Biological-type thermoplastic polyurethane elastomer and preparation method thereof

A thermoplastic polyurethane, bio-based technology, applied in the field of polyurethane materials, can solve the problems of polyurethane performance improvement without further research, and achieve the effects of excellent hydrolysis resistance and molding performance, high crystallization rate, and good hydrolysis resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

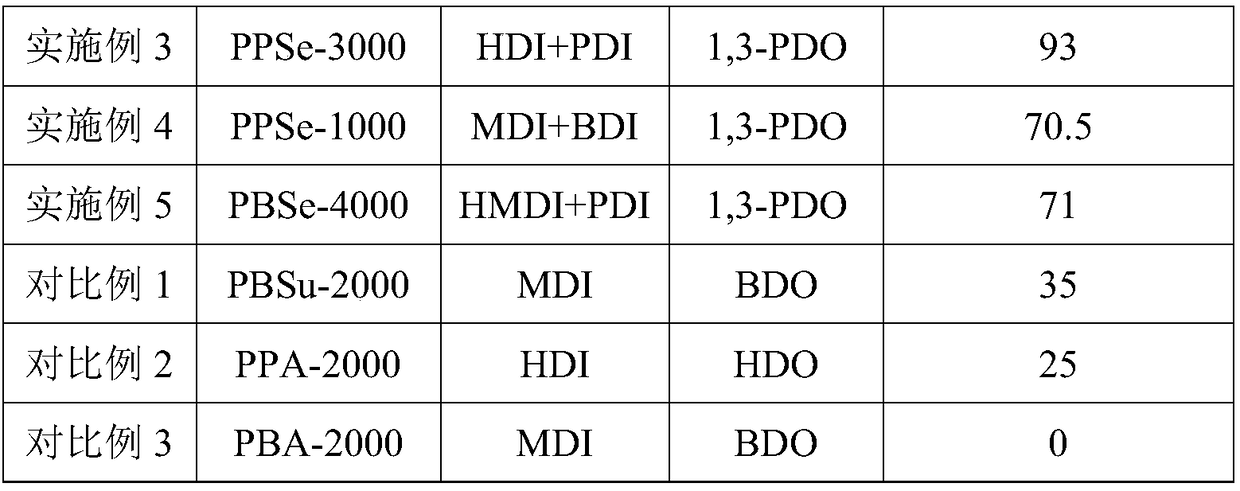

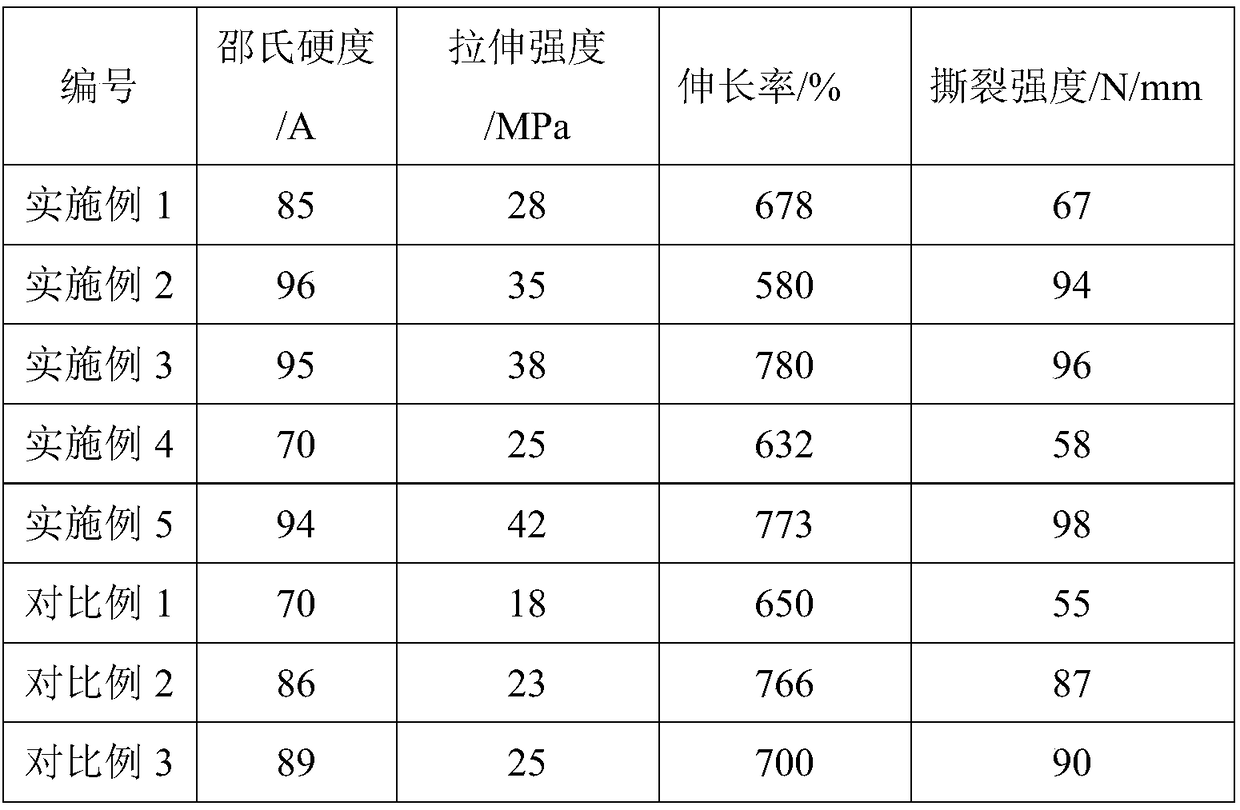

[0034]Preparation of bio-based thermoplastic polyurethane elastomers:

[0035] The bio-based raw material information involved in the embodiments of the present invention is as follows:

[0036] Bio-based polyester polyols:

[0037] Bio-based succinic acid, purchased from BioAmber company;

[0038] Bio-based sebacic acid was purchased from Hebei Kaide Biomaterials Co., Ltd.

[0039] Bio-based 1,3-propanediol was purchased from DuPont.

[0040] Preparation of bio-based poly(1,3-propylene glycol succinate):

[0041] Add bio-based succinic acid and bio-based 1,3-propanediol in a molar ratio of 1:1.2 into a reaction kettle with a fractionation tower and a distillation receiver, and heat up to 180°C for reaction. When the acid value drops to 15mg KOH / g , evacuate to below 100pa, raise the temperature to 200°C to continue the reaction, stop the reaction when the acid value is less than 1.5mg KOH / g, and the hydroxyl value reaches the predetermined value. A hydroxyl value of 56 m...

Embodiment 1

[0055] 67 wt% PPSu (bio-based polypropylene succinate), 16.7 wt% MDI (4,4-diphenylmethane diisocyanate), 7 wt% BDI (bio-based 1, 4-butylene diisocyanate), 9.29wt% PDO (bio-based 1,3-propanediol), 0.01wt% bismuth isooctanoate were mixed evenly, and then extruded through twin-screw reaction (extruder temperature 160 ° C) to obtain bio-based thermoplastic polyurethane elastomer.

Embodiment 2

[0057] 41.5 wt% PPSu (bio-based polypropylene succinate) with a molecular weight of 1000 g / mol, 25.48 wt% MDI (4,4-diphenylmethane diisocyanate), 14.01 wt% BDI (bio-based 1,4-butylene diisocyanate), 19wt% PDO (bio-based 1,3-propanediol), 0.01wt% bismuth isooctanoate, mixed evenly, and then extruded through twin-screw reaction (extruder temperature 180°C) to obtain bio-based Thermoplastic polyurethane elastomer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com