Low-gloss heat-resistant ABS resin composition and preparation method thereof

一种ABS树脂、低光泽的技术,应用在低光泽耐热ABS树脂组合物及其制备领域,能够解决力学性能恶化、光泽度不够低、分布不均匀等问题,达到促进光泽度的降低、表面柔和、光泽度超低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

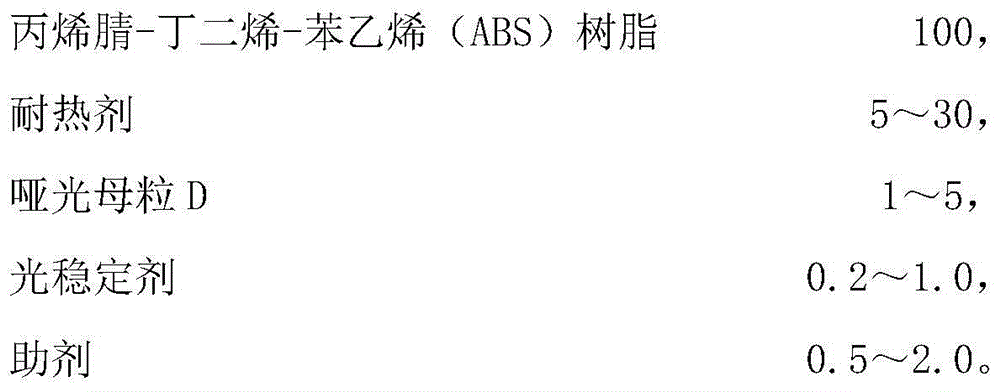

[0039] This embodiment relates to a low-gloss heat-resistant ABS resin composition and a preparation method thereof, which are specifically described as follows.

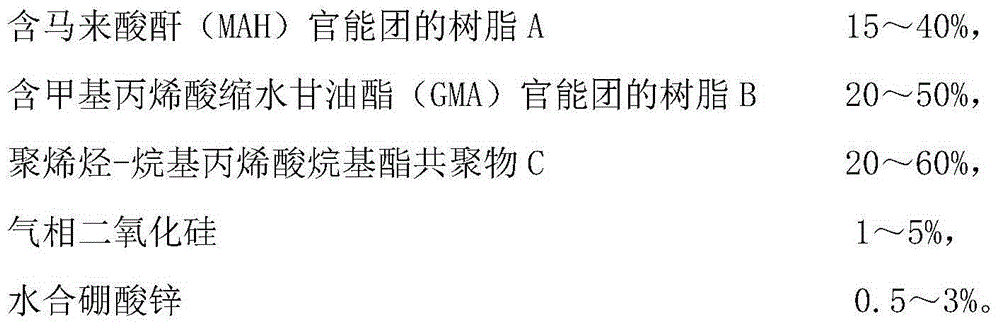

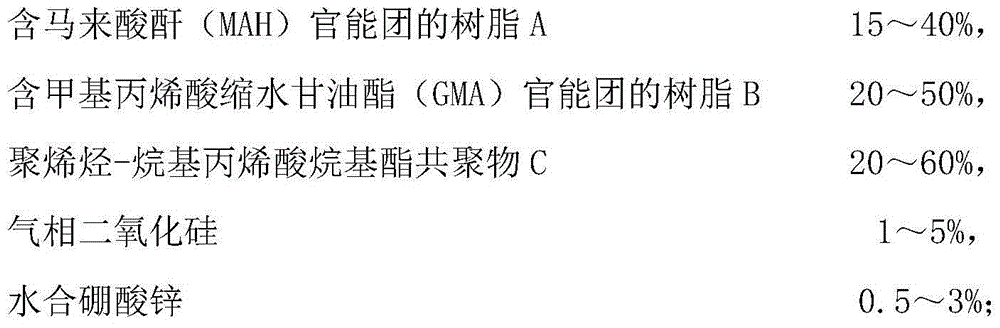

[0040] 1. Preparation of matte masterbatch D (see Table 1 for components and weight content):

[0041] Resin A containing maleic anhydride (MAH) functional group, resin B containing glycidyl methacrylate (GMA) functional group, polyolefin-alkyl acrylate copolymer C, fumed silica, zinc borate hydrate and Antioxidant B9000.3phr and lubricant EBS 1.0phr are fully stirred and mixed in a high-speed mixer, and then sent into a twin-screw extruder through a metering device. Under the conveying, shearing and mixing of the screws, the materials are melted and compounded. Then through the steps of extruding, drawing, cooling and pelletizing, matt masterbatches D1-D8 with uniform particle size are obtained.

[0042] The aspect ratio of the screw of the twin-screw extruder is 40, the temperature of the front section is 200-230...

Embodiment 2~6

[0056] Embodiments 2-6 relate to the preparation of low-gloss heat-resistant ABS resin compositions, and the preparation method is the same as that of Embodiment 1. The components and parts by weight of the low-gloss heat-resistant ABS resin compositions corresponding to Examples 2-6 are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com