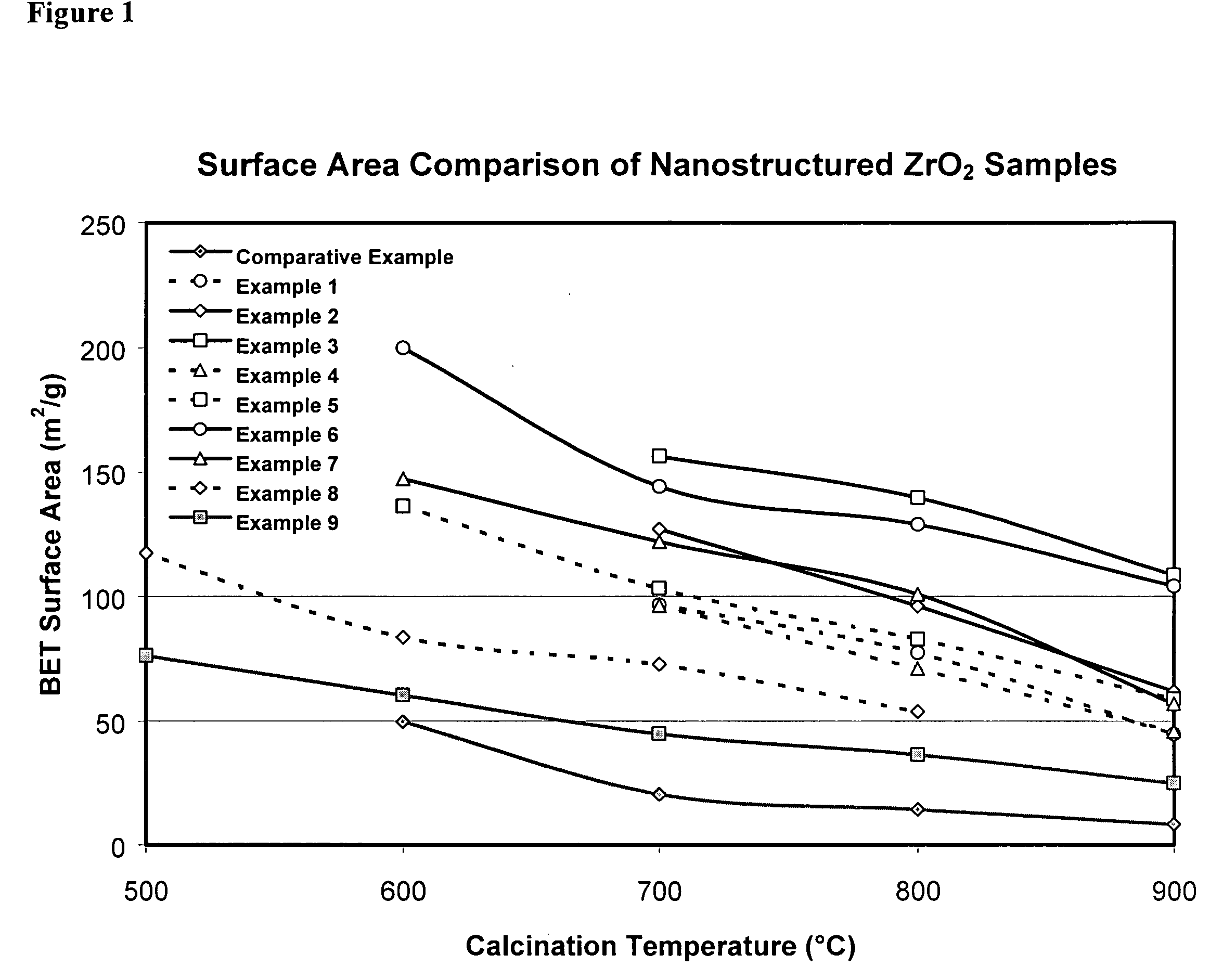

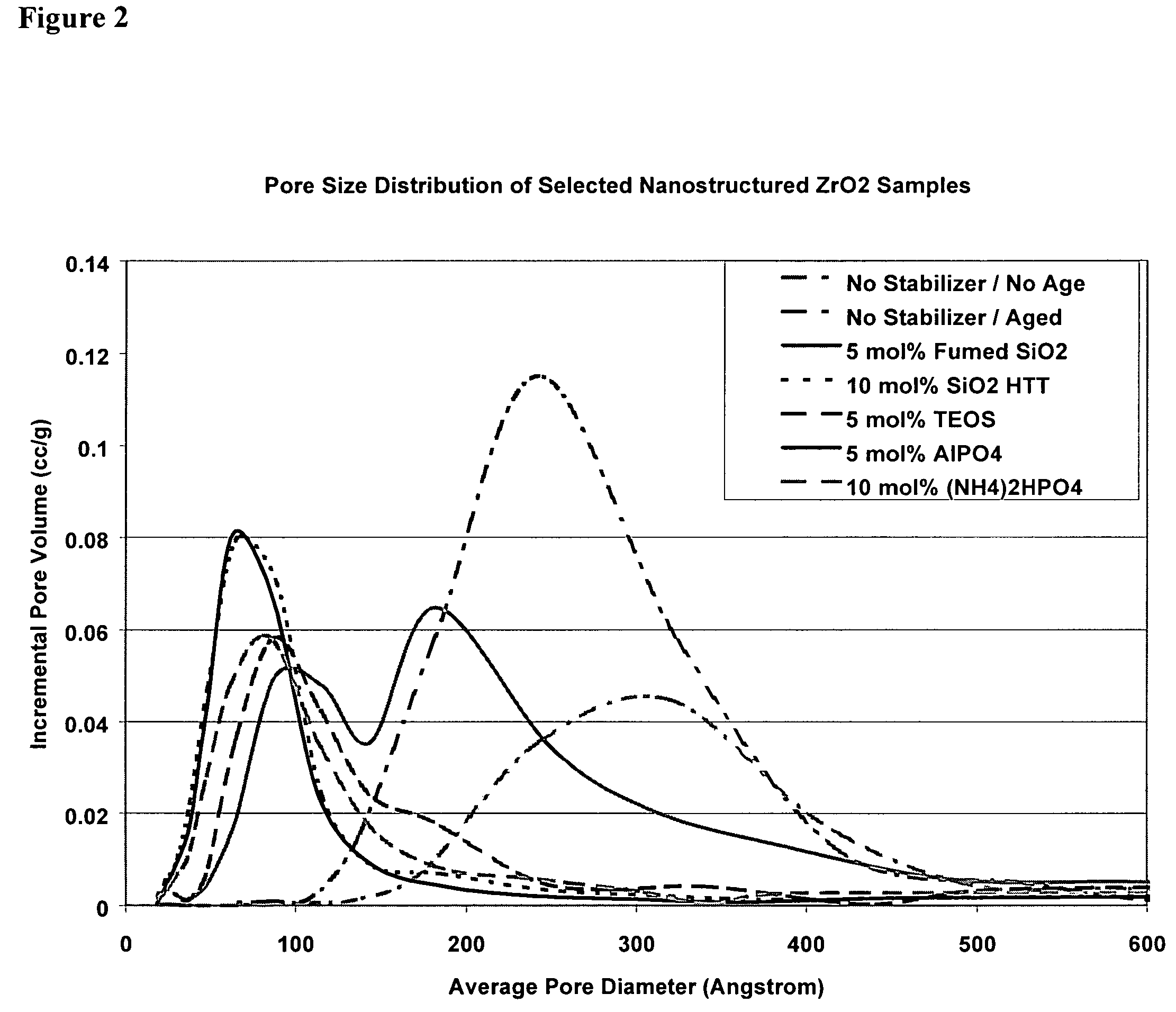

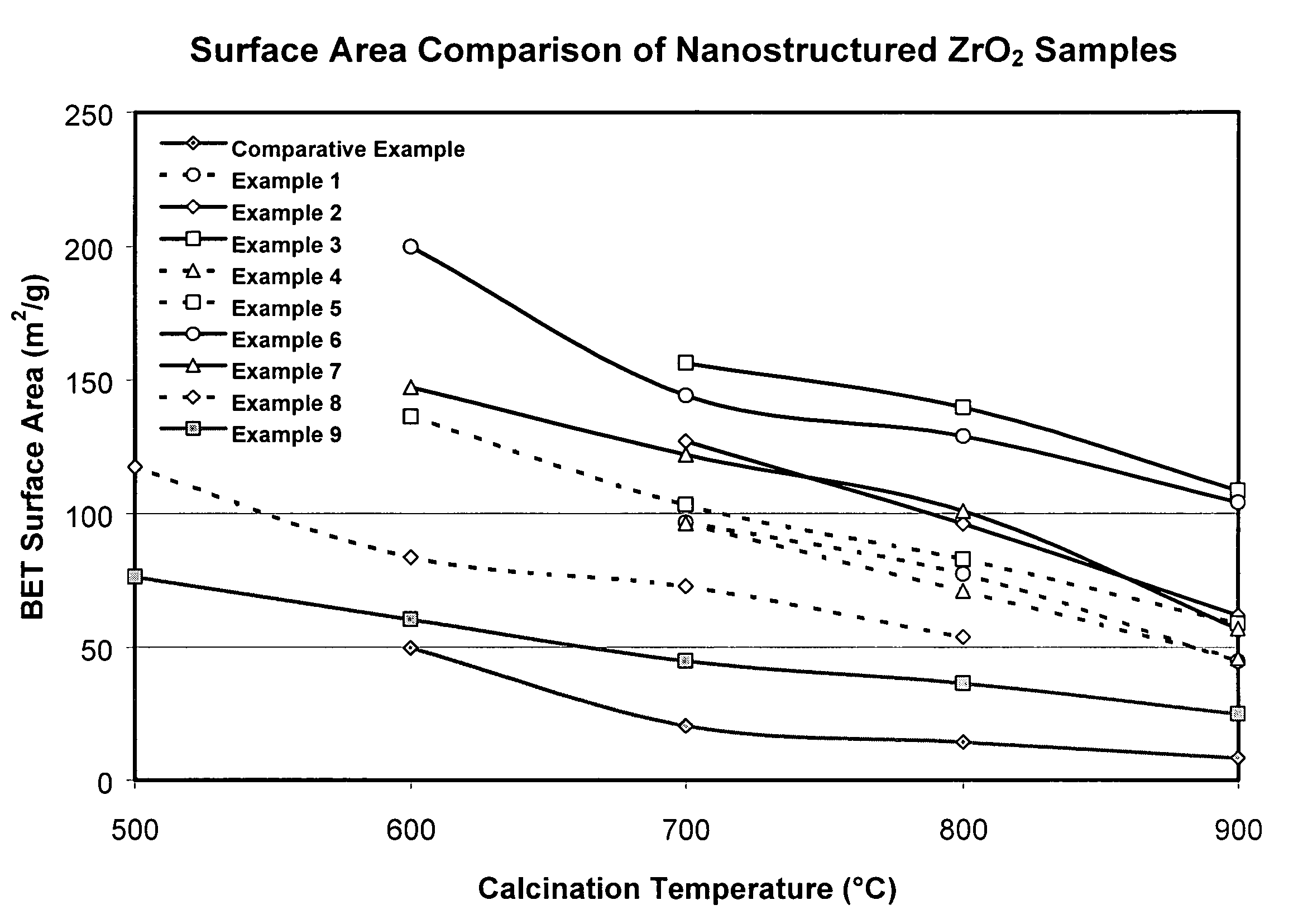

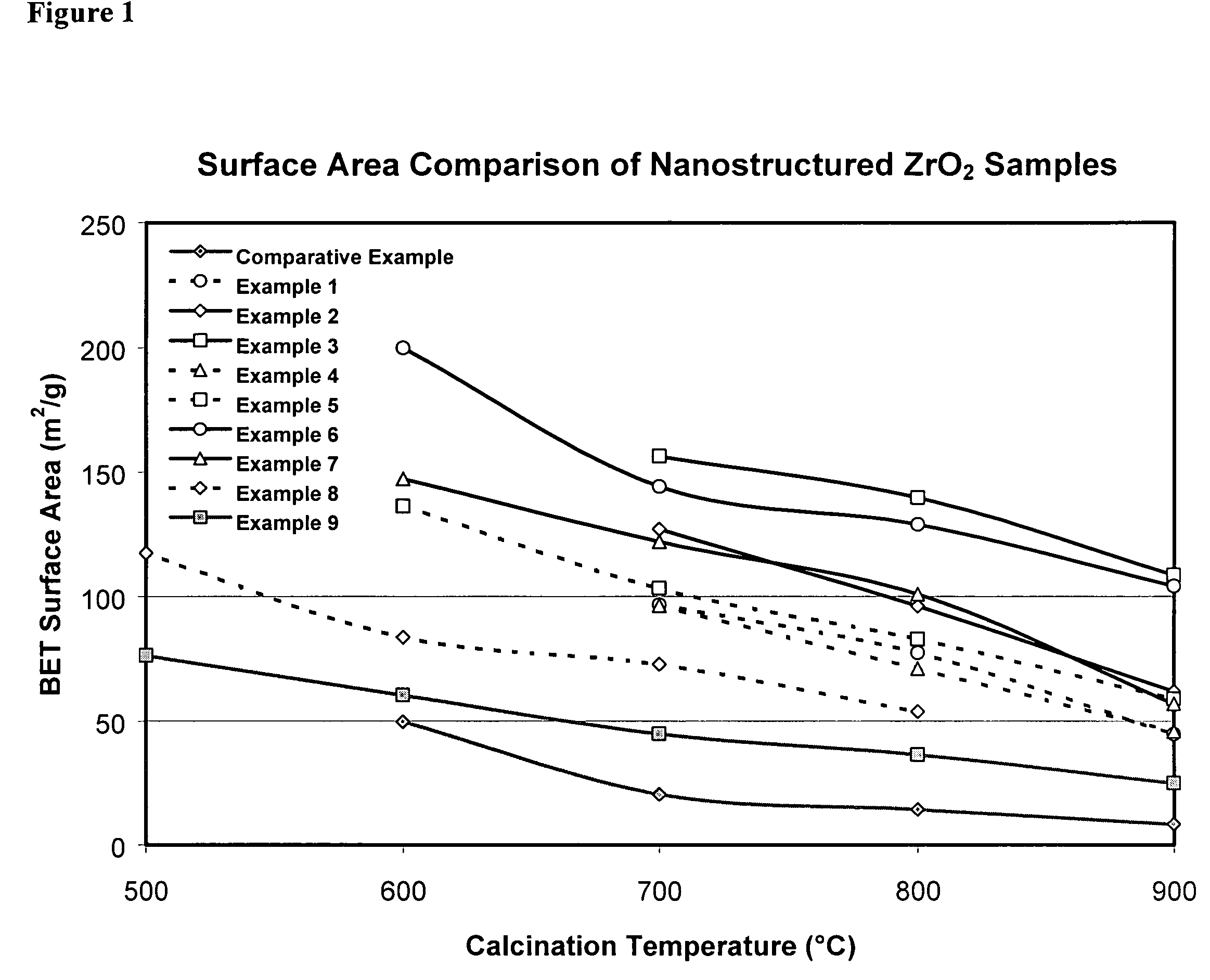

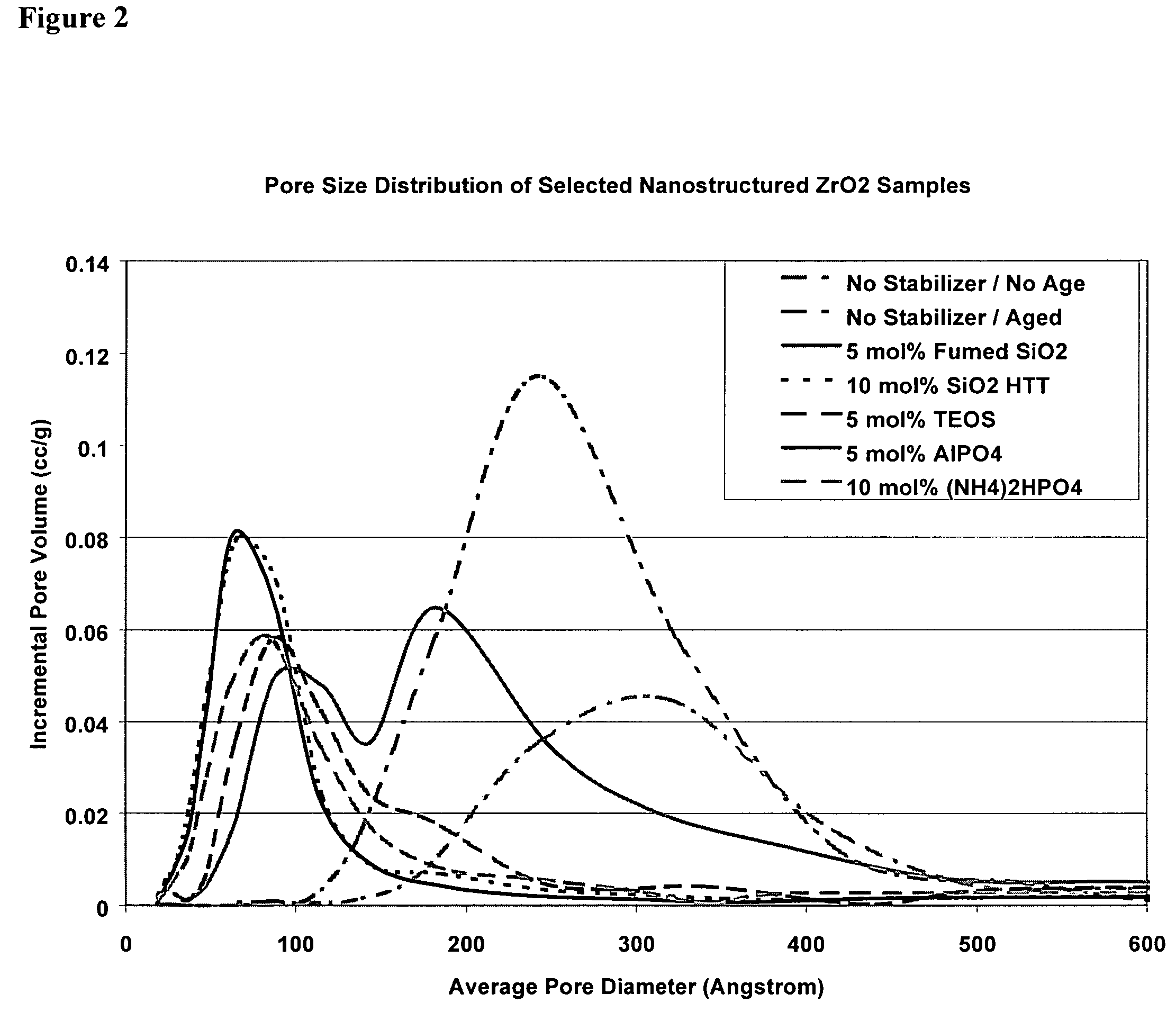

Nano-structured particles with high thermal stability

ActiveUS20050175525A1Large specific surface areaImprove thermal stabilityMaterial nanotechnologyNanostructure manufactureNanoparticleThermal stability

The present invention is directed to producing nano-structured particles that have high specific surface-areas and high thermal stability. By aging nanoparticle precursors, and processing them under appropriate conditions, one is able to generate nano-structured particles that may be used in catalysts. By adding a stabilizing agent one is able to further improve the high thermal stability. These nano-structured particle products are particularly advantageous in applications as catalysts or catalyst supports that operate at high temperatures.

Owner:TRONOX LLC

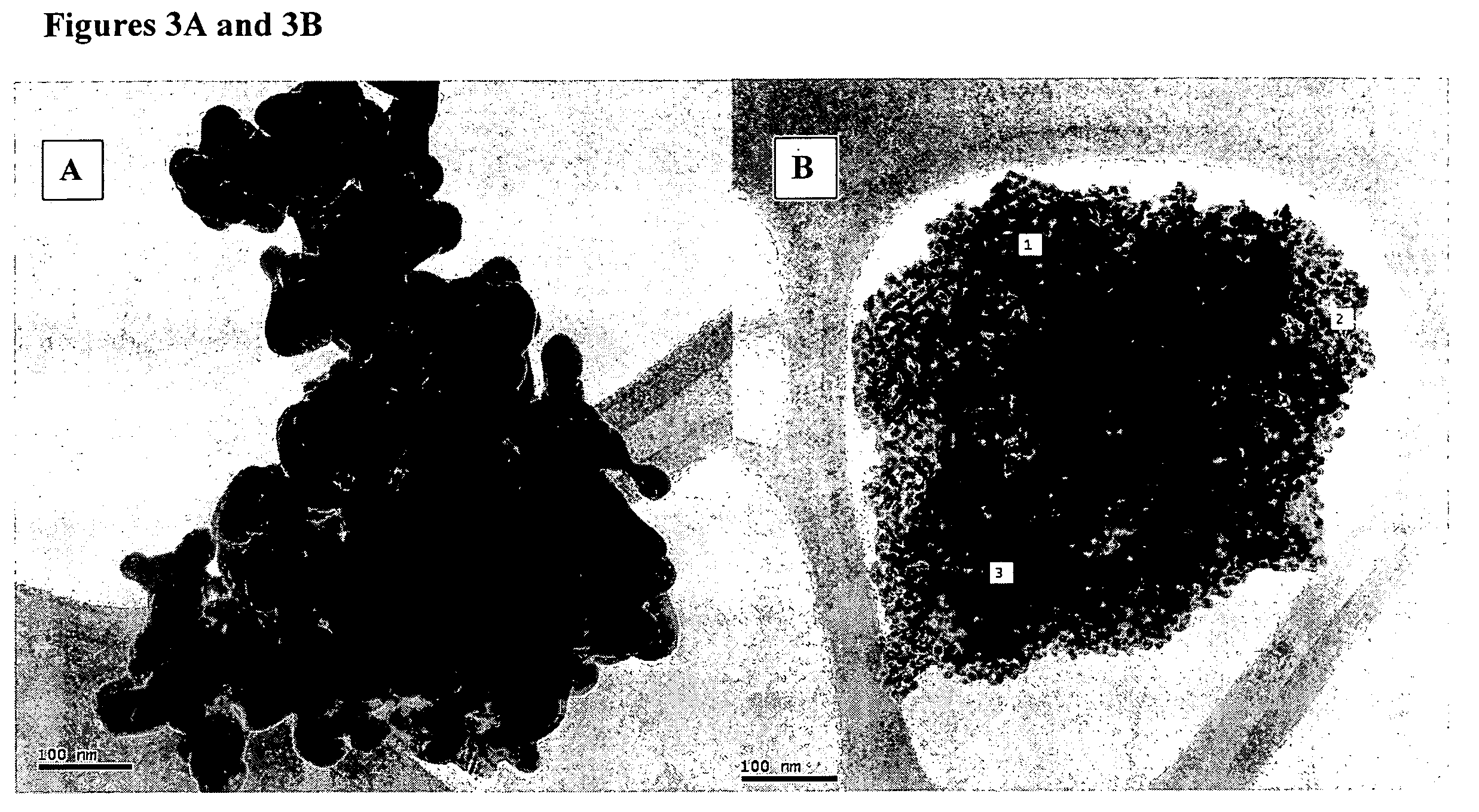

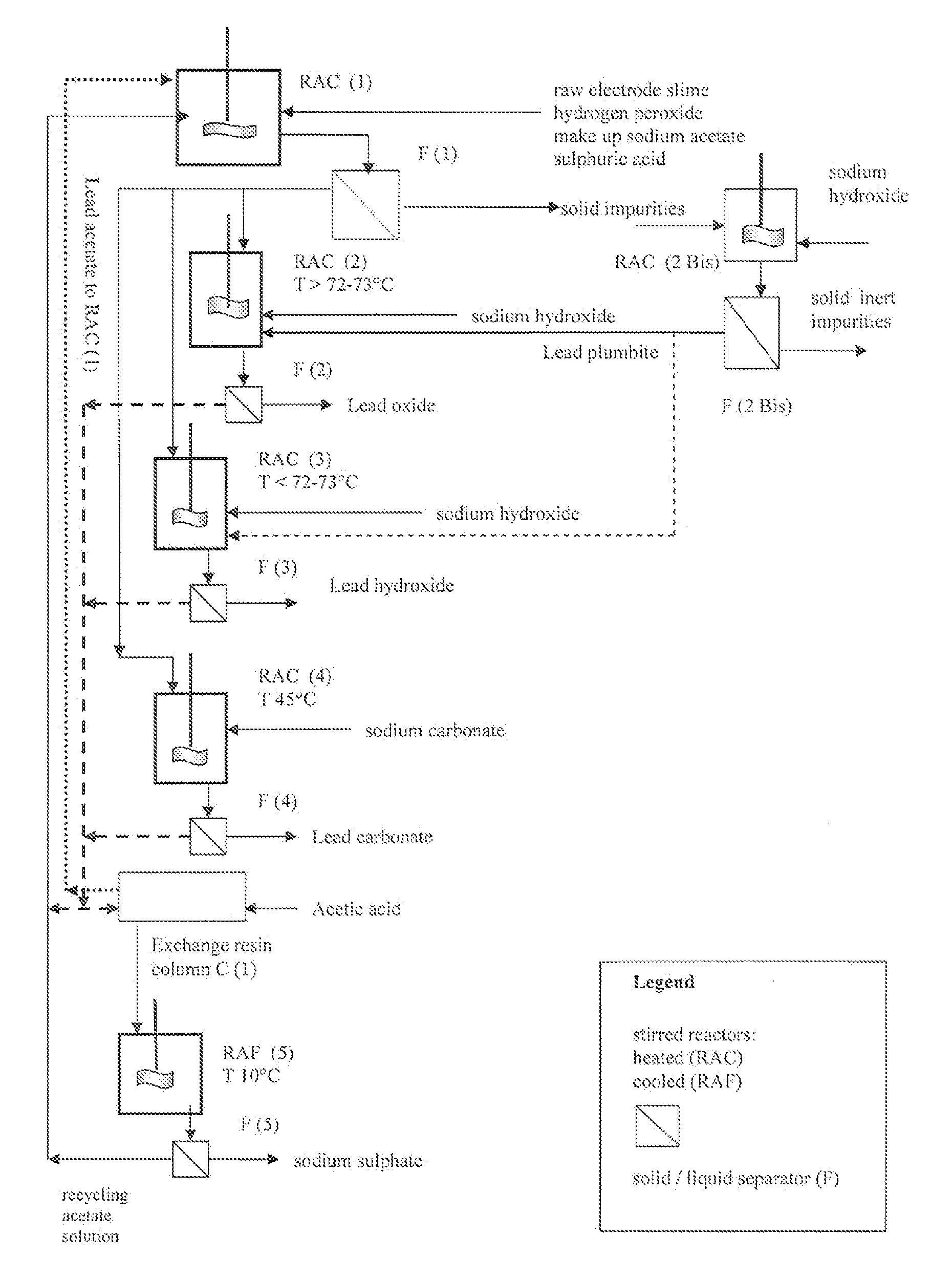

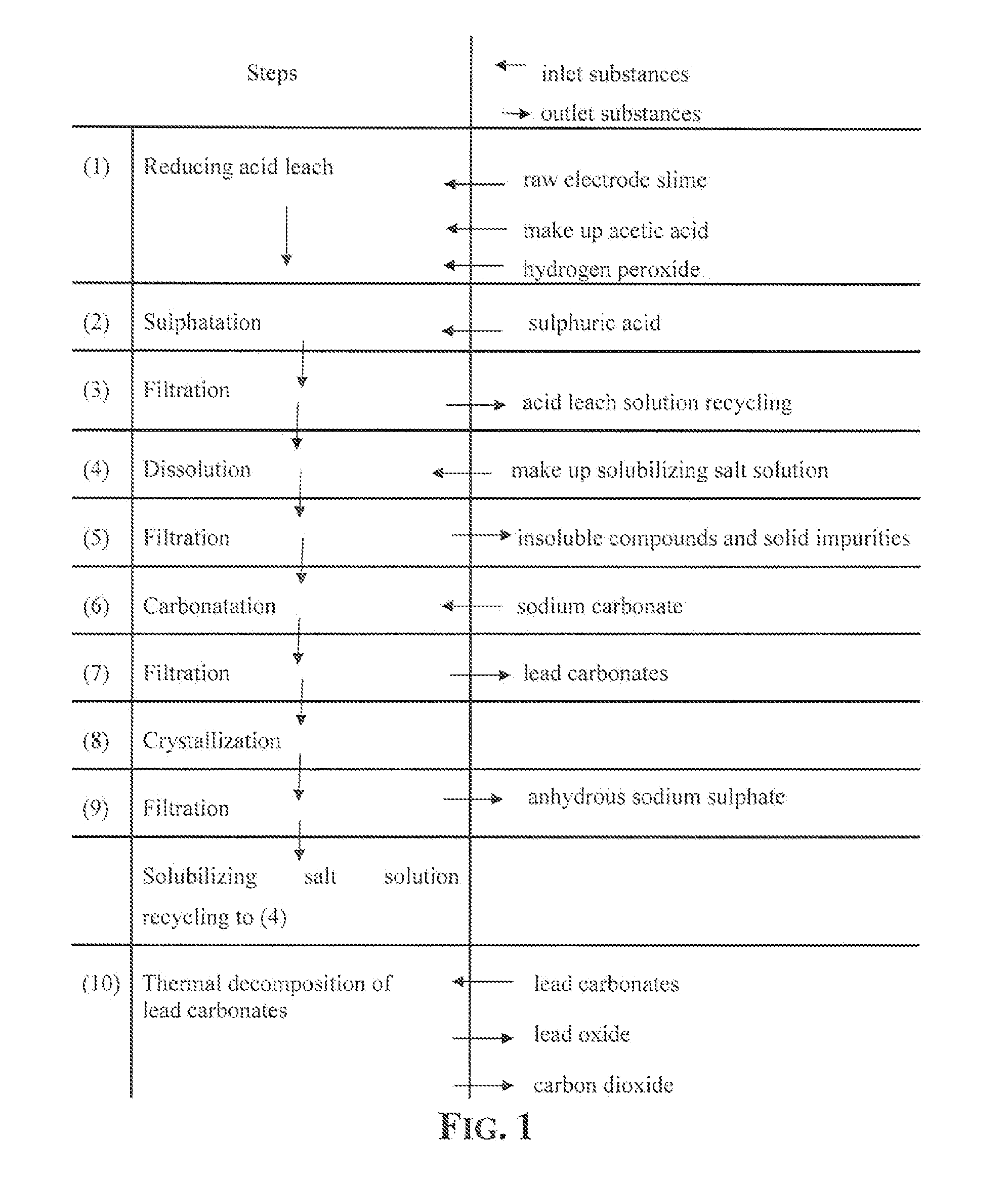

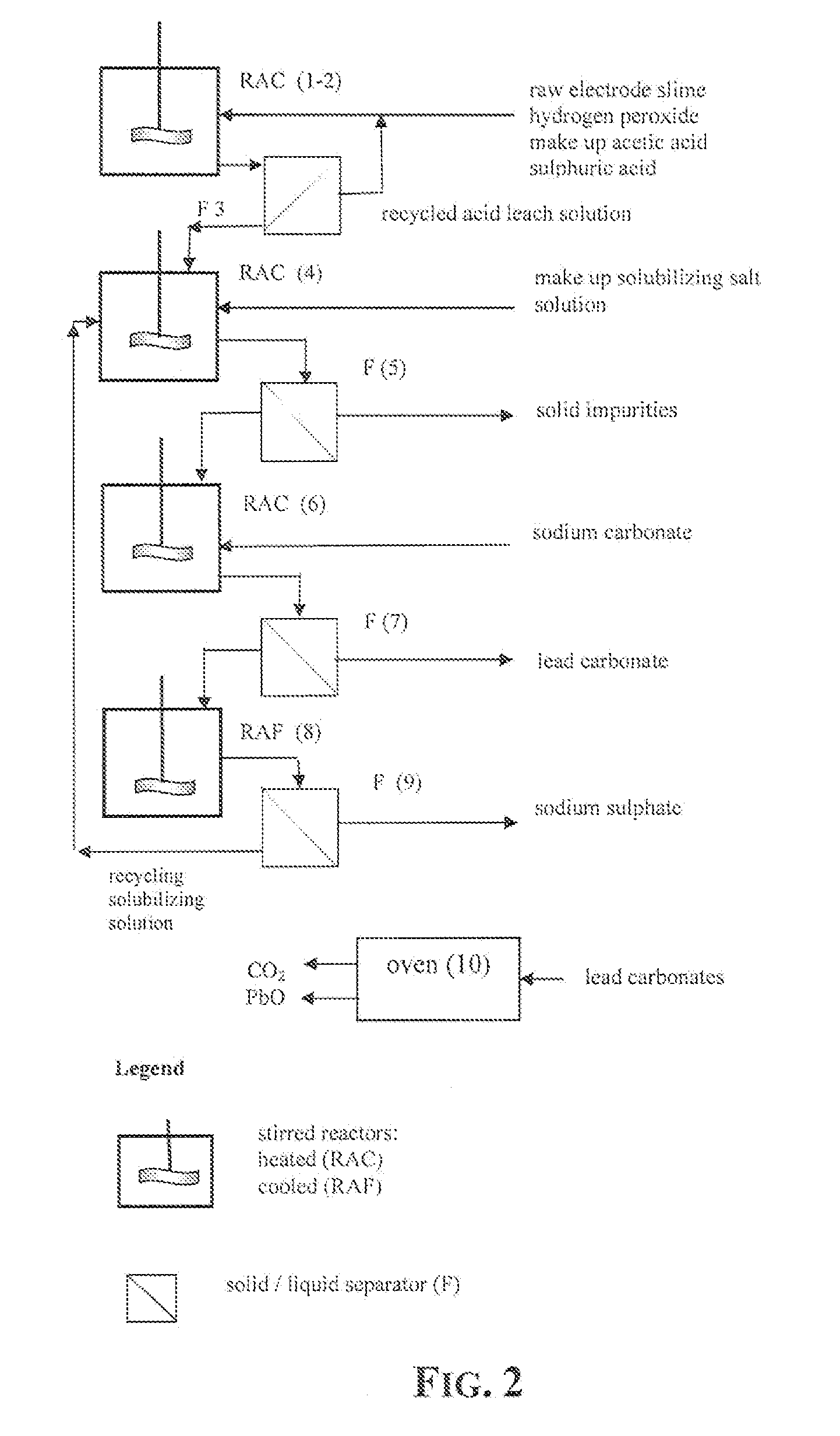

Reclaiming of lead in form of high purity lead compound from recovered electrode paste slime of dismissed lead batteries and/or of lead minerals

An outstandingly low environmental impact wet process recovers the lead content of an electrode slime and / or of lead minerals in the valuable form of high purity lead oxide or compound convertible to highly pure lead oxide by heat treatment in oven at relatively low temperature, perfectly suited for making active electrode pastes of new batteries or other uses. The process basically comprises the following treatments:a) suspending the impure lead containing material in an aqueous bath containing at least a lead oxide dissolving acid;b) reducing any insoluble lead dioxide to lead oxide by introducing in the suspension either hydrogen peroxide, a sulphite or sulphurous anhydride;c) converting all dissolved lead oxide to lead sulphate in the aqueous bath;d) obtaining a solution of lead sulphate obtained in an aqueous solution containing an acetate salt;e) precipitating and separating a purified lead compound in the form of either carbonate / oxycarbonate or of oxide / or hydroxide by adding to said acetate salt solution a carbonate salt or a hydroxide of the same cation of said acetate salt, respectively.Exemplary flow sheets according to several alternative embodiments and related processing plant diagrams are disclosed.

Owner:MILLBROOK LEAD RECYCLING TECH

Method for the preparation of IV-VI semiconductor nanoparticles

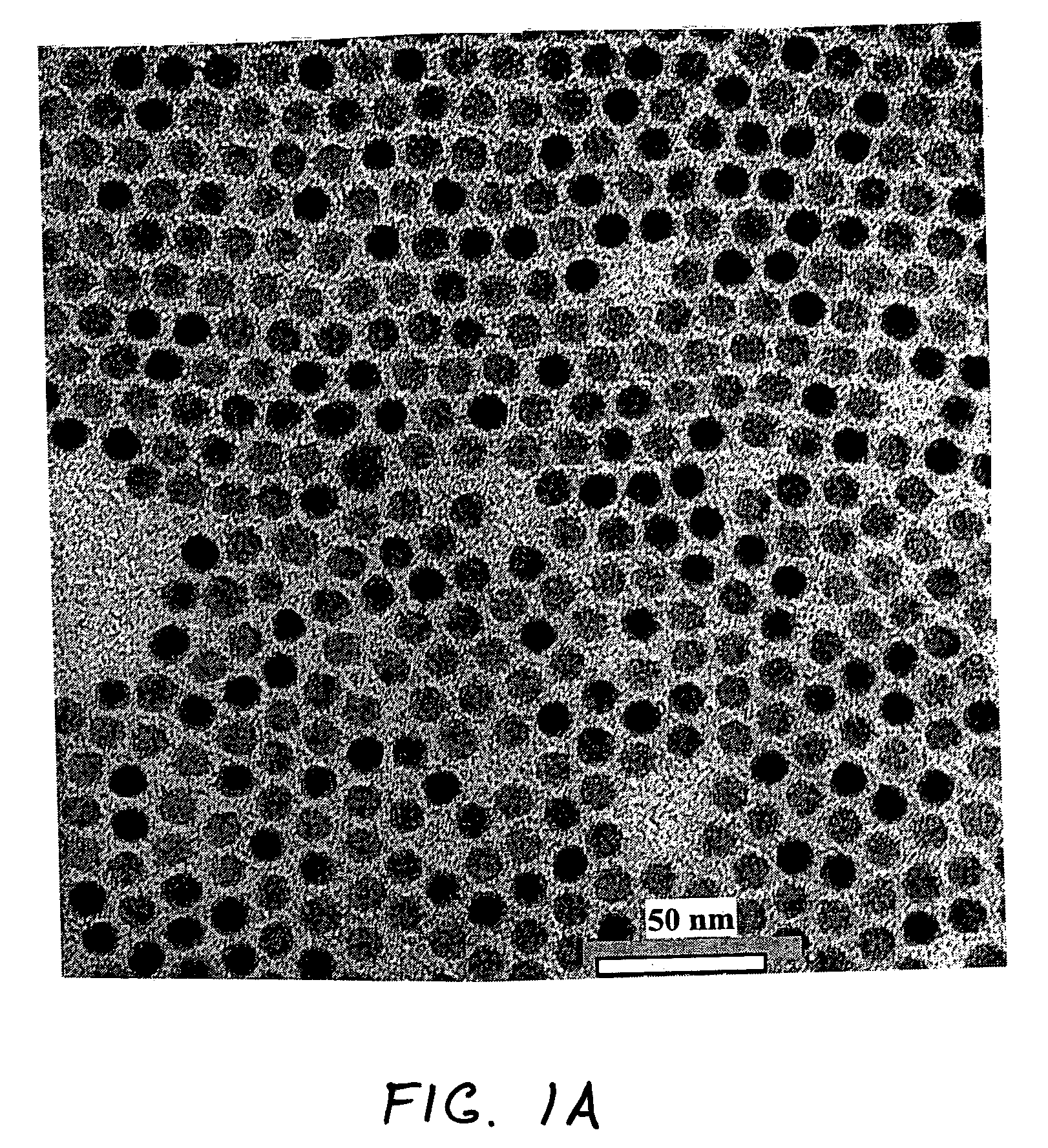

InactiveUS20060110313A1Controlled in sizeControl shapeMaterial nanotechnologyNitrogen compoundsOrganic solventQuantum dot

A high temperature (on the order of about 90° C. or above) non-aqueous synthetic procedure for the preparation of substantially monodisperse IV-VI semiconductor nanoparticles (quantum dots) is provided. The procedure includes first introducing a first precursor selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element into a reaction vessel that comprises at least an organic solvent to form a mixture. Next, the mixture is heated to a temperature of about 90° C. or above and thereafter a second precursor which is different from the first precursor and is selected from the group consisting of a molecular precursor of a Group IV element and a molecular precursor of a Group VI element is added into the heated mixture. The reaction mixture is then mixed to initiate nucleation of IV-VI nanocrystals and the temperature of the reaction mixture is controlled to provide substantially monodispersed IV-VI nanoparticles having a diameter of about 20 nm or less.

Owner:GLOBALFOUNDRIES INC +1

Sputtering target, oxide semiconductor film and semiconductor device

A sputtering target including an oxide sintered body, the oxide sintered body containing indium (In) and at least one element selected from gadolinium (Gd), dysprosium (Dy), holmium (Ho), erbium (Er) and ytterbium (Yb), and the oxide sintered body substantially being of a bixbyite structure.

Owner:IDEMITSU KOSAN CO LTD

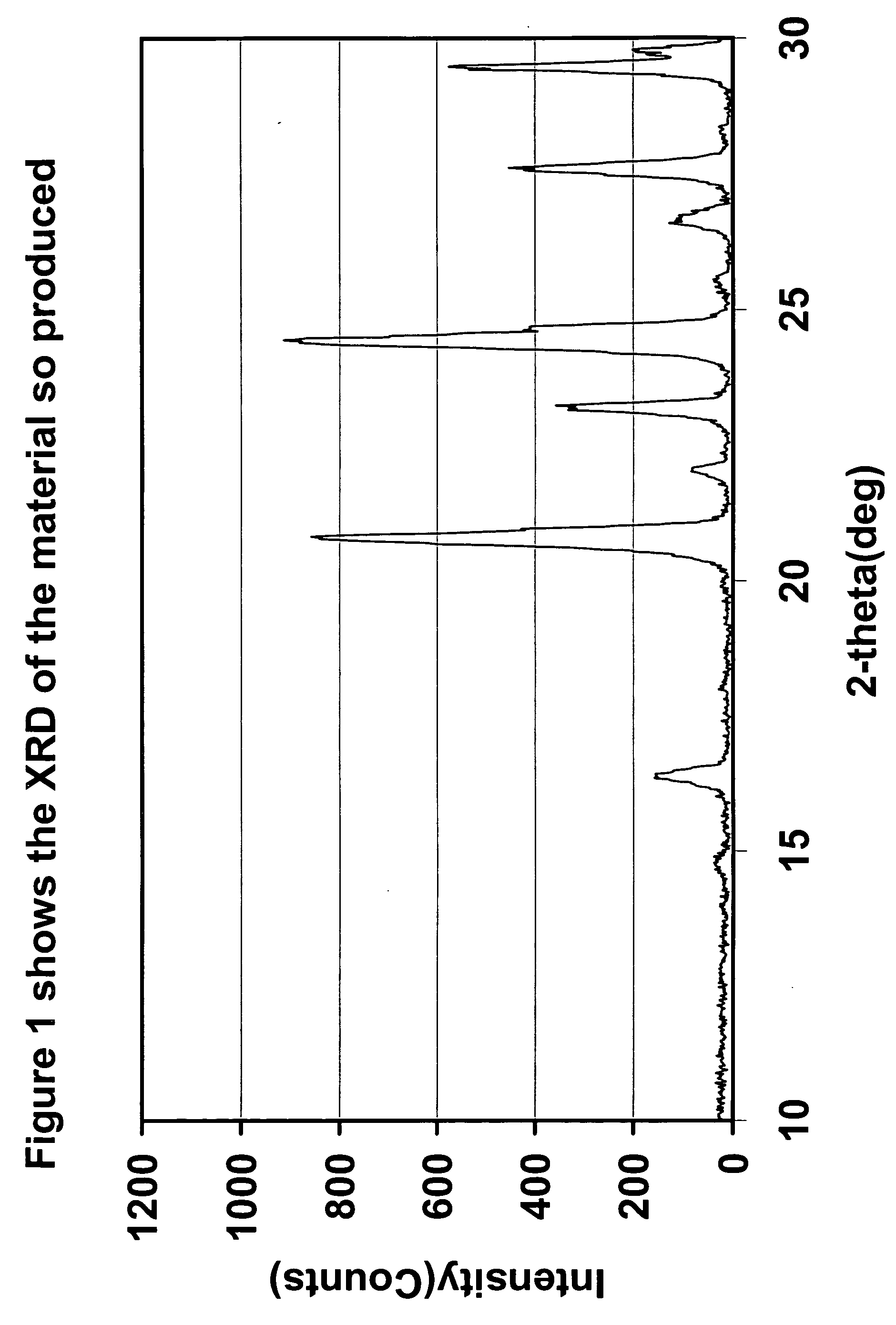

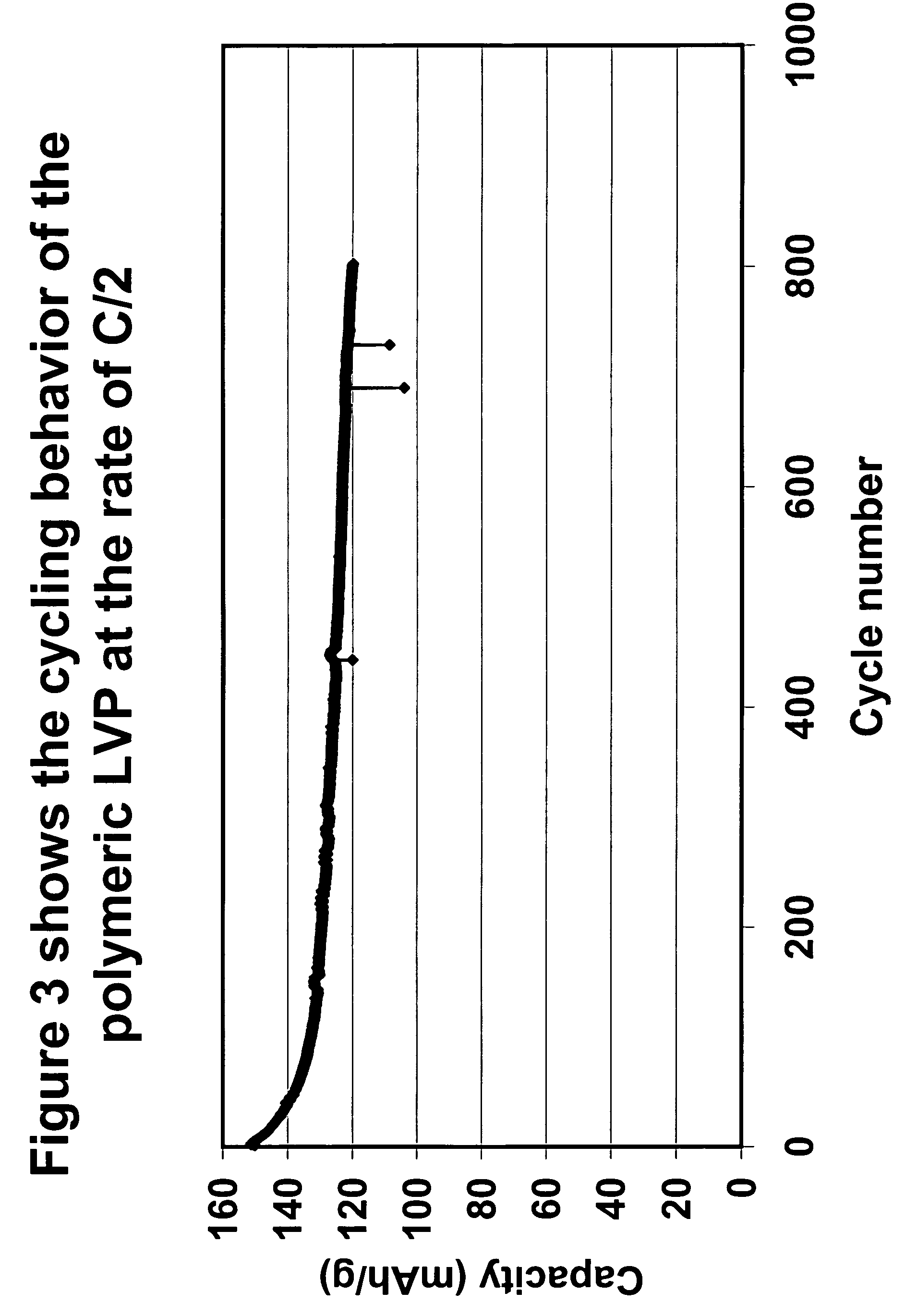

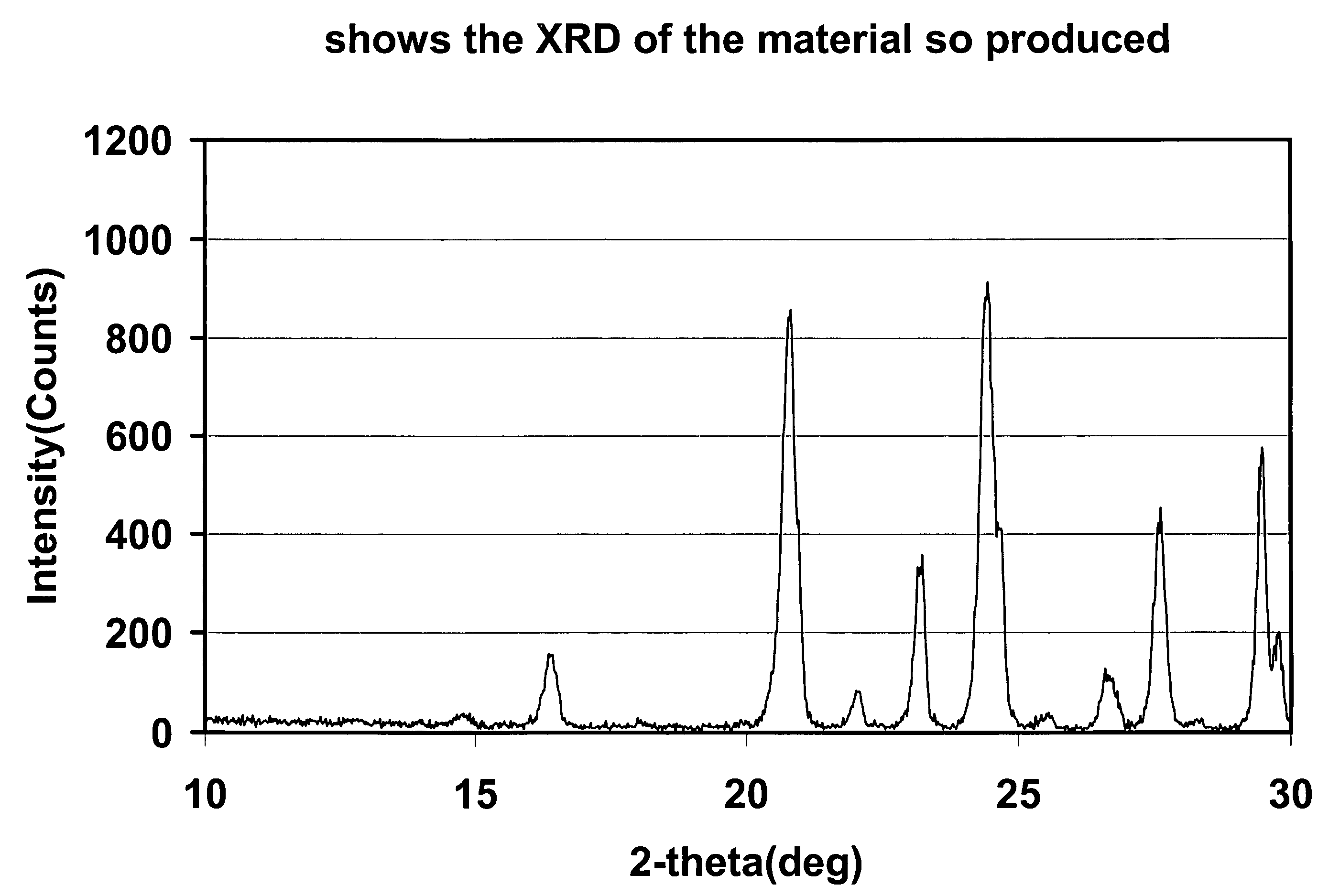

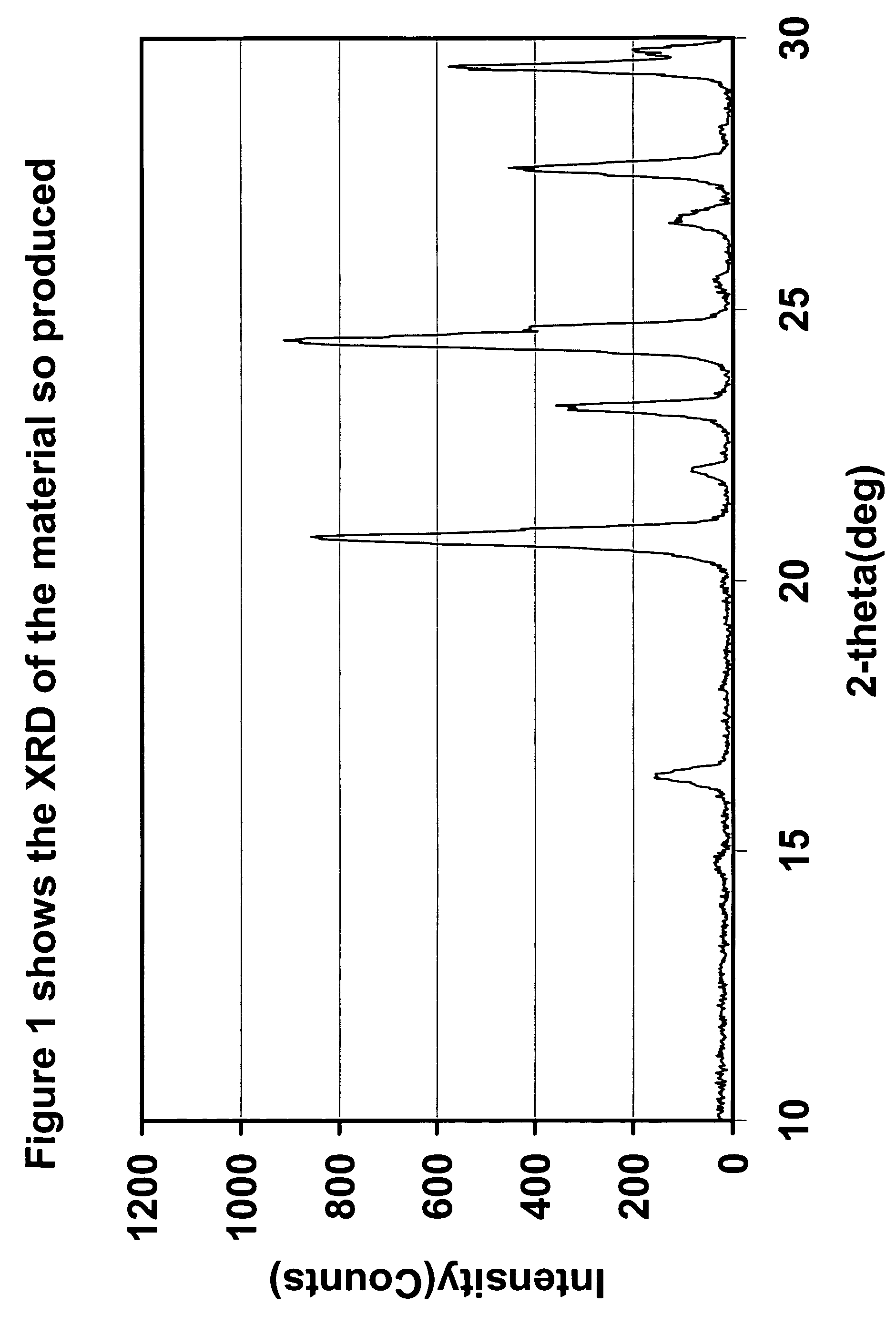

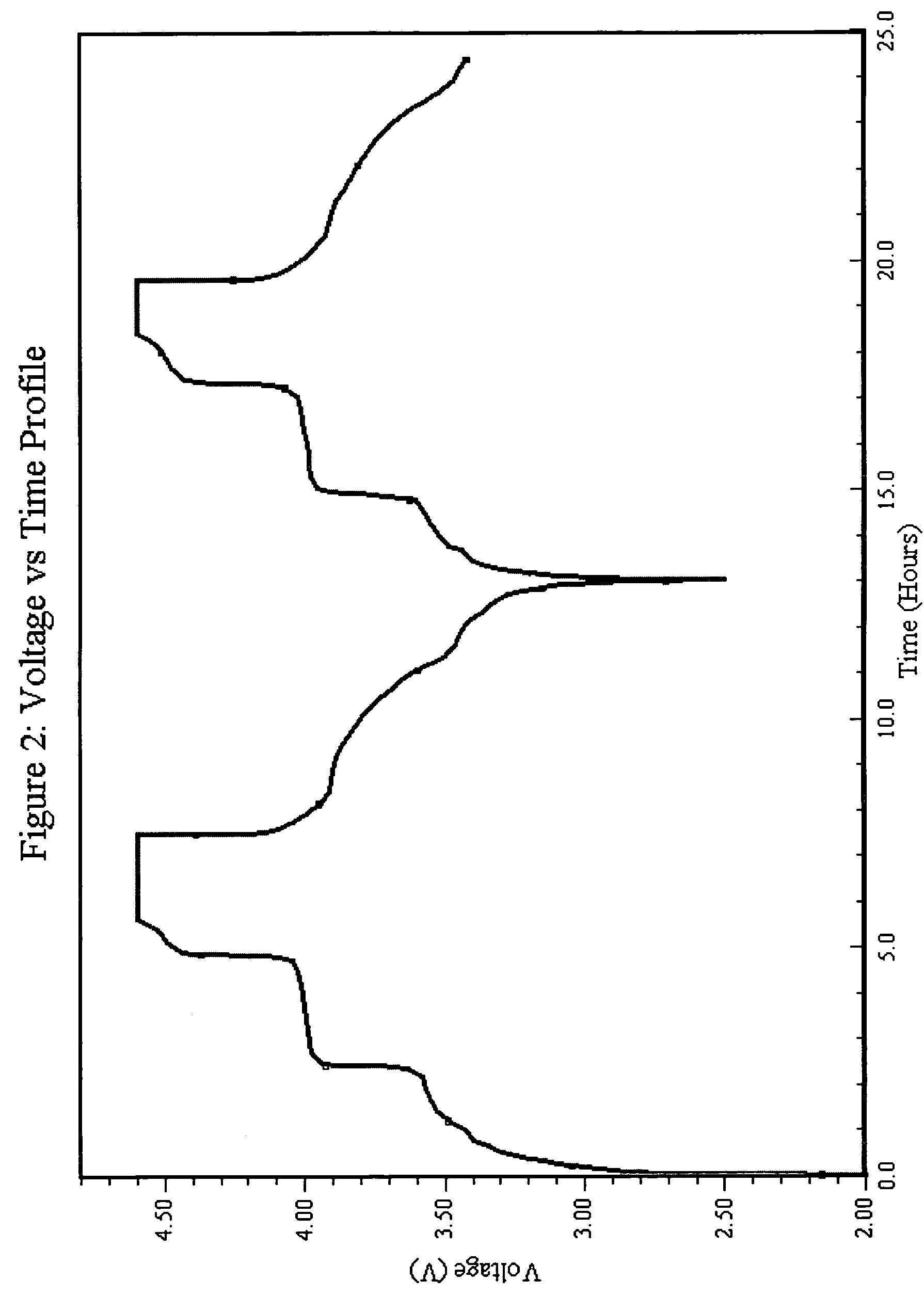

Synthesis of cathode active materials

The present invention relates to a method for preparing an electroactive metal polyanion or a mixed metal polyanion comprising forming a slurry comprising a polymeric material, a solvent, a polyanion source or alkali metal polyanion source and at least one metal ion source; heating said slurry at a temperature and for a time sufficient to remove the solvent and form an essentially dried mixture; and heating said mixture at a temperature and for a time sufficient to produce an electroactive metal polyanion or electroactive mixed metal polyanion. In an alternative embodiment the present invention relates to a method for preparing a metal polyanion or a mixed metal polyanion which comprises mixing a polymeric material with a polyanion source or alternatively an alkali metal polyanion source and a source of at least one metal ion to produce a fine mixture and heating the mixture to a temperature higher than the melting point of the polymeric material, milling the resulting material and then heating the milled material. It is another object of the invention to provide electrochemically active materials produced by said methods. The electrochemically active materials so produced are useful in making electrodes and batteries.

Owner:LITHIUM WERKS TECH BV +1

Hydrothermal synthesis of perovskite nanotubes

ActiveUS7147834B2The instrumentation is simpleReduce the amount requiredNanoinformaticsDigital storageStrontium titanateBarium titanate

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

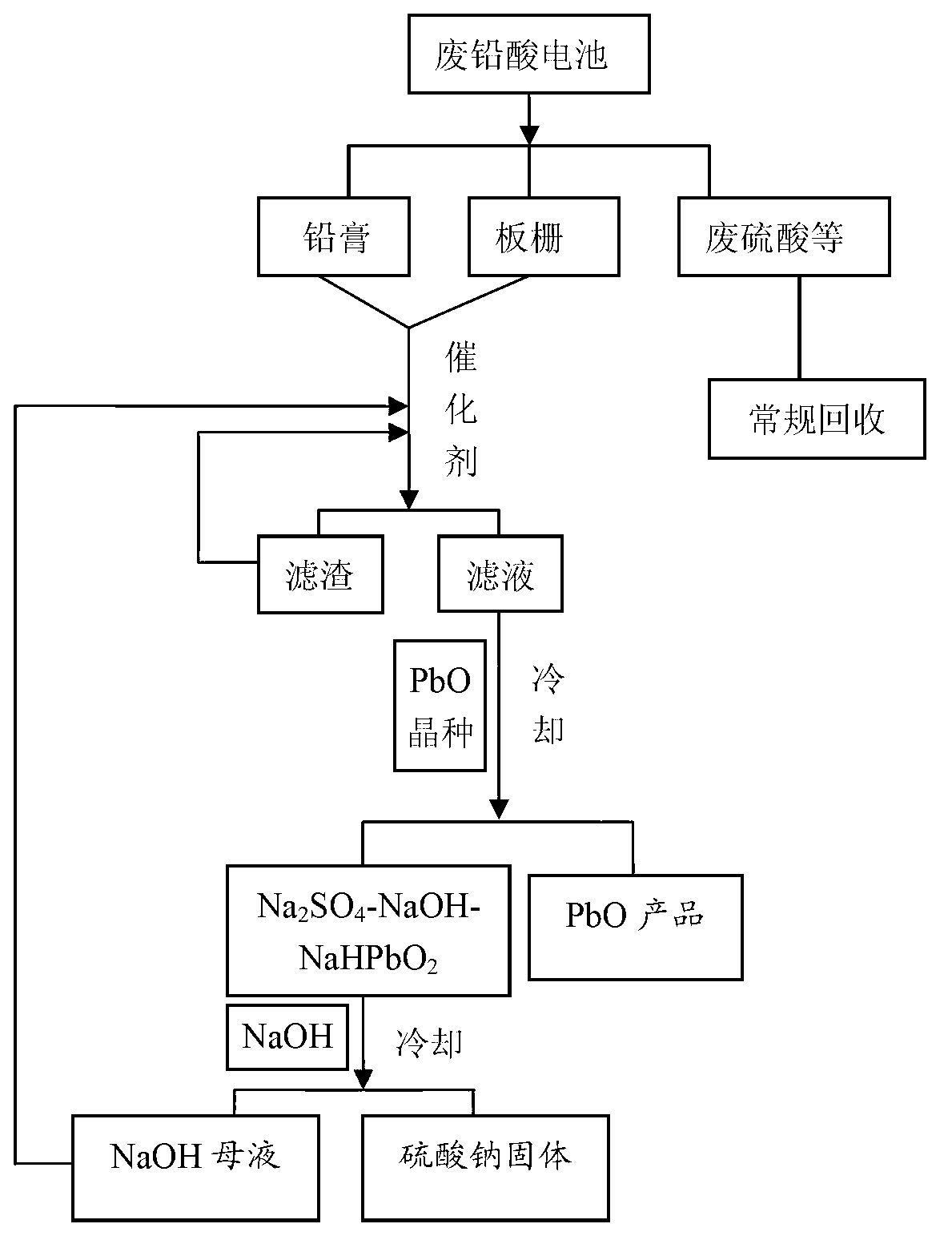

Method for recycling waste lead-acid cells to directly produce lead oxide

ActiveCN103014347AImprove recycling efficiencyMeet the needs of high-purity PbOLead oxidesProcess efficiency improvementLead oxideEngineering

The invention discloses a method for recycling waste lead-acid cells to directly produce lead oxide, belonging to the wet-process metallurgical field of recycling lead from lead-containing materials and waste lead-acid cells. The method for recycling waste lead-acid cells to directly produce lead oxide comprises the following steps of: carrying out a reaction on diachylum, lead powder and sodium hydroxide solution in the presence of catalyst to obtain a mixed solution containing NaHPbO2, sodium sulfate and sodium hydroxide, and un-reacted lead powder and impurities, and separating the mixed solution; cooling and filtering the mixed solution to obtain PbO crystals, and an alkaline solution containing Na2SO4 and the residual NaHPbO2; adding the NaOH to the solution, re-cooling the mixture to separate out sodium sulfate solid and obtain the NaOH solution containing the residual NaHPbO2; and carrying out re-dissolving-filtering-re-crystallizing to the PbO in the NaOH solution with mass concentration of 15-50% to obtain the pure lead oxide solid. The lead recovery ratio is generally between 98.5% and 99.2%, and the purity of the lead oxide is as high as 99.99% or higher.

Owner:BEIJING UNIV OF CHEM TECH

Process for producing lithium-containing composite oxide for positive electrode for lithium secondary battery

ActiveUS20060154146A1Improve featuresSolve the small densityMagnesium halidesCell electrodesAlkaline earth metalNiobium

It is to provide a positive electrode active material for a lithium secondary battery, which has a large volume capacity density and high safety, is excellent in uniform coating properties and is excellent in the charge and discharge cyclic durability and low temperature characteristics even at a high charge voltage. A process for producing a lithium-containing composite oxide represented by the formula LipQqNxMyOzFa (wherein Q is at least one element selected from the group consisting of titanium, zirconium, niobium and tantalum, N is at least one element selected from the group consisting of Co, Mn and Ni, M is at least one element selected from the group consisting of Al, alkaline earth metal elements and transition metal elements other than the Q element and the N element, 0.9≦p≦1.1, 0<q≦0.03, 0.97≦x<1.00, 0≦y<0.03, 1.9≦z≦2.1, q+x+y=1 and 0≦a≦0.02) from a lithium source, an Q element source and an N element source, and if necessary, at least one source selected from the group consisting of an M element source and a fluorine source, characterized by using as the Q element source an Q element compound aqueous solution having a pH of from 0.5 to 11.

Owner:SUMITOMO CHEM CO LTD

Nano-structured particles with high thermal stability

ActiveUS7125536B2Large specific surface areaImprove thermal stabilityMaterial nanotechnologyNanostructure manufactureNanoparticleALUMINUM PHOSPHATE

This invention relates to a composition comprising nano-structured metal oxide particles (particularly, zirconia) and at least one stabilizing agent, a method to produce the composition, and a method to produce the thermally stable nano-structured particles. The method to produce the nano-structured particles comprises first preparing a base solution and a nanoparticle precursor solution, then combining these solutions at a final pH 7 or greater to precipitate a colloidal hydrous oxide. The colloidal hydrous oxide is then treated with at least one silicate, phosphate, or aluminum phosphate stabilizing agent and dried. These nano-structured particle products have high thermal stability and are particularly advantageous in applications as catalysts or catalyst supports that operate at high temperatures.

Owner:TRONOX LLC

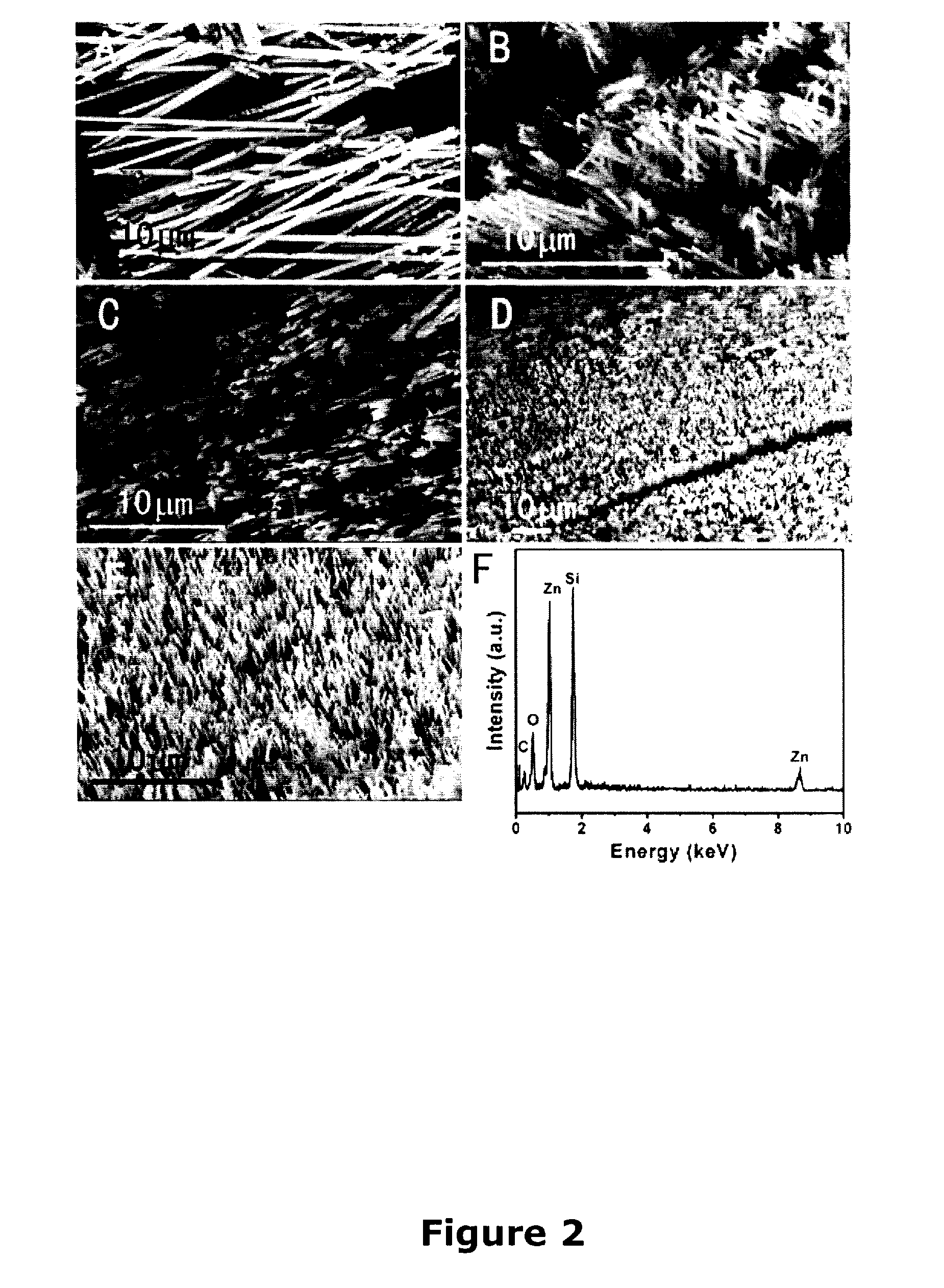

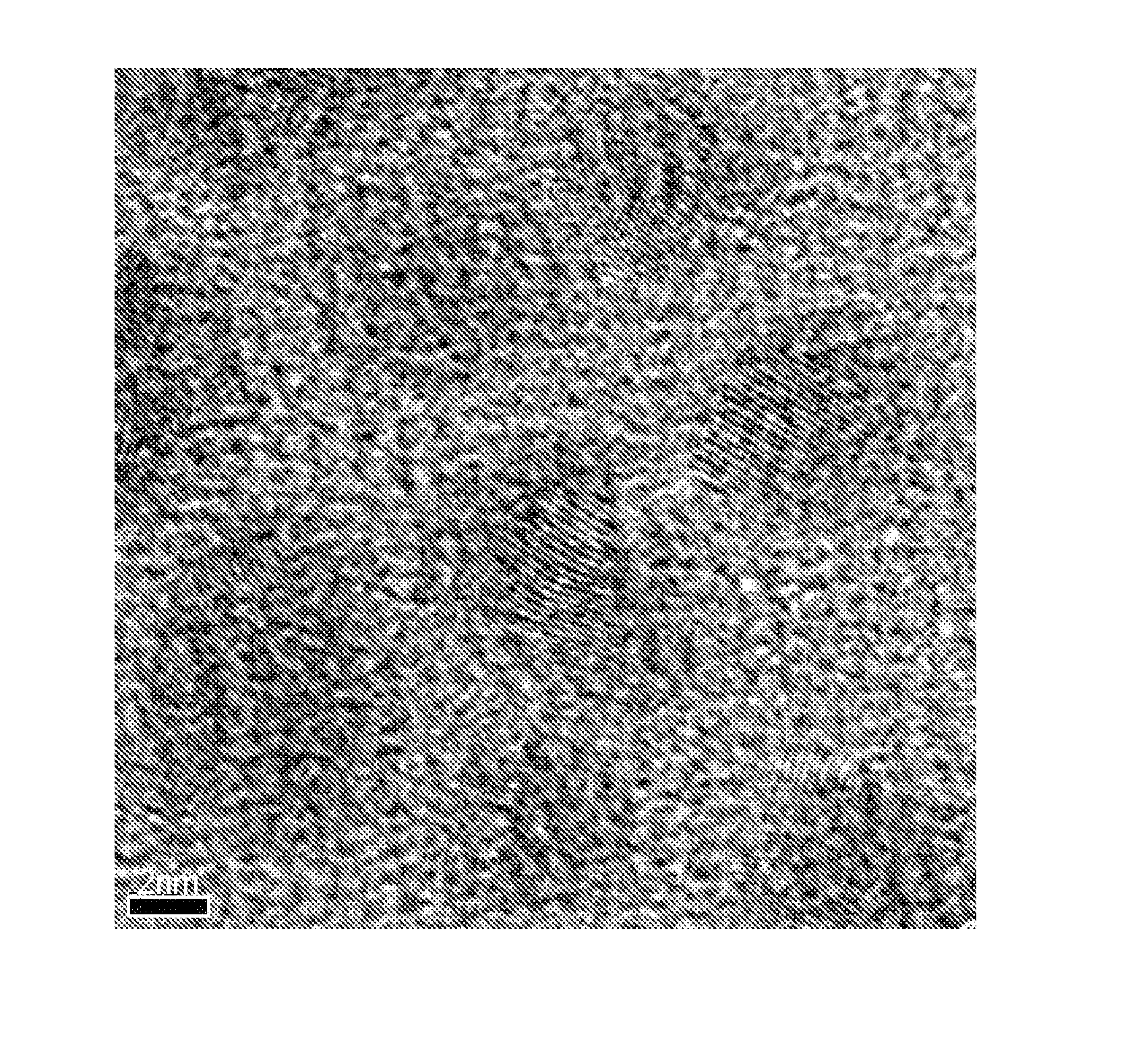

Semiconducting oxide nanostructures

Briefly described, new types of nanostructures and methods of fabrication thereof are disclosed. A representative nanostructure includes a free-standing, helical semiconductor oxide nanostructure. The free-standing, helical semiconductor oxide nanostructure includes a nanobelt having a substantially rectangular cross-section. The the nanobelt is about 5 nanometers to about 200 nanometers in width and about 3 nanometers to about 50 nanometers in height, and the radius of the helical semiconductor oxide nanostructure is about 200 to 5000 nanometers.

Owner:GEORGIA TECH RES CORP

Biomimetic Hydroxyapatite Synthesis

A method for preparing nanoscale hydroxyapatite particles by combining an amount of a calcium ion source, which includes calcium acetate, and an amount of a phosphate ion source, wherein the amounts are sufficient to produce nanoscale hydroxyapatite particles and the amounts are combined under ambient conditions to produce the hydroxyapatite particles. Nanoscale hydroxyapatite particles are also presented.

Owner:RUTGERS THE STATE UNIV

Synthesis of cathode active materials

Owner:LITHIUM WERKS TECH BV +1

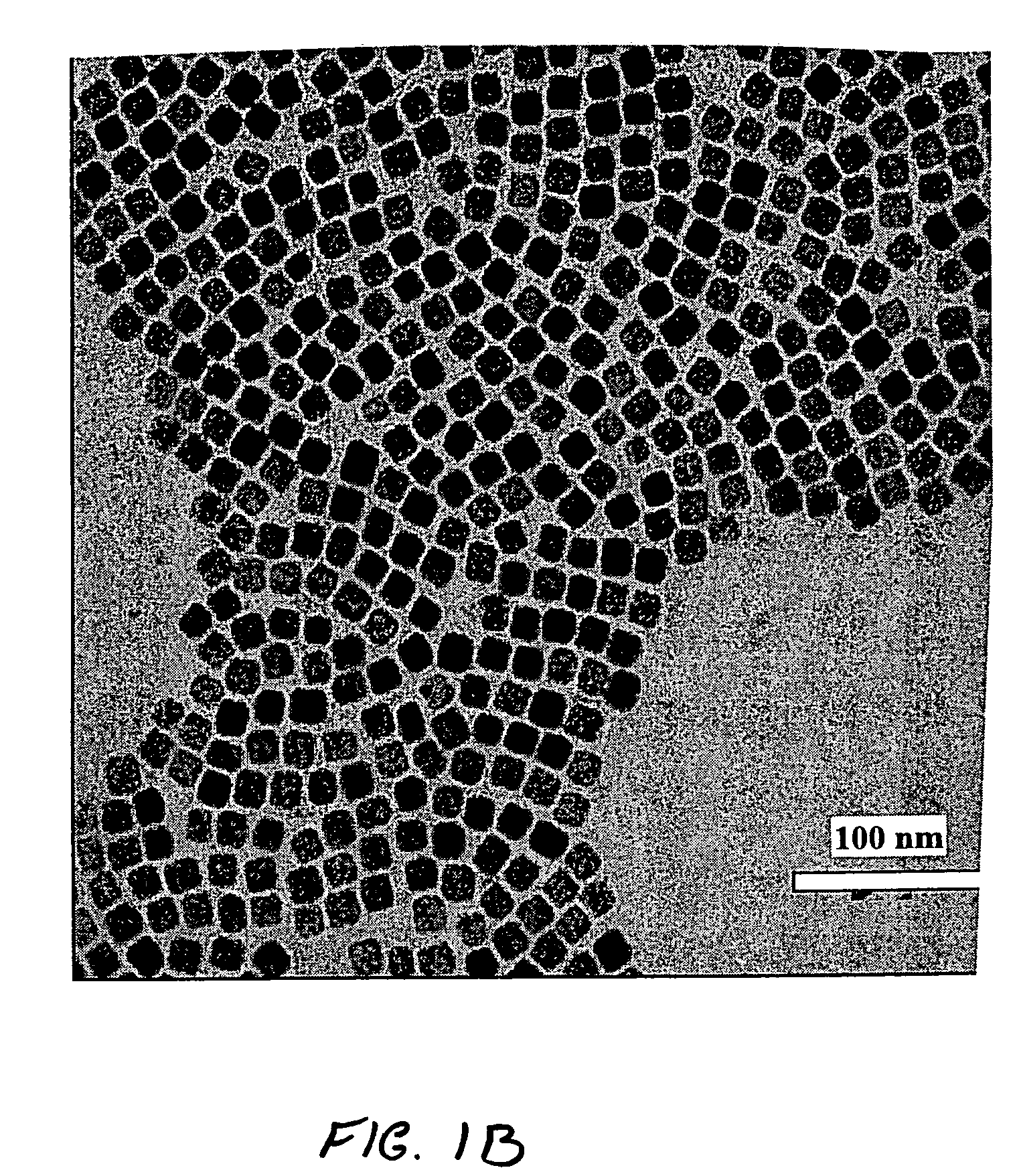

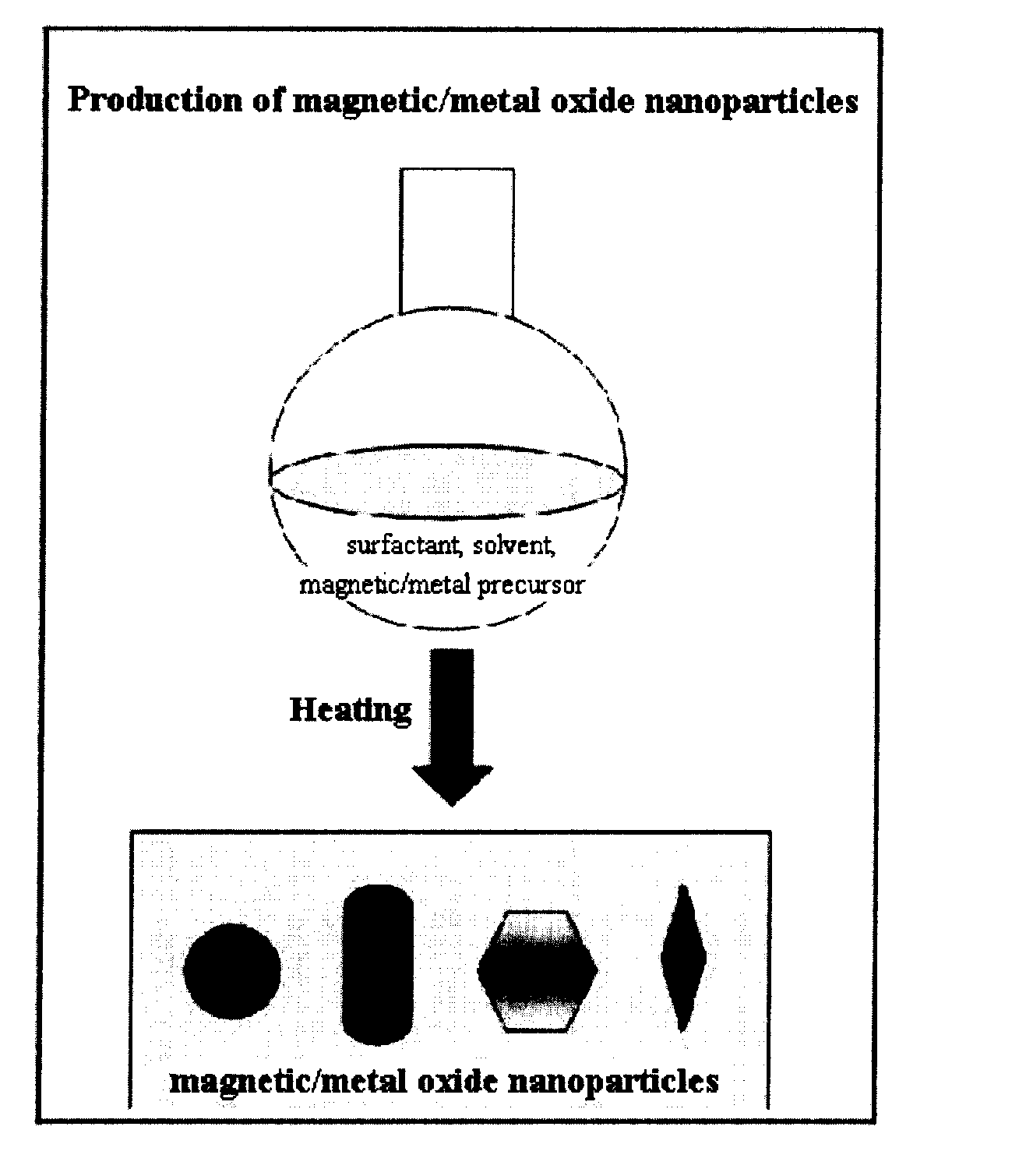

Preparation Method of Magnetic and Metal Oxide Nanoparticles

ActiveUS20080003159A1Efficient mass productionUniform shapeCopper oxides/halidesManganese oxides/hydroxidesMetal oxide nanoparticlesMagnetic oxide

This invention relates, in general, to a method of producing magnetic oxide nanoparticles or metal oxide nanoparticles and, more particularly, to a method of producing magnetic or metal oxide nanoparticles, which comprises (1) adding a magnetic or metal precursor to a surfactant or a solvent containing the surfactant to produce a mixed solution, (2) heating the mixed solution to 50-6001 C to decompose the magnetic or metal precursor by heating so as to form the magnetic or metal oxide nanoparticles, and (3) separating the magnetic or metal oxide nanoparticles. Since the method is achieved through a simple process without using an oxidizing agent or a reducing agent, it is possible to simply mass-produce uniform magnetic or metal oxide nanoparticles having desired sizes compared to the conventional method.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

Biologically inspired synthesis of thin films and materials

InactiveUS20070254141A1Easy to adjustMaximize absorption efficiencyCell electrodesVacuum evaporation coatingVolumetric Mass DensityNanostructure

A method for the fabrication of nanostructured semiconducting, photoconductive, photovoltaic, optoelectronic and electrical battery thin films and materials at low temperature, with no molecular template and no organic contaminants. High-quality metal oxide semiconductor, photovoltaic and optoelectronic materials can be fabricated with nanometer-scale dimensions and high dopant densities through the use of low-temperature biologically inspired synthesis routes, without the use of any biological or biochemical templates.

Owner:RGT UNIV OF CALIFORNIA

Ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and method thereof

InactiveCN103374658ALead volatility is smallReduce soot rateReclaiming serviceable partsLead oxidesLead carbonateLead oxide

The invention discloses ultrafine lead oxide prepared from desulfurated lead plaster by means of three-stage process and a method for preparing the ultrafine lead oxide. The method comprises the following steps of: carrying out a desulfurization and lead plaster acid leaching process by causing the desulfurated lead plaster to react with acid, simultaneously adding a reducing agent, and carrying out solid-liquid separation after the reaction is ended to obtain a plumbic acid containing solution; carrying out a lead carbonate preparation process by causing the plumbic acid containing solution to react with sodium carbonate, carrying out solid-liquid separation, washing and drying to obtain the lead carbonate; carrying out a roasting process by preparing the ultrafine lead carbonate by roasting the lead carbonate, wherein the ultrafine lead oxide can be PbO, Pb3O4, or the mixture of the PbO and the Pb3O4, the mean particle granularity of the ultrafine lead oxide is less than 2 mu m, and the nanocrystalline grain size is less than 500nm. Compared with the prior art, the preparation method of the ultrafine lead oxide disclosed by the invention has the following beneficial effects: the active material of the ultrafine lead oxide powder compound for the production of a storage battery enterprise can be directly prepared, lead volatilize quantity is small, the ash rate is low, the direct lead yield is high, the energy consumption is low, pollutants of sulfur dioxide and the like are not generated, and the like.

Owner:湖北金洋冶金股份有限公司 +1

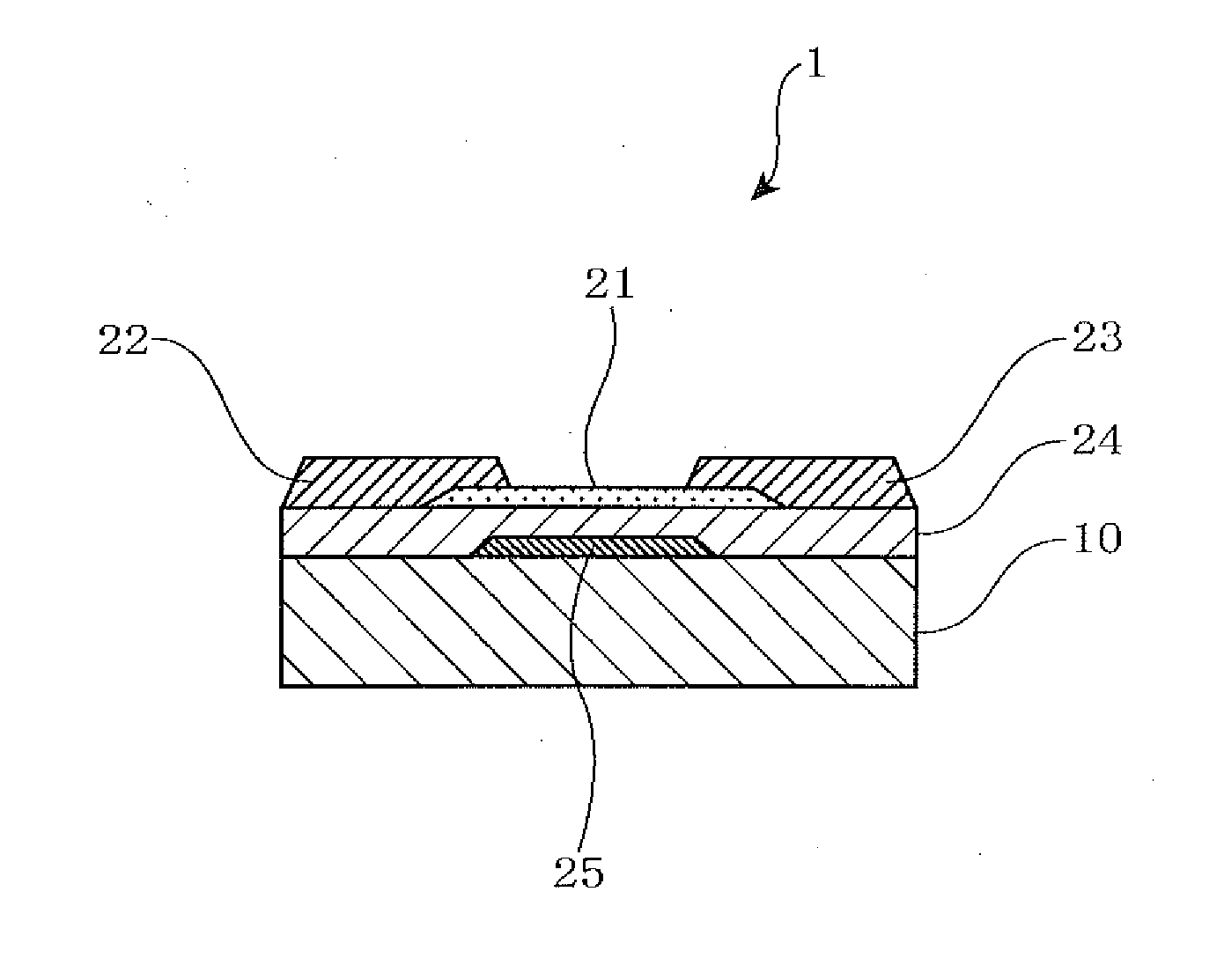

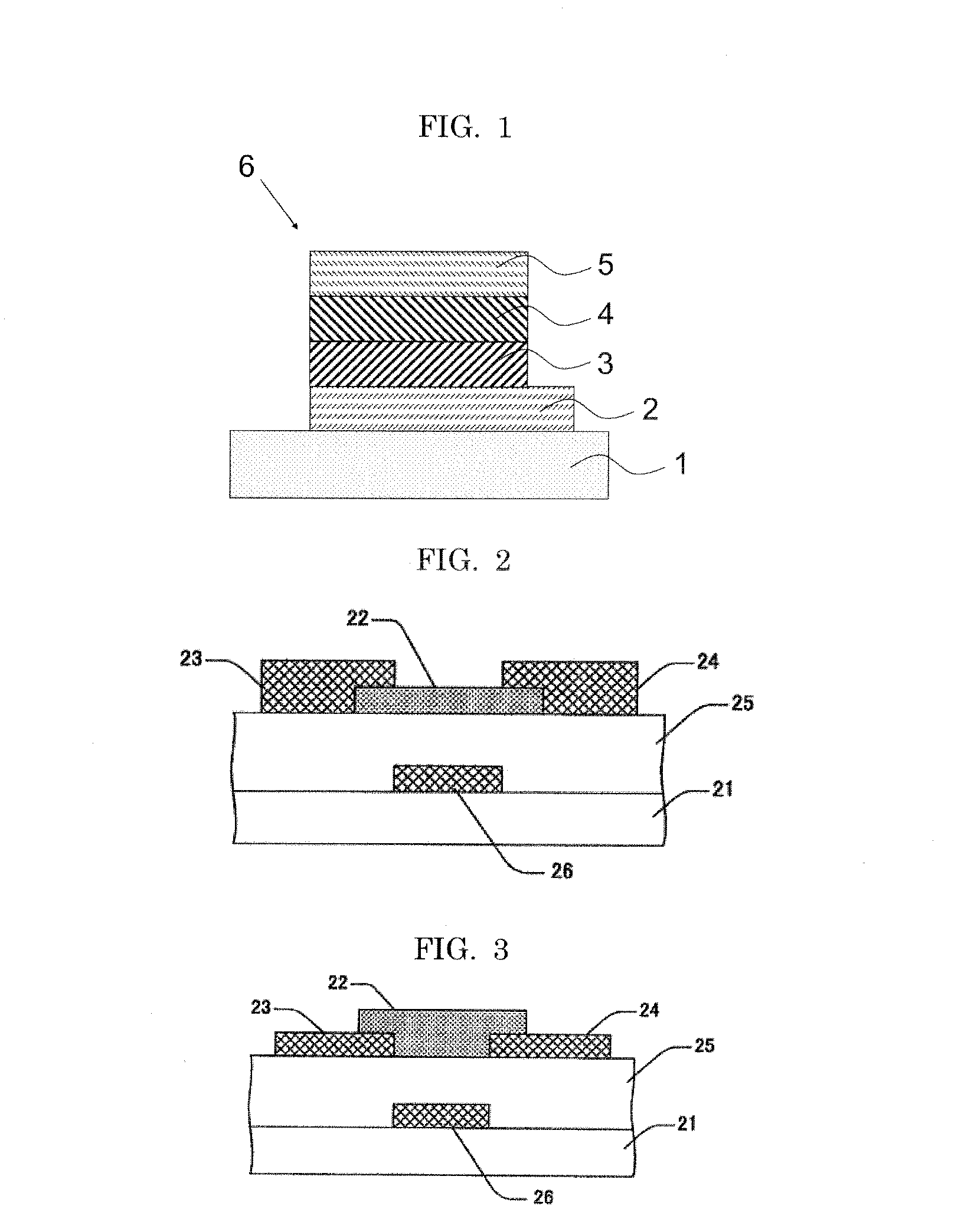

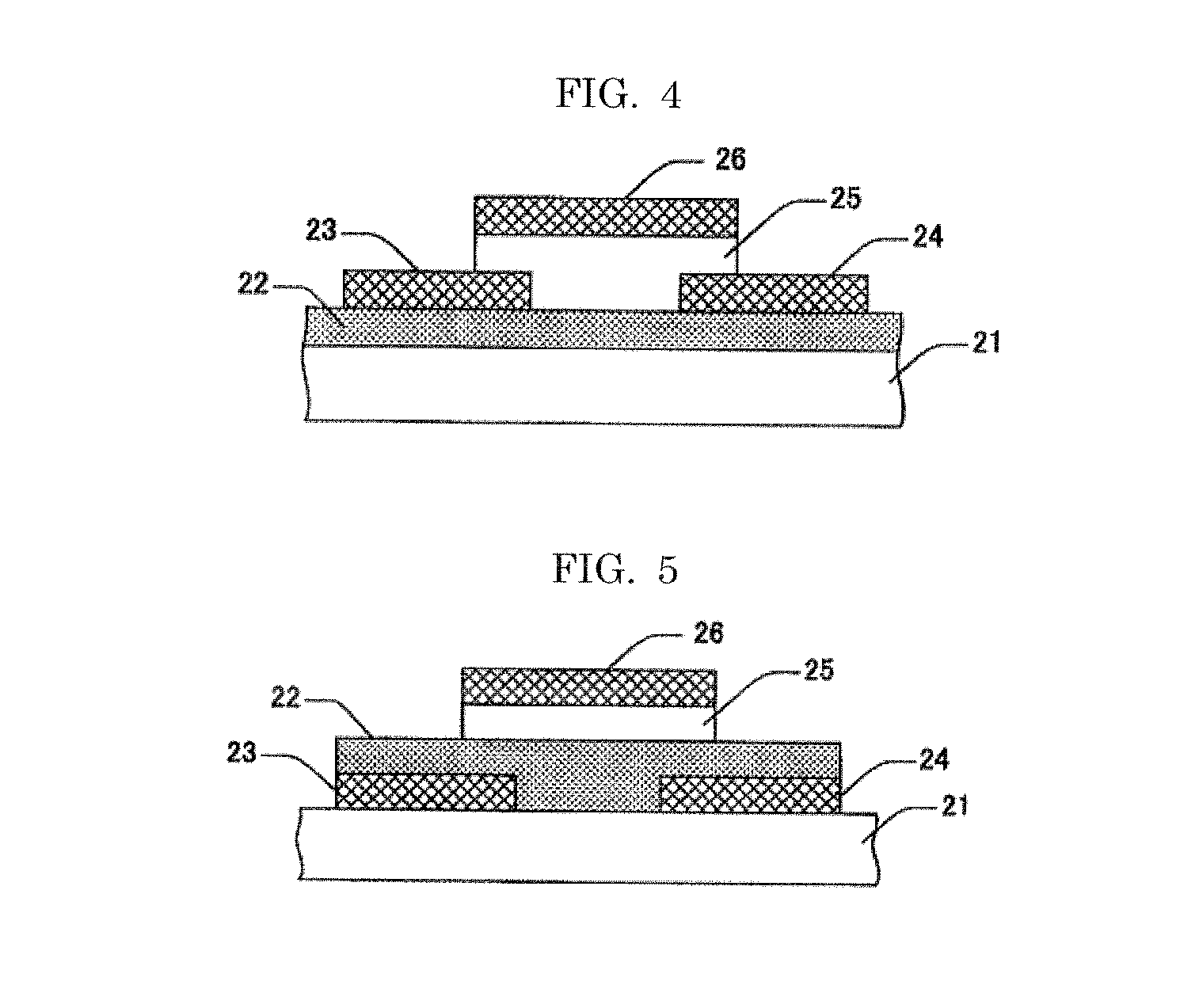

P-type oxide, composition for producing p-type oxide, method for producing p-type oxide, semiconductor element, display element, image display device, and system

ActiveUS20140353648A1Maintain good propertiesSufficient electrical conductivityConductive materialSolid-state devicesPhysical chemistrySemiconductor

To provide is a p-type oxide, including an oxide, wherein the oxide includes: Cu; and an element M, which is selected from p-block elements, and which can be in an equilibrium state, as being present as an ion, wherein the equilibrium state is a state in which there are both a state where all of electrons of p-orbital of an outermost shell are lost, and a state where all of electrons of an outermost shell are lost, and wherein the p-type oxide is amorphous.

Owner:RICOH KK

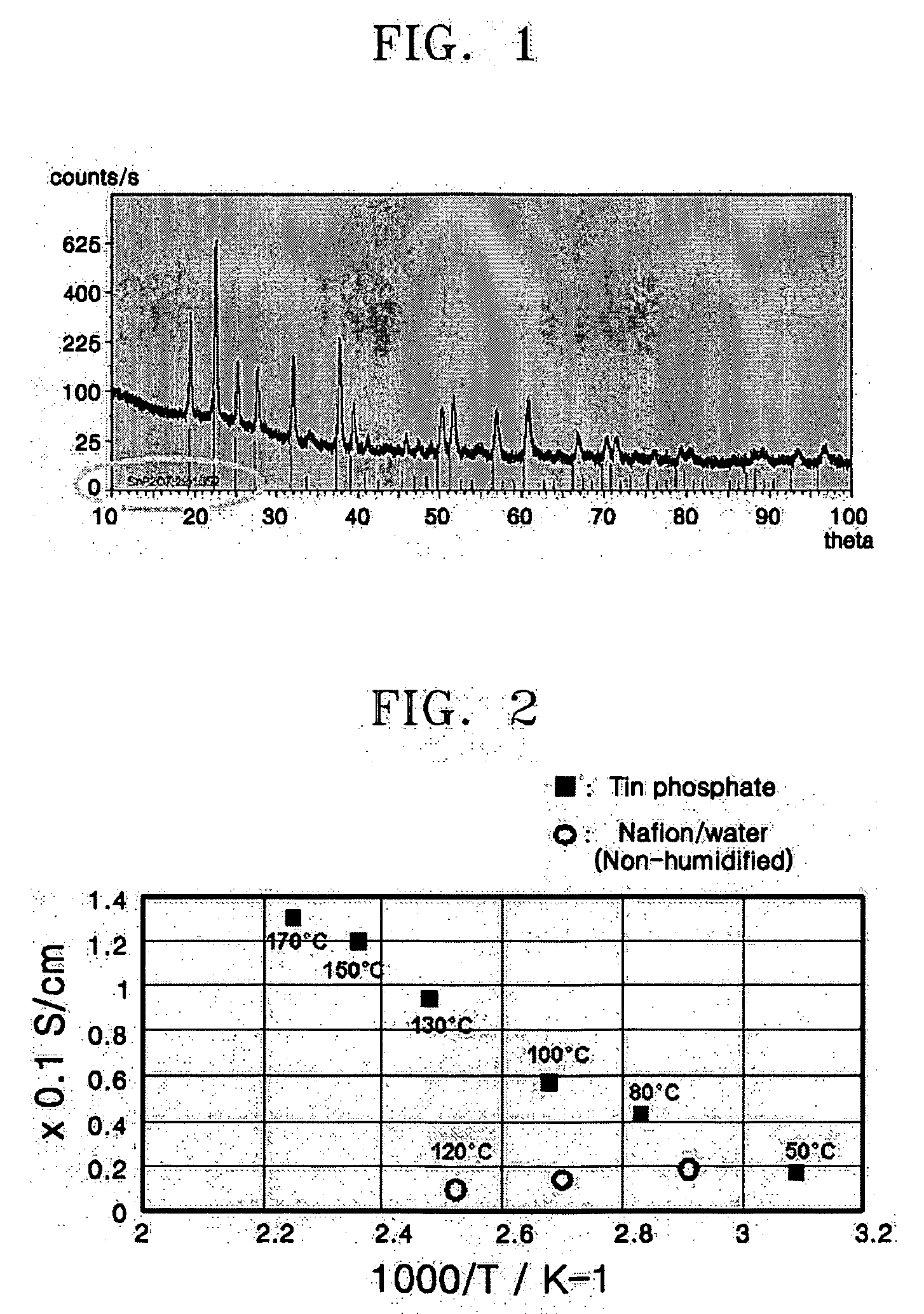

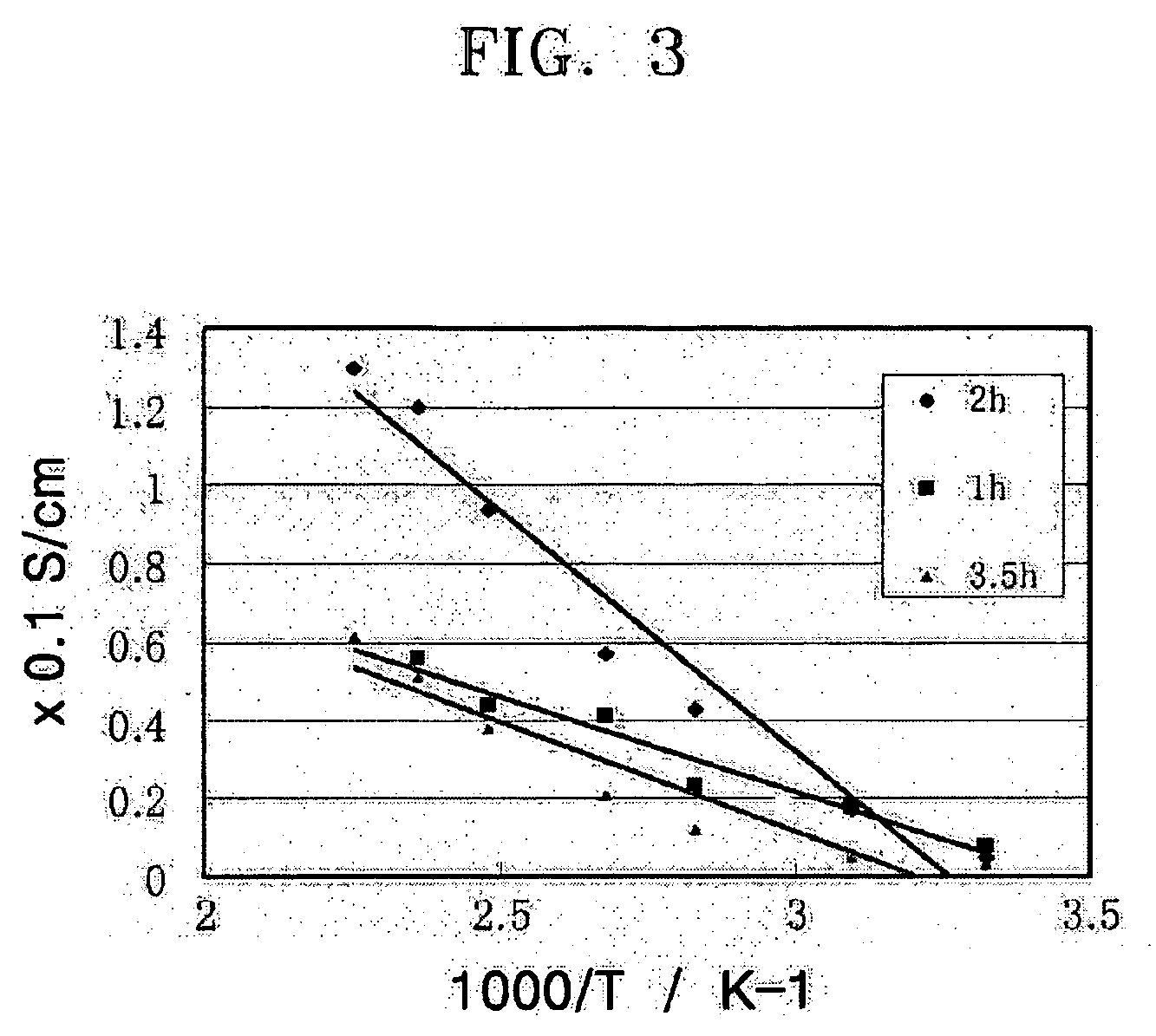

Proton conductor

The present invention provides a proton conductor comprising SnP2O7. The present invention also provides a fuel cell that comprising a cathode, an anode, and an electrolyte membrane, in which one of these components comprises SnP2O7. The SnP2O7 has high ionic conductivity of about 10−1 to 10−2 S / cm at about 80° C. or greater when non-humidified. In addition, SnP2O7 is water-insoluble, and stable at high temperatures. These properties make SnP2O7 suitable to act as a non-humidified proton conductor, or a high temperature non-humidified proton conductor.

Owner:SAMSUNG ELECTRONICS CO LTD +2

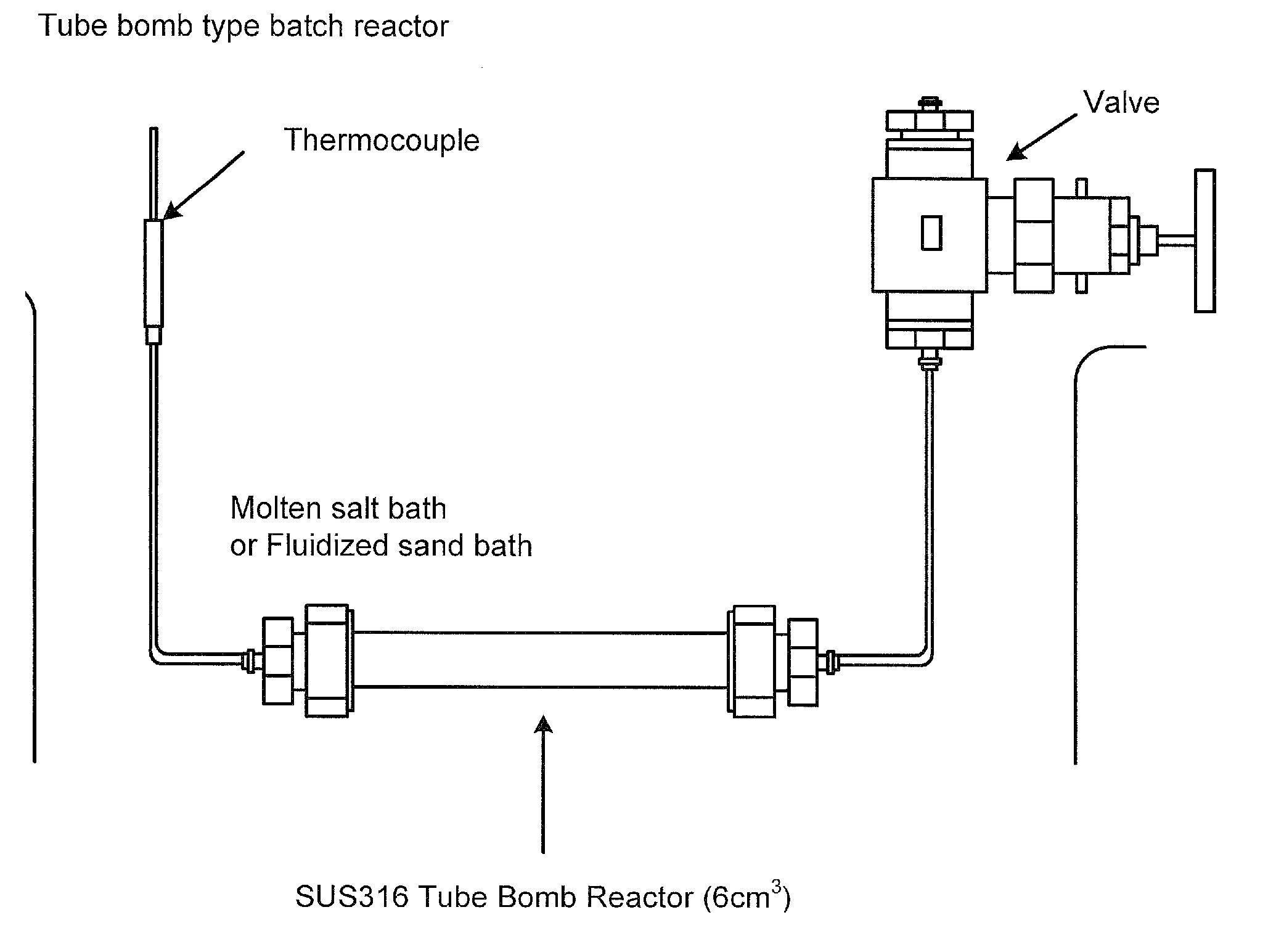

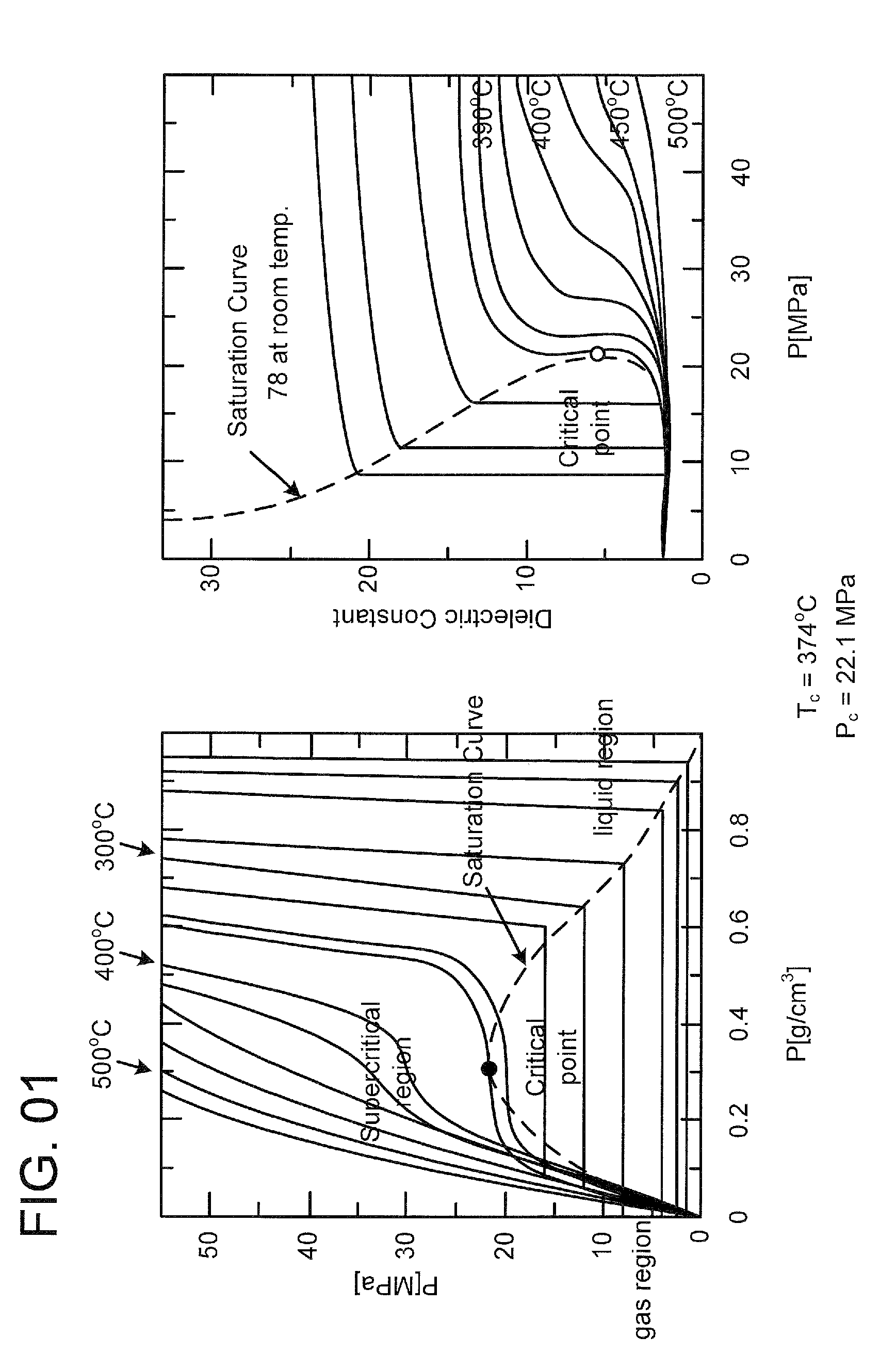

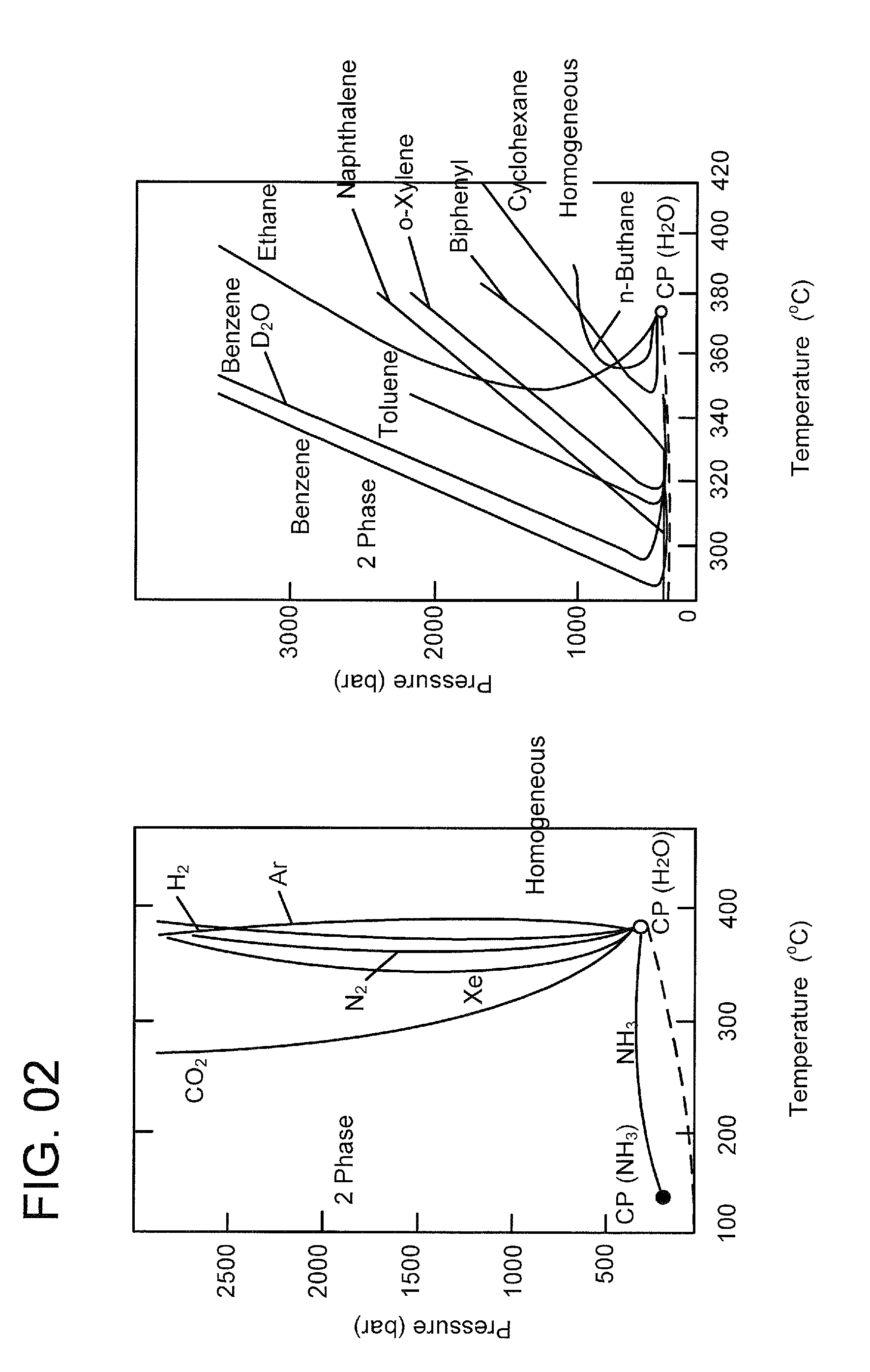

Organically modified fine particles

A technique for bonding an organic group with the surface of fine particles such as nanoparticles through strong linkage is provided, whereas such fine particles are attracting attention as materials essential for development of high-tech products because of various unique excellent characteristics and functions thereof. Organically modified metal oxide fine particles can be obtained by adapting high-temperature, high-pressure water as a reaction field to bond an organic matter with the surface of metal oxide fine particles through strong linkage. The use of the same condition enables not only the formation of metal oxide fine particles but also the organic modification of the formed fine particles. The resulting organically modified metal oxide fine particles exhibit excellent properties, characteristics and functions.

Owner:SUPER NANO DESIGN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com