Biodegradable polyester/cellulose composite film blowing material and preparation method thereof

A technology for biodegrading polyester and cellulose, which is applied in the field of composite materials, can solve the problems of high molecular weight of modifiers and poor plasticizing effect of starch, and achieve the effects of excellent product performance, reduced strength, and not easy to age

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

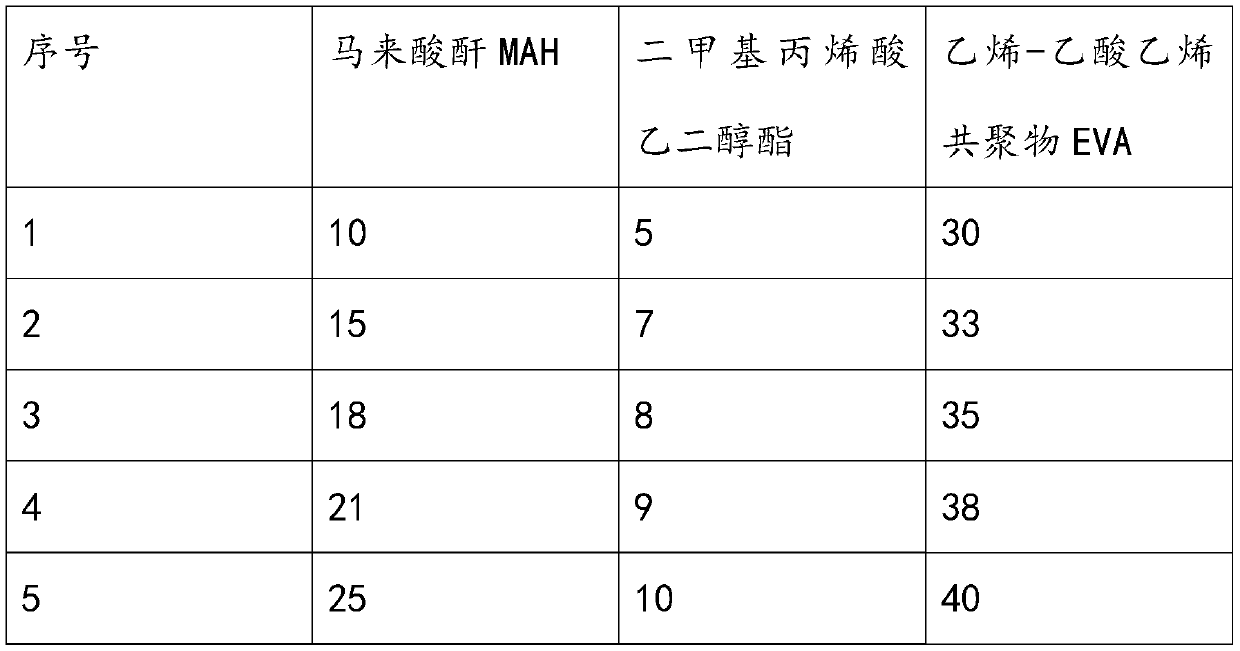

[0027] Example 1. The influence of the content of different compatibilizer components on the properties of biodegradable polyester / cellulose composite blown film materials

[0028] A biodegradable polyester / cellulose composite blown film material is made of the following components: 35 parts of polyadipate / butylene terephthalate PBAT, 10 parts of polypropylene carbonate polyol PPC, chain extension 0.01 parts of polylactic acid PLA, 8 parts of PLA, 25 parts of starch, 20 parts of cellulose, 2 parts of compatibilizer, 1 part of stabilizer, 1 part of anti-aging agent; of which, the compatibilizer components and their weight percentages are shown in Table 1. .

[0029] Table 1 Different components of compatibilizer and their weight percentages

[0030]

[0031] Refer to GB / T 1040.3, QB / T 2538, GB / T 1038 and GB / T 2679.3 to determine the properties of the materials obtained. See Table 2 for the results obtained.

[0032] Table 2 Material performance test results of different components of ...

Embodiment 2

[0035] Embodiment 2. Biodegradable polyester / cellulose composite blown film material and preparation method thereof

[0036] Formula: 40 parts of polyadipate / butylene terephthalate, 12 parts of polypropylene carbonate polyol, 0.02 parts of trimethylolpropane, 10 parts of polylactic acid PLA, 30 parts of starch, 21 parts of cellulose , Maleic anhydride grafted vinyl acetate copolymer 3 parts, stabilizer (calcium stearate and zinc laurate mixed in a weight ratio of 1:1) 2 parts and benzophenone-3 1.5 parts.

[0037] Among them, the compatibilizer maleic anhydride grafted vinyl acetate copolymer is polymerized from the following raw materials and their weight percentages: maleic anhydride 18%, benzoyl peroxide 8% and ethylene-vinyl acetate copolymer 35%.

[0038] Preparation:

[0039] S1. Put starch and cellulose into a high-speed mixer at a speed of 300 rpm / min and stir for 5 minutes to mix the starch and cellulose uniformly to form a premix;

[0040] S2. The stabilizer and anti-aging ag...

Embodiment 3

[0042] Example 3. Biodegradable polyester / cellulose composite blown film material and preparation method thereof

[0043] Formula: 45 parts of polyadipate / butylene terephthalate, 14 parts of polypropylene carbonate polyol, 0.025 parts of trimethylolpropane, 12 parts of polylactic acid, 33 parts of starch, 23 parts of cellulose, Maleic anhydride grafted vinyl acetate copolymer 4 parts, stabilizer (calcium stearate and zinc laurate mixed at a weight ratio of 1:1) 2.5 parts, benzophenone-3 2 parts.

[0044] Among them, the compatibilizer maleic anhydride grafted vinyl acetate copolymer is polymerized from the following raw materials and their weight percentages: maleic anhydride 15%, benzoyl peroxide 7% and ethylene-vinyl acetate copolymer 33%.

[0045] Preparation:

[0046] S1. Put the starch and cellulose into a high-speed mixer, rotate at 300 rpm / min, and stir for 7 minutes to mix the starch and cellulose uniformly to form a premix;

[0047] S2. The stabilizer and anti-aging agent are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com