Method for preparing high-quality lead citrate by waste lead paste wet method

A technology of lead citrate and waste lead paste, applied in the directions of carboxylate preparation, carboxylate preparation, chemical instruments and methods, etc., can solve the problems of inability to directly recycle, low metal recovery rate, and high SO2 concentration, and achieve resource The effect of good recovery effect, high quality and high desulfurization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

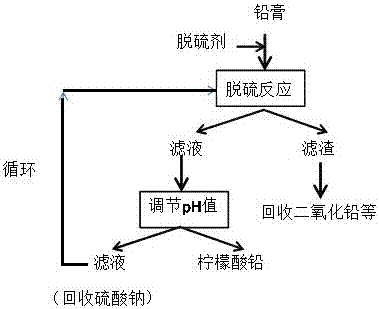

[0024]Embodiment 1: The method for preparing high-quality lead citrate by waste lead paste wet method, comprising the following steps: (a) obtain lead paste from the positive plate and negative plate of waste lead storage battery, the main components are lead sulfate and lead dioxide , lead oxide, lead and some impurities; (b) the lead plaster is first mixed with a solution containing sodium citrate, lead oxide and lead sulfate in the lead plaster are dissolved in the sodium citrate solution, and there is no reaction or the remaining substances are simple lead, di Lead oxide and impurities, the mass concentration of sodium citrate in sodium citrate solution is 5%, the desulfurization reaction temperature is 10°C, and the desulfurization reaction time is 0.5h. After sufficient desulfurization reaction, the desulfurization rate of the lead paste is ≥99%. Liquid separation, separation to obtain solid matter mainly lead dioxide and metal lead, used to purify lead dioxide or prepare...

Embodiment 2

[0025] Embodiment 2: The method for preparing high-quality lead citrate by waste lead paste wet method, comprising the following steps: including the following steps: (a) obtaining lead paste from the positive and negative plates of waste lead storage batteries, the main component of which is lead sulfate , lead dioxide, lead oxide, lead and some impurities; (b) the lead plaster is first mixed with a solution containing sodium citrate, and the lead oxide and lead sulfate in the lead plaster are dissolved in the sodium citrate solution, and there is no reaction or the remaining substances are Elemental lead, lead dioxide and impurities, the mass concentration of sodium citrate in sodium citrate solution is 15%, the desulfurization reaction temperature is 25°C, and the desulfurization reaction time is 1h. After sufficient desulfurization reaction, the desulfurization rate of the lead paste is ≥99% %, solid-liquid separation, separation to obtain solid matter mainly lead dioxide a...

Embodiment 3

[0026] Embodiment 3: The method for preparing high-quality lead citrate by waste lead plaster wet method, comprising the following steps: including the following steps: (a) obtaining lead plaster from the positive and negative plates of waste lead storage batteries, the main component of which is lead sulfate , lead dioxide, lead oxide, lead and some impurities; (b) the lead plaster is first mixed with a solution containing sodium citrate, and the lead oxide and lead sulfate in the lead plaster are dissolved in the sodium citrate solution, and there is no reaction or the remaining substances are Elemental lead, lead dioxide and impurities, the mass concentration of sodium citrate in sodium citrate solution is 30%, the desulfurization reaction temperature is 55°C, and the desulfurization reaction time is 2.5h. After sufficient desulfurization reaction, the desulfurization rate of the lead paste is ≥ 99%, solid-liquid separation, separation to obtain solid matter mainly lead diox...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com