Permanent antistatic ABS (acrylonitrile butadiene styrene) flame-retardant material

A flame retardant material and antistatic technology, applied in the field of ABS materials, can solve the problems of long-term antistatic and flame retardant of office equipment, and achieve the effect of good processing performance and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

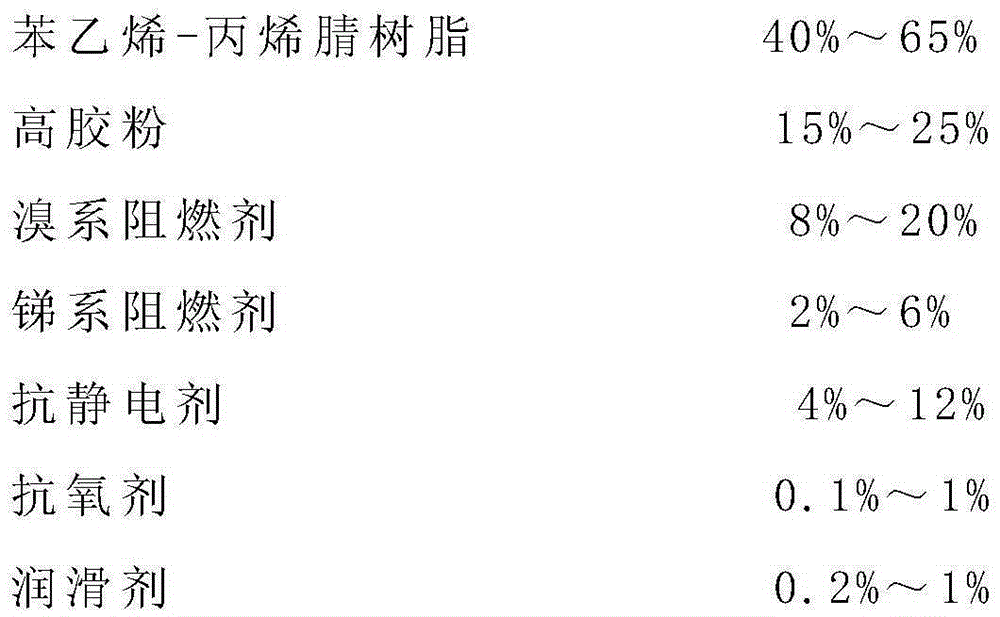

[0017] Embodiment 1: A permanent antistatic ABS flame retardant material, including styrene-acrylonitrile resin, high rubber powder, brominated flame retardant, antimony flame retardant, antistatic agent, antioxidant and lubricant, each The proportion of ingredients is:

[0018]

[0019] Wherein, the styrene-acrylonitrile resin is a SAN resin with a melt flow index greater than 2.5; the high rubber powder is butadiene, and the rubber content of the butadiene is 45%-65%. The brominated flame retardant is one of decabromodiphenylethane, tetrabromobisphenol A or bromotriazine. The antimony-based flame retardant is antimony trioxide or sodium antimonate. The antistatic agent is a polyether ester antistatic agent. The antioxidant is a compound of Ciba Irganox 1076 and Ciba Irgafos 168, and the ratio of the two is 1:2. Described lubricant is polyethylene wax or vinylbisstearamide.

Embodiment 2

[0020] Embodiment 2: A permanent antistatic ABS flame-retardant material. In this embodiment, 59 parts of styrene-acrylonitrile resin, 25 parts of high-grade rubber powder, 9 parts of brominated flame retardant, and 3 parts of antimony-based flame retardant are used. part, 4 parts of antistatic agent, 0.3 part of antioxidant and 0.5 part of lubricant to test the physical properties of ABS material. Under the standard of ISO527, the tensile strength is 35Mpa when the measurement speed is 50mm / min; Under the standard, the bending strength is 60 when the measuring speed is 2mm / min, and the Izod notched impact strength is 19KJ / m under the condition of 23°C under the ISO180 standard 2 , under the UL94 standard, the thickness is 1.6mm, the flame retardancy level is HB; under the GB / T1410 standard, the length is 100mm, the width is 80mm, the thickness is 3mm, and the surface resistance is 10 15 Ω.

Embodiment 3

[0021] Embodiment 3: A permanent antistatic ABS flame-retardant material. In this embodiment, 60 parts of styrene-acrylonitrile resin, 16 parts of high-grade rubber powder, 12 parts of brominated flame retardant, and 4 parts of antimony-based flame retardant are used. part, 8 parts of antistatic agent, 0.3 part of antioxidant and 0.5 part of lubricant to test the physical properties of ABS material. Under the standard of ISO527, the tensile strength is 42Mpa when the measuring speed is 50mm / min; Under the standard, the bending strength is 66 when the measuring speed is 2mm / min, and the Izod notched impact strength is 12KJ / m under the condition of 23°C under the ISO180 standard 2 , under the UL94 standard, the thickness is 1.6mm, the flame retardancy level is V1; under the GB / T1410 standard, the length is 100mm, the width is 80mm, the thickness is 3mm, and the surface resistance is 10 12 Ω.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Notched impact strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com