Mixed additive for electrolytic copper foil, preparation method for mixed additive, and method for preparing ultralow-profile electrolytic copper foil

A technology of mixing additives and electrolytic copper foil, which is applied in electrolytic process, electroforming, etc., can solve the problems of no major breakthrough in technology, and achieve the effect of easy control and improved bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

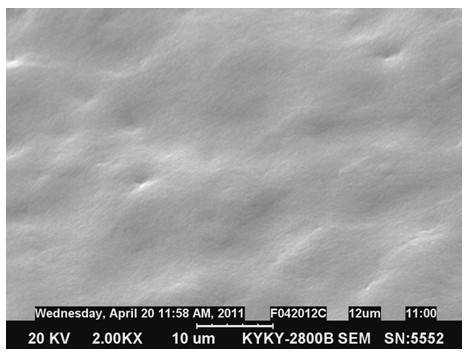

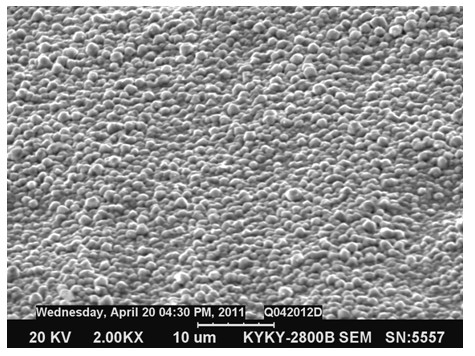

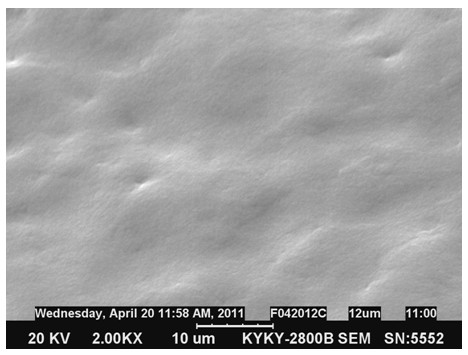

Image

Examples

Embodiment 1

[0030] Mixed additives for electrolytic copper foil, the raw materials contained in the aqueous solution of mixed additives per liter are: 1.0g gum arabic, 1.5g hydroxyethyl cellulose, 0.8g gelatin, 0.8g sodium dimercaptodipropane sulfonate, 0.02 ethylene thiourea g.

Embodiment 2

[0032] Mixed additives for electrolytic copper foil, the raw materials contained in the aqueous solution of mixed additives per liter are: 0.5g of gum arabic, 2.5g of hydroxyethyl cellulose, 1.2g of gelatin, 1.2g of sodium dimercaptodipropanesulfonate, 0.05g of ethylene thiourea g.

Embodiment 3

[0034] Mixed additives for electrolytic copper foil, the raw materials contained in the aqueous solution of mixed additives per liter are: 1.6g of gum arabic, 2.0g of hydroxyethyl cellulose, 1.0g of gelatin, 1.0g of sodium dimercaptodipropane sulfonate, 0.03 ethylene thiourea g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com