Method for converting lead sulfate into lead tetraoxide

A technology of trilead tetroxide and lead sulfate, applied in lead oxide, lead dan and other directions, can solve the problems of high energy consumption, affect the health of operators, affect the environment, etc., and achieve the effect of low energy consumption, no need for high temperature, and simple method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

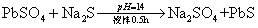

[0011] Weigh 3.03kg of lead sulfate and 1kg of sodium sulfide, add them to 10kg of deionized water, add a certain amount of ammonia water, adjust the pH to about 14, stir and react for 0.5h, and obtain 2.4kg of white (slightly yellow) solid precipitated lead sulfide, filter The precipitate was removed and washed.

[0012]

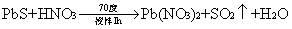

[0013] Add the above 2.4kg of lead sulfide to 8L of nitric acid solution with a concentration of 15% by mass, heat, keep the solution temperature at about 70°C, and continue stirring for 1 hour to completely dissolve the lead sulfide.

[0014]

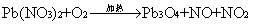

[0015] The above solution was evaporated to dryness and heated in a sand bath (temperature 280°C) to obtain 2.6kg of white (slightly yellow) solid lead nitrate.

[0016] Add the above 2.6kg of lead nitrate into the stirring ball mill, continuously feed the nitrogen-oxygen mixed gas with an oxygen content of 35% (volume percentage), the ball mill speed is 80 rpm, and continue the ball milling for 2 hours. The ...

Embodiment 2

[0019] Weigh 3.03kg of lead sulfate, 0.5kg of sodium sulfide and 0.5kg of ammonium sulfide, add them to 10kg of deionized water, add a certain amount of ammonia water, adjust the pH to about 14, stir for 1 hour, and obtain a white (slightly yellow) solid precipitate of about 2.4kg, filter out the precipitate, and wash.

[0020] Add the above 2.4kg of lead sulfide to 5L of nitric acid solution with a concentration of 25% by mass, heat, keep the temperature of the solution at about 70°C, and continue stirring for 0.6h to completely dissolve the lead sulfide.

[0021] The above solution was evaporated to dryness and heated in a sand bath (temperature 250° C.) to obtain 2.6 kg of a white (slightly yellow) solid.

[0022] Add the above 2.6kg of solids into the stirring ball mill, continuously feed the nitrogen-oxygen mixed gas with an oxygen content of 55% (volume percentage), the speed of the ball mill is 120 rpm, and continue the ball milling for 0.6h. The final product is red le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com