Stretch-proof cable sheath insulation material and preparation method thereof

A cable sheathing and insulating material technology, applied in the direction of insulated conductors, insulated cables, rubber insulators, etc., can solve the problems of compatibility, low temperature resistance, compression set resistance, reduced thermal aging performance, low tear resistance, and water resistance. Poor properties and other problems, to achieve the effect of low shrinkage, excellent physical properties and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

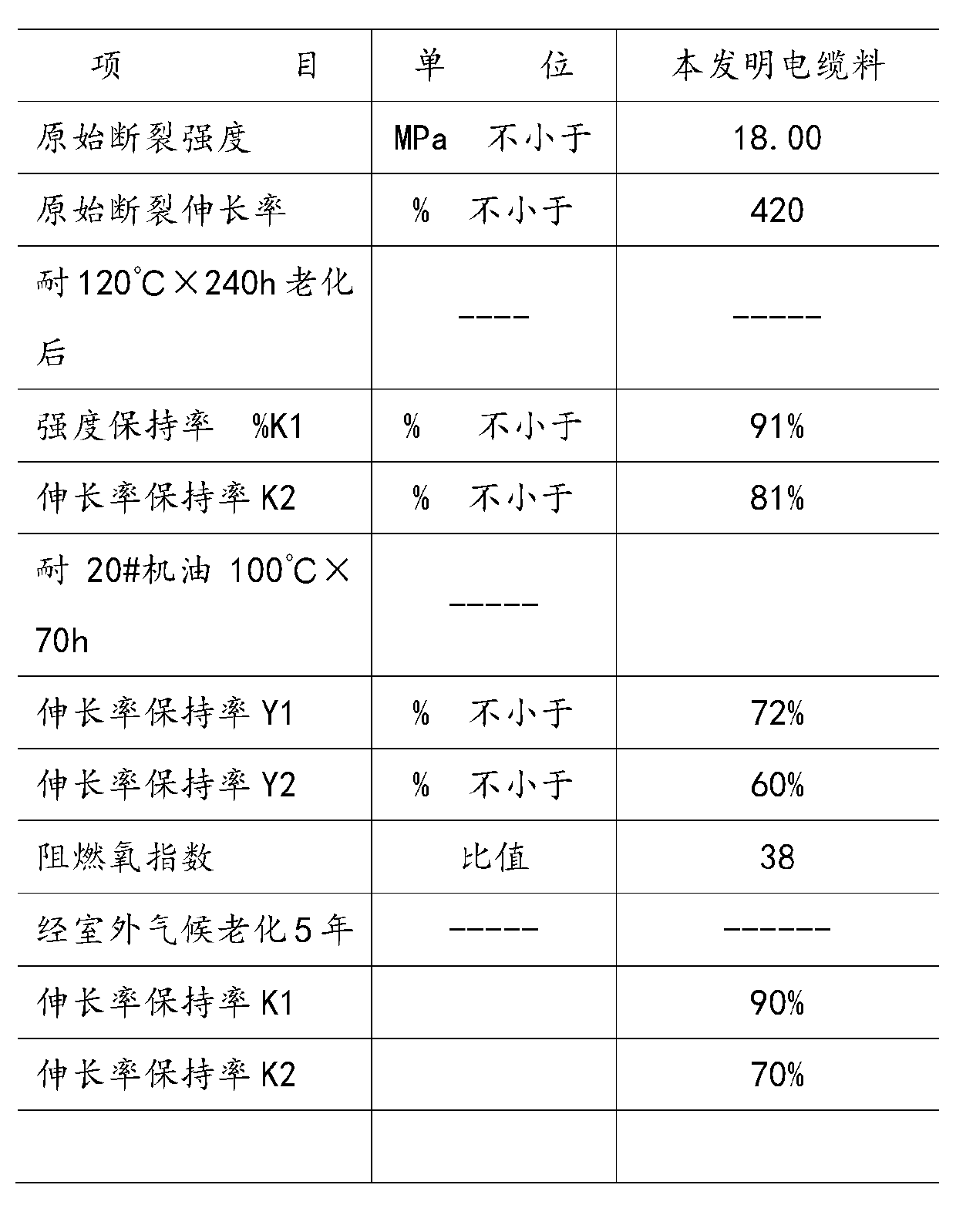

Examples

Embodiment 1

[0016] A stretch-resistant cable sheath insulation material, which is composed of the following raw materials in parts by weight (kg):

[0017] Neoprene CR121105, chlorinated polyethylene 12, semi-reinforcing carbon black N774 15-25, zinc oxide 3, ferrocene 2, mica powder 35, antioxidant MB 2, 2-mercaptobenzimidazole 2, horse Dioctyl maleate 8, accelerator DM 2, dibasic lead phosphite 1, nano silicon dioxide 15, 4,4'-oxobisbenzenesulfonyl hydrazide 3, antioxidant DSTP4, glass powder 4-6 , Zinc Oxide 0.8, Modified Calcium Carbonate 3, Antimony Trioxide 6, Ethylene Thiourea 6;

[0018] The preparation method of the modified calcium carbonate is as follows: mix quicklime and boiled water at a mass ratio of 1:10, digest for 5 hours, filter and remove slag through a 180 μm resonance sieve, and then further remove slag through a hydrocyclone to obtain Ca(OH) 2 Suspension, in Ca(OH) 2 Add its quality 8% chelating agent ethylenediammonium tetraacetic acid, its quality 12% magnesium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com