Patents

Literature

259 results about "Polycarbonic acid" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

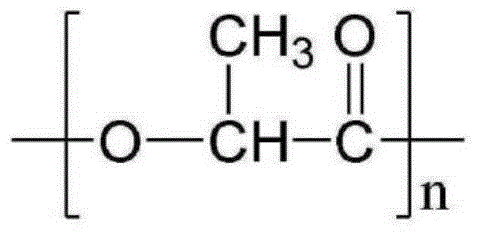

Full-biodegradable film and preparation method thereof

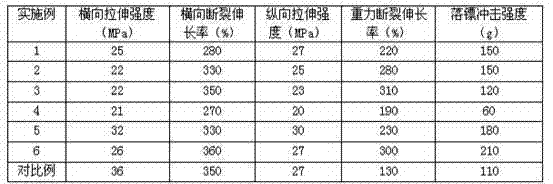

The invention relates to a composition of a high-tenacity full-biodegradable film and a preparation method thereof. The film is prepared from polylactic acid (PLA), poly propylene carbonate (PPC), polybutylene adipate terephthalate (PBAT) and a heat stabilizer. Blending modification sections are prepared by adopting a twin-screw extruder, blow molding is carried out by adopting a single-screw extruder, the prepared film has excellent tenacity and full biodegradable performance, and meanwhile the cost is low, so that the film is an ideal substitute for a current non-degradable film packing material.

Owner:NANTONG LONGDA BIO TECH NEW MATERIALS CO LTD

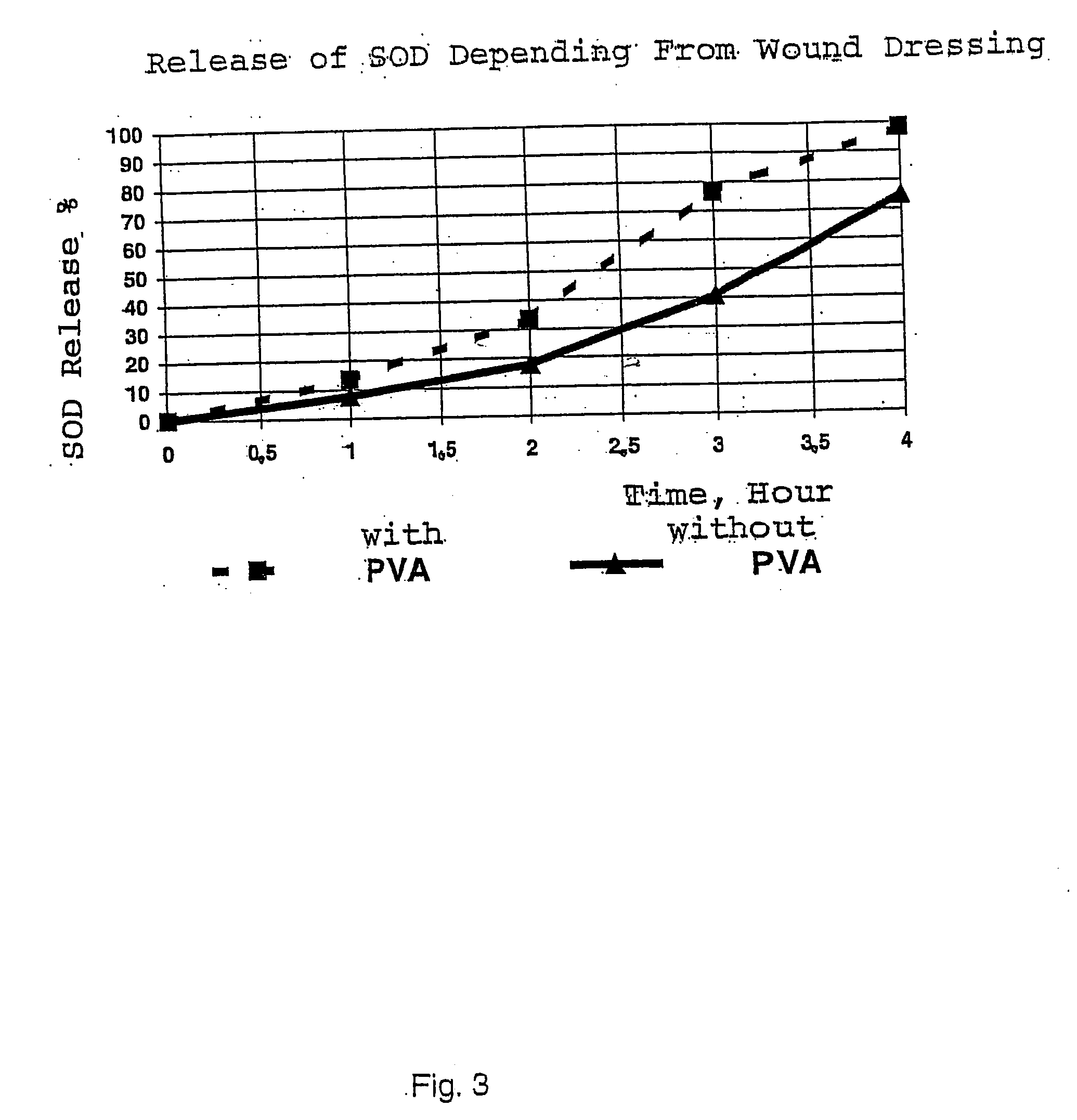

Therapeutically active dressings, their manufacture and use

The invention relates to therapeutically active wound dressings based on polysaccharides, in particular chitosan, and protein, in particular collagen / gelatine, with improved properties, their manufacture, in particular the use of polycarbonic acids and polyfunctional amino acids, and their use, especially in the medical field.

Owner:SANGUIBIOTECH

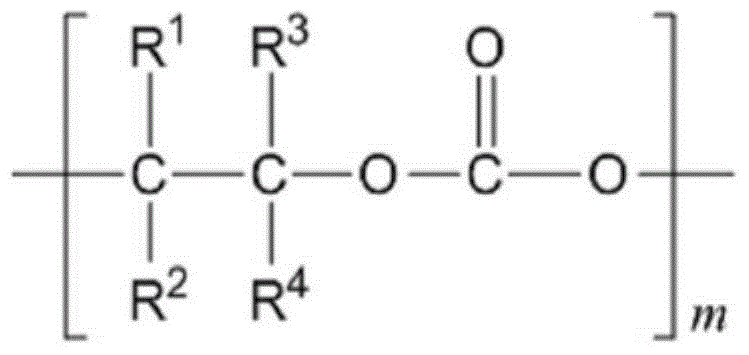

Polymer blends

ActiveUS20130209775A1High elongationSynthetic resin layered productsThin material handlingPolyolefinPolymer science

The present invention provides, among other things, extruded blends of aliphatic polycarbonates and polyolefins. In one aspect, provided blends comprise aliphatic polycarbonates such as poly(propylene carbonate) and a lesser amount of a crystalline or semicrystalline polymer. In certain embodiments, provided blends are characterized in that they exhibit unexpected improvements in their elongation properties. In another aspect, the invention provides methods of making such materials and applications of the materials in applications such as the manufacture of consumer packaging materials.

Owner:NOVOMER INC

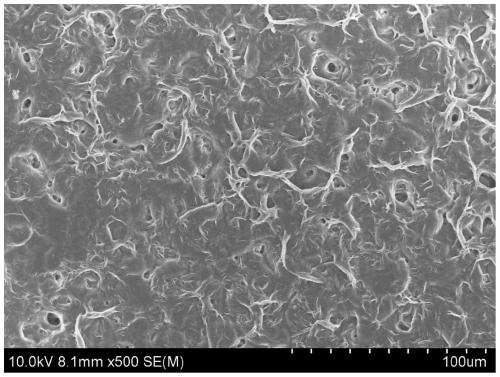

Wholly-degradable poly(propylene carbonate) compound film material and preparation thereof

The invention discloses a completely-degradable poly (propylene carbonate) composite film material and a preparation method thereof. The composite film material is formed by blending and compounding poly (propylene carbonate) with polylactic acid, wherein the content of the polylactic acid is between 10 and 50 weight percent, and the content of the poly (propylene carbonate) is between 50 and 90 weight percent. The preparation method comprises the following steps that: the poly (propylene carbonate) and the polylactic acid are respectively dissolved in organic solvents and made into solutions; the two solutions are well mixed pro rata and volatilized at room temperature so as to eliminate most of the solvents, and then mixed liquid is cast in a plate glass mold; and after the mixed liquid is vacuum-dried to constant mass, a PPC-PLA composite film material can be obtained. The composite film material provided by the invention obviously improves the properties of the poly (propylene carbonate), effectively solves the increasingly serious white pollution problem, and has important significance for ecological environment protection. The preparation method is simple in process, convenient to operate, easy to realize, low in equipment dependence and little in material consumption.

Owner:HAINAN UNIVERSITY

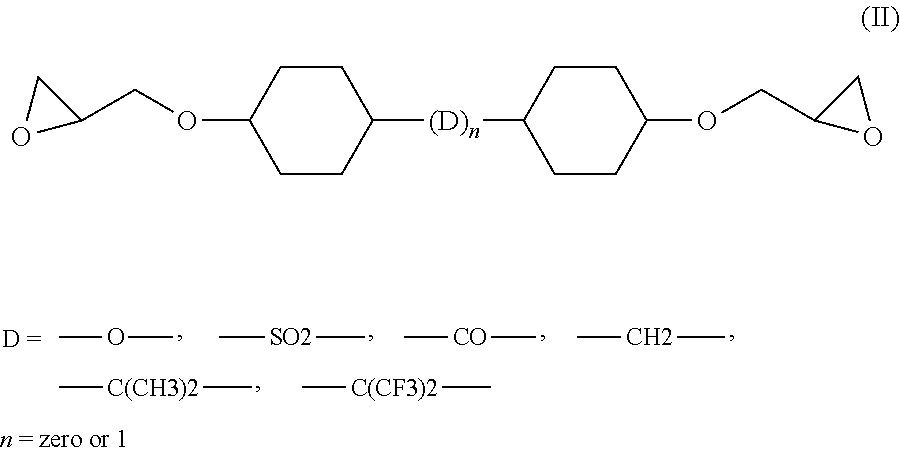

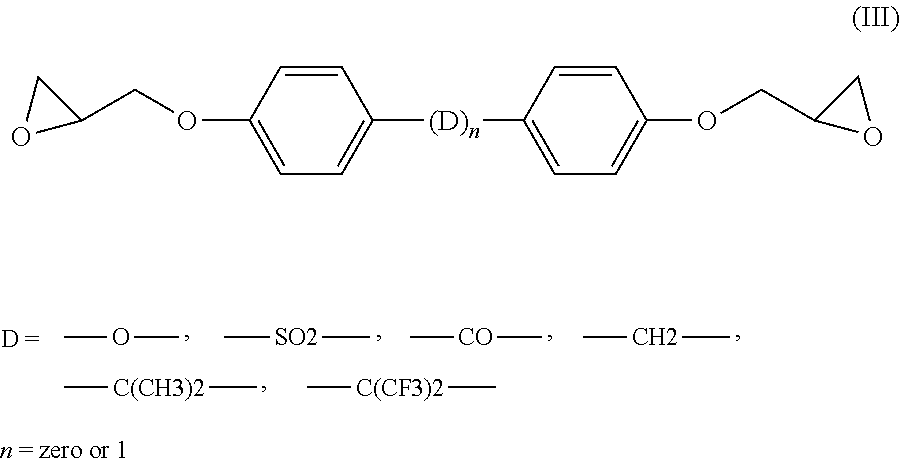

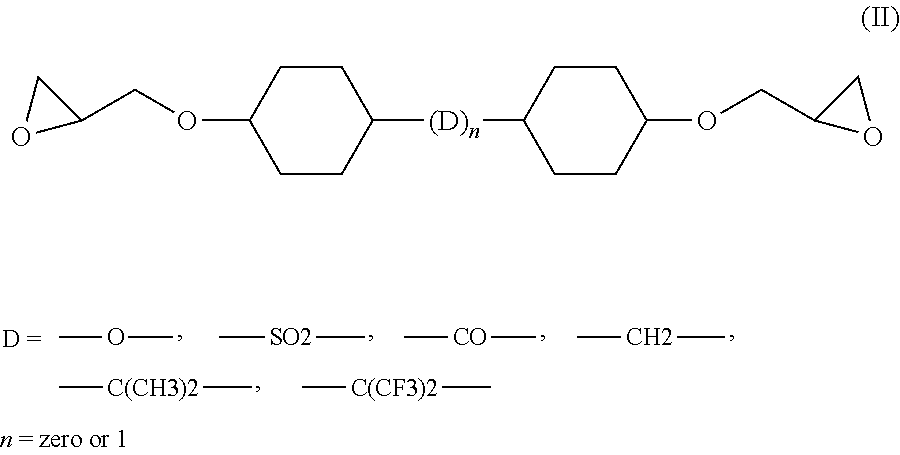

Curable epoxy resin composition

InactiveUS20120202918A1Low costImprove performancePlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsEpoxyChemistry

A curable epoxy resin composition including at least an epoxy resin component and a hardener component, and optionally further additives, wherein: (a) the epoxy resin component is an epoxy resin compound or a mixture of such compounds; (b) the hardener component includes (b1) an aliphatic and cycloaliphatic or aromatic polycarbonic acid anhydride; and (b2) a polyether-amine of the general formula (I), H2N—(CnH2n—O)m—CnH2n—NH2, wherein n is an integer from 2 to 8; and m is from about 3 to about 100; (c) the polycarbonic acid anhydride [component (b1)] is present in the curable epoxy resin composition in a concentration of 0.60 Mol to 0.93 Mol; and (d) the polyether-amine of the general formula (I) [component (b2)] is present in the curable epoxy resin composition in a concentration of about 0.02 Mol to about 0.1 Mol.

Owner:ABB RES LTD

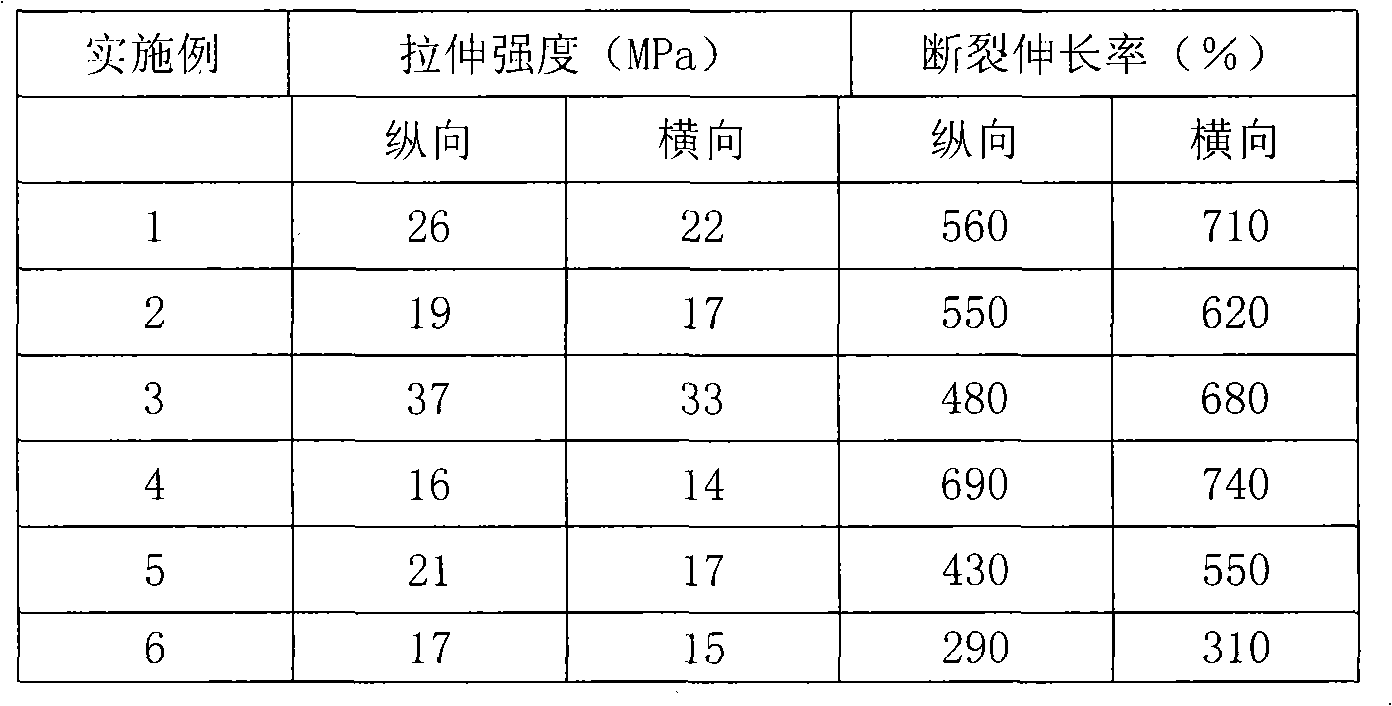

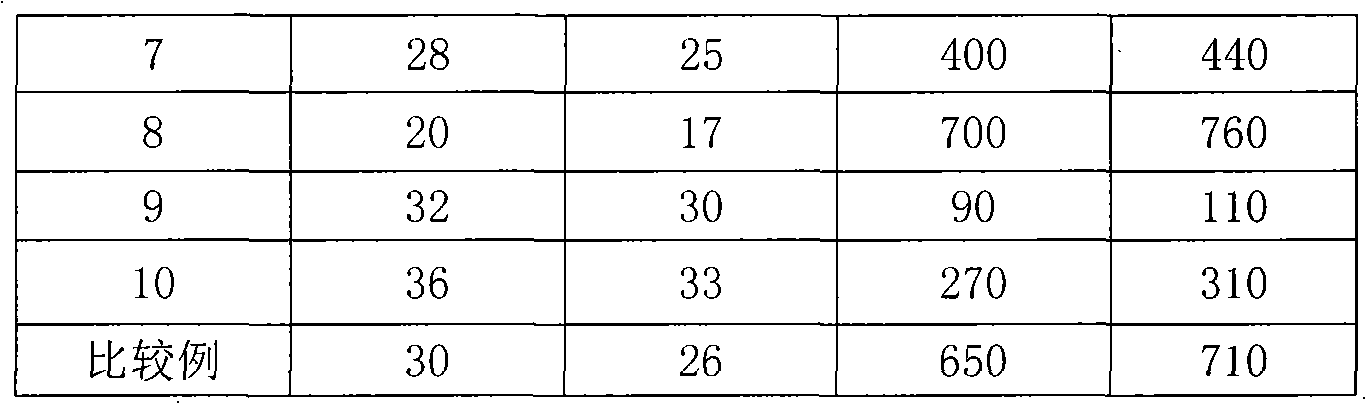

Full-biodegradable film with poly-carbonic acid 1,2-propylene diester as substrate and production method thereof

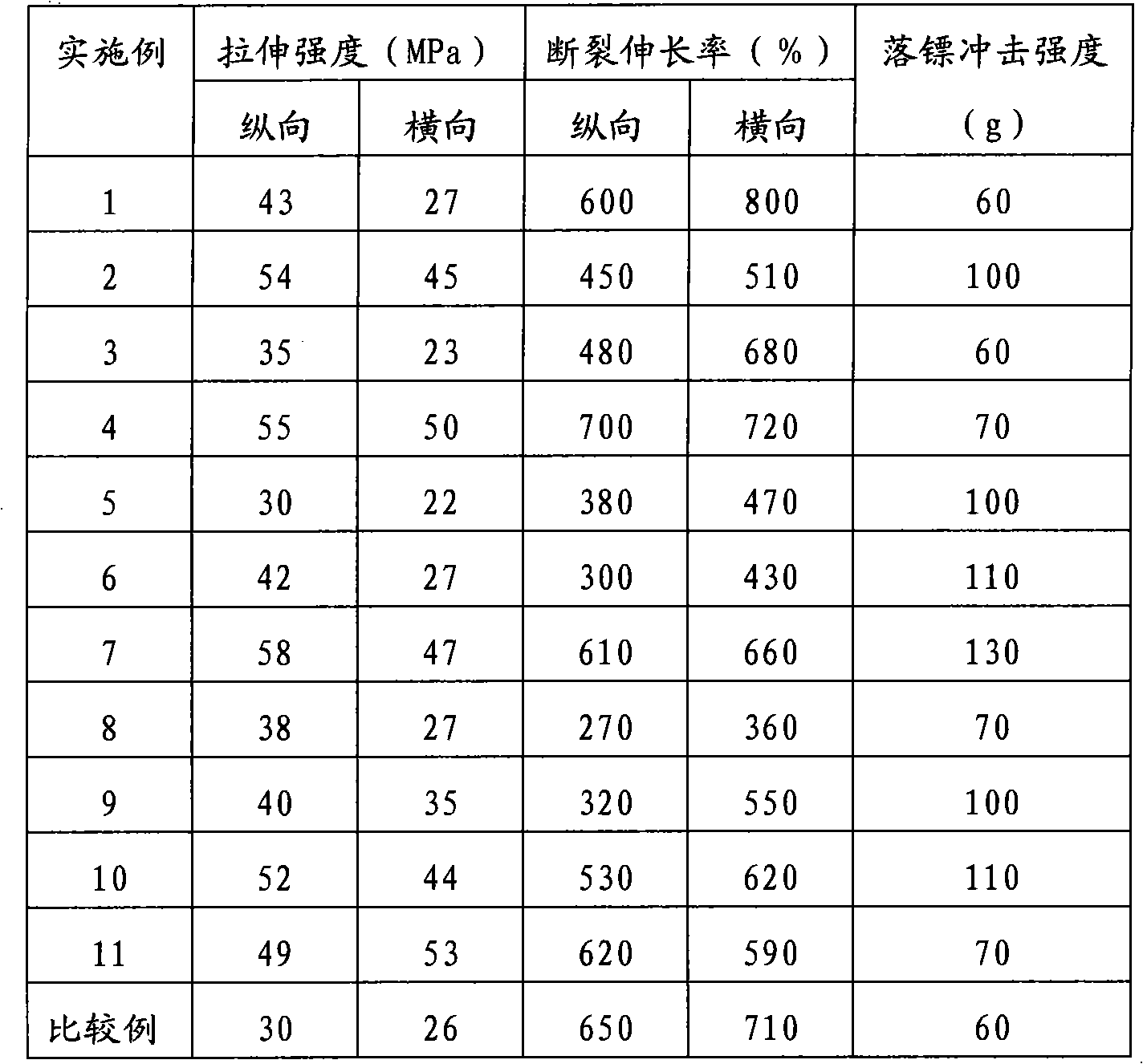

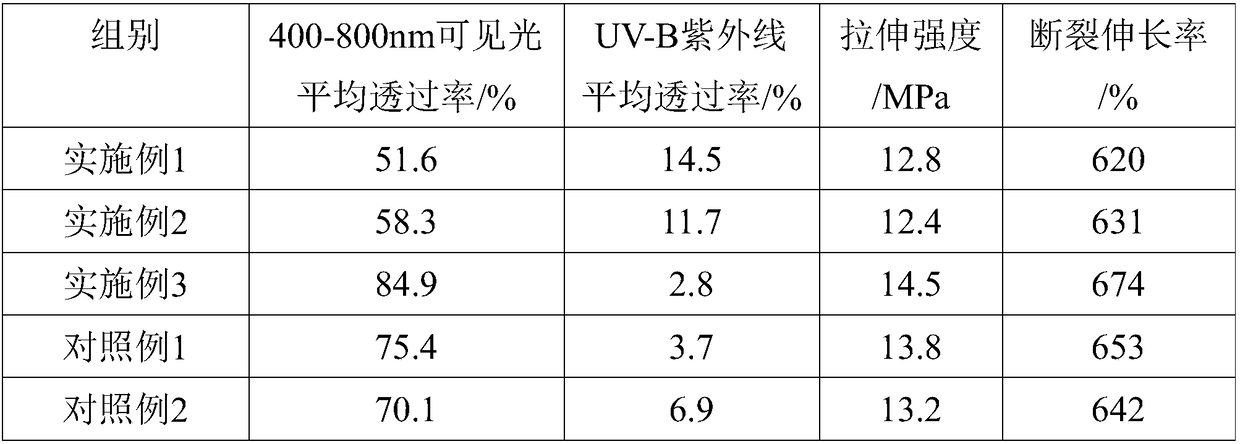

The invention relates to a biodegradation thin film which takes poly (propylene carbonate) as matrix and a preparation method thereof. The thin film takes biodegradation poly (propylene carbonate) as matrix and is blended with biodegradation polyester and an auxiliary agent which can be in contact with food directly to prepare a special material for blown film. If a blown film is produced by common blown film equipment, the mechanical property of the film is close to that of linear low density polyethylene. The tensile strength and the elongation at break of the biodegradation thin film provided by the invention can respectively reach as high as 37MPa and 680 percent; and the tensile strength and the elongation at break of the linear low density polyethylene sold on markets are respectively 30MPa and 710 percent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Biodegradable film containing aliphatic polycarbonate and preparation method thereof

InactiveCN101857718ABiodegradableRaise the processing temperatureFlat articlesPolymer scienceButanedioic acid

The invention, which belongs to the technical field of biodegradable films, relates to a biodegradable film containing aliphatic polycarbonate. The biodegradable film is characterized in that the biodegradable film consists of the following components in part by weight: 30 to 60 parts of polycarbonate1, 2-malonic ester; 40 to 70 parts of one or the mixture of poly(butanediol succinate) and poly(butanediol succinate / adipate) copolyester; 5 to 15 parts of toughening agent; 0.5 to 5 parts of plasticizer; 0.5 to 3 parts of heat stabilizer; and 1 to 40 parts of inorganic filler. The prepared film is biodegradable, and can be directly contacted with food. By adding the heat stabilizer, the thermolysis of bend is inhibited, so that the processing temperature of the film can be increased to 190 DEG C; by adding the toughening agent and the plasticizer, the impact resistance of the finished film product is enhanced, the maximum dart drop impact on the film with the thickness of 20Mum can be up to 130g, the tensile strength is higher than 50MPa, the elongation at break is higher than 600 percent, and therefore the film can fully meet the requirements of ordinary packaging materials.

Owner:NANTONG HUASHENG PLASTIC PRODS +1

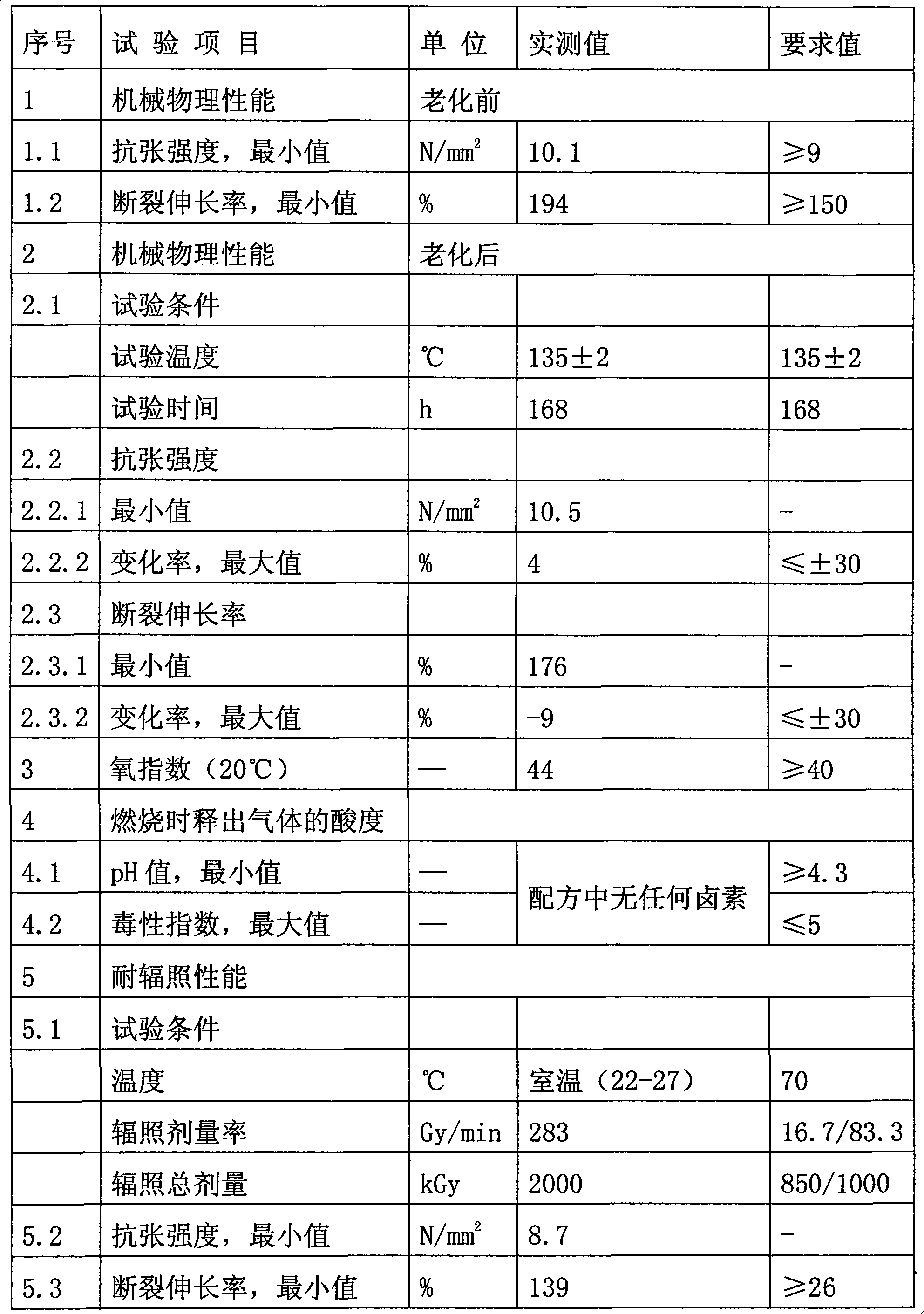

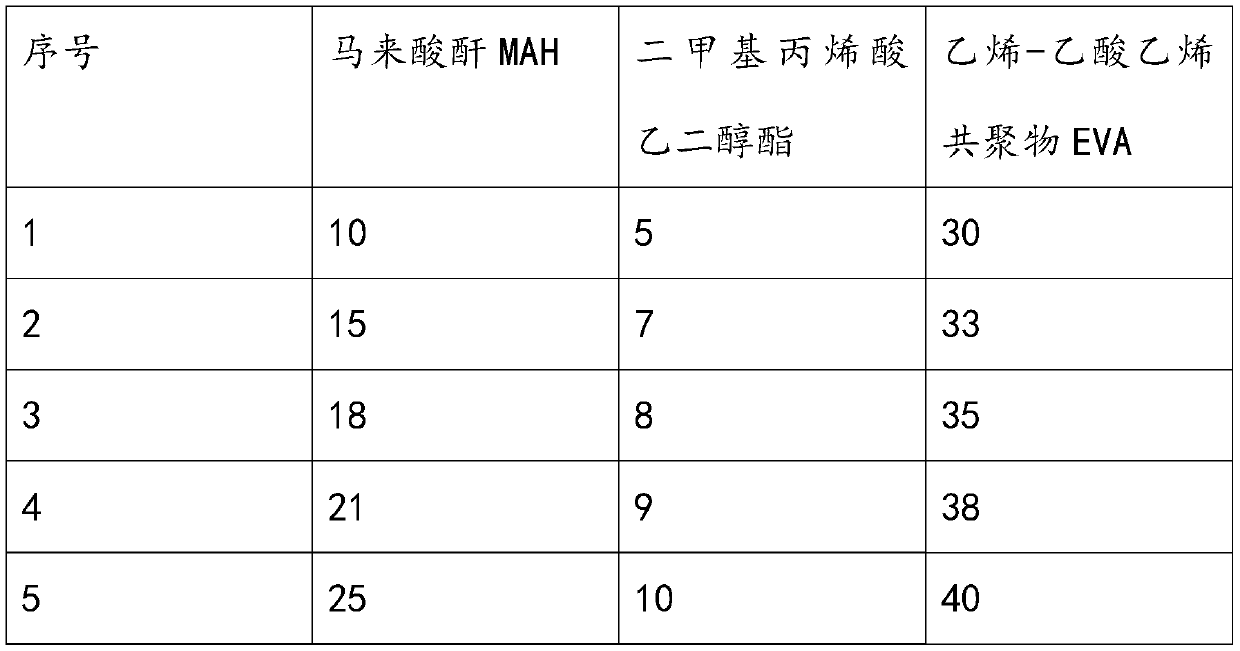

Irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and preparation method

ActiveCN101597397AImprove radiation resistanceThe ratio is scientific and reasonableInsulated cablesInsulated conductorsDi-tert-butyl peroxideNuclear power

The invention discloses an irradiation resistant non-halogen low smoke flame-retardant sheathing material applied to nuclear power stations and a preparation method. The raw materials comprises ethane-vinyl acetate rubber, maleic anhydride stem grafting ethane-vinyl acetate rubber, magnesium hydroxide fire retardant, organic silicon fire retardant, nano cerium oxide, FEF, zinc stearate, stearic acid, vinyl trisilane, Aflux A-16, Aflux A-25, polycarbonate diimine(PCD-50), 2, 2, 4-trimethyl-1, 2-dihydride quinoline, antiager DDA, di-tert-butyl peroxide cumene, triene propylcyanide uric acid ester and decanedioic acid dioctyl, which are heated and mixed to obtain the materials of the invention. The invention features scientific and reasonable formula and proportion, and the process is advanced. The sheathing material features fine irradiation resistance, excellent mechanical properties and long service life, thus being a good irradiation resistant non-halogen low smoke and flame-retardant sheathing material applied to nuclear power stations.

Owner:BAOSHENG SCI & TECH INNOVATION

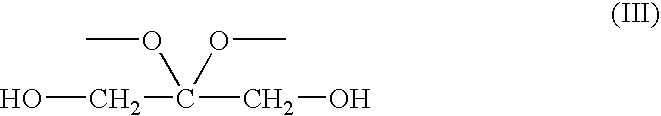

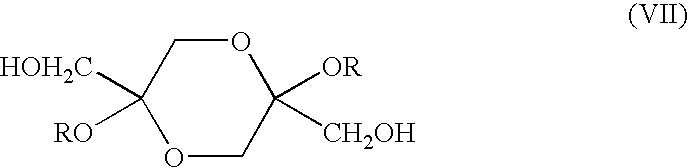

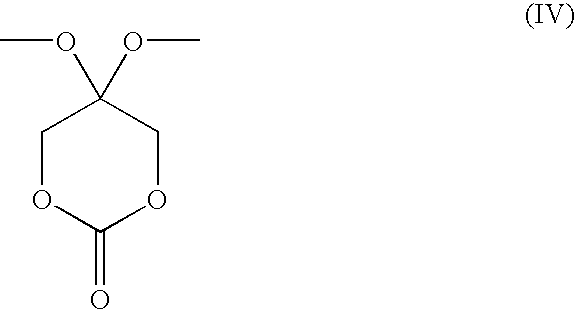

Dihydroxyacetone-Based Polymers

Chemically protected dihydroxyacetone and / or dimers are used to make polycarbonates, poly(acetal carbonate)s, poly(spiroacetal)s, polyesters and polyurethanes.

Owner:CORNELL RES FOUNDATION INC

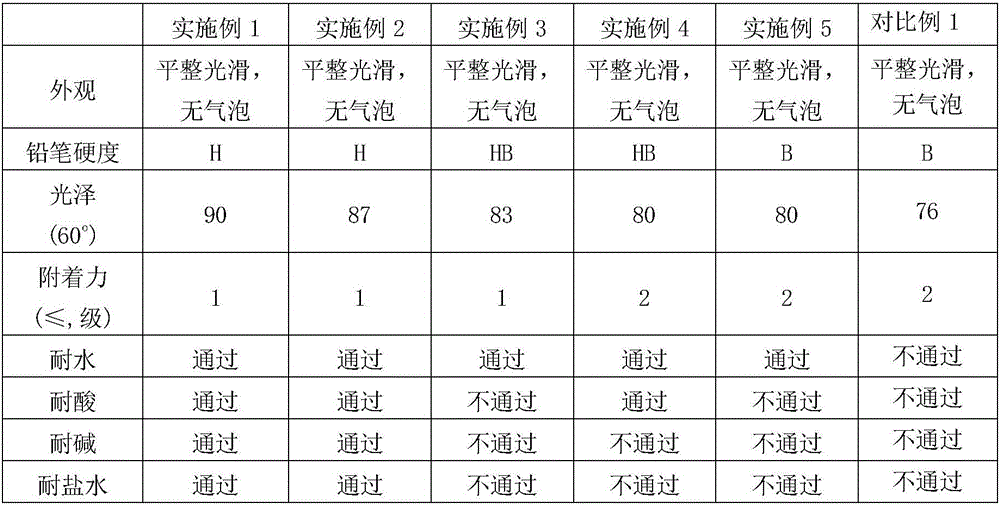

Preparation method and application of high-solid-content water-based polyurethane resin and coating thereof

ActiveCN106750130AHigh hardnessImprove performancePolyurea/polyurethane coatingsWater basedPolymer science

The invention discloses a preparation method and application of high-solid-content water-based polyurethane resin and coating thereof. The preparation method comprises the following steps: reacting poly (propylene carbonate) polyols or a mixture of poly (propylene carbonate) polyols and other conventional polypolyols with isocyanate, a chain extender, a crosslinking agent, a catalyst and a sulfonic acid type hydrophilic chain extender, adding water to perform emulsification, and removing a solvent to obtain the high-solid-content water-based polyurethane resin; adding aids such as a leveling agent, a thickening agent, color paste, an environment-friendly cosolvent and a defoaming agent to obtain high-solid-content water-based polyurethane resin coating prepared from the poly(propylene carbonate)polyols. Film-forming and drying speed is high, plumpness is high, and high adhesive force, hardness, water resistance and solvent resistance are achieved.

Owner:JIANGSU ZHONGKE JINLONG CHEM

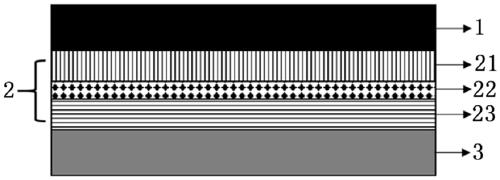

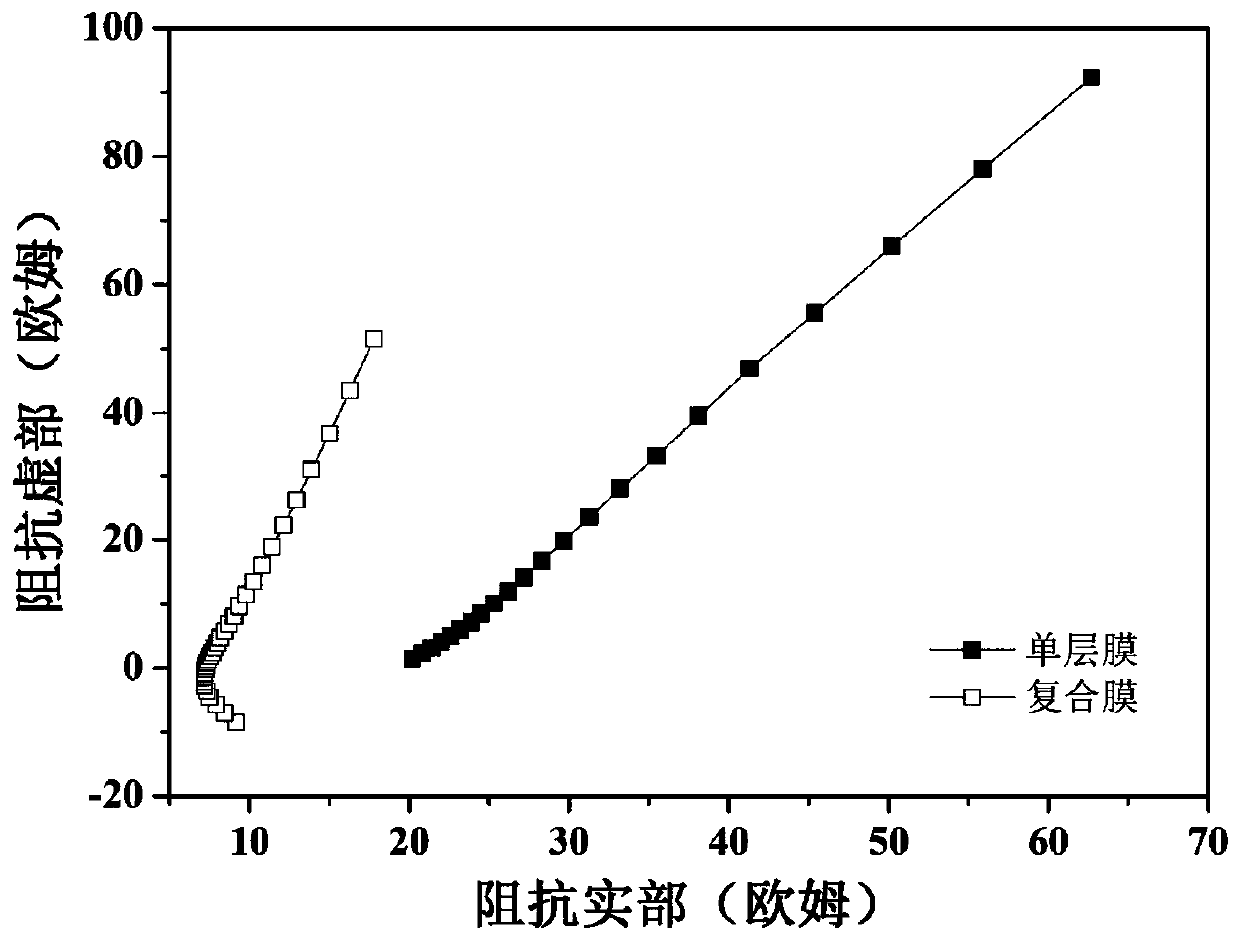

Composite solid-state electrolyte membrane, preparation method and solid-state lithium battery

InactiveCN111430788AImprove cycle stabilityImprove capacity playMaterial nanotechnologySolid electrolytesSolid state electrolytePolyvinyl chloride

The invention discloses a composite solid-state electrolyte membrane, a preparation method and a solid-state lithium battery. The composite solid-state electrolyte membrane comprises a support membrane, an organic-inorganic composite coating A coated on the surface of the positive electrode side of the support membrane, and an organic-inorganic composite coating B coated on the surface of the negative electrode side of the support membrane, wherein the coating A comprises an organic polymer A, a lithium salt and a nano inorganic solid electrolyte, and the organic polymer A is one or more thantwo of polyvinylidene fluoride, a polyvinylidene fluoride copolymer, polyacrylonitrile and polyvinyl chloride; the coating B comprises an organic polymer B, a lithium salt and a nano inorganic solid electrolyte; and the organic polymer B is one or more than two of polyoxyethylene, polypropylene carbonate, polycarbonate and poly trimethylene carbonate. Aiming at different requirements of positive and negative electrode layers in the solid-state lithium battery on the electrolyte membranes, the graphene oxide membrane is used as a support, and the electrolyte membranes containing different polymer groups are designed on the two sides of the graphene oxide membrane respectively so that the comprehensive performance of the battery is further improved.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

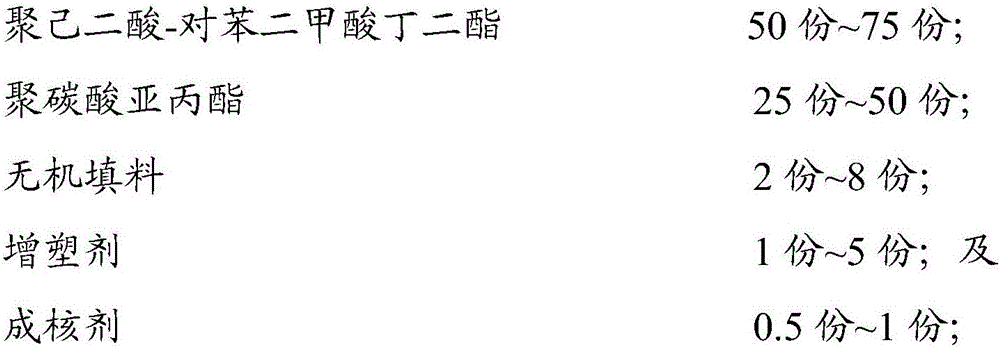

Biodegradable material and preparation method thereof

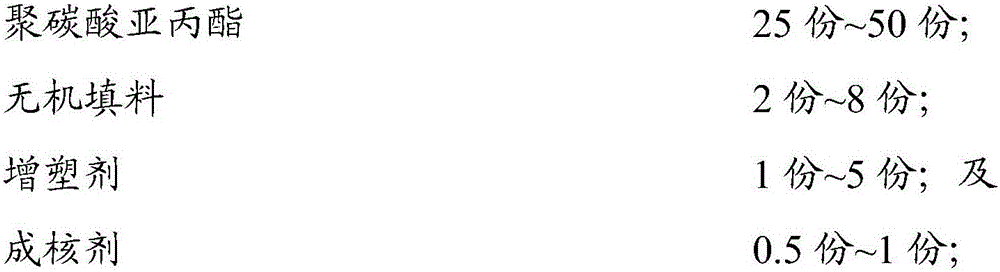

The invention relates to a biodegradable material and a preparation method thereof. The biodegradable material comprises, by weight, 50-75 parts of poly(butyleneadipate-co-terephthalate), 25-50 parts of polypropylene carbonate, 2-8 parts of inorganic filler, 1-5 parts of plasticizers and 0.5-1 part of nucleating agents, wherein the inorganic filler is selected from at least one of montmorillonite, talcum powder, mica and nano-Al2O3. The biodegradable material is capable of blocking off water vapor effectively.

Owner:SHENZHEN PRINCE NEW MATERIALS CO LTD

Biodegradable polylactic acid agricultural mulching film and processing technology thereof

ActiveCN108690336AStrong environmental protectionEasy to useClimate change adaptationPlant protective coveringsCyclodextrinBiology

The invention discloses a biodegradable polylactic acid agricultural mulching film and a processing technology thereof, and relates to the technical field of agricultural mulching films. The biodegradable polylactic acid agricultural mulching film is prepared from the following raw materials in parts by weight: 100-120 parts of polylactic resin, 15-30 parts of light calcium carbonate, 5-10 parts of polypropylene carbonate, 5-10 parts of carboxymethyl-beta-cyclodextrin, 1-5 parts of PEG-60 hydrogenated castor oil, 1-5 parts of hexakis(methoxymethyl)melamine, 1-5 parts of ultraviolet screening agent and 0.5-2 parts of antioxidant. According to the biodegradable polylactic acid agricultural mulching film and the processing technology thereof, the polylactic acid film is prepared by taking thepolylactic resin as a main material and co-taking a plurality of auxiliary materials, and the prepared polylactic acid film belongs to the biodegradable film and is non-toxic, harmless and strong inuse environmental protection property; and in addition, the usability is excellent, and the use requirement of the agricultural mulching film is met.

Owner:湖北嘉鑫环保新材料科技有限公司

Biodegradable polyester/cellulose composite film blowing material and preparation method thereof

The invention relates to the field of composite materials, and provides a biodegradable polyester / cellulose composite film blowing material and a preparation method thereof, aiming at the problems ofpoor starch plasticizing effect, low material comprehensive performance and the like. According to a technical scheme, the material is prepared from the following raw materials in parts by weight: 35to 50 parts of poly(butylene adipate-co-terephthalate) (PBAT), 10 to 15 parts of polypropylene carbonate polyol (PPC), 0.01 to 0.03 part of a chain extender, 8 to 15 parts of polylactic acid (PLA), 25to 35 parts of starch, 20 to 25 parts of cellulose, 2 to 5 parts of a compatilizer, 1 to 3 parts of a stabilizer and 1 to 3 parts of an anti-aging agent. The material is simple in formula, good in compatibility and good in mechanical property, the plasticity and strength of the composite material are improved, the degradation property is excellent, and the environment is not polluted.

Owner:SHENZHEN HONGCAI NEW MATERIAL TECH

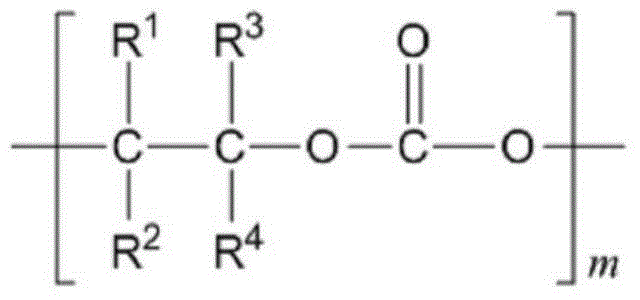

Resin composition containing polyalkylene carbonate

ActiveCN105051108AHigh transparencyPromote degradationSynthetic resin layered productsVehicle componentsPolyresinMechanical property

The present invention relates to a resin composition comprising polyalkylene carbonate, polylactide and polyalkyl(meth)acrylate, and exhibiting greatly improved degree of transparency while having excellent biodegradable properties, mechanical properties and thermal properties. The resin composition of the present invention can be used in various fields such as various films, sheets, disposable products, electronic products and automotive interior parts.

Owner:LG CHEM LTD

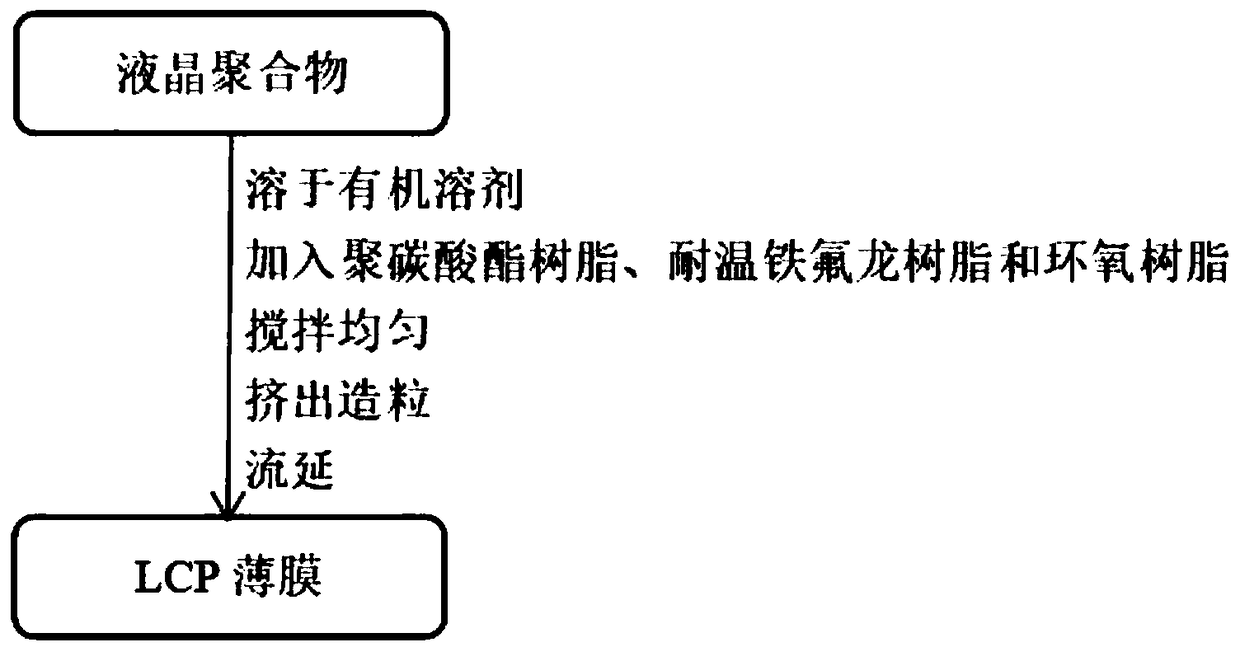

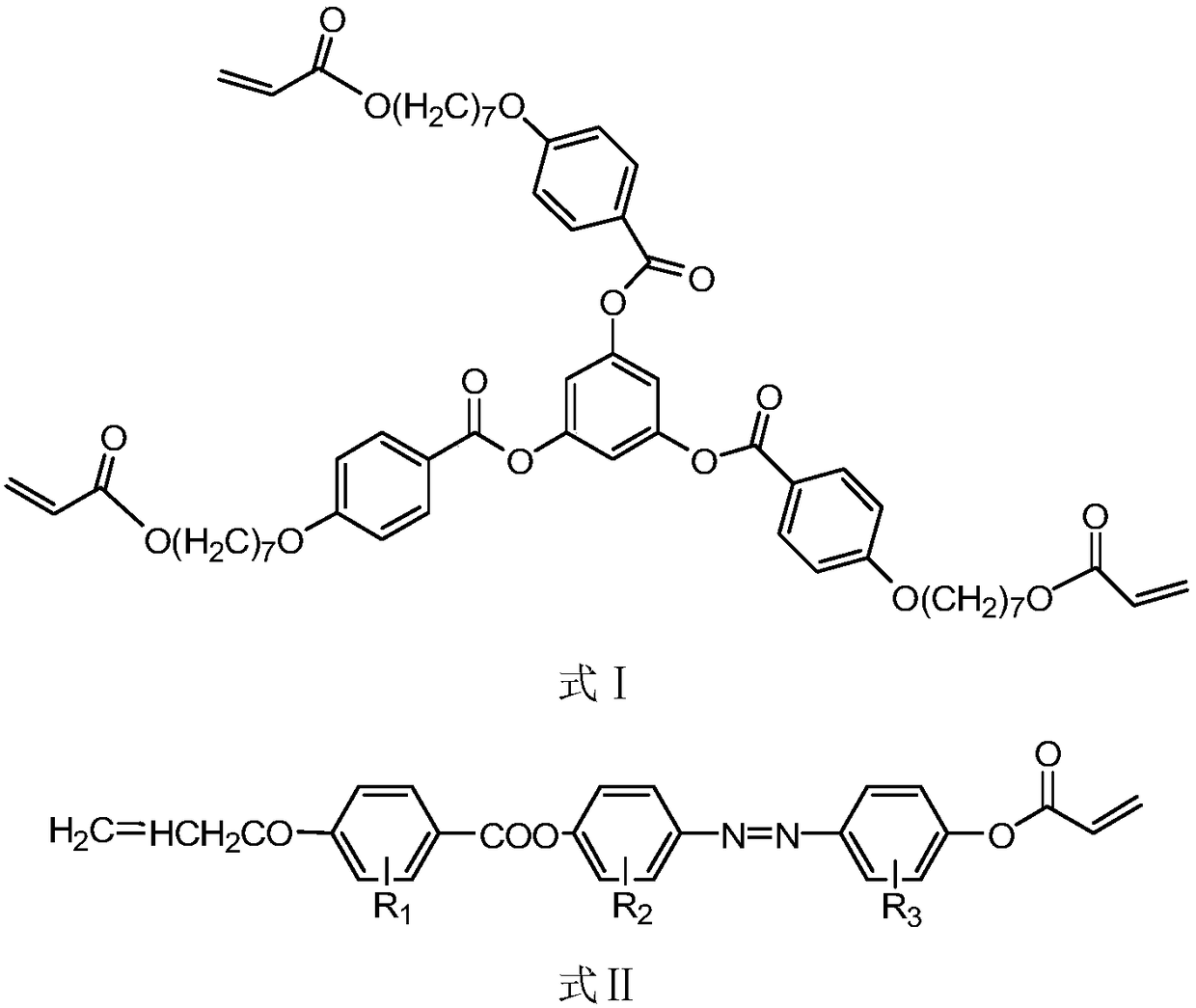

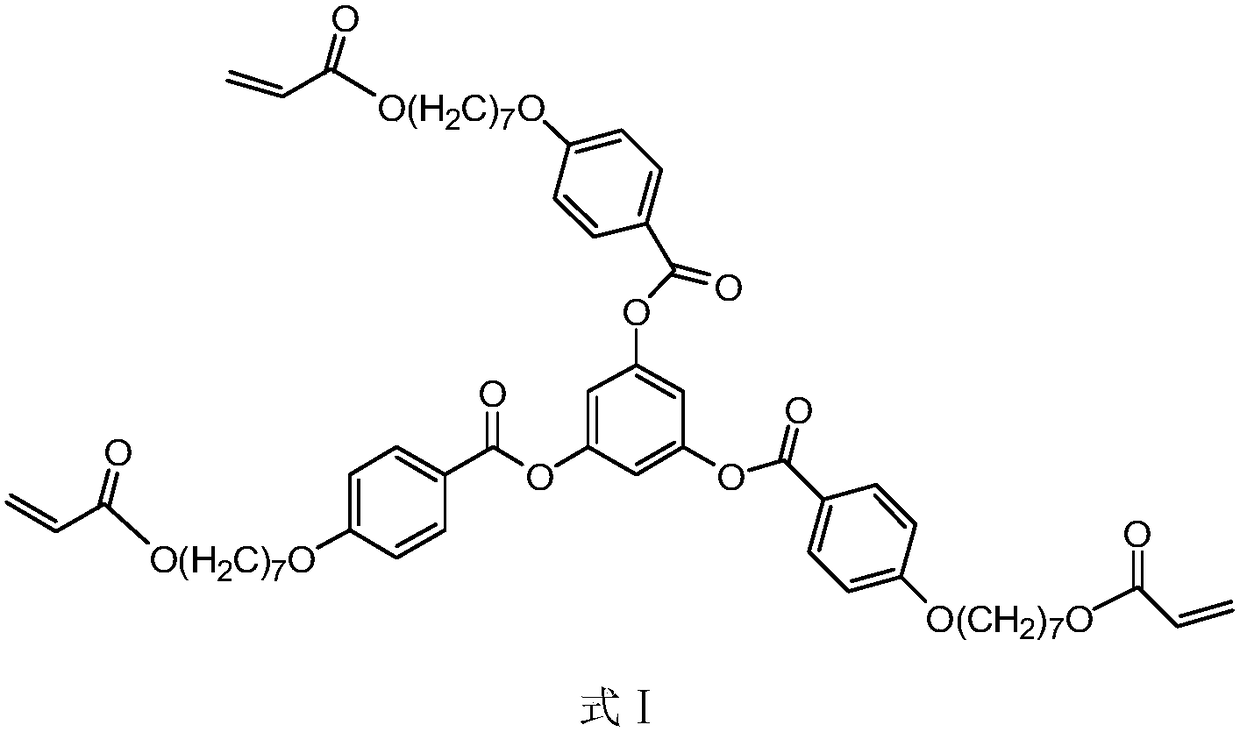

LCP film for FPC industry and preparation method thereof

The invention provides an LCP film for FPC industry and a preparation method thereof. The film is prepared from liquid crystal monomers shown as a formula I and a formula II. The preparation method comprises the following steps: pouring the liquid crystal monomers shown as the formula I and the formula II, a photoinitiator and an ultraviolet absorbent into a liquid crystal box, and inducing polymerization and exposure under ultraviolet light with the intensity of 2 mW / cm<2> and the wavelength of 365 nm at 95 DEG C for 30 min to obtain a liquid crystal polymer; dissolving the liquid crystal polymer in an organic solvent, sequentially adding polycarbonate resin, temperature-resistant Teflon resin and epoxy resin, stirring and mixing uniformly, transferring an obtained reaction liquid to a twin-screw extruder for extrusion granulation, and finally preparing dried particles into the LCP film according to a casting technology. The LCP film has low dielectric constant at high frequency, hasincreased signal transmission speed, and can be widely applied to 5G network.

Owner:苏州市新广益电子股份有限公司

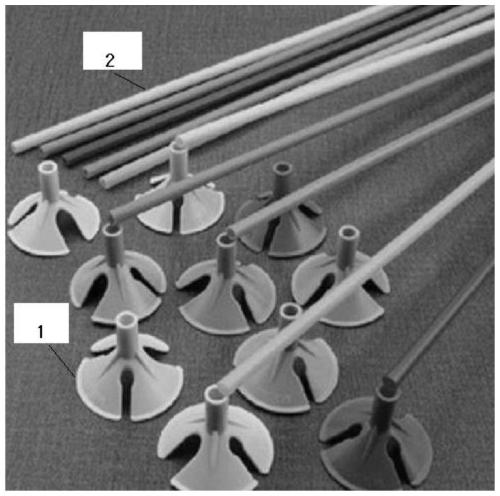

Full-biodegradable balloon bottom support and preparation method thereof

The invention provides a full-biodegradable balloon bottom support and a preparation method. The bottom support is prepared through extrusion and injection molding from the following materials: 70-90parts by mass of polylactic acid, 5-30 parts by mass of a toughening agent, 0-20 parts by mass of a filler, 0.1-2 parts by mass of a lubricant, and 0.1-1 part by mass of a compatibilizer, wherein thetoughening agent is selected from one or more of poly(butyleneadipate-co-terephthalate), polycaprolactone, polyhydroxyalkanoate, polypropylene carbonate, an acrylate degradable polymer and a maleic anhydride grafted degradable polymer, and the compatilizer is selected from one or more of a silane coupling agent, an aluminate substance and a titanate substance. The bottom support component not onlymeets the use requirements of the balloon bottom support, but also can realize complete biodegradation. Meanwhile, the process is simple, the cost is low, and the market competitiveness of the product is stronger.

Owner:海南明宸新材料有限公司 +1

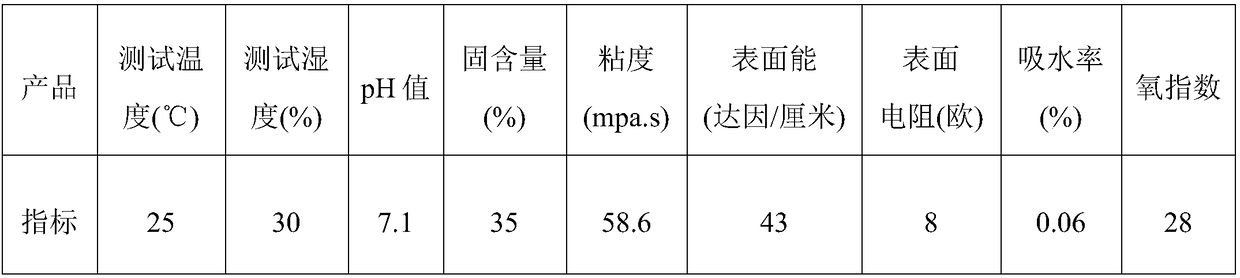

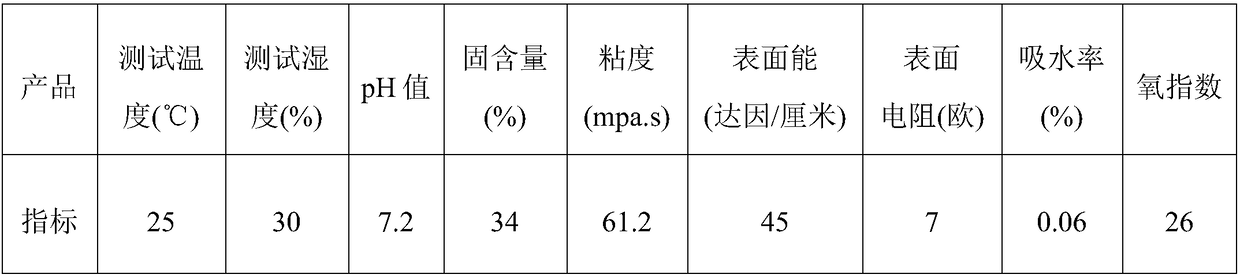

Multifunctional membrane coating liquid suitable for ink-jet and laser printing, and preparation method thereof

ActiveCN108912873AGood weather resistanceHigh peel strengthPolyurea/polyurethane coatingsLaser printingAntistatic agent

The invention discloses a multifunctional membrane coating liquid suitable for ink-jet and laser printing, and a preparation method thereof. The preparation method comprises following steps: firstly,isophorone diisocyanate and a polycarbonate diol are subjected to polymerization, an appropriate amount of a hydroxyl acrylate is added, chain propagation, neutralization, and emulsification are carried out so as to obtain a primarily modified aqueous polyurethane; polyvinyl alcohol solutions with different functions are prepared, and a mixed dispersion solution of silica and alumina is prepared,and at last, mixing with auxiliary agents such as a wetting agent, an anti-foaming agent, a thickening agent, and an antistatic agent is carried out so as to obtain the multifunctional membrane coating liquid suitable for ink-jet and laser printing. The preparation method is low in preparation cost and excellent in printing effect; the production technology is simple; the multifunctional membranecoating liquid is convenient for coating; the solid content is as high as 35%; the multifunctional membrane coating liquid is suitable for coating of a plurality of polyester or polyolefin membranes such as PET, PVC, and PETG membranes, and can be used for production of coated products with different functions.

Owner:JIANGSU HUAXIN NEW MATERIAL

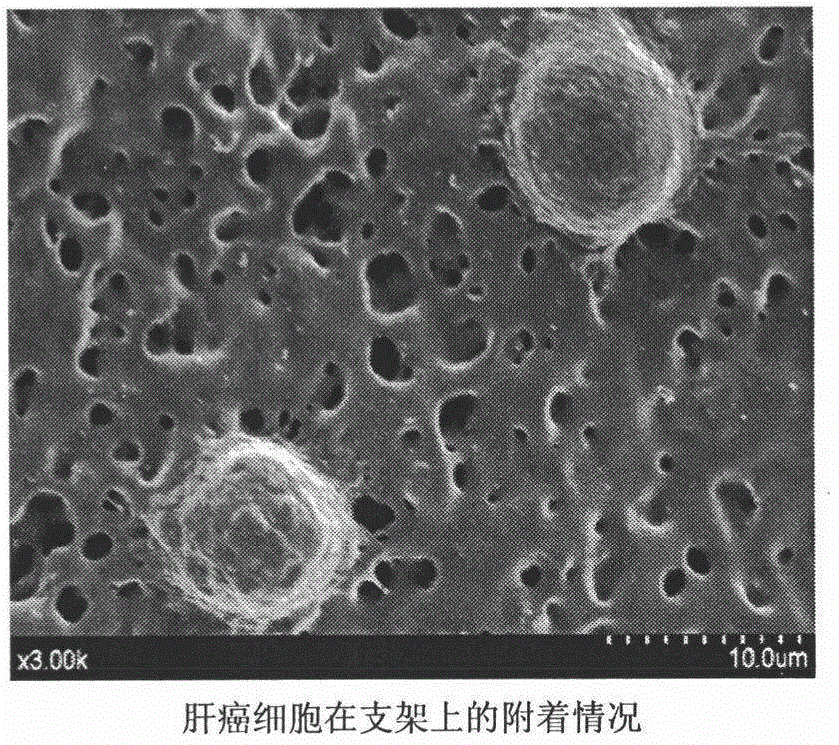

Novel construction method of biodegradable porous PHBV/PPC (poly (3-hydrobutyrate-3-hydroxyvalerate)/polypropylene carbonate) composite scaffold

InactiveCN105879111AImprove brittlenessAdjustable degradation performanceProsthesisPolypropylene carbonateChemistry

The invention discloses a construction method of a poly (3-hydrobutyrate-3-hydroxyvalerate) / polypropylene carbonate (PHBV-PPC) porous scaffold by virtue of a reactive melt blending-ultrasonic particulate leaching-alkali treatment technology. The construction method comprises the following steps: mixing MA (1-2%), DCP (0.1-0.5%) and the PPC at 130-160 DEG C by 30rpm, so that MA-terminated PPC (MA-PPC) is obtained; mixing the PHBV with GMA (1-15%) and DCP (0.1-0.5%) at 165-175 DEG C, so that GMA-modified PHBV is obtained; and conducting reactive blending and ultrasonic particulate leaching on the MA-PPC, the GMA-modified PHBV and NaCl at 165-175 DEG C, soaking in 1-2mol / L of NaOH for 60-120min, washing in water and freeze-drying. The constructed scaffold, applied to tissue repair, is expected to achieve popularization and application in the fields of bio-medical materials and ecological environmental protection.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

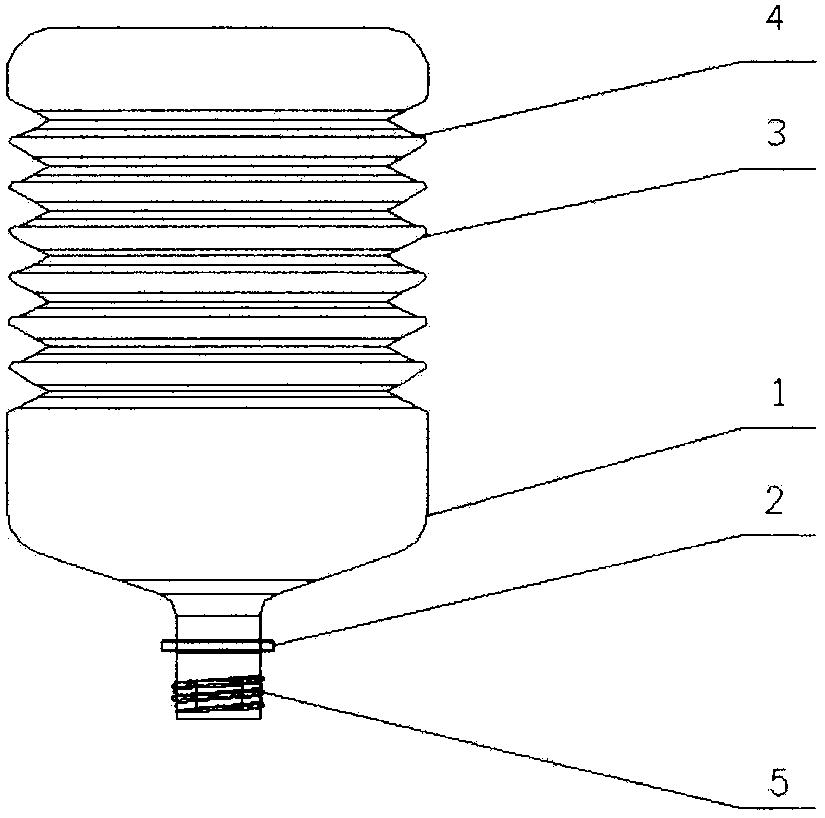

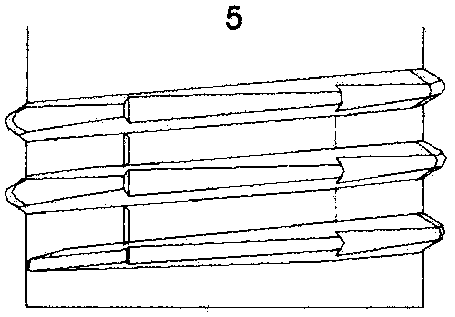

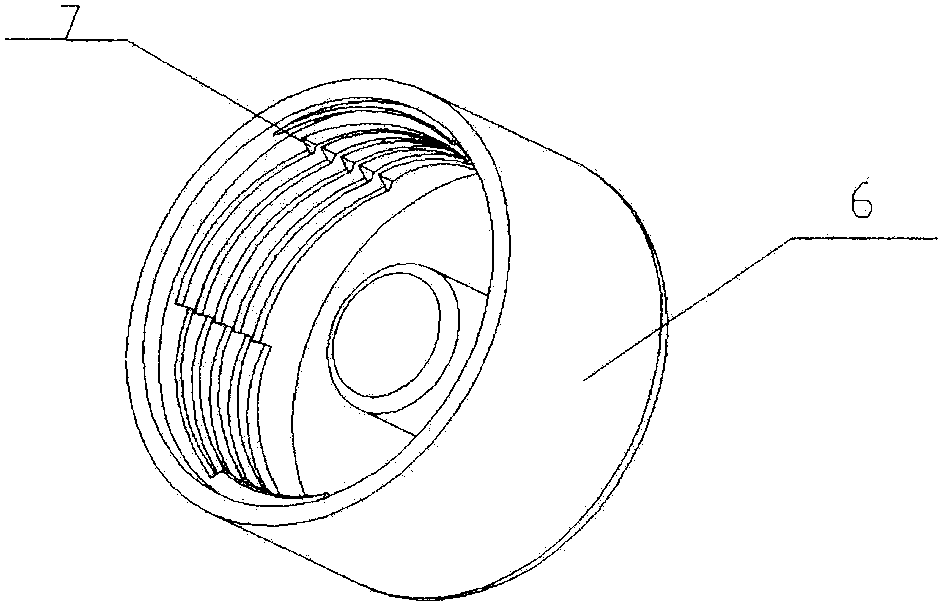

Flexible drinking water barrel

InactiveCN103482169AOvercome the disadvantages of micro-gapLower unit costCapsPackage recyclingPolyethylene terephthalate glycolHazardous substance

The invention discloses a flexible drinking water barrel and relates to a container for food drinking water. The supporting force and stability of a barrel body are improved through a triangular `WM`-shaped thin wall structure, the flexibility of the barrel and the times of repeated use of bottled water are determined by the thickness of the barrel wall and the physical and chemical properties of the material, the barrel extends during water filling and automatically shrinks in the water drinking process, air inside and outside the barrel is not exchanged, the difficult problem of secondary pollution during water drinking is radically solved, a barrel opening is combined with a barrel cover through non-return threads, the defect that the barrel opening is difficult to seal through the gland manner under the conditions of large diameter and inconsistent sizes is solved, a support rib is arranged on the exterior of a barrel neck and is supported on a slightly-modified filling equipment diversion rail for filling production, the selection range of the barrel body on plastics is more extensive, the defect that polycarbonate (PC) and polyethylene glycol terephthalate (PET) are easily decomposed to generate harmful substances to the human body under high temperature or direct sunlight, the barrel can be formed more easily through injection, stretching and blow-molding, the barrel can be transported and stored after being compressed, consumers have no need to change a water dispenser, and the water drinking is truly safe and reliable.

Owner:王胜荣

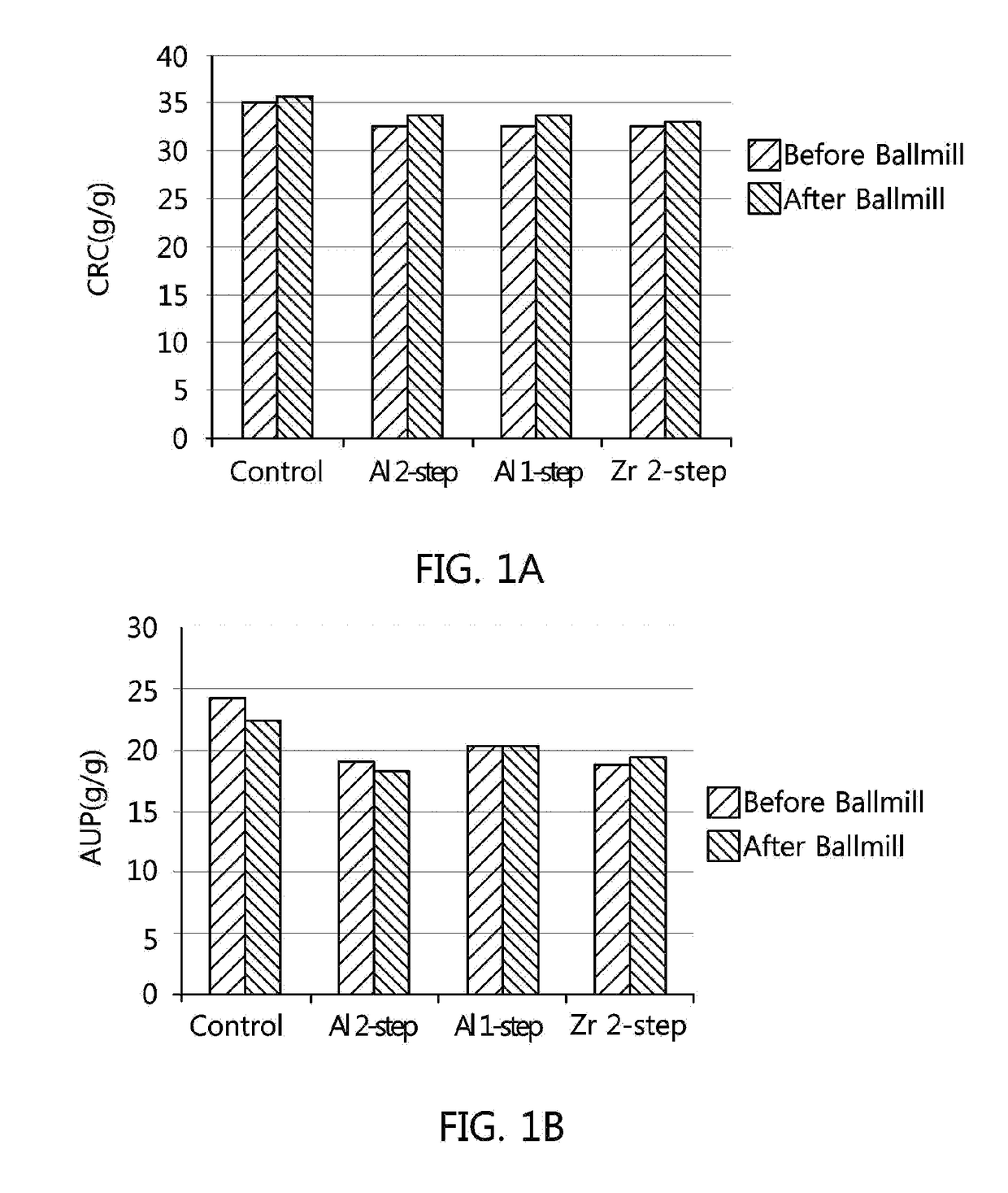

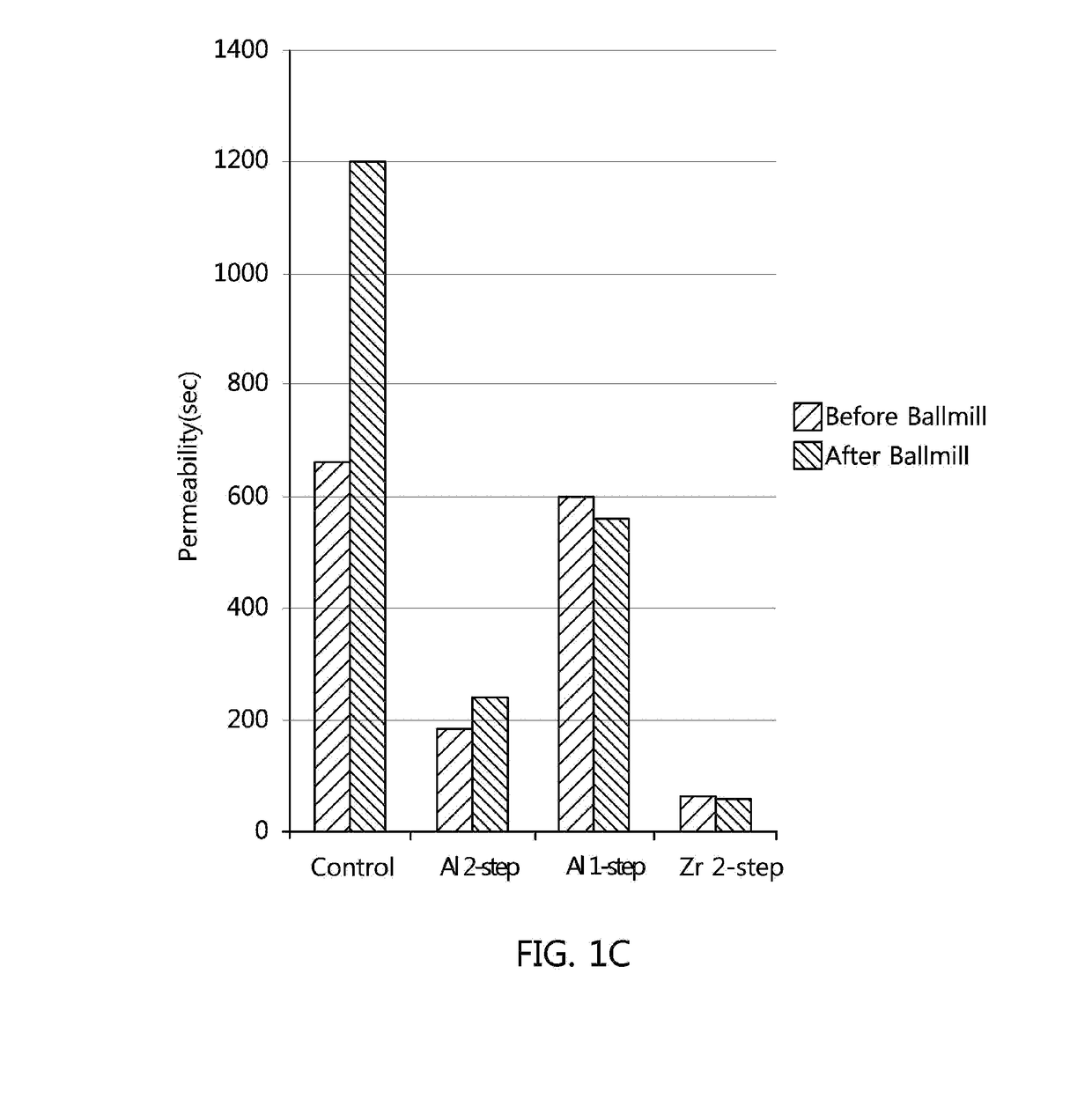

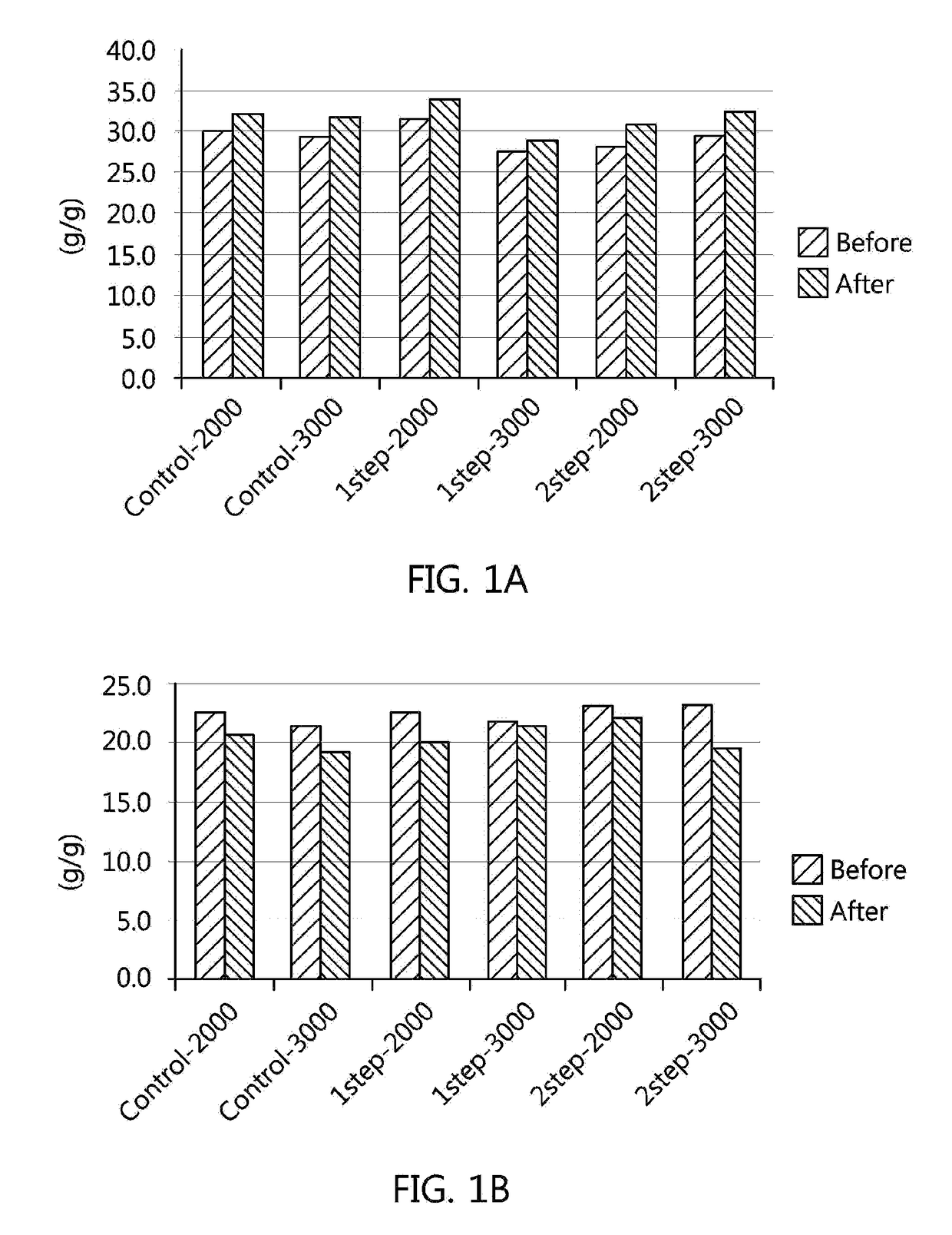

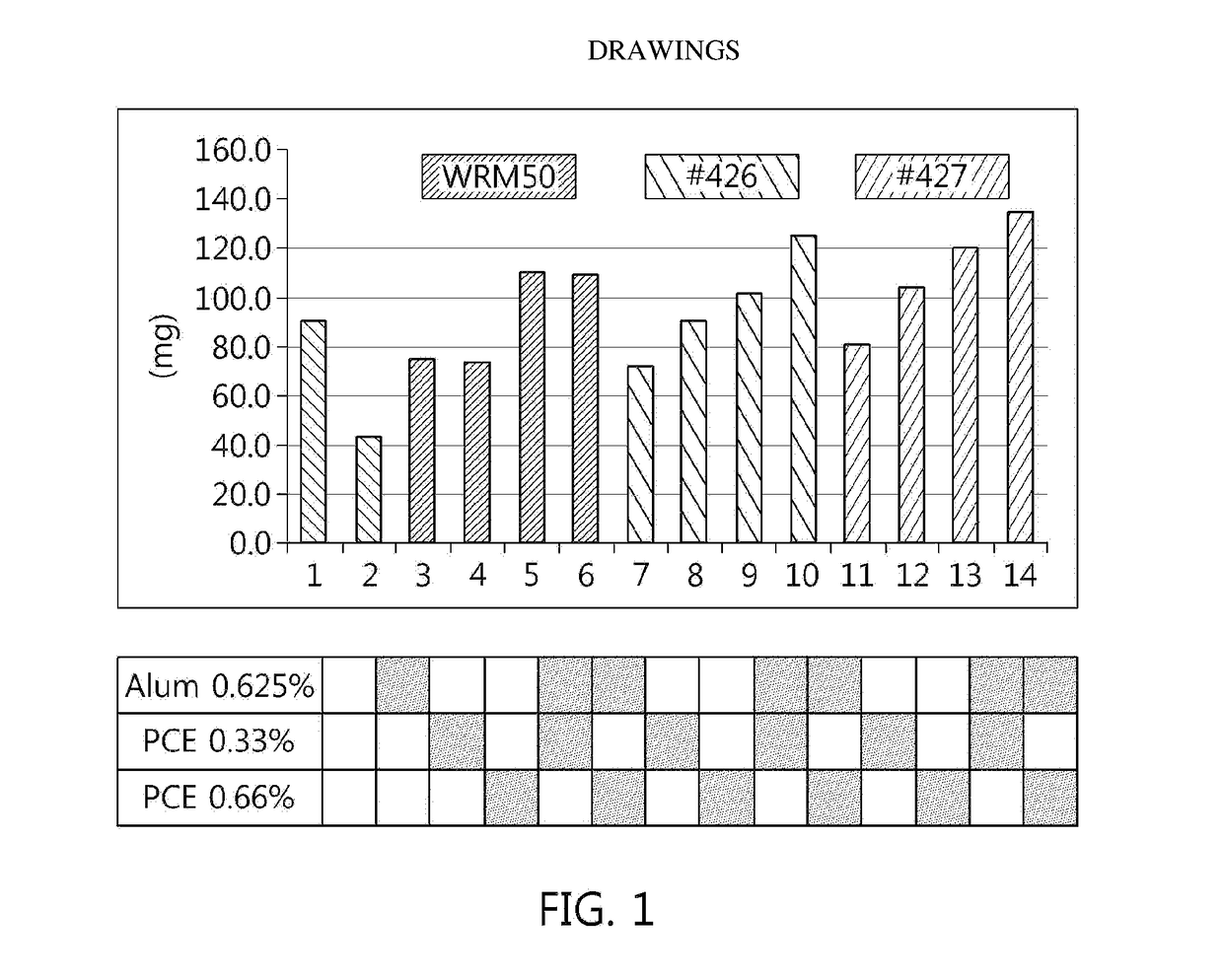

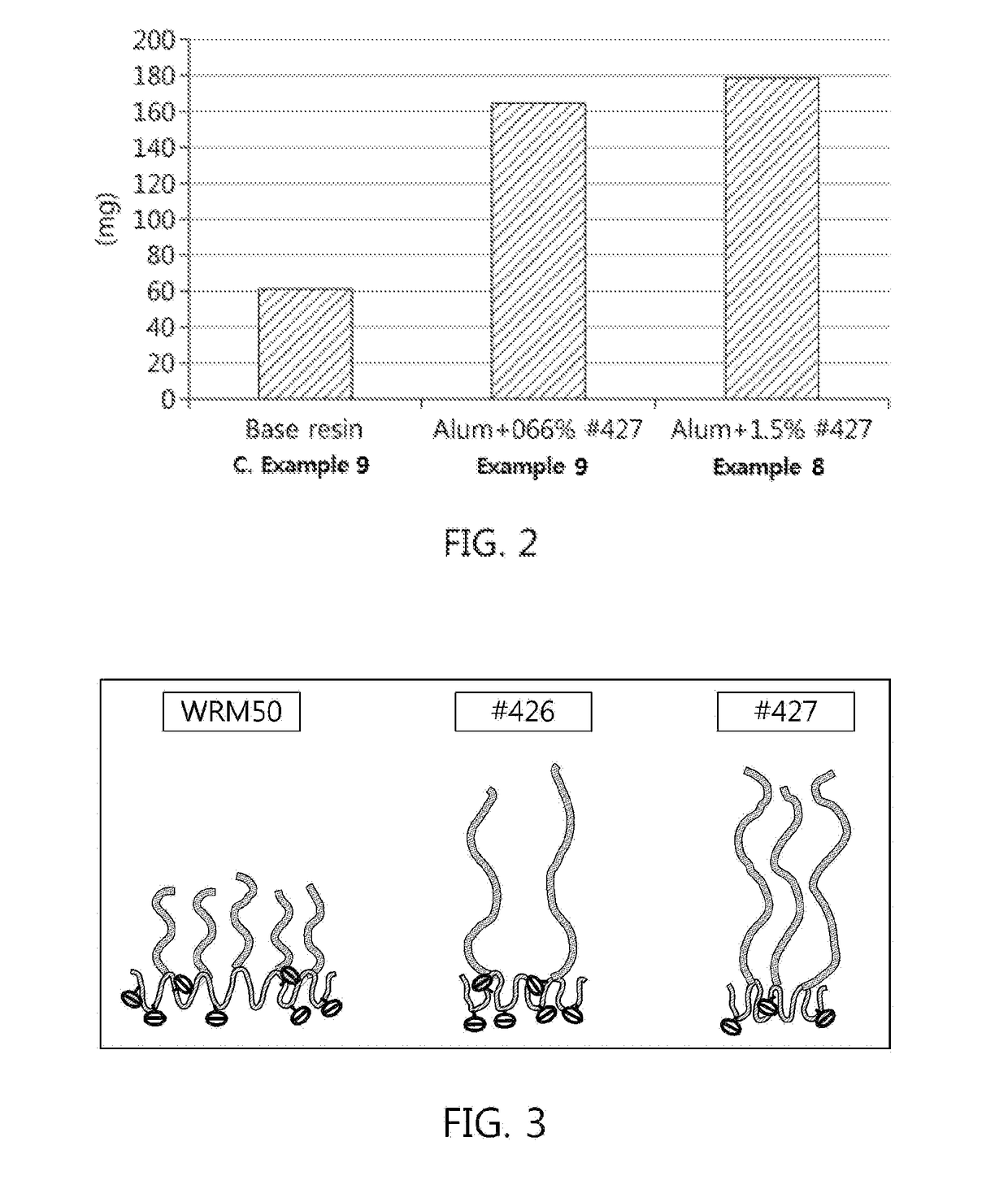

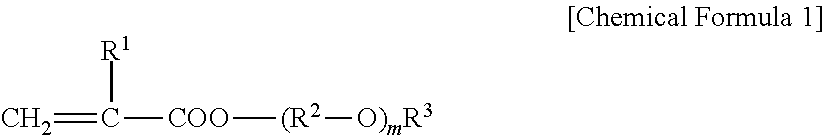

Surface-modified super absorbent resin and method for preparing same

ActiveUS20170095792A1Easy to processReduce loadOther chemical processesPolymer scienceSuper absorbent

Disclosed herein is a superabsorbent polymer with a surface modified with both a water-soluble polyvalent cationic salt and a polycarbonic acid-based copolymer, wherein an improvement is brought about in processability without significant degradation of other properties and a method is provided for preparing the surface-modified superabsorbent polymer.

Owner:LG CHEM LTD

Rust-proof paint

InactiveCN103483937AImprove rust resistanceStrong color fixing abilityAnti-corrosive paintsPolycarbonate coatingsPhosphoric acidTriphosphoric acid

The invention discloses rust-proof paint. The rust-proof paint comprises the following components in parts by weight: 75-80 parts of acrylic emulsion, 20-30 parts of iron red, 5-10 parts of polycarbonate, 10-15 parts of inositol hexaphosphate, 1-3 parts of aluminum dihydrogen tripolyphosphate, 0.5-2 parts of iron phosphating agent, 0.02-1 part of silicon dioxide and 100 parts of water. Compared with the ordinary water-based rust-proof paint, the rust-proof paint provided by the invention has a better rust-proof effect, has a very strong color fixing effect, still does not lose the color and luster after being affected by high temperature and harsh environment for a long time under, and is low in cost.

Owner:佛山市顺德区明邦化工实业有限公司

Modified polycarbonate PC and method for preparing same

The invention relates to a modified polycarbonate (PC) and a method for preparing the same. The PC comprises the following components in portion by weight: based on a 100 portion total, 50 to 58 portions of polycarbonate granules, 17 to 23 portions of titanium dioxide, 8 to 12 portions of glass fiber, 5 to 10 portions of ABS plastic granules, 4 to 6 portions of toughener, 0.9 to 1.1 portions of dispersing agent, 1.8 to 2.2 portions of compatilizer, 0.18-0.22 portions of antioxidant, and 0.009-0.011 portion of toner. The method for preparing the same is mainly as follows: placing, according to proportion, polycarbonate granules and ABS plastic granules in to a stirring machine for mixing, adding raw materials in the sequence of the titanium dioxide, the glass fiber, the tougher, the dispersing agent, the compatilizer, the antioxidant and the toner, mixing the raw materials with stirring for 5 to 8 minutes, subjecting the mixture to fusion and extrusion by a double-screw extruder, and making granules. Compared with pure PC, the modified PC has the characteristics of high strength, high toughness, solvent resistance, resistance deformation, high opacity, excellent fluidity, high temperature resistance, etc. and is suitable for making LED digital displays and various special displays.

Owner:HANGZHOU WEILIGUANG TECH

Water-proof two-component polyurethane coating and preparation method thereof

InactiveCN104673075AHigh hardnessHigh softening temperatureFireproof paintsPolyurea/polyurethane coatingsPolymer sciencePtru catalyst

The invention discloses a water-proof two-component polyurethane coating. The polyurethane coating comprises a component A and a component B mixed in the equal ratio, wherein the component A comprises components as follows: diisocyanate, poly propylene carbonate diol, a micromolecule chain extender, a catalyst, a catalyst capturing agent, an organic solvent, a flame retardant and a foaming agent; the component B comprises components as follows: a curing agent and a coupling agent. The invention further designs a preparation method of the water-proof two-component polyurethane coating. The preparation method of the coating is simple and easy to operate, the cost is low, and the prepared coating is good in corrosion resistance, excellent in electrical performance, good in decoration and protection performance and good in temperature resistance.

Owner:JIANGSU XIN AN NEW MATERIALS TECH

Surface cross-linked super absorbent resin and method for preparing same

ActiveUS20170114192A1Improve breathabilityEasy to controlAbsorbent padsBandagesCross-linkPolymer science

Disclosed herein is a superabsorbent polymer with a surface crosslinked with a water-soluble polyvalent cationic salt, a polycarbonic acid-based copolymer, and a surface crosslinking agent wherein an improvement is brought about in physical properties, with the concomitant reduction of process time and cost. Also, a method is provided for preparing the surface-crosslinked superabsorbent polymer.

Owner:LG CHEM LTD

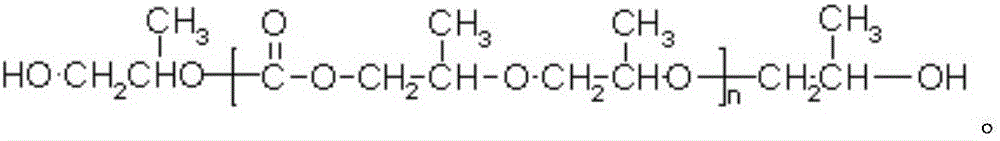

Preparation method of strippable waterborne polyurethane resin and application thereof in coating

ActiveCN110483728ABiodegradableImprove stabilityPolyurea/polyurethane coatingsPullulanRotary evaporator

The invention provides a preparation method of strippable waterborne polyurethane resin and application thereof in coating. The preparation method comprises the following steps: uniformly stirring andmixing 10-40 parts of polypropylene carbonate polyol, 20-40 parts of isocyanate and 0.5-6 parts of a hydrophilic agent, and then adding 0.1-0.2 part of a catalyst to obtain a mixed solution A; adding1-5 parts of a chain extender and 20-70 parts of acetone into the mixed solution A obtained in the step 1 to obtain a mixed solution B; cooling the mixed solution B in the step 2 to 35-60 DEG C, adding 0.3-3 parts of triethylamine, adding deionized water, emulsifying the mixture at a high speed, and stirring the mixture for 10-20 minutes to obtain an emulsion; and 4, placing the emulsion obtainedin step 3 on a rotary evaporator, carrying out vacuum pressure reduction concentrating, and removing the solvent to obtain the strippable waterborne polyurethane resin. The resin is mixed with pullulan and the like to obtain the coating. The waterborne strippable coating has biodegradability, does not pollute the environment, can reduce the investment of manpower and financial resources, and hasmore obvious environmental protection advantages compared with traditional films and other strippable resins.

Owner:青岛水性七彩新材料有限公司

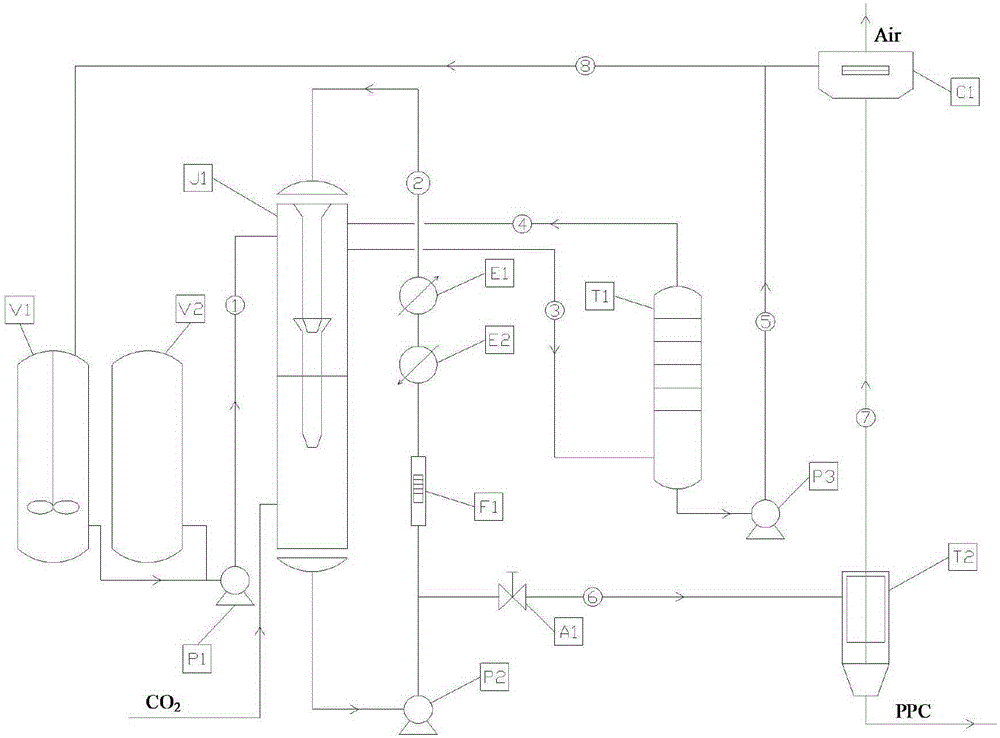

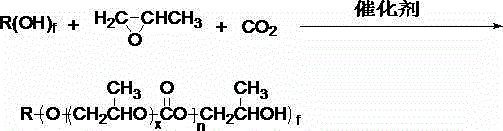

Device and method for continuously synthesizing poly (propylene carbonate) polyols

The invention provides a device and a method for continuously synthesizing poly (propylene carbonate) polyols (PPC). The device comprises a duplex injection reactor and a scraper film evaporator. Circular reaction is carried out with the duplex injection reactor; when the reaction is finished, a liquid phase product is delivered to the scraper film evaporator from the bottom of the duplex injection reactor; vacuuming and heating treatments are carried out, and PPC is collected from the bottom. According to the invention, the duplex injection reactor is applied, such that gas-liquid mass transfer rate is improved, gas-liquid mixing degree is improved, and reaction rate is improved. Also, the invention provides a continuous production process, such that purposes of reducing investment and production energy consumption, improving productivity and conversion rate, realizing continuous production, and improving production efficiency are achieved.

Owner:NANJING UNIV

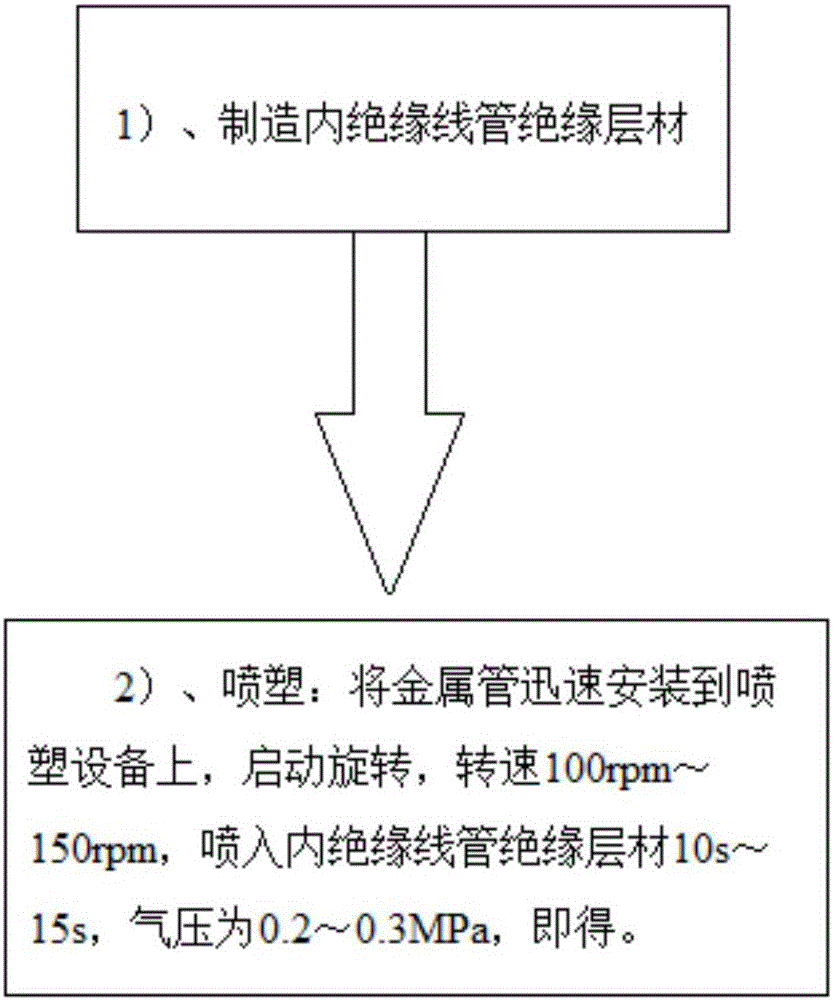

Internal insulation spool and manufacturing method thereof

InactiveCN106833320AImprove wear resistanceNo deformationInsulating bodiesPolycarbonate coatingsFiberInsulation layer

The invention discloses an inner insulating wire tube, which comprises a metal tube, the inner wall of the metal tube is provided with an insulating layer, and the insulating layer includes the following components in parts by weight: 25-40 parts by weight of nano silicon dioxide, 15-25 parts of polycarbonate resin, 0.2-0.6 parts of polyvinyl chloride, 0.8-1.6 parts of carbon fiber, 2-5 parts of alkyd resin, 1-3 parts of coupling agent, 0.1-0.5 parts of zinc oxide, 4 parts of bamboo leaf residue ~8 parts, the inner insulating wire tube made of the material of the present invention does not deform under high temperature, has high wear resistance, uniform thickness of the inner insulating layer, uniform thickness of the port insulating layer, simple manufacturing method, low cost and wide application.

Owner:JIANGSU BIDE SCI & TECH CO LTD

Method for synthesizing high molecular weight polycarbonate, catalyst and application

The invention relates to a method for synthesizing high molecular weight polycarbonate, a catalyst and application in the technical field of polymer synthesis. The method comprises that diphenyl carbonate and dihydric alcohol as raw materials undergo a one-step melt transesterification polycondensation reaction to produce high molecular weight polycarbonate. The method can be widely used for aliphatic polycarbonate, aromatic polycarbonate, isosorbide-based polycarbonate and tricyclodecane dimethanol-based polycarbonate. After the transesterification polycondensation reaction, the catalyst canbe used as an inorganic filler directly residual in the polymer without separation and subsequent treatment. The catalyst is selected from a metal oxide and / or a metal-aluminum complex oxide and the metal is at least one of alkaline earth metals and zinc. Compared with the existing homogeneous catalyst systems such as a titanium group, a transition metal salt and a strong base, the catalyst used by the method has the advantages of simple preparation processes, low toxicity, good polymer color and no use of a catalyst in the separation process.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Super absorbent resin for absorbing blood or high viscosity liquid and method for preparing same

ActiveUS20170144130A1Promote blood flowImprove liquidityOther chemical processesAbsorbent padsViscous liquidSuper absorbent

Disclosed herein is a superabsorbent polymer with a surface modified with both a polyvalent cationic salt and a polycarbonic acid-based copolymer, which is able to effectively absorb blood or highly viscous liquid, and a method for preparing the same.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com