Printing ink for advertising art design wrapping paper

A technology for printing ink and wrapping paper, applied in the direction of ink, household appliances, application, etc., can solve the problem of single function of ink, and achieve the effect of improving product performance and superior flame retardant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

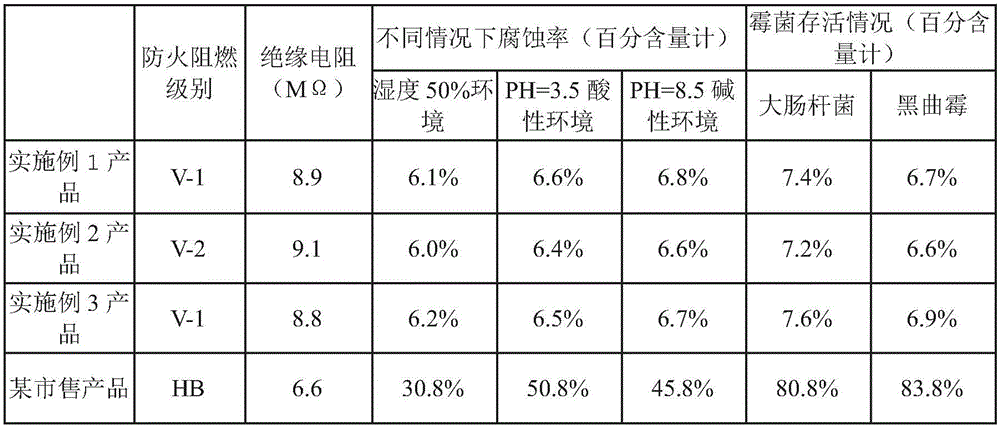

Examples

Embodiment 1

[0016] The advertising art design wrapping paper printing ink in the present embodiment is made up of the following components by mass: 22 parts of polyester urethane resins, 20 parts of halogenated butyl rubber, 20 parts of fluorosilicone resins, 18 parts of amyl acetate 20 parts of isobutyltriethoxysilane, 20 parts of epichlorohydrin, 18 parts of litsea cubeba oil, 20 parts of hydrogenated castor oil, 20 parts of borax powder, 18 parts of triethyltin chloride, 18 parts of eugenol 18 parts of sodium dehydroacetate, 20 parts of artificial mica, 18 parts of molybdenum trioxide powder, 16 parts of chromium trioxide powder, 20 parts of gypsum powder, 18 parts of graphite powder, 16 parts of trilead tetraoxide powder, barium titanate 18 parts of powder, 16 parts of niobium carbide powder, 16 parts of zinc hydroxystannate, 18 parts of hexabromocyclododecane, 18 parts of trichloroethyl phosphate, 18 parts of amidinourea phosphate, and 18 parts of methylbenzotriazole 18 parts, 18 par...

Embodiment 2

[0022] The advertising art design packaging paper printing ink in the present embodiment is made up of the following components by mass: 24 parts of polyester urethane resins, 22 parts of halogenated butyl rubber, 22 parts of fluorosilicone resins, 20 parts of amyl acetate 22 parts of isobutyltriethoxysilane, 22 parts of epichlorohydrin, 20 parts of litsea cubeba oil, 22 parts of hydrogenated castor oil, 22 parts of borax powder, 20 parts of triethyltin chloride, 20 parts of eugenol 20 parts of sodium dehydroacetate, 22 parts of artificial mica, 20 parts of molybdenum trioxide powder, 18 parts of chromium trioxide powder, 22 parts of gypsum powder, 20 parts of graphite powder, 18 parts of trilead tetraoxide powder, barium titanate 20 parts of powder, 18 parts of niobium carbide powder, 18 parts of zinc hydroxystannate, 20 parts of hexabromocyclododecane, 20 parts of trichloroethyl phosphate, 20 parts of amidinourea phosphate, and 20 parts of methylbenzotriazole 20 parts, 20 pa...

Embodiment 3

[0028] The advertising art design wrapping paper printing ink in the present embodiment is made up of the following components in mass parts: 26 parts of polyester urethane resins, 24 parts of halogenated butyl rubbers, 24 parts of fluorosilicone resins, 22 parts of amyl acetates 24 parts, isobutyltriethoxysilane 24 parts, epichlorohydrin 24 parts, litsea cubeba oil 22 parts, hydrogenated castor oil 24 parts, borax powder 24 parts, triethyltin chloride 22 parts, eugenol 22 parts 22 parts of sodium dehydroacetate, 24 parts of artificial mica, 22 parts of molybdenum trioxide powder, 20 parts of chromium trioxide powder, 24 parts of gypsum powder, 22 parts of graphite powder, 20 parts of trilead tetraoxide powder, barium titanate 22 parts of powder, 20 parts of niobium carbide powder, 20 parts of zinc hydroxystannate, 22 parts of hexabromocyclododecane, 22 parts of trichloroethyl phosphate, 22 parts of amidinourea phosphate, and 22 parts of methylbenzotriazole 22 parts, 22 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com