Degradable foaming slipper material with high starch content and preparation method thereof

A technology with high starch content, applied in the field of slipper materials, can solve the problems of mechanical strength that still needs to be improved, and achieve the effects of stable and uniform coloring, cost reduction, and good resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

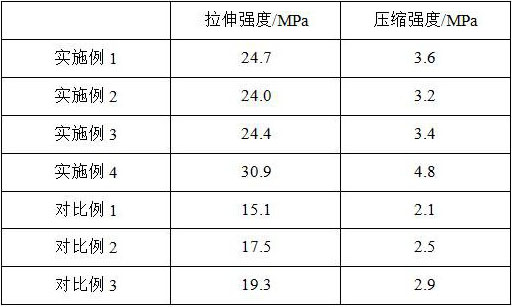

Examples

Embodiment 1

[0040] A degradable foamed slipper material with high starch content, prepared from the following raw materials in parts by weight: 55 parts of starch, 28 parts of EVA resin, 5 parts of modified plant fiber, 4 parts of reactive additives, and 2.5 parts of compatibilizer , 2 parts of blowing agent, 1.8 parts of hydrophobic auxiliary agent, 0.8 part of lubricant, 0.6 part of grafting auxiliary agent, 0.15 part of antibacterial agent, 0.15 part of antioxidant.

[0041] The slipper material is degradable, has high bio-based content, and has good mechanical strength, and the foamed slipper material has good resilience, and uses starch as the base material, which can significantly reduce costs. Compared with traditional EVA foam material, the cost can be reduced by 30%, with starch as the base material, the coloring is stable and uniform, and there is no obvious plastic taste.

[0042] The hydrophobic aid is composed of silane coupling agent KH550, isopropyl dioleic acid acyloxy (di...

Embodiment 2

[0060] A degradable foamed slipper material with high starch content, prepared from the following raw materials in parts by weight: 43.5 parts of starch, 40 parts of EVA resin, 2 parts of modified plant fiber, 8 parts of reactive additives, and 0.6 parts of compatibilizer , 3 parts of foaming agent, 0.8 part of hydrophobic auxiliary agent, 1 part of lubricant, 0.5 part of grafting auxiliary agent, 0.5 part of antibacterial agent, 0.1 part of antioxidant.

[0061] The hydrophobic aid is composed of silane coupling agent KH550, isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate and stearic acid in a weight ratio of 2:3:5.

[0062] The lubricant is composed of polyethylene wax and polytetrafluoroethylene wax in a weight ratio of 2:1.

[0063] The antioxidant is antioxidant 1010.

[0064] The antibacterial agent is chitosan.

[0065] The reactive auxiliary agent is composed of sorbitol and maltitol in a weight ratio of 2:1.

[0066] The foaming agent is compose...

Embodiment 3

[0079] A degradable foamed slipper material with high starch content, prepared from the following raw materials in parts by weight: 55.8 parts of starch, 30 parts of EVA resin, 4 parts of modified plant fiber, 3 parts of reactive additives, and 0.6 parts of compatibilizer , 3 parts of foaming agent, 0.8 part of hydrophobic auxiliary agent, 1 part of lubricant, 1.2 part of grafting auxiliary agent, 0.1 part of antibacterial agent, 0.5 part of antioxidant.

[0080] The hydrophobic aid is composed of silane coupling agent KH550, isopropyl dioleic acid acyloxy (dioctyl phosphate acyloxy) titanate and stearic acid in a weight ratio of 2:3:5.

[0081] The lubricant is composed of polyethylene wax and polytetrafluoroethylene wax in a weight ratio of 2:1.

[0082] The antioxidant is antioxidant 1010.

[0083] The antibacterial agent is chitosan.

[0084] The reactive auxiliary agent is composed of sorbitol and maltitol in a weight ratio of 2:1.

[0085] The foaming agent is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com