Patents

Literature

49results about How to "High biobased content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bio-based biodegradable multi-block copolymer as well as preparation method and application thereof

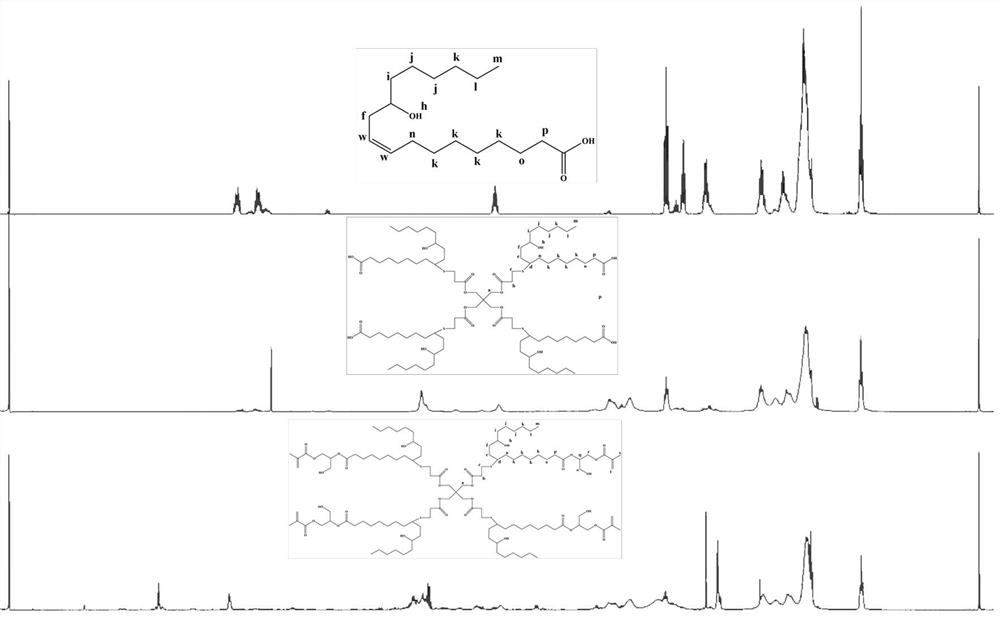

InactiveCN108192105AGuaranteed biodegradabilitySolve the melting point is too lowFlexible coversWrappersDimer acidMechanical property

The invention discloses bio-based biodegradable multi-block copolymer as well as a preparation method and application thereof. The multi-block copolymer comprises a chain segment A and a chain segmentB; the chain segment A is fat-aromatic coplyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on C2-C36 fatty diacid and derivatives thereof, C6-C20 aromatic diacid and derivatives thereof, C2-C36 divalent alcohol, and 0.0 to 10% by weight of polyhydroxyl or polycarboxyl compound and performing condensation polymerization; the chain segment B is fatty copolyester with number average molecular weight of 3000 to 100000, which is obtained by performing esterification (ester exchange) on dimer acid and derivatives thereof, C2-C12 fatty diacid and derivatives thereof, C2-C36 divalent alcohol as well as 0.0 to 10% of polyhydroxyl or polycarboxyl compound and performing condensation polymerization. The chain segment A and the chain segment B react with a polyfunctional chain extender of polyisocyanate, a polyepoxy compound and carbodiimide which is 0.01 to 10% of the polymer to form the multi-block copolymer. The product prepared by the method has high biodegradability, mechanical property and processing property, and can be widely applied to the fields of packaging, biological medicine, medical treatment and thelike.

Owner:王肖桦

Biodegradable polyols having higher biobased content

InactiveUS20180155490A1Promote degradationHigh biobased contentOrganic chemistryPolymer scienceTriol

The present invention is directed to biodegradable polyester polyol polymers having high bio-based content and methods for producing biodegradable polyester polyol polymers having high bio-based content. In preferred embodiments, β-lactone monomers may be produced from epoxide and carbon monoxide having high bio-based content. In certain preferred embodiment, the β-lactone is β-propiolactone produced from ethylene oxide and carbon monoxide. In certain embodiments, β-lactones may be polymerized with diols, triols, and polyols to form the biodegradable polyester polyol polymers having high bio-based content. In some embodiments, the biodegradable polyester polyol polymers having high bio-based content may be terpolymers formed from a first β-lactone, a diol, triol, or polyol, and a second β-lactone. In some other embodiments, the biodegradable polyester polyol polymers having high bio-based content may be copolymers formed from a polylactone oligomer and a diol, triol, or polyol.

Owner:NOVOMER INC

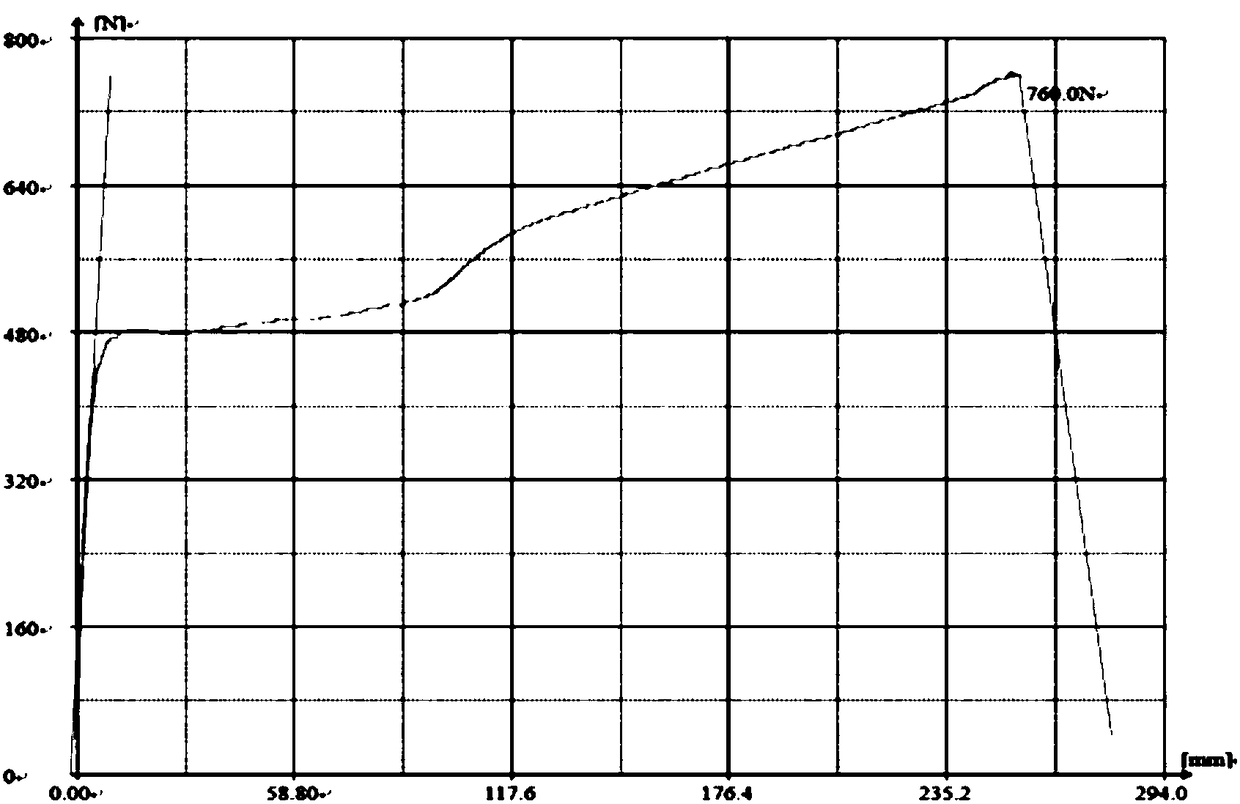

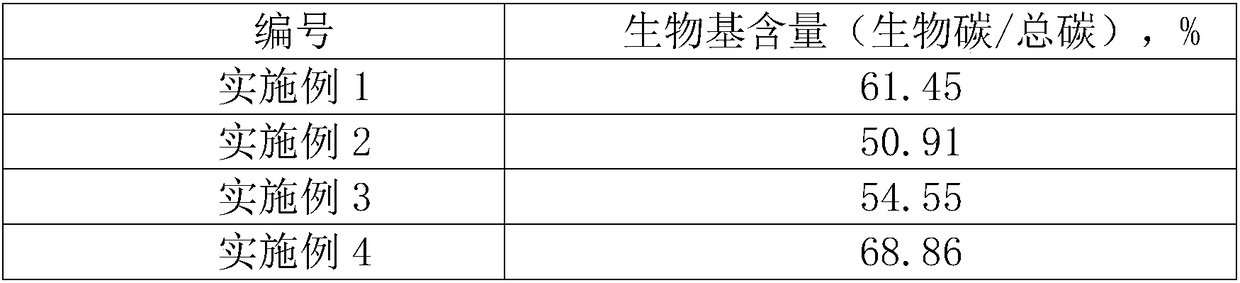

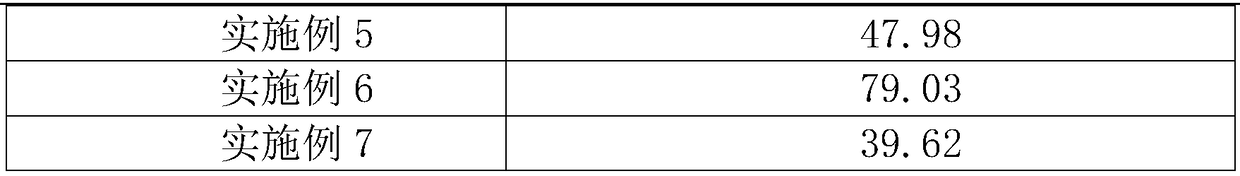

Environmental-friendly foamed insole material, and preparation method thereof

The invention provides an environmental-friendly foamed insole material, and a preparation method thereof. The environmental-friendly foamed insole material is prepared from an EVA composite materialthrough foaming; the EVA composite material comprises, by weight, 30 to 40 parts of ethylene-vinyl acetate copolymer, 10 to 35 parts of biological Ethylene-Propylene-Diene Monomer, 10 to 20 parts of adegradable resin, 0 to 20 parts of polyolefin elastomer, 10 to 20 parts of plant fiber powder, 0.5 to 0.8 part of a cross-linking agent, 2.5 to 3 parts of a foaming agent, and 2.5 to 3.5 parts of anactivator. The degradable resin is one or a mixture of a plurality of components selected from poly (butyleneadipate-co-terephthalate and polylactic acid. The environmental-friendly foamed insole material is degradable, is high in biomass content, is excellent in performance. The preparation method is capable of recycling waste resource, and reducing using of non-renewable petroleum resources; thedegradable part is capable of reducing carbon dioxide emission; and energy saving and carbon emission environmental protection effect is achieved.

Owner:ANTA CHINA

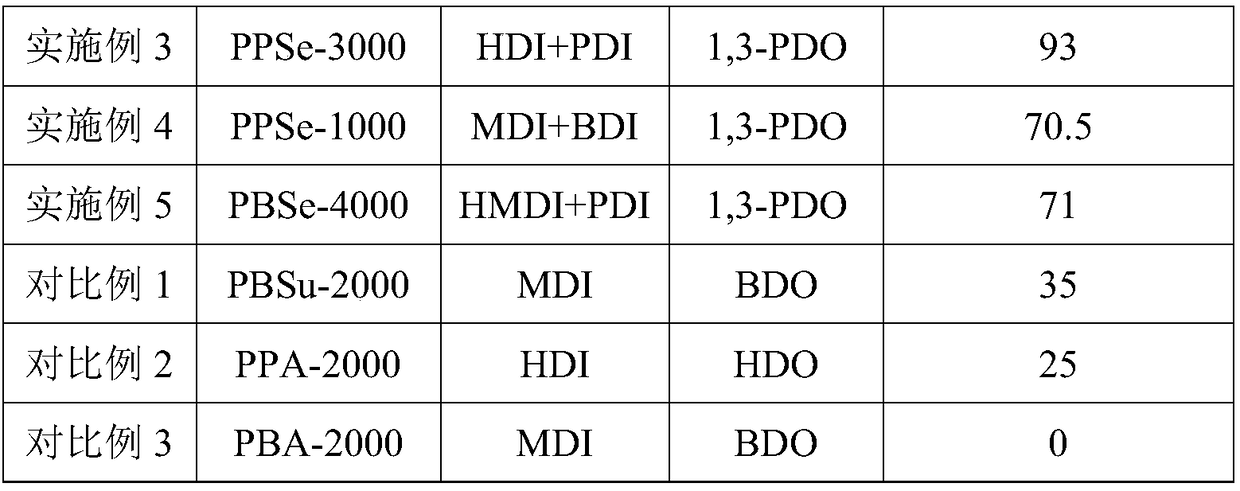

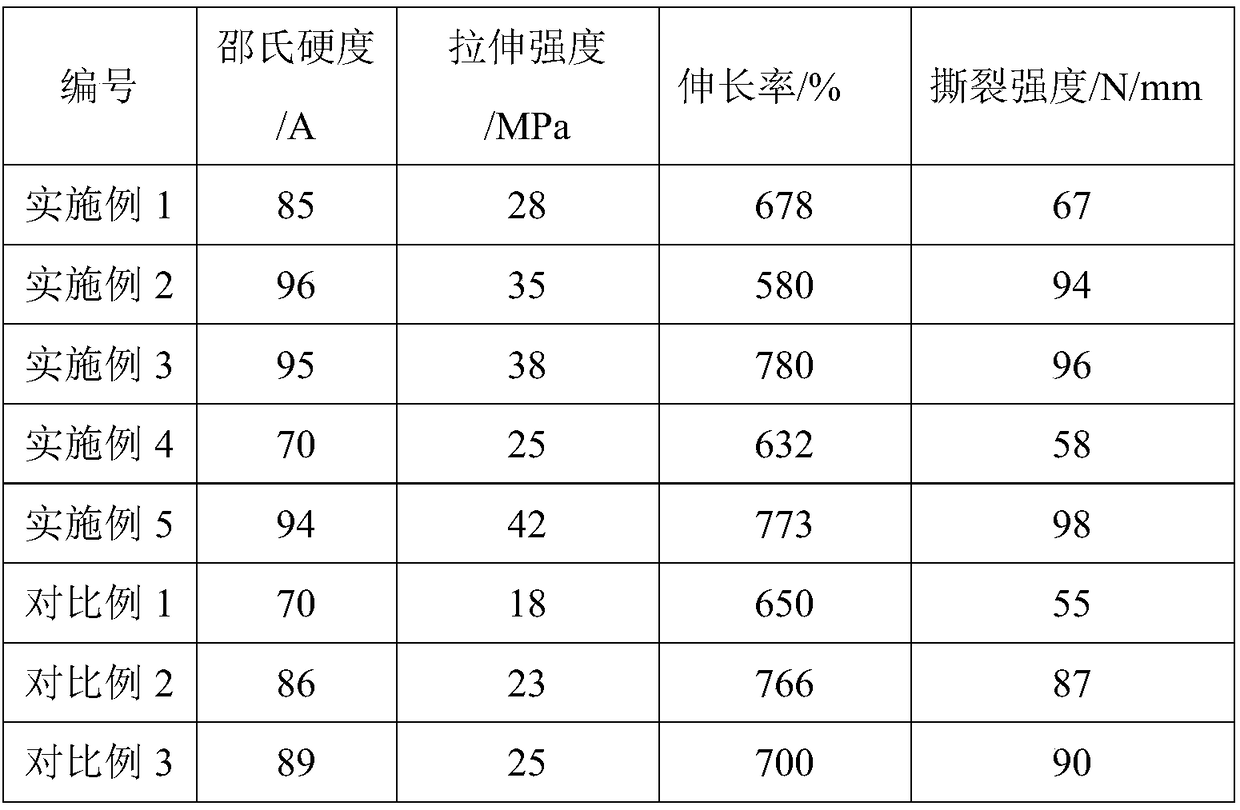

Biological-type thermoplastic polyurethane elastomer and preparation method thereof

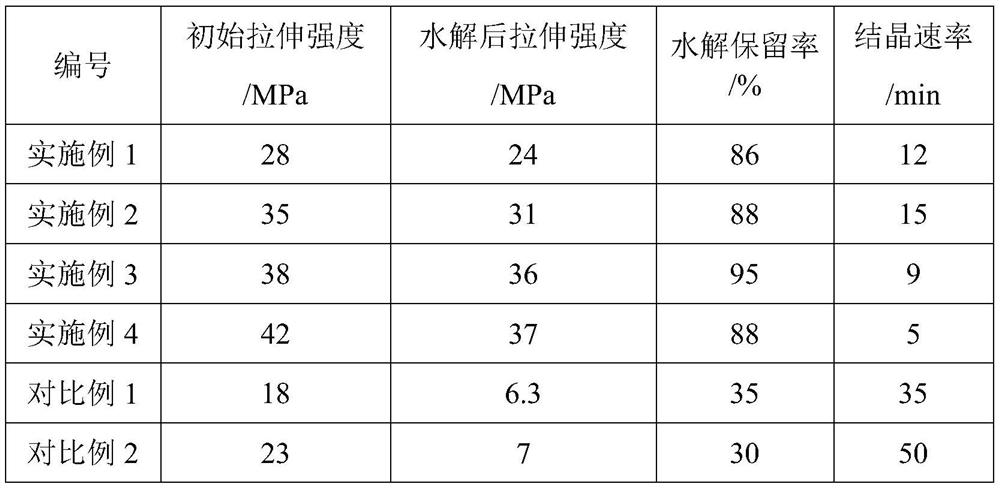

ActiveCN109438653AExcellent hydrolysis resistance and formabilityHigh biobased contentIsocyanatePrepolymer

The invention discloses a biological-type thermoplastic polyurethane elastomer and a preparation method thereof. The biological-type thermoplastic polyurethane elastomer is high in biological base content, and excellent in comprehensive performance, and composition thereof is as follows: a) 30-95 wt% of a polyhydric alcohol component, wherein a number-average molecular weight of the polyhydric alcohol is 800-6000 g / mol, and the polyhydric alcohol contains 50-100 wt% of biological base polyester polyhydric alcohol; b) 0-25 wt% of a chain extender component, wherein the chain extender contains 50-100 wt% of a biological base chain extender; c) 5-45 wt% of a diisocyanate component, wherein the diisocyanate contains 10-60 wt% of biological base diisocyanate; and d) 0.001-0.1 wt% of a catalystcomponent, wherein the catalyst contains 50-100 wt% of a non-tin-ring environment-friendly catalyst. Total content of the biological bases of the components a)-c) is greater than or equal to 50 wt%. The thermoplastic polyurethane elastomer can be prepared by using a one-step method, an intermittent method or a prepolymer method.

Owner:WANHUA CHEM GRP CO LTD

Completely biodegradable resin made of non-staple grain plant modified starch and its preparation method

ActiveCN102408588AIncrease the amount addedHigh resource substitutionBiodegradable copolymersTemperature and pressure

The invention discloses a preparation method of a completely biodegradable resin made of non-staple grain plant modified starch. The method comprises the steps of: first putting non-staple grain plant starch into a reaction vessel, adding water to prepare it into starch milk, and heating it to a proper temperature, conducting stirring and washing, then adding chemicals into a water solution for modification grafting treatment, and then separating water and starch through centrifugation, and conveying the separated modified starch to an airflow drying system for dewatering and drying, then taking 100 parts of dried modified starch, adding 5-50 parts of a compatilizer, 2-15 parts of an anti-block agent, 0-100 parts of polylactic acid, and 150-250 parts of a completely biodegradable copolymer of dibasic acid and dibasic alcohol, and mixing them uniformly, carrying out extrusion granulating or tabletting under an appropriate temperature and pressure, thus obtaining a resin material or sheet special for complete biodegradation. The resin of the invention has both the usage function similar to ordinary plastic products and a complete biodegradability. And after being used and abandoned, the resin can be degraded into carbon dioxide and water that can be consumed by the environment.

Owner:SUZHOU HANFENG NEW MATERIAL

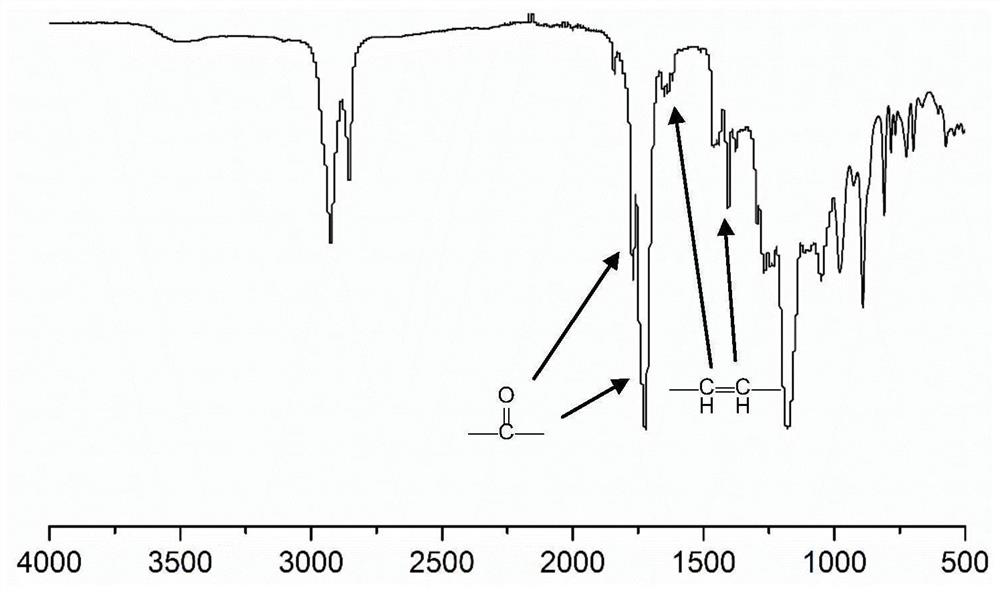

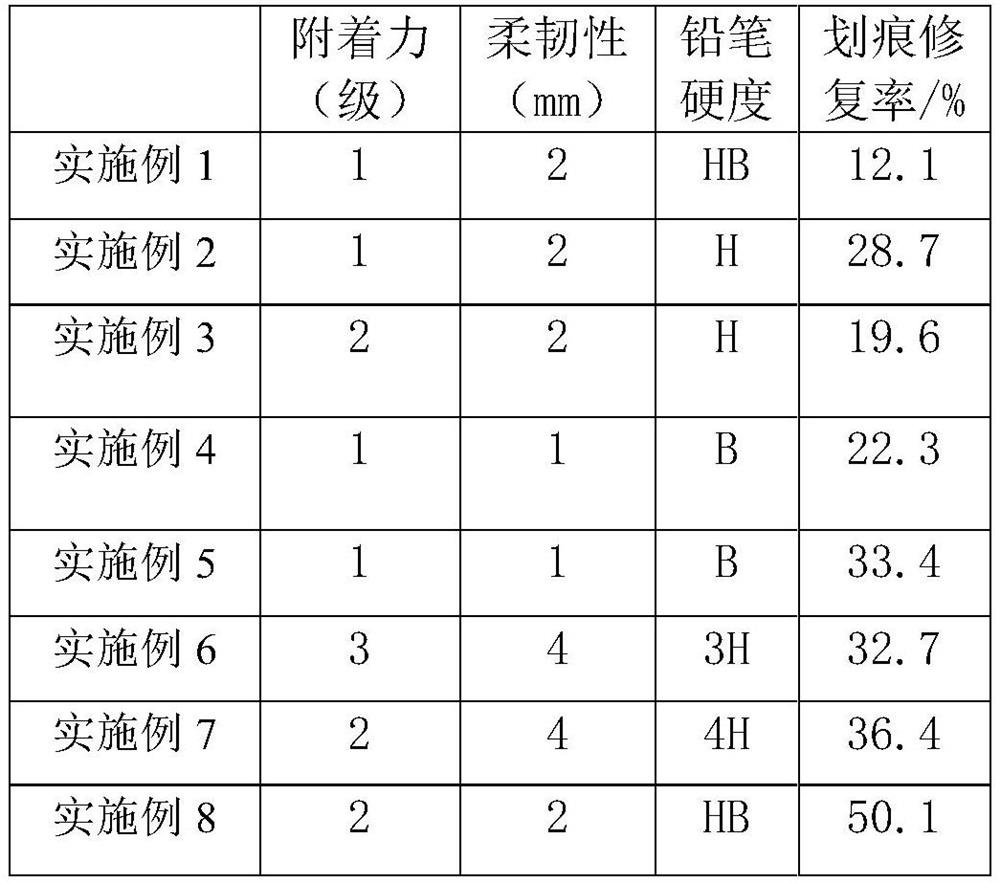

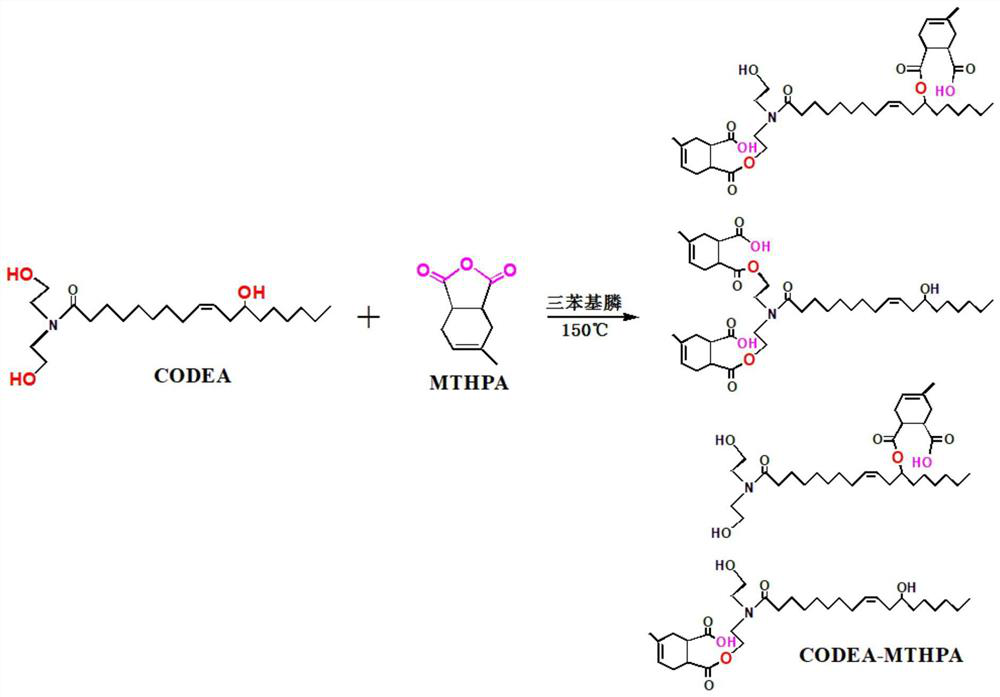

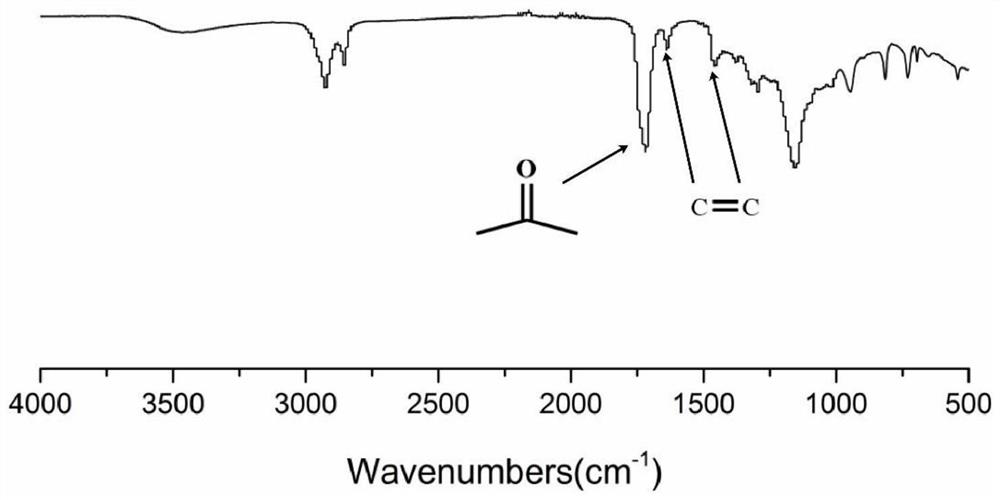

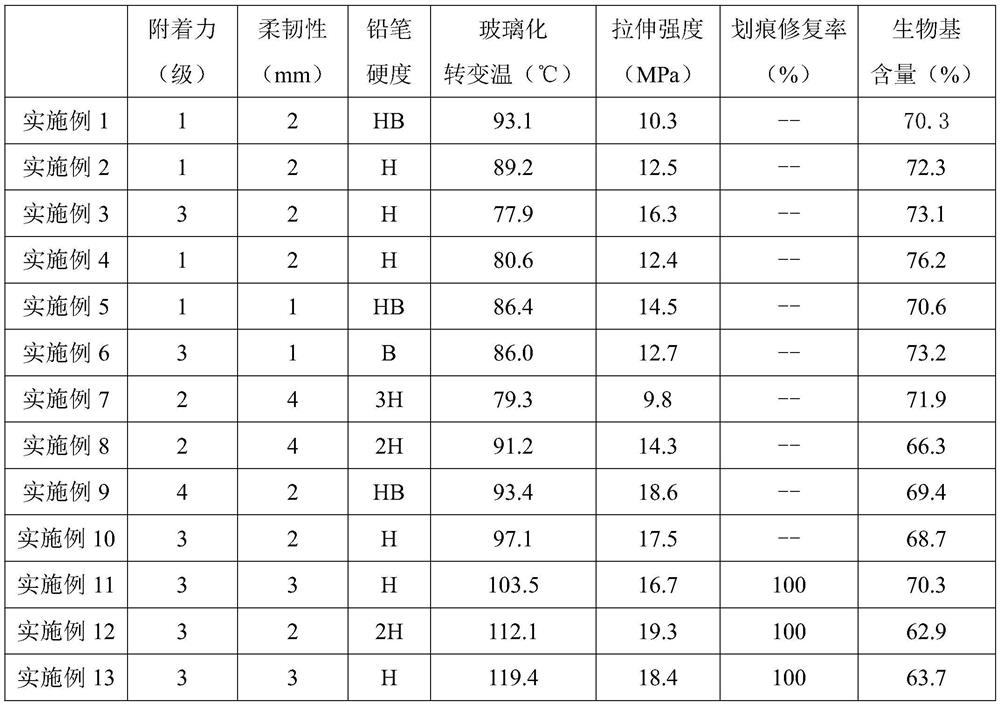

Bio-based self-repairing photocureable coating as well as preparation method and application thereof

The invention provides a preparation method of a grease-based self-repairing photocureable coating. The grease-based self-repairing photocureable coating is prepared from 40-60 parts of epoxy vegetable oil-based acrylate, 20-50 parts of a diluent, 1-4 parts of a photoinitiator, 1-8 parts of a polymerization inhibitor and 5-10 parts of a catalyst. The grease-based self-repairing photocureable resinmaterial prepared by the method does not contain other solvents to participate in reaction, is simple and quick to prepare, and is suitable for green industrial flow line production. The obtained coating shows good self-repairing performance. The coating can be widely applied to the coating fields of metal, woodware, plastics and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Special pbs modified biological fully-degradable film material

The present invention relates to the technical field of biodegradable plastic films, particularly to a special pbs modified biological fully-degradable film material, which comprises the following raw materials by weight: 5-30 parts of polylactic acid, 20-40 parts of starch, 40-60 parts of polyadipic acid / butylene terephthalate, 0-20 parts of lignocellulose, 0-1 part of an antioxidant, 2-10 parts of a melt reinforcing agent, 5-20 parts of a starch modified plasticizer, and 0.1-10 parts of a coupling agent. According to the present invention, the special pbs modified biological fully-degradable film material is disclosed, the film prepared from the special pbs modified biological fully-degradable film material has advantages of excellent mechanical property, excellent thermal stability and excellent film uniformity, the prepared special pbs modified biological fully-degradable film material belongs to the completely biodegradable material, can solve the white pollution problem caused by the plastic, and belongs to the environmentally friendly material, and the prepared plastic film has the high bio-base content, has advantages of low cost and environmental protection, and has great industrialization advantages at home and abroad.

Owner:新疆蓝山屯河型材有限公司 +1

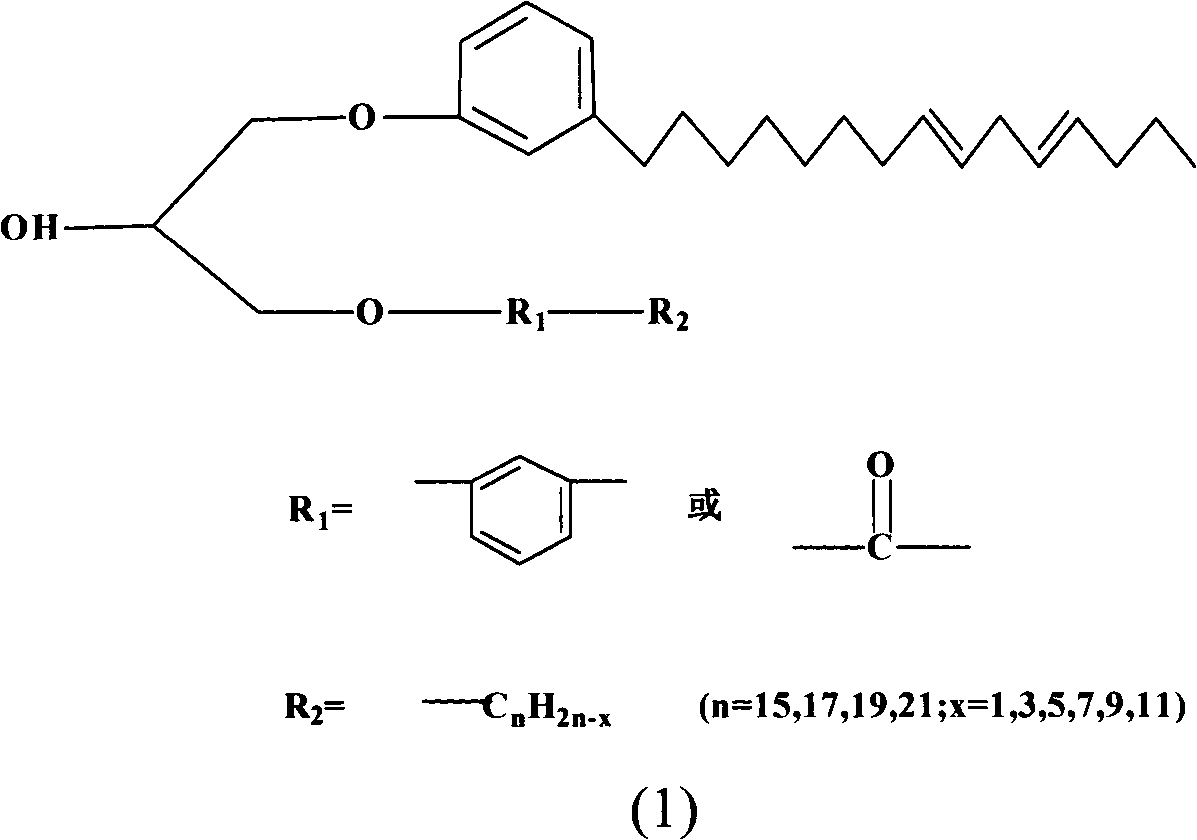

Preparation method of novel monohydroxy biology-based epoxy resin

ActiveCN102796063ASimple processMild reaction conditionsOrganic chemistryChemical industryPolymer science

The invention discloses a preparation method of novel monohydroxy biology-based epoxy resin, which belongs to the technical field of chemical industry. The method comprises the following steps of: reacting cardanol glycidyl ether with unsaturated fatty acid or cardanol to generate monohydroxy unsaturated biology-based resin A; and performing epoxidation on unsaturated double bonds on an aliphatic chain of the resin A to obtain monohydroxy epoxy resin with high biology content. The novel epoxy resin has the characteristics of environment-friendly and reproducible raw materials, simple synthesis process, high stability, high heat resistance and high electric insulating property after curing, and the like; the biology content is over 90 percent, and the epoxy value is up to 0.28-0.51eq / 100g; and the method is suitable for the fields of coatings, composite materials, casting materials, electronic electrical appliance materials, bonding agents, resists and the like.

Owner:JIANGNAN UNIV

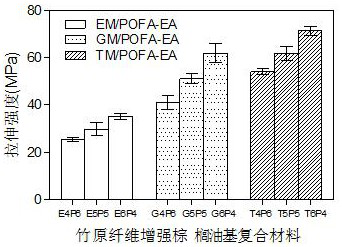

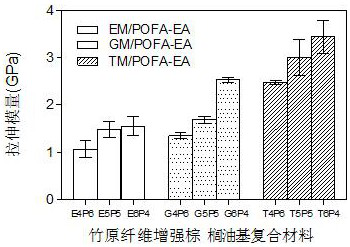

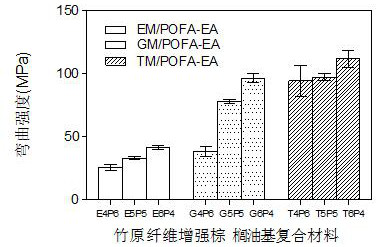

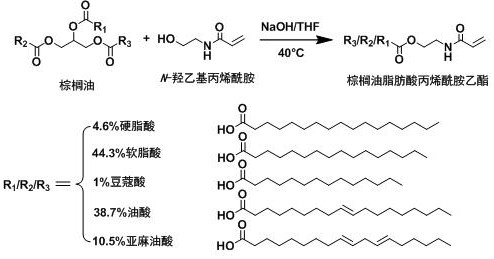

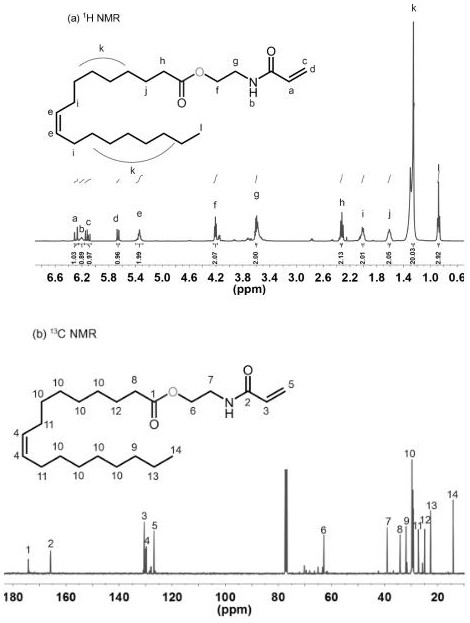

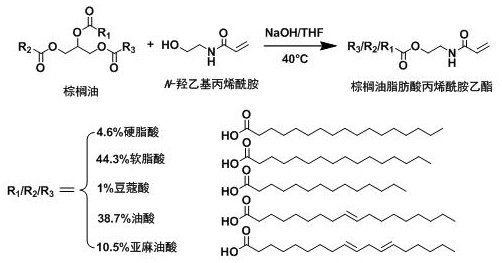

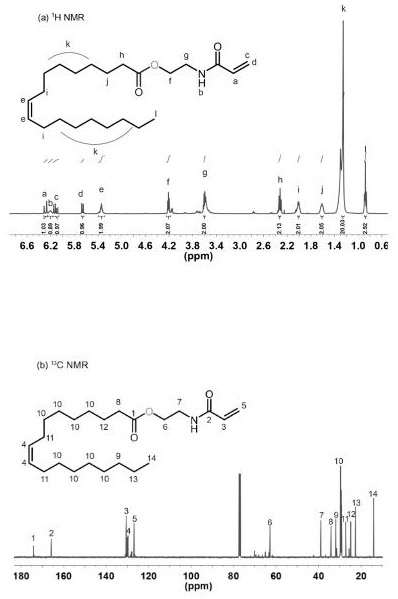

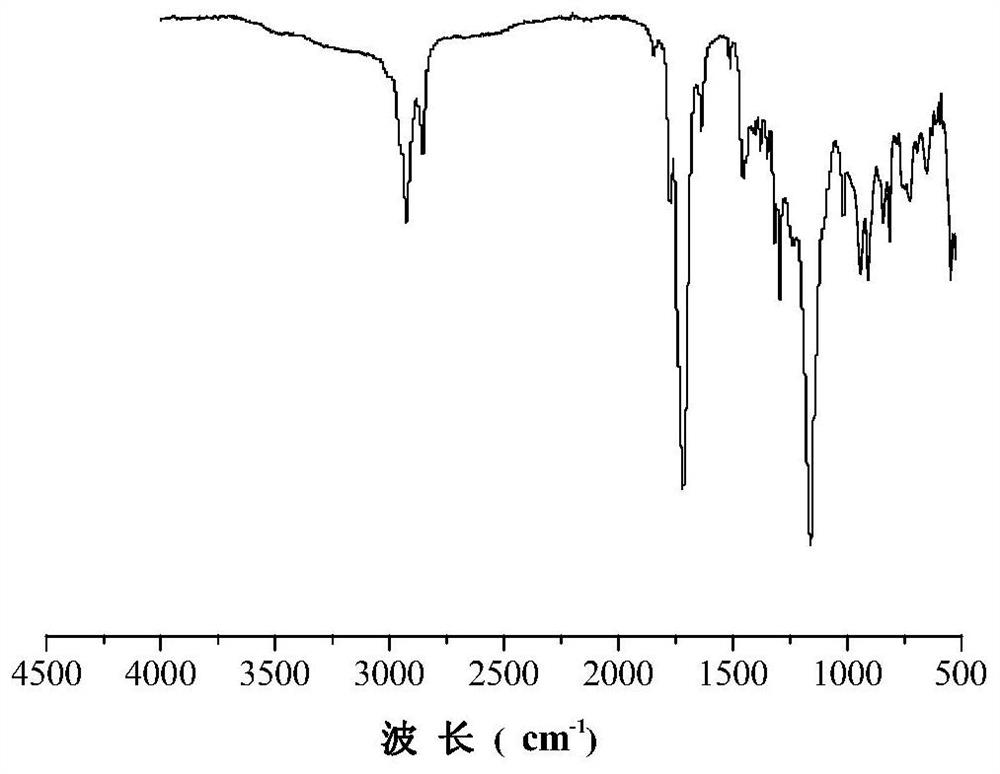

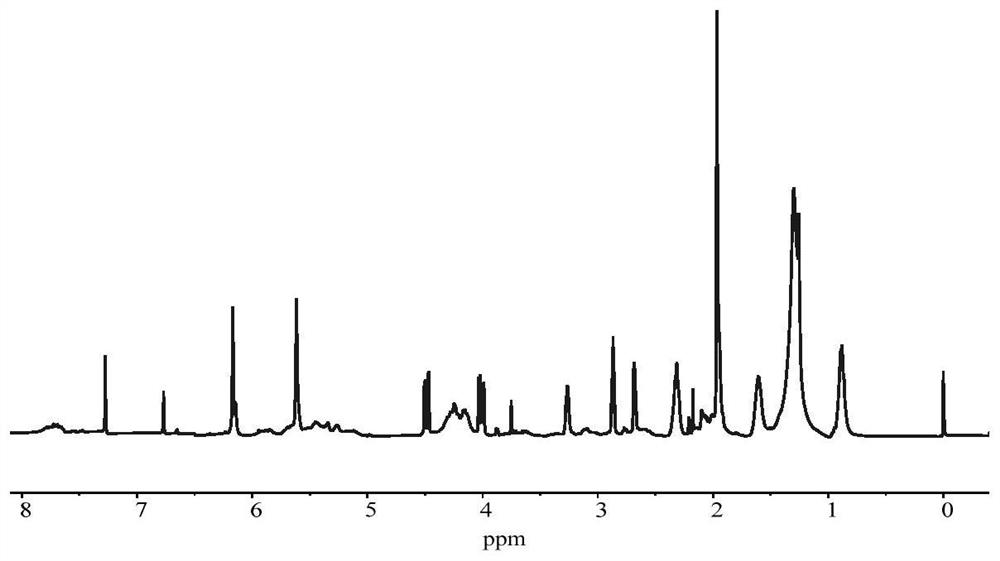

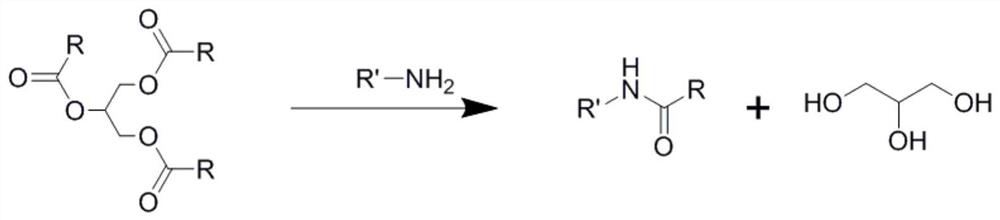

Natural bamboo fiber reinforced composite material based on natural polyphenol cross-linked palm oil-based resin and preparation method of natural bamboo fiber reinforced composite material

The invention belongs to the technical field of resin composite materials, and particularly relates to a natural bamboo fiber reinforced composite material based on natural polyphenol cross-linked palm oil-based resin and a preparation method of the natural bamboo fiber reinforced composite material. The environment-friendly palm oil-based resin is prepared by blending a natural polyphenol cross-linking agent and palm oil fatty acid acrylamide ethyl ester, and natural bamboo fibers, the palm oil-based resin and an initiator are subjected to hot press molding to obtain the natural bamboo fiberreinforced palm oil-based resin composite material. The natural bamboo fiber reinforced palm oil-based resin composite material prepared by the invention is environment-friendly and has good tensile strength, tensile modulus, bending strength and bending modulus.

Owner:FUJIAN AGRI & FORESTRY UNIV

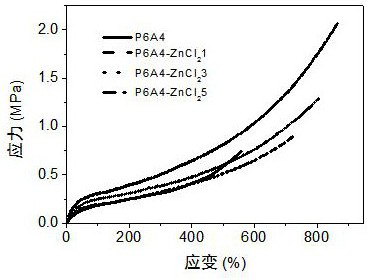

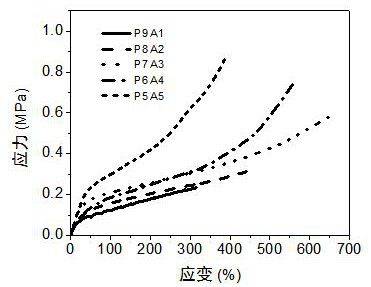

3D printing inorganic salt reinforced palm oil-based high-performance elastomer

ActiveCN111808232AHigh biobased contentLow priceAdditive manufacturing apparatusFatty acid chemical modification3d printInorganic salts

The invention belongs to the technical field of polymer elastomer materials, and particularly relates to a 3D printing inorganic salt reinforced palm oil-based high-performance elastomer and a preparation method thereof. A bio-based palm oil-based monomer and acrylic acid are used as raw materials, inorganic salt particles are used as a reinforcing material, and the palm oil-based high-performanceelastomer is obtained through a digital light treatment 3D printing technology under the action of a photoinitiator. The prepared palm oil-based high-performance elastomer is environment-friendly andhas good tensile strength and tensile elongation at break.

Owner:FUJIAN AGRI & FORESTRY UNIV

Palm oil-based thermoplastic elastomer for digital light processing 3D printing

ActiveCN111848867AIncrease productionHigh biobased contentAdditive manufacturing apparatusElastomerPolymer science

The invention belongs to the technical field of polymer elastomer materials, and particularly relates to a palm oil-based thermoplastic elastomer for digital light treatment 3D printing and a preparation method of the palm oil-based thermoplastic elastomer. According to the invention, the biomass resource palm oil is used as a raw material to synthesize palm oil fatty acid acrylamide ethyl ester,the palm oil fatty acid acrylamide ethyl ester is blended with acrylic acid, and the environment-friendly palm oil-based thermoplastic elastomer is prepared through a digital light treatment 3D printing technology under the action of a photoinitiator. The palm oil-based thermoplastic elastomer prepared by the invention is environment-friendly and has good tensile strength and tensile elongation atbreak.

Owner:FUJIAN AGRI & FORESTRY UNIV

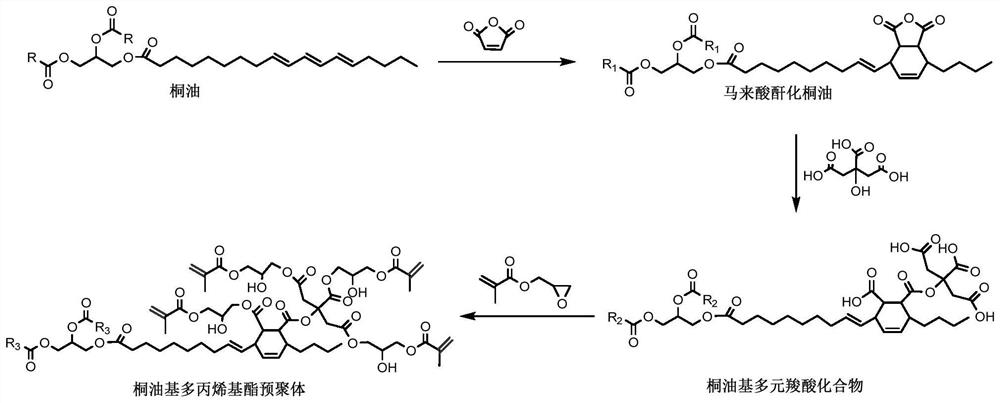

Photosensitive resin based on vegetable oil and citric acid as well as preparation method and application thereof

ActiveCN111732679AHigh functionalityHigh biobased contentOrganic compound preparationCarboxylic acid esters preparationPolymer scienceVegetable oil

The invention discloses photosensitive resin based on vegetable oil and citric acid as well as a preparation method and application thereof. The preparation method comprises the following steps: reacting vegetable oil with maleic anhydride to generate maleic anhydride vegetable oil; then carrying out anhydride ring-opening modification on the generated maleic anhydride vegetable oil by utilizing citric acid to obtain vegetable oil-based polycarboxylic acid; modifying the generated vegetable oil-based polycarboxylic acid compound by using glyceryl methacrylate to obtain a vegetable oil-based polypropenyl ester prepolymer; and finally, adding a vinyl diluting monomer, and uniformly dispersing the components to obtain a final product. The photosensitive resin has excellent mechanical, thermaland coating properties after photocuring, and can be used for photocuring coatings, printing ink and the like. The method is simple in process and environmentally friendly, most of the raw materialscome from renewable resources, and therefore the method has great significance in promoting sustainable development of the light-cured material industry.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

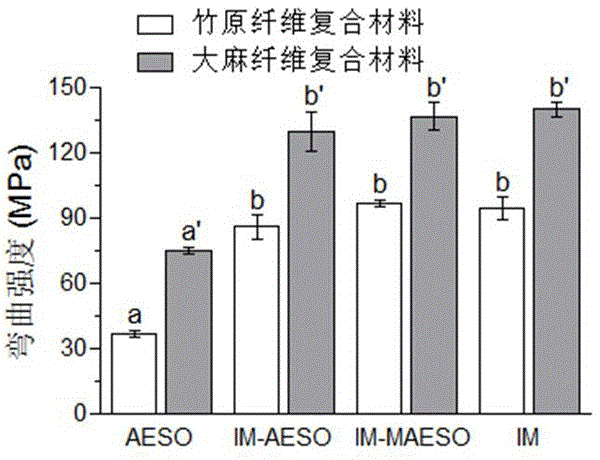

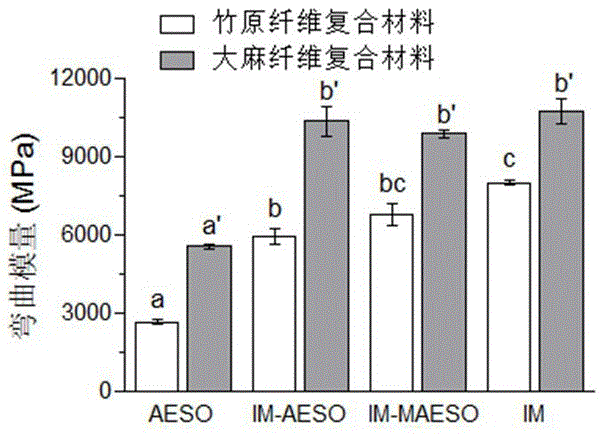

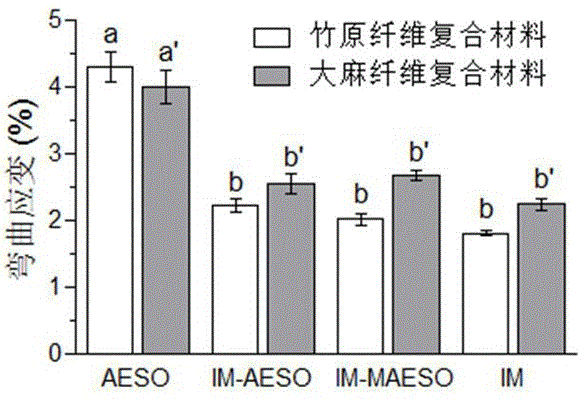

Plant fiber reinforced bio-based thermosetting resin composite

The invention discloses a plant fiber reinforced bio-based thermosetting resin composite and a preparation method thereof. Bio-based reactive solvent iosorbide-methacrylate is blended with acrylated epoxidized soybean oil to prepare bio-based thermosetting resin, and plant fibers, the bio-based thermosetting resin and an initiator are subjected to thermo-compression formation to obtain the plant fiber reinforced bio-based thermosetting resin composite. The plant fiber reinforced bio-based thermosetting resin composite and a plant fiber reinforced modified bio-based thermosetting resin composite prepared by the method have good bending strength, bending modulus and bending strain performance.

Owner:FUJIAN AGRI & FORESTRY UNIV

A kind of biotype thermoplastic polyurethane elastomer and preparation method thereof

The invention discloses a bio-type thermoplastic polyurethane elastomer and a preparation method thereof. The bio-type thermoplastic polyurethane elastomer has high bio-based content and excellent comprehensive performance. The polyol number average molecular weight is 800-6000g / mol, and the polyol contains 50-100wt% bio-based polyester polyol; b) 0-25wt% chain extender component, and the chain extender contains 50-100wt% Bio-based chain extender; c) 5-45wt% diisocyanate component, said diisocyanate containing 10-60wt% bio-based diisocyanate; d) 0.001-0.1wt% catalyst component, said catalyst containing 50-100wt% Non-tin environment-friendly catalyst. The total bio-based content of components a) to c) is greater than or equal to 50 wt%. The thermoplastic polyurethane elastomer can be prepared by one-step method, batch method or prepolymer method.

Owner:WANHUA CHEM GRP CO LTD

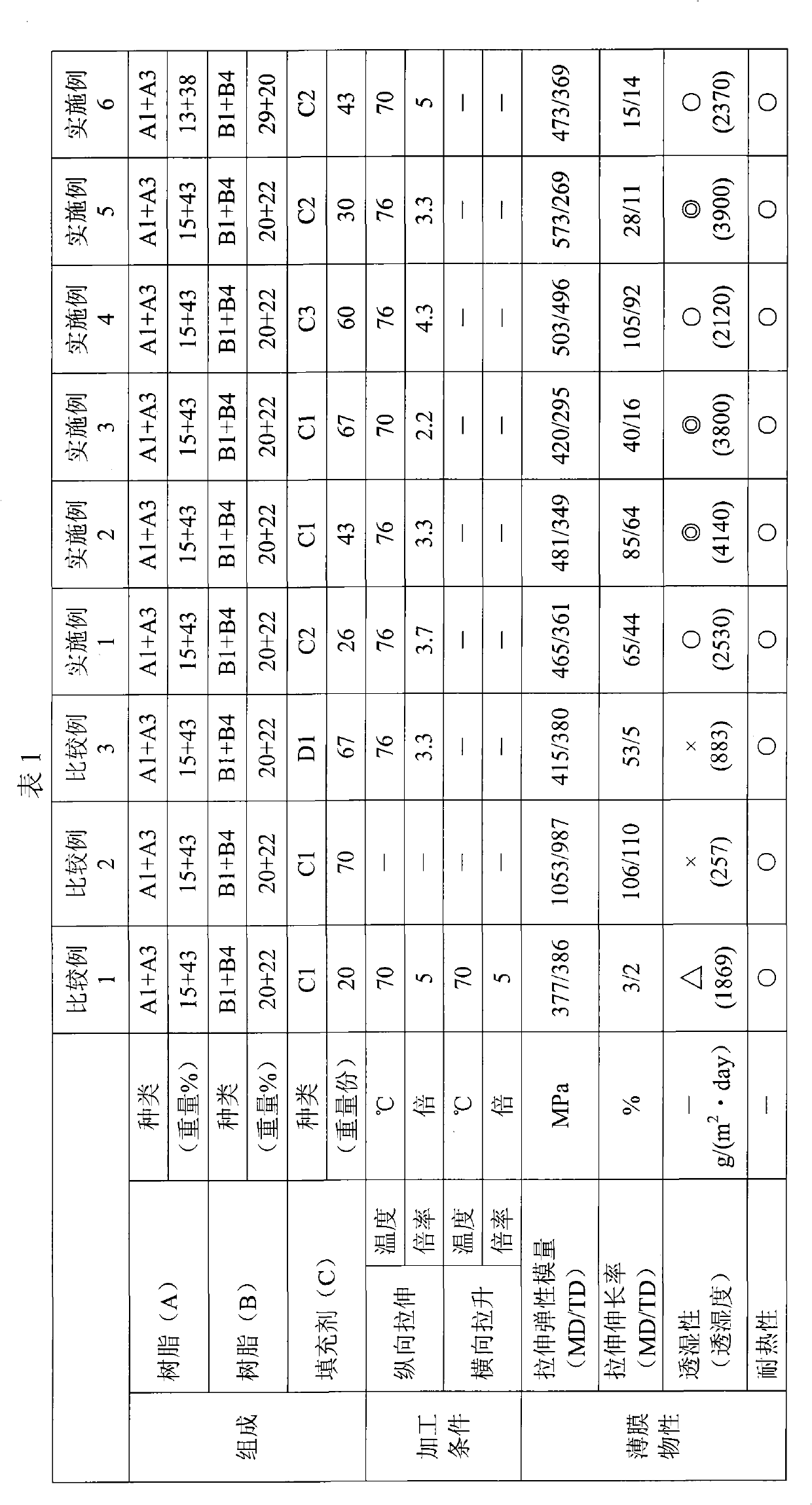

Moisture permeable porous film

InactiveCN103319863AHigh biobased contentGood moisture permeabilityHeat resistanceMoisture permeability

The invention discloses a moisture permeable porous film. The film comprises following ingredients, by weight: 10 to 95 portions of polylactic resin (A), 5 to 90 portions of thermoplastic resin (B) which is not a polylactic resin, and zeolite which is used as a filling agent, wherein the total amount of polylactic resin (A) and thermoplastic resin (B) is 100 portions. The porous film possesses excellent moisture permeability, flexibility, heat resistance, and is biodegradable. The porous film can be applied in the production of the substrates of bedsheets, pillowcases, sanitary towels, disposable diapers and the like which possess hydroscopicity, and materials of raincoats, gloves, garbage bags, fertilizer bags, vegetable or fruit packing bags, and packing bags of industrial products.

Owner:TORAY ADVANCED MATERIALS RES LAB CHINA

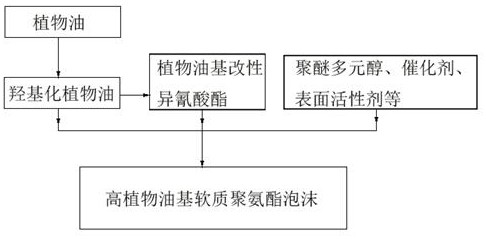

Synthesis process and application of vegetable oil-based modified isocyanate

The invention relates to a synthesis process and application of vegetable oil-based modified isocyanate. Vegetable oil modified isocyanate is adopted, isocyanate and hydroxylated vegetable oil react,the content of modified TDI isocyanate radicals is 30%-42%, the content of modified MDI isocyanate radicals is 15%-25%, and the content of modified TDI / MD mixed isocyanate radicals is 18%-35%. The isocyanate comprises: TDI, MDI, or a mixture of TDI and MDI. Hydroxylated vegetable oil, petroleum-based polyether polyol, petroleum-based polymer polyol, a catalyst, a silicone oil surfactant and a foaming agent are mixed and react with vegetable oil-based isocyanate, and the high vegetable oil-based soft polyurethane foam plastic is obtained. The plant oil-based polyurethane foam has the advantagesthat the proportion of the plant oil-based material in the soft polyurethane foam is 30%-50%, great help is provided for reducing dependence on petroleum-based polyurethane raw materials and improving the degradation rate of the soft polyurethane foam, and powerful support is provided for national environmental protection policies.

Owner:江苏君晟家居科技有限公司

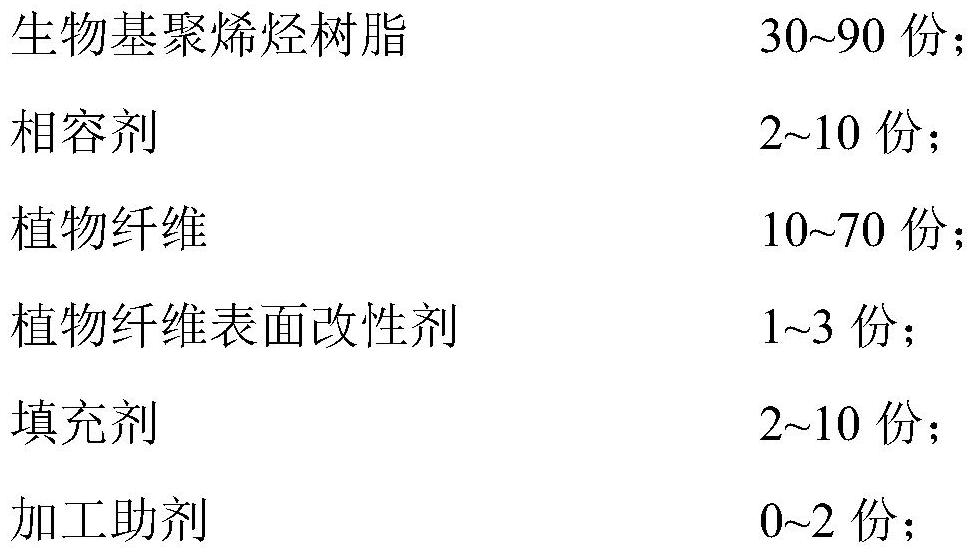

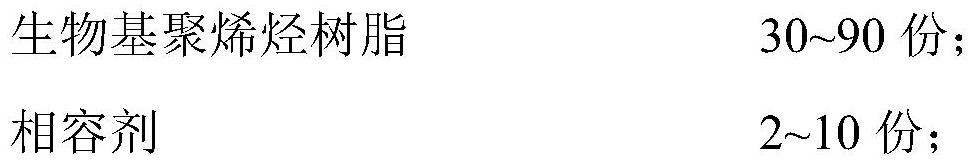

Wood-plastic composite material with high bio-based content as well as preparation method and application thereof

Owner:KINGFA SCI & TECH CO LTD

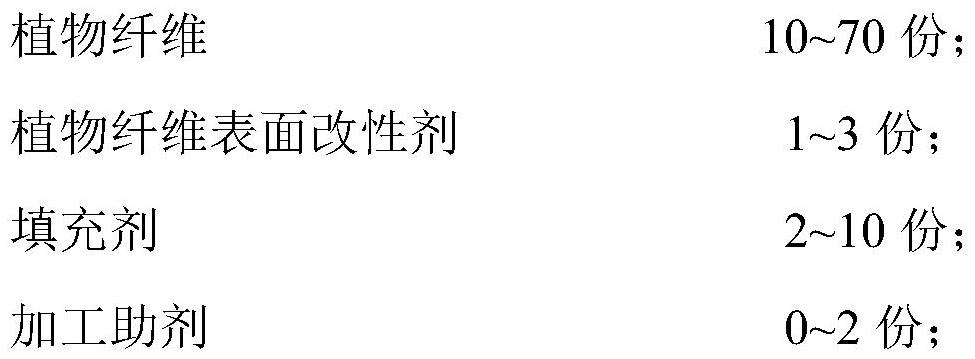

Vegetable oil-based polyol, preparation method thereof, thermocuring vegetable oil-based polyurethane, and preparation method and application of thermocuring vegetable oil-based polyurethane

ActiveCN114853972AHigh hardnessImprove toughnessPolyureas/polyurethane adhesivesInksPolymer scienceVegetable oil

The invention belongs to the technical field of high polymer materials, and particularly relates to vegetable oil-based polyol and a preparation method thereof, and thermocuring vegetable oil-based polyurethane and a preparation method and application thereof. The preparation method comprises the following steps: preparing aminolysis vegetable oil by using an aminolysis agent, carrying out esterification modification on the aminolysis vegetable oil by using acid anhydride, and finally adding epoxidized vegetable oil for blending to obtain the vegetable oil-based polyol with high functionality and high bio-based content. And blending the prepared vegetable oil-based polyol with isocyanate to prepare the thermocuring vegetable oil-based polyurethane. A large number of hydroxyl groups, cyclic structures and epoxidized vegetable oil are introduced into the vegetable oil, the tensile strength and toughness of polyurethane can be effectively improved, and the obtained polyurethane is good in storage stability and high in crosslinking density.

Owner:SOUTH CHINA AGRI UNIV +1

Light-cured resin based on vegetable oil and itaconic acid and preparation method and application of light-cured resin

InactiveCN113416610AGood for cross-linking and curingHigh functionalityFatty acid chemical modificationCoatingsPolymer scienceGlycidyl methacrylate

The invention discloses light-cured resin based on vegetable oil and itaconic acid and a preparation method and application of the light-cured resin. The preparation method comprises the following steps: firstly, synthesizing an unsaturated itaconic acid half ester precursor by utilizing itaconic acid and glycidyl methacrylate, and then modifying epoxidized vegetable oil by utilizing the precursor to obtain a vegetable oil-based epoxy acrylate prepolymer; and finally, adding a vinyl diluent, and uniformly blending to obtain a final product. The synthetic process is solvent-free, the volatility is low, the synthetic route is simple, the main raw materials of the resin material are the vegetable oil and the itaconic acid, the bio-based content is high, and the use of a large amount of petroleum-based raw materials is expected to be reduced, so that the method is very green and environment-friendly. The obtained bio-based light-cured resin has good mechanical, thermal and coating properties, can be used as a main component of general paint or self-repairing paint, and is used for surface coatings of woodware, metal, plastic and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

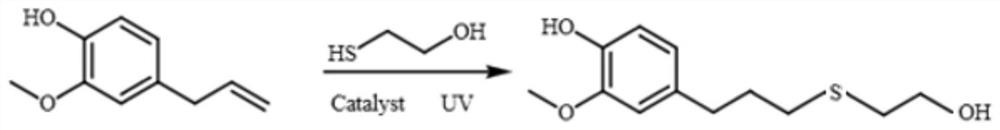

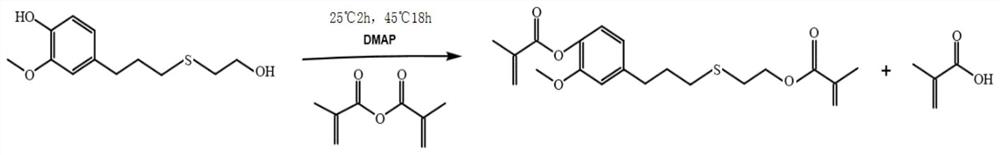

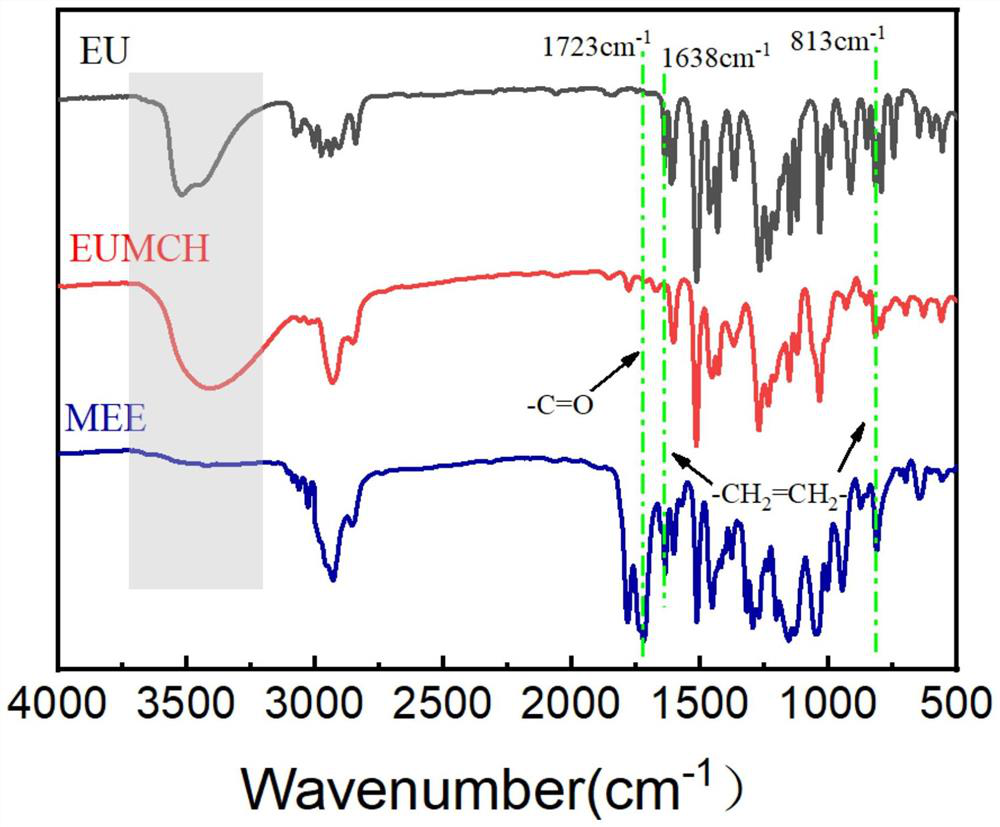

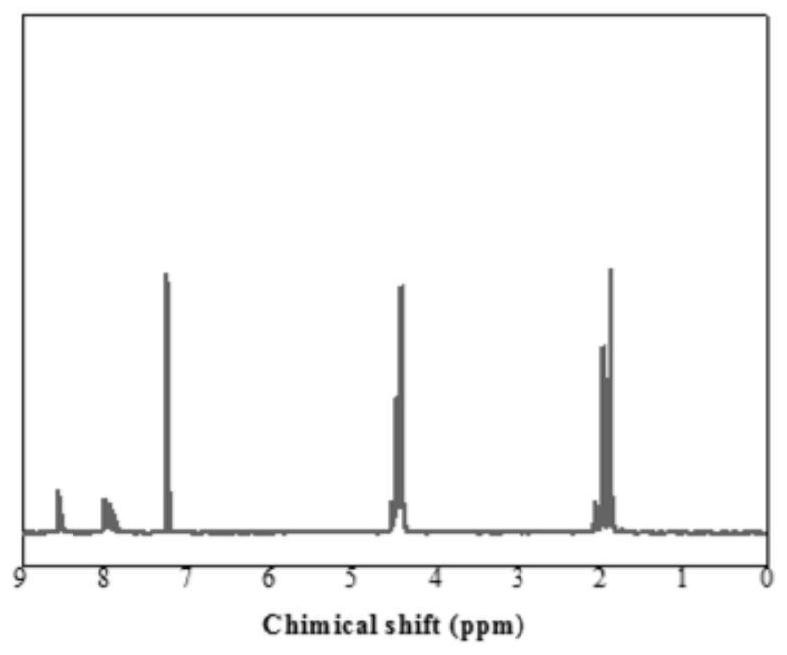

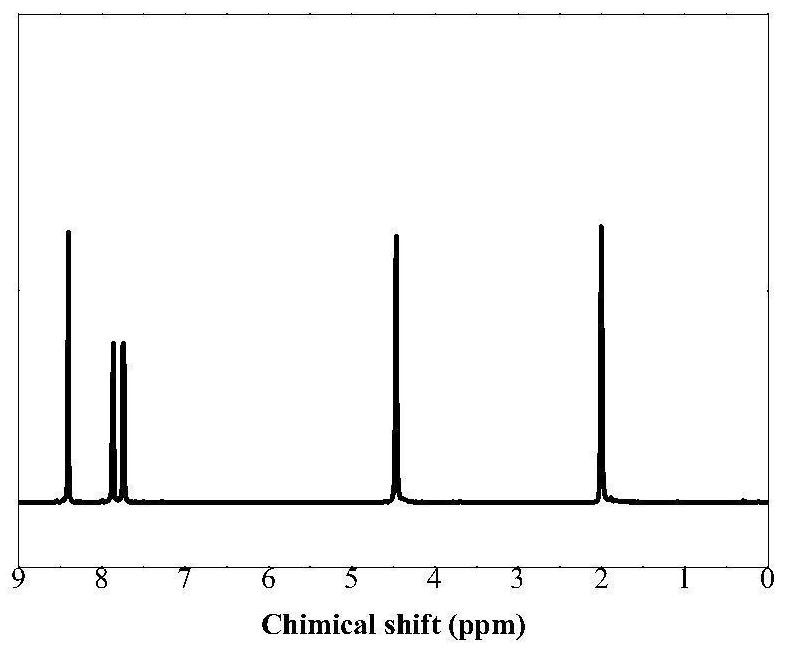

Eugenol methacrylate, preparation method thereof, eugenol-based epoxy vegetable oil acrylate UV curing system and application of eugenol-based epoxy vegetable oil acrylate UV curing system

PendingCN114736145AWell mixedImprove corrosion resistanceAdditive manufacturing apparatusInksPolymer scienceVegetable oil

The invention belongs to the technical field of UV curing materials, and particularly relates to eugenol methacrylate and a preparation method thereof as well as an eugenol-based epoxy vegetable oil acrylate UV curing system and application of the eugenol-based epoxy vegetable oil acrylate UV curing system. Eugenol and 2-mercaptoethanol are used as raw materials, eugenol polyol is prepared through a thiol-ene light click reaction, then eugenol polyol and methacrylic anhydride are subjected to an esterification reaction, and methacrylic acid eugenol is synthesized. Then, epoxy vegetable oil and acrylic acid are subjected to a ring-opening reaction to prepare epoxy vegetable oil acrylate, methacrylic acid eugenol is used as a reactive diluent and is blended with the epoxy vegetable oil acrylate to prepare a film, and the eugenol-based epoxy vegetable oil acrylate light-cured film is obtained. A large number of benzene ring structures and double bonds are introduced into epoxy vegetable oil acrylic acid, the tensile strength of a cured film can be effectively improved, the light curing time is shortened, the corrosion resistance of the film is improved, and the crosslinking density is high.

Owner:SOUTH CHINA AGRI UNIV

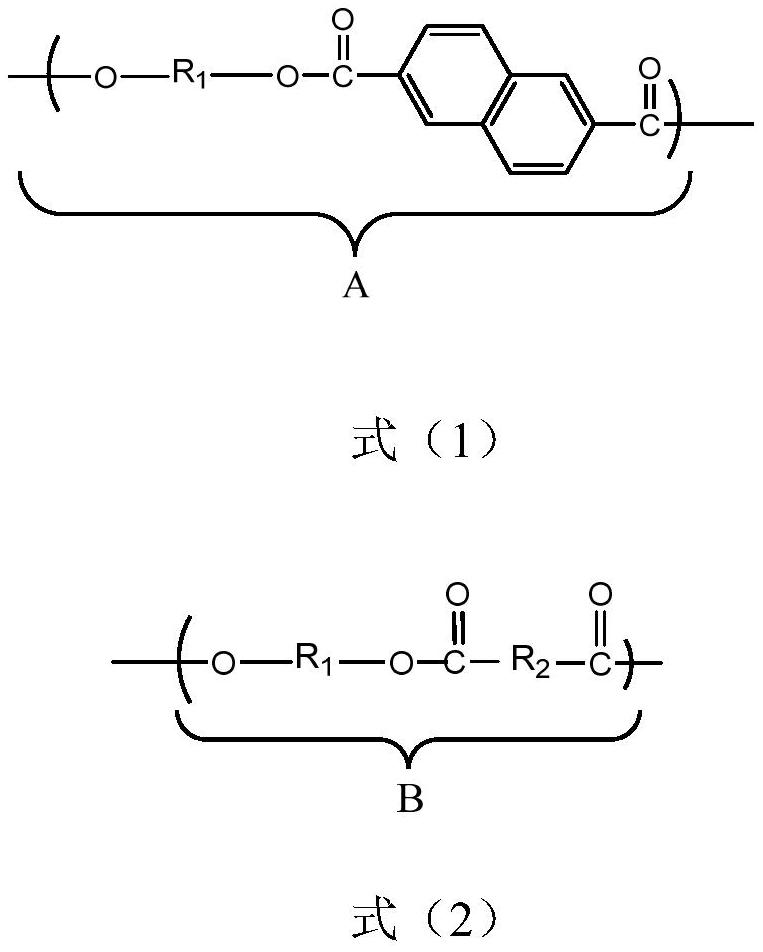

2, 6-naphthalic acid-based copolyester material and preparation method thereof

The invention provides a 2, 6-naphthalic acid-based copolyester material and a preparation method thereof, and the structural formula of the material is composed of structural units represented by a general formula (1) and a general formula (2). The invention also provides a preparation method of the 2, 6-naphthalic acid-based copolyester material. According to the invention, 2, 6-naphthalic acid (2, 6-naphthalic acid diester compound), 2, 5-thiophenedicarboxylic acid (2, 5-thiophenedicarboxylic acid diester compound) or 2, 5-furandicarboxylic acid (2, 5-furandicarboxylic acid diester compound) and diol are subjected to direct esterification or ester exchange reaction to prepare the copolyester material, and the bio-based monomer 2, 5-thiophenedicarboxylic acid (2, 5-thiophenedicarboxylic acid diester compound) or 2, 5-furandicarboxylic acid (2, 5-furandicarboxylic acid diester compound) can easily increase the bio-based content of the 2, 6-naphthalic acid-based polyester, improve the toughness, and improve the barrier property.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Highly-water-resistant polyurethane emulsion having high biobased content, and its preparation method

InactiveCN103073694BImprove water resistanceHigh biobased contentPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsHydrophilic monomerVegetable oil

The invention discloses a vegetable oil based polyurethane emulsion containing a vegetable based carboxylic acid type hydrophilic monomer, and its preparation method. The emulsion is prepared through using the following substances, by weight, 27.59-38.06 parts of diisocyanate, 23.42-32.34 parts of castor oil, 0.1-0.2 parts of an organic tin catalyst, 6.68-10.87 parts of a salt forming reagent, 22.95-37.42 parts of the vegetable oil based carboxylic acid type hydrophilic monomer, and 160.0-216.70 parts of deionized water. The dry film of the vegetable oil based highly-water-resistant polyurethane emulsion has the characteristics of no whitening and no cracking after the immersion in water for 30 days, and has a water absorption rate of 5.6-12.1% after the immersion for 192h; and the highly-water-resistant polyurethane emulsion has the advantages of low cost, renewability, no environmental pollution, biodegradable property and the like because main used raw materials are renewable resources, can be used for coatings and adhesives as a resin, and can be especially used in occasions having a high water resistance requirement.

Owner:JIANGXI SCI & TECH NORMAL UNIV

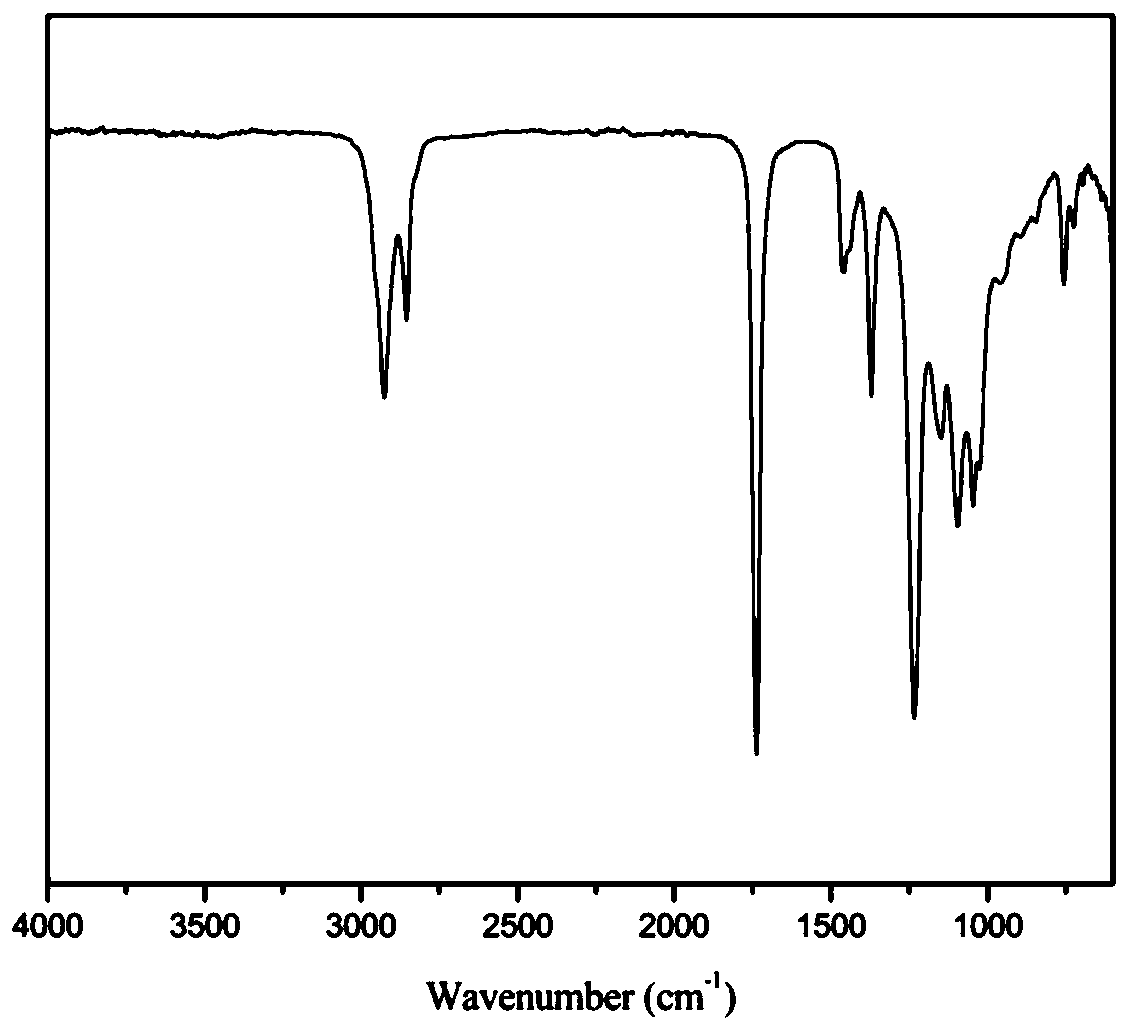

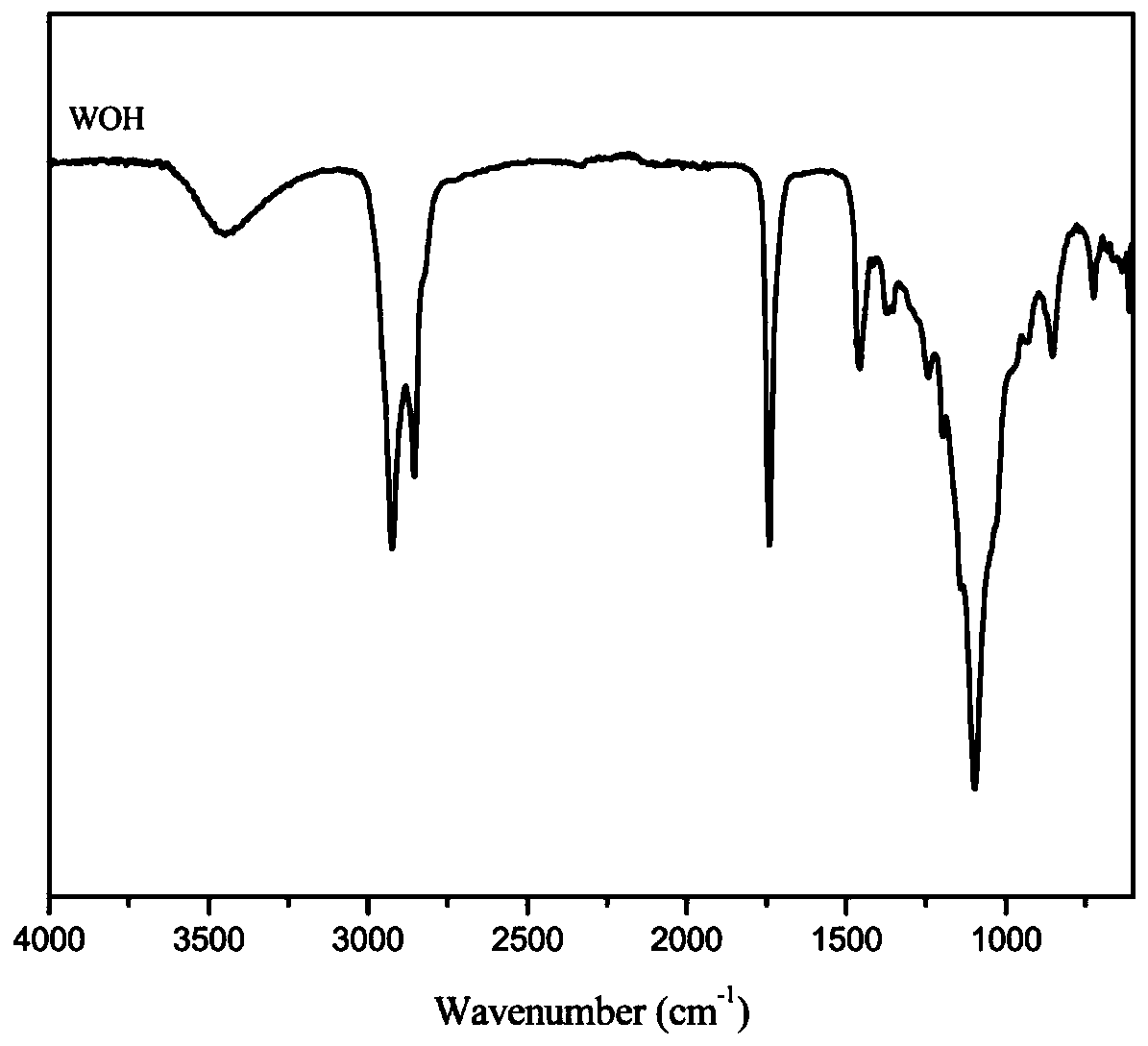

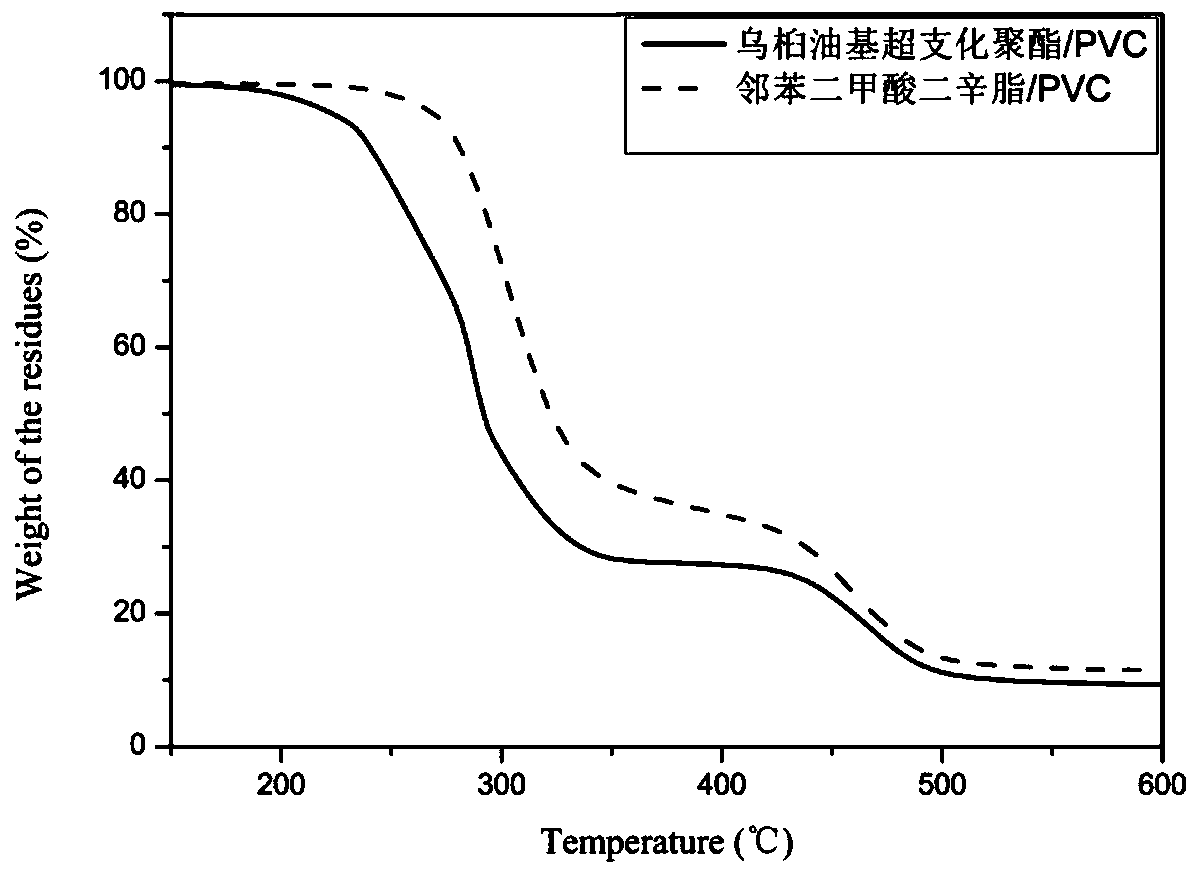

Sapium sebiferum oil-based hyperbranched polyester plasticizer and preparation method thereof

The invention discloses a sapium sebiferum oil-based hyperbranched polyester plasticizer and a preparation method thereof. The preparation method comprises: synthesizing sapium sebiferum oil polyol byusing industrial woody grease resource sapium sebiferum oil as a raw material through a one-step method; adding glycidyl ether and a catalyst, and synthesizing a hyperbranched polymer by adopting a solvent-free one-pot method under the protection of nitrogen; and continuously carrying out a hydroxyl-terminated modification reaction to prepare the sapium sebiferum oil-based hyperbranched polyesterplasticizer product. According to the invention, the raw materials are wide in source and renewable and do not depend on petroleum; the byproducts in the preparation process are few, the product quality is stable, the process is simple and reasonable, and the energy consumption is low; and the product is non-toxic, environment-friendly, good in heat resistance and durability and excellent in plasticizing performance, and has good application prospect.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

Biodegradable polyols having higher biobased content

InactiveCN110352208AHigh Bio-Based Carbon ContentPromote degradationOrganic chemistryPolymer scienceOligomer

The present invention is directed to biodegradable polyester polyol polymers having high bio-based content and methods for producing biodegradable polyester polyol polymers having high bio-based content. In preferred embodiments, beta-lactone monomers may be produced from epoxide and carbon monoxide having high bio-based content. In certain preferred embodiment, the beta-lactone is beta-propiolactone produced from ethylene oxide and carbon monoxide. In certain embodiments, beta-lactones may be polymerized with diols, triols, and polyols to form the biodegradable polyester polyol polymers having high bio-based content. In some embodiments, the biodegradable polyester polyol polymers having high bio-based content may be terpolymers formed from a first beta-lactone, a diol, triol, or polyol,and a second beta-lactone. In some other embodiments, the biodegradable polyester polyol polymers having high bio-based content may be copolymers formed from a polylactone oligomer and a diol, triol,or polyol.

Owner:NOVOMER INC

Completely biodegradable resin made of non-staple grain plant modified starch and preparation method thereof

ActiveCN102408588BIncrease the amount addedHigh resource substitutionBiodegradable copolymersAlant starch

The invention discloses completely biodegradable resin made of non-staple grain plant modified starch and its preparation method. The method comprises the steps of: first putting non-staple grain plant starch into a reaction vessel, adding water to prepare it into starch milk, and heating it to a proper temperature, conducting stirring and washing, then adding chemicals into a water solution for modification grafting treatment, and then separating water and starch through centrifugation, and conveying the separated modified starch to an airflow drying system for dewatering and drying, then taking 100 parts of dried modified starch, adding 5-50 parts of a compatilizer, 2-15 parts of an anti-block agent, 0-100 parts of polylactic acid, and 150-250 parts of a completely biodegradable copolymer of dibasic acid and dibasic alcohol, and mixing them uniformly, carrying out extrusion granulating or tabletting under an appropriate temperature and pressure, thus obtaining a resin material or sheet special for complete biodegradation. The resin of the invention has both the usage function similar to ordinary plastic products and a complete biodegradability. And after being used and abandoned, the resin can be degraded into carbon dioxide and water that can be consumed by the environment.

Owner:SUZHOU HANFENG NEW MATERIAL

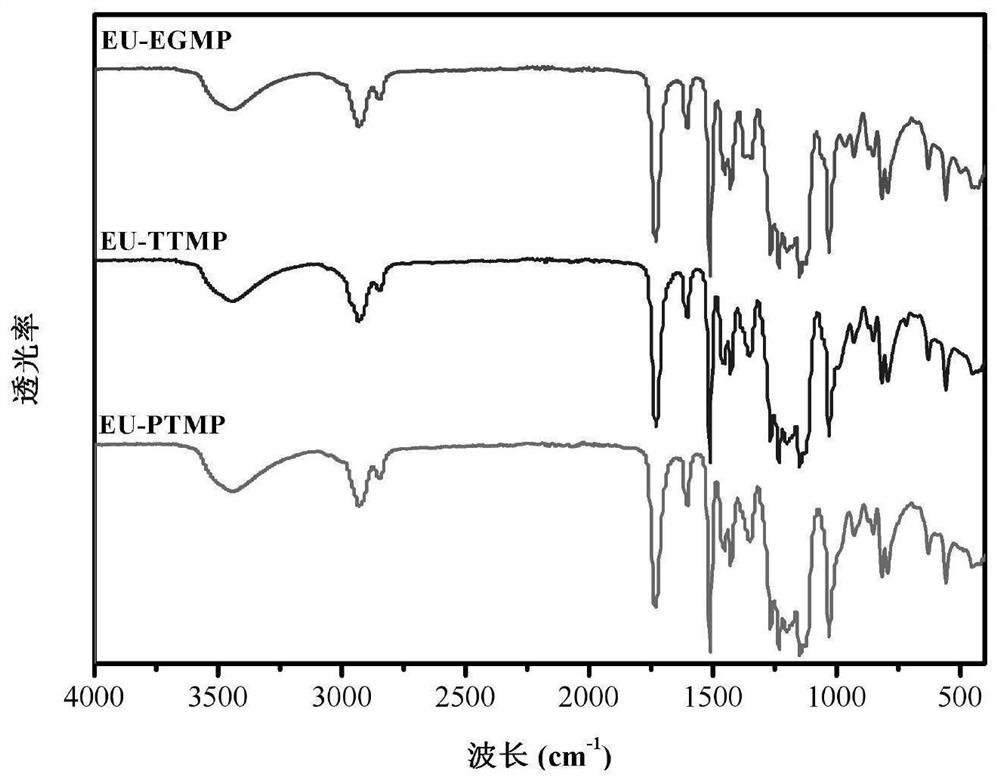

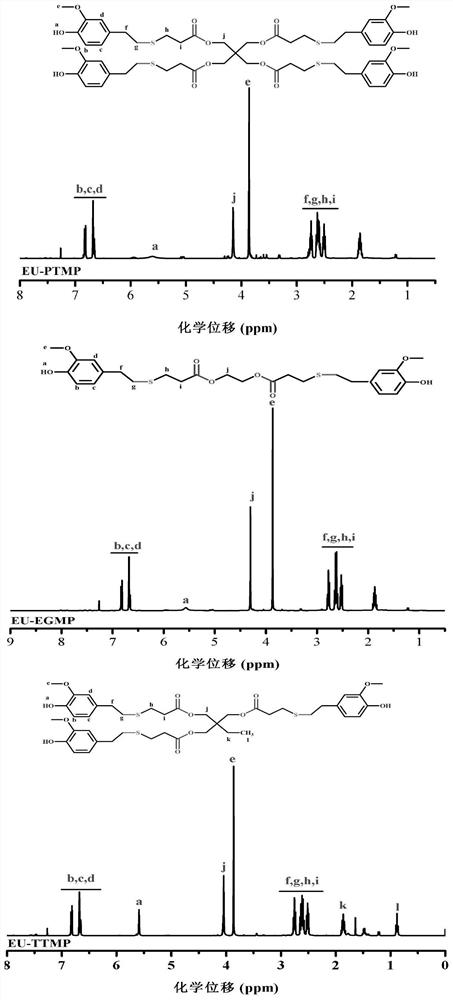

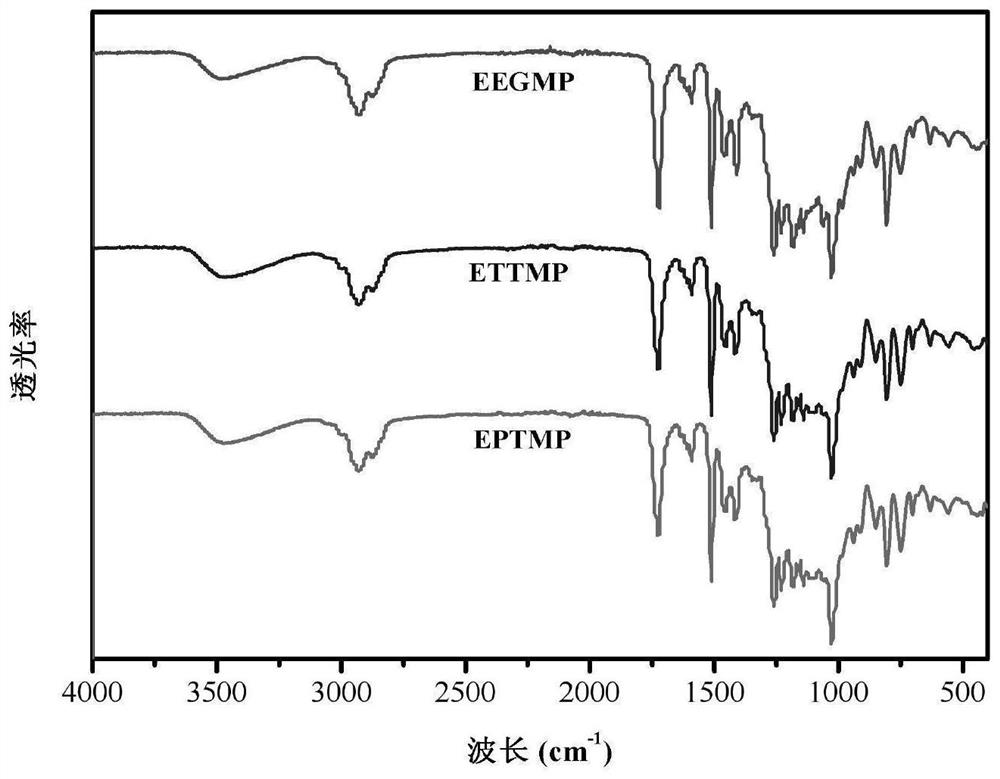

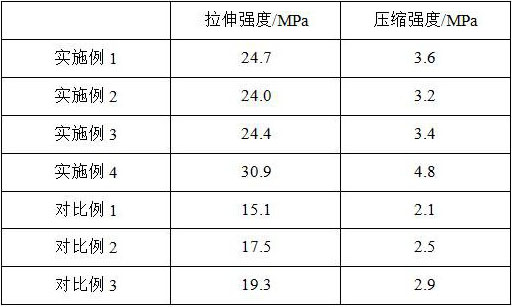

Preparation method of bio-based self-repairing flame-retardant material with high dielectric property

PendingCN113956438AAvoid dependence on petrochemical raw materialsReduce pollutionChemistryFlame resistance

The invention discloses a preparation method of a bio-based self-repairing flame-retardant material with high dielectric property and a product thereof. The bio-based self-repairing flame-retardant material with high dielectric property is synthesized by taking eugenol, multi-sulfydryl ester and disulfide bond-containing amine as main raw materials and sequentially adopting click chemistry, epoxidation and melt polymerization methods. The main raw materials are wide in source, renewable and independent of petroleum; the preparation process is simple and reasonable and low in energy consumption; the product has good thermal stability, can be recycled, and is easy to degrade and recover. Test results show that the self-repairing self-flame-retardant epoxy resin prepared by the invention has a 100% repairing effect (160DEG C) and excellent dielectric properties and flame retardancy.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Degradable foaming slipper material with high starch content and preparation method thereof

The invention belongs to the technical field of slipper materials, and particularly discloses a degradable foaming slipper material with high starch content and a preparation method thereof. The composite material is prepared from the following raw materials in parts by weight: 40-65 parts of starch, 15-45 parts of EVA resin, 2-6 parts of modified plant fibers, 3-8 parts of a reactive aid, 0.6-4 parts of a compatibilizer, 1-3 parts of a foaming agent, 0.8-2 parts of a hydrophobic aid, 0.4-1 part of a lubricant, 0.5-1.2 parts of a grafting aid, 0.1-0.5 part of an antibacterial agent and 0.1-0.5 part of an antioxidant. The slipper material is degradable, high in bio-based content and good in mechanical strength, the foaming slipper material is good in rebound resilience, starch is adopted as a base material, the cost can be remarkably reduced, compared with a traditional EVA foaming material, the cost can be reduced by 30%, the starch is adopted as the base material, coloring is stable and uniform, and no obvious plastic taste exists.

Owner:深圳国至新材料科技有限公司

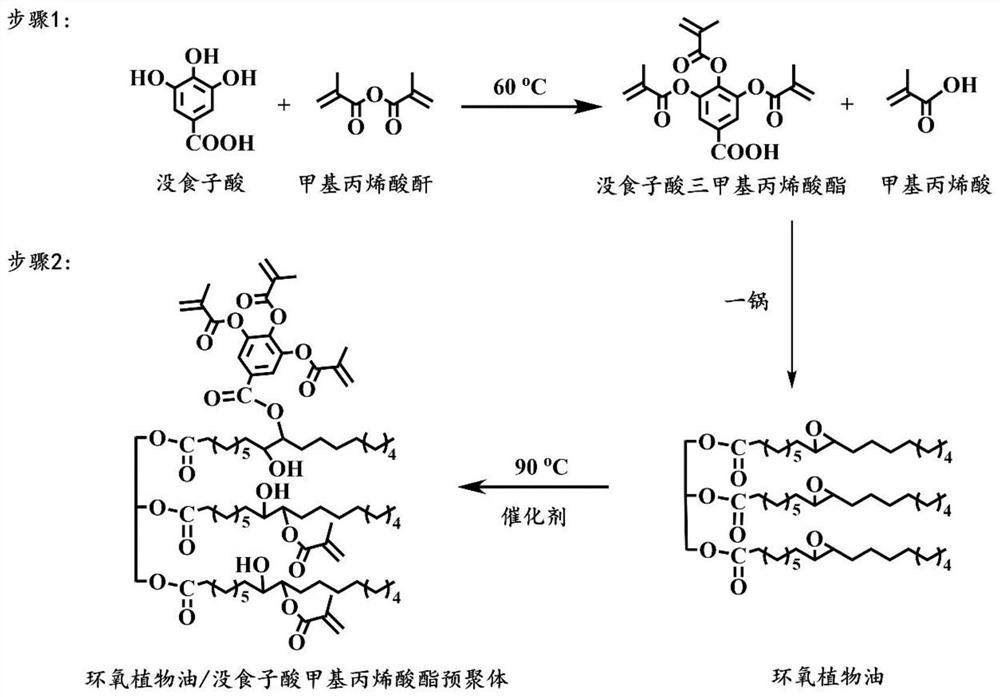

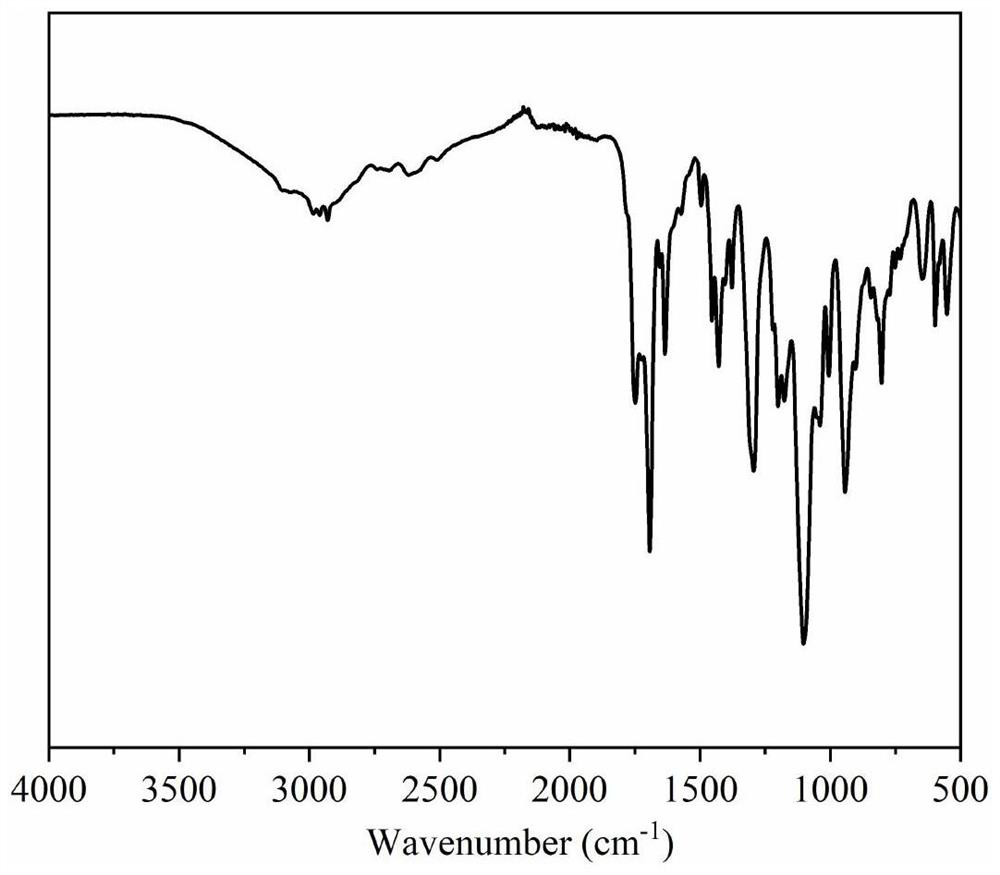

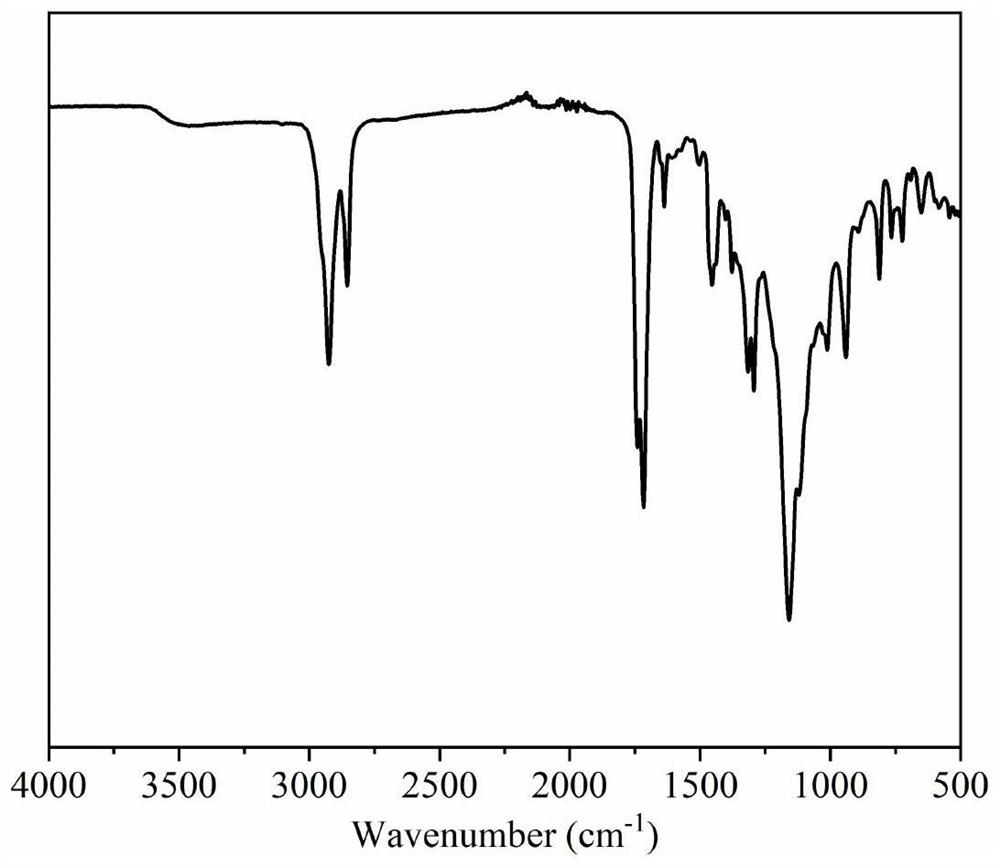

A kind of photocurable resin based on epoxy vegetable oil and gallic acid and its preparation method and application

ActiveCN113461847BHigh biobased contentIncreased double bond contentAdditive manufacturing apparatusOrganic compound preparationPolymer scienceGallic acid ester

The invention discloses a photocurable resin based on epoxy vegetable oil and gallic acid, a preparation method and application thereof. The present invention first uses gallic acid and acrylic anhydride compounds to react to obtain a gallic acid triacrylate / acrylic acid compound mixed intermediate; then uses epoxy vegetable oil to perform epoxy ring-opening reaction with the obtained mixed intermediate to obtain a novel bio-based ring Oxyacrylate prepolymer; finally add diluting monomer, photoinitiator, polymerization inhibitor, etc., and disperse evenly to obtain bio-based photocurable resin. The obtained resin has the advantages of low viscosity, fast curing speed and the like, and the mechanical and thermodynamic properties of the cured material are excellent. Therefore, it can be used as matrix resin applications such as photocurable 3D printing materials, coatings and inks. The process of the invention is simple and environment-friendly, and most of the raw materials come from renewable resources, so it has great significance for promoting the sustainable development of light-curing materials.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

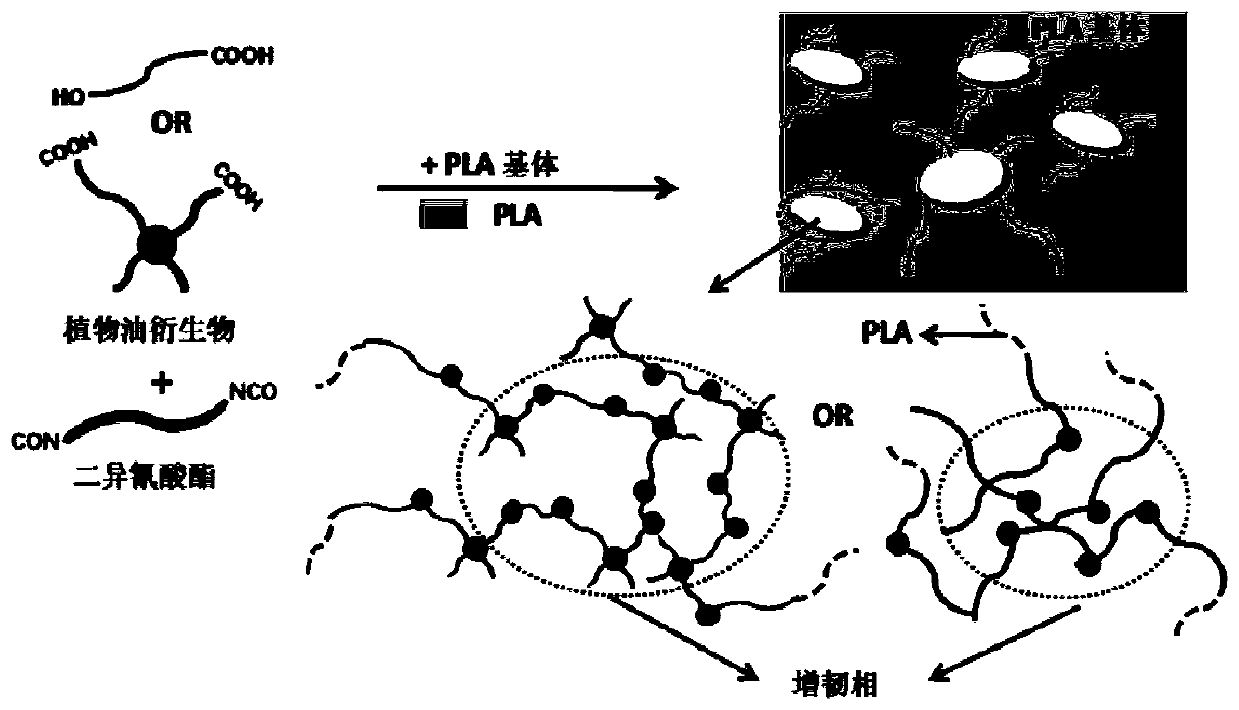

Method for preparing polylactic acid composites with high impact toughness by reactive blending of vegetable oil derivatives

The invention discloses a vegetable oil derivative reactive blending method for preparing a high-impacting toughness polylactic acid compound. The method adopts carboxy groups or a hydroxyl group anda carboxy group at the two ends of a toughening monomer a, and the carboxy groups or the hydroxyl group and the carboxy group and a toughening monomer b isocyanate group are subjected to a high-activity condensation reaction; if the toughening monomer a further contains an unsaturated C=C double bond, a free radical cross-linking reaction is conducted again, in the PLA melt blending process, a bio-based elastomer toughening phase which has good compatibility with a PLA base body and is dispersed uniformly is generated in situ, and the required product is finally obtained. The prepared PLA compound has higher biological base content, better biodegradability and better biocompatibility, and due to the fact that the toughening monomer a (namely, a dual functional group vegetable oil derivative containing binary carboxy groups or the hydroxyl group and the carboxy group) skeleton has a hydrophobicity character, the generated PLA compound has a better water resisting property.

Owner:ZHEJIANG FORESTRY UNIVERSITY

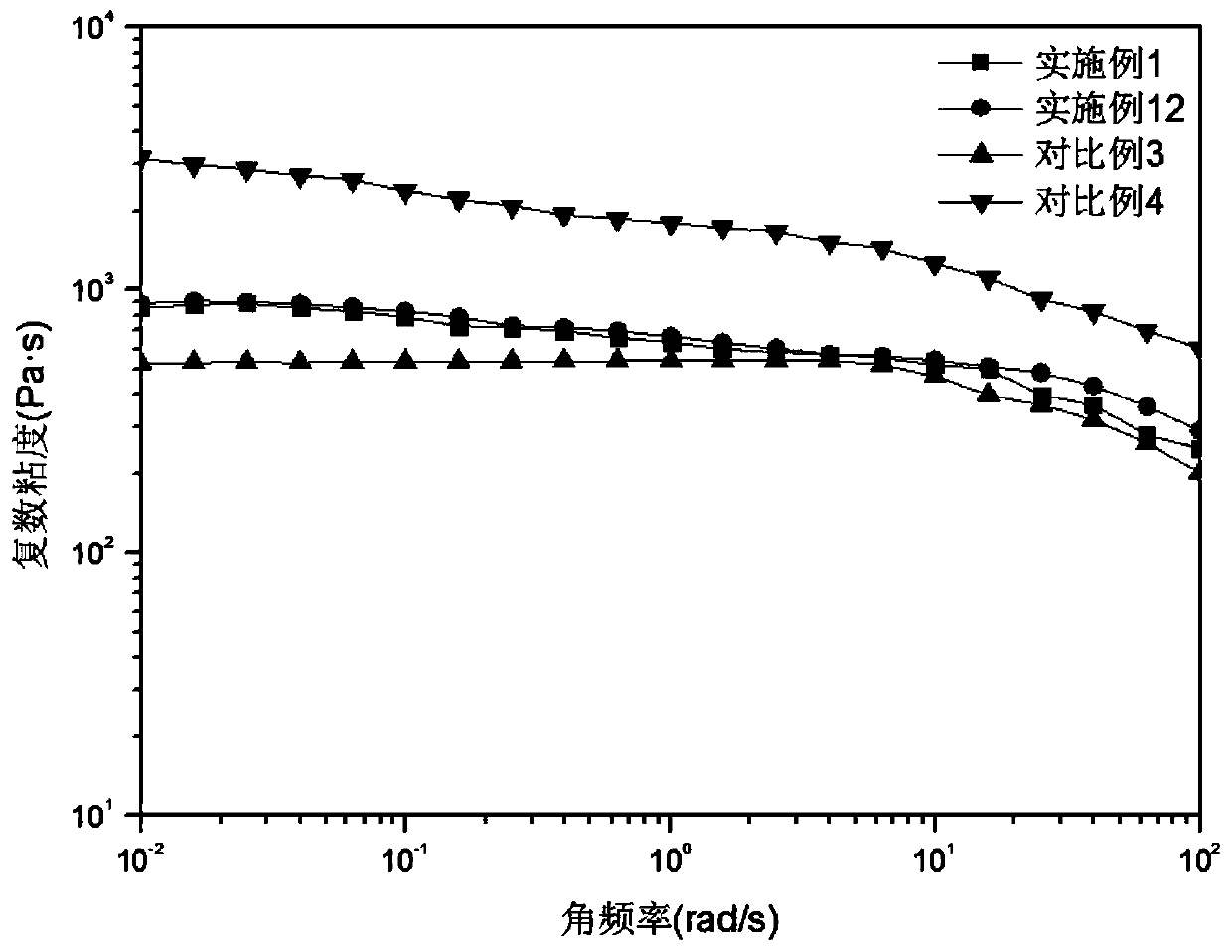

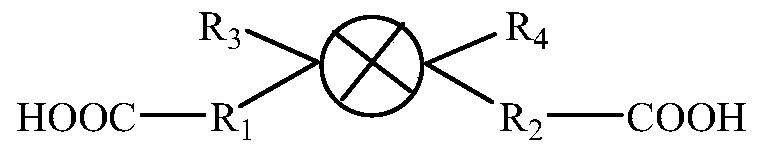

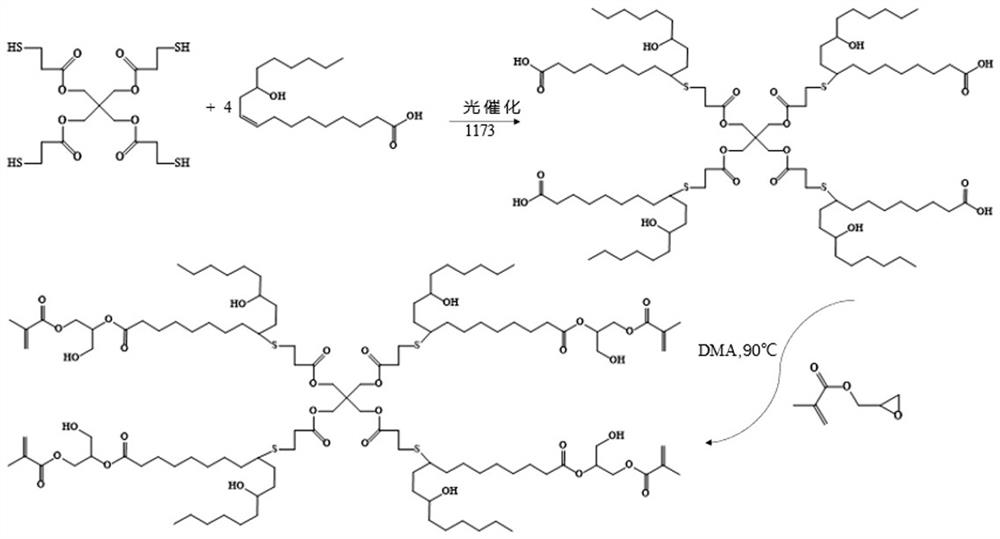

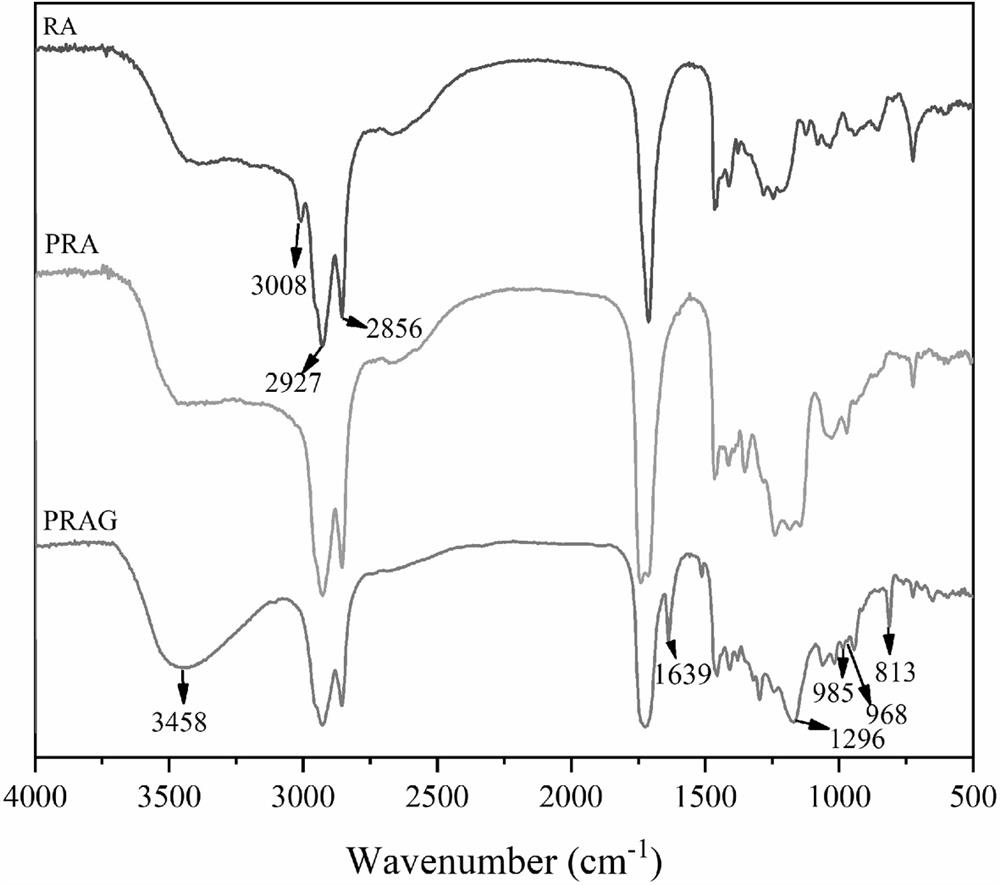

A kind of multifunctional bio-based acrylate prepolymer and its preparation method and application

ActiveCN112961084BReduce consumptionHigh biobased contentAdditive manufacturing apparatusInksPolymer scienceGlycidyl methacrylate

The invention belongs to the field of UV curing materials, and specifically relates to a preparation method of a multifunctional bio-based acrylate prepolymer, comprising: reacting tetrakis(3-mercaptopropionic acid) pentaerythritol ester and vegetable oleic acid to obtain vegetable oil-based polycarboxylic acid; Vegetable oil-based polycarboxylic acid, stir and control the temperature to 50-70°C, add a tertiary ammonium salt catalyst, raise the temperature to 70-90°C and add glycidyl methacrylate containing a polymerization inhibitor to react, then raise the temperature to 90-100°C reaction to obtain a functional bio-based acrylate prepolymer, and then compound with isobornyl methacrylate to prepare a bio-based UV curable material. On the one hand, the yield of the prepolymer of the present invention can be as high as more than 99%; secondly, four vegetable oleic acids are introduced into the mercapto groups of tetrakis (3-mercaptopropionic acid) pentaerythritol ester, thereby improving the bio-based content of UV curable coatings ; Third, introducing bio-based raw materials into acrylate and compounding bio-based active diluent isobornyl methacrylate reduces the consumption of fossil resources.

Owner:SOUTH CHINA AGRI UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com