SEBS elastomer composite material for high-performance refrigerator sealing strip and preparation method thereof

A technology of composite materials and thermoplastic elastomers, which is applied in the field of preparation of SEBS elastomer composite materials, can solve the problems of reducing product quality and use value, and achieve the effects of shortening welding time, simple preparation process, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11

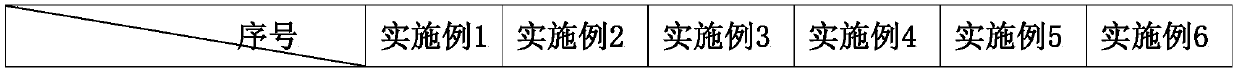

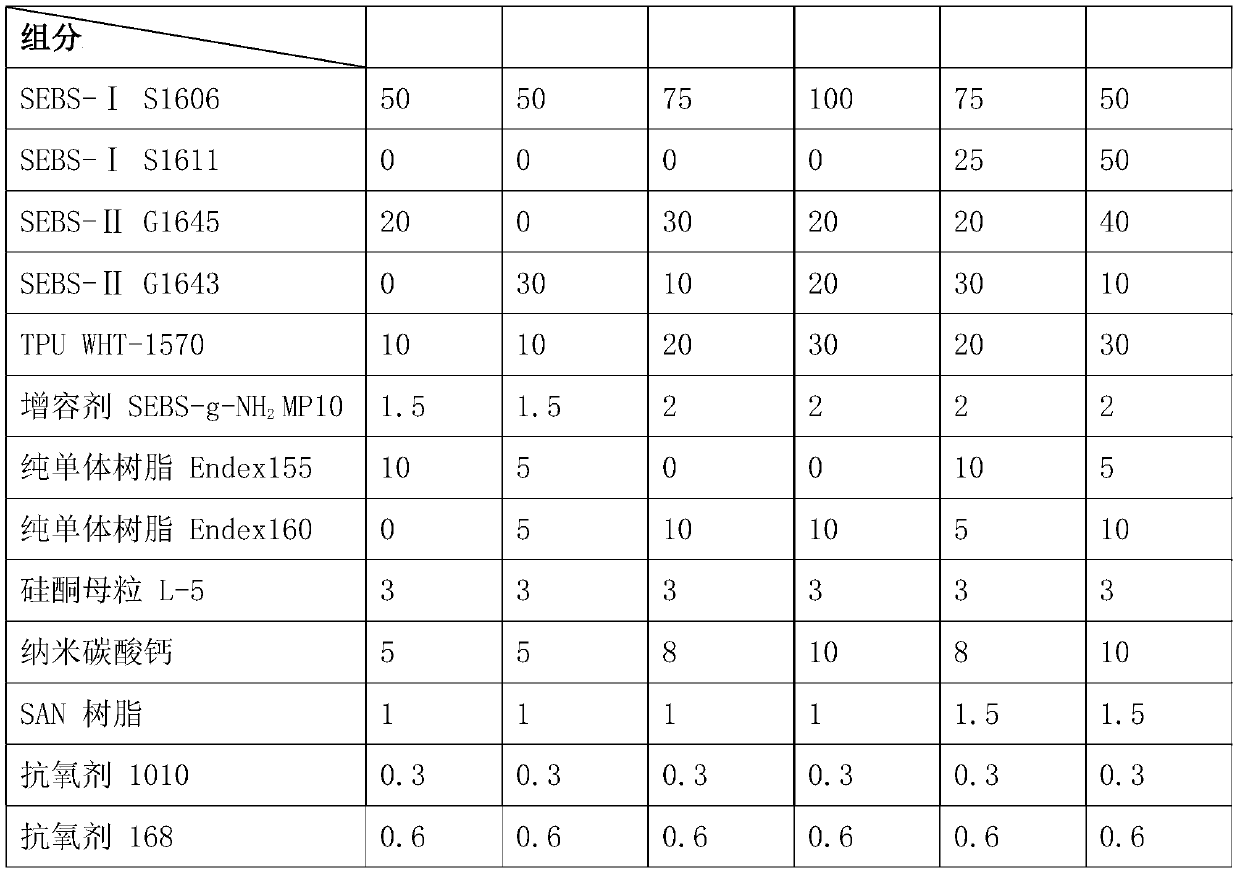

[0032] Embodiments 1 to 11: A SEBS elastomer composite material for a high-performance refrigerator sealing strip, the composition and parts by weight of its raw materials are as follows in Table 1 and Table 2:

Embodiment 1~6

[0034]

[0035]

Embodiment 7~11

[0037]

[0038]

[0039] A high-performance refrigerator sealing strip SEBS elastomer composite material, its preparation method is as follows:

[0040] The raw material components SEBS-I, SEBS-II, TPU, compatibilizer SEBS-g-NH 2 , pure monomer resin, silicone masterbatch, nano-calcium carbonate, SAN resin and antioxidant are added to the mixer in sequence, and mixed at a high speed at 60°C for 5-8 minutes to obtain a mixed material;

[0041] The above-mentioned mixed material is fed into a twin-screw extruder, melted, mixed, extruded and granulated to prepare a high-performance SEBS elastomer material for refrigerator sealing strips. Its technological conditions are as shown in table 3:

[0042] table 3:

[0043]

[0044] Table 4, the raw material composition and parts by weight of Comparative Examples 1 to 4 are as follows:

[0045]

[0046] The preparation method of the above comparative examples 1-4 adopts the same preparation method as the embodiment.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com