Preparation method of bio-based self-repairing flame-retardant material with high dielectric property

A flame-retardant material and bio-based technology, applied in the field of polymer synthesis and functional application, can solve the problems of difficult secondary processing, poor dielectric properties, etc., and achieve the effects of stable quality, reduced pollution, and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

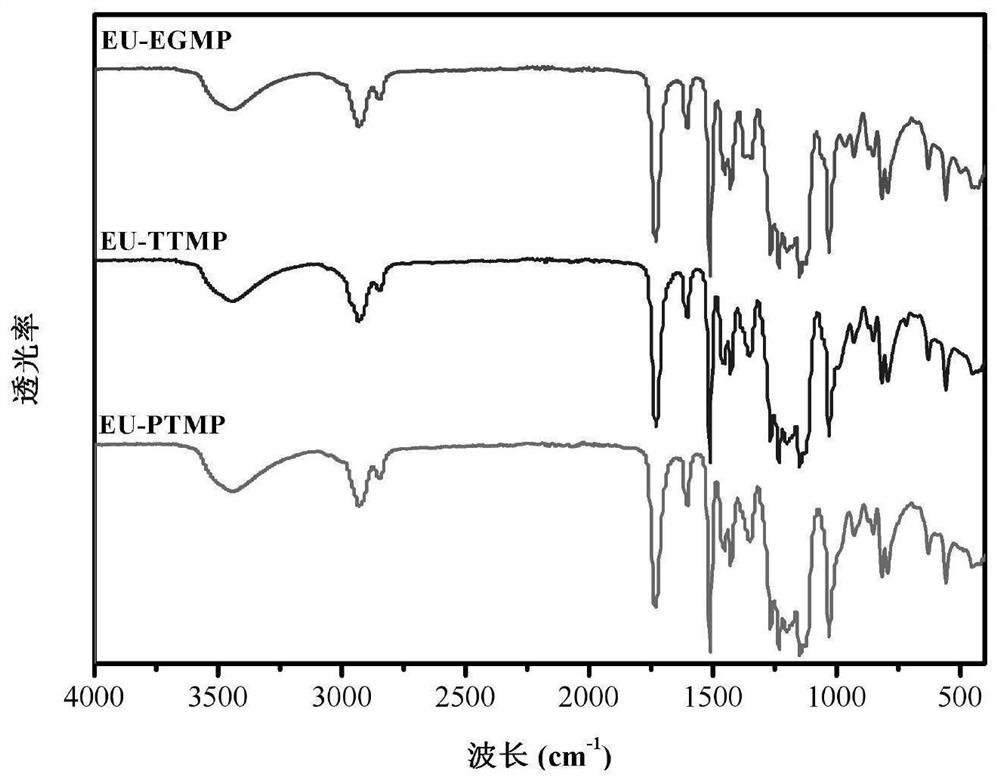

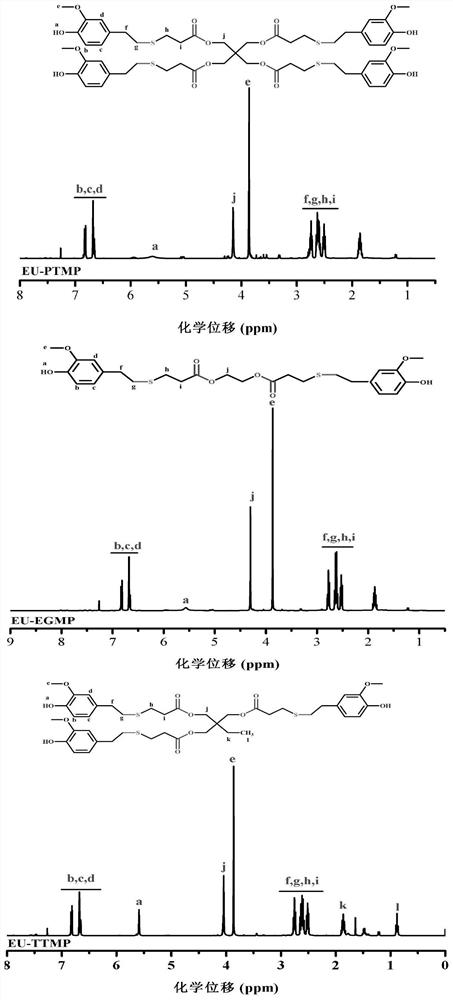

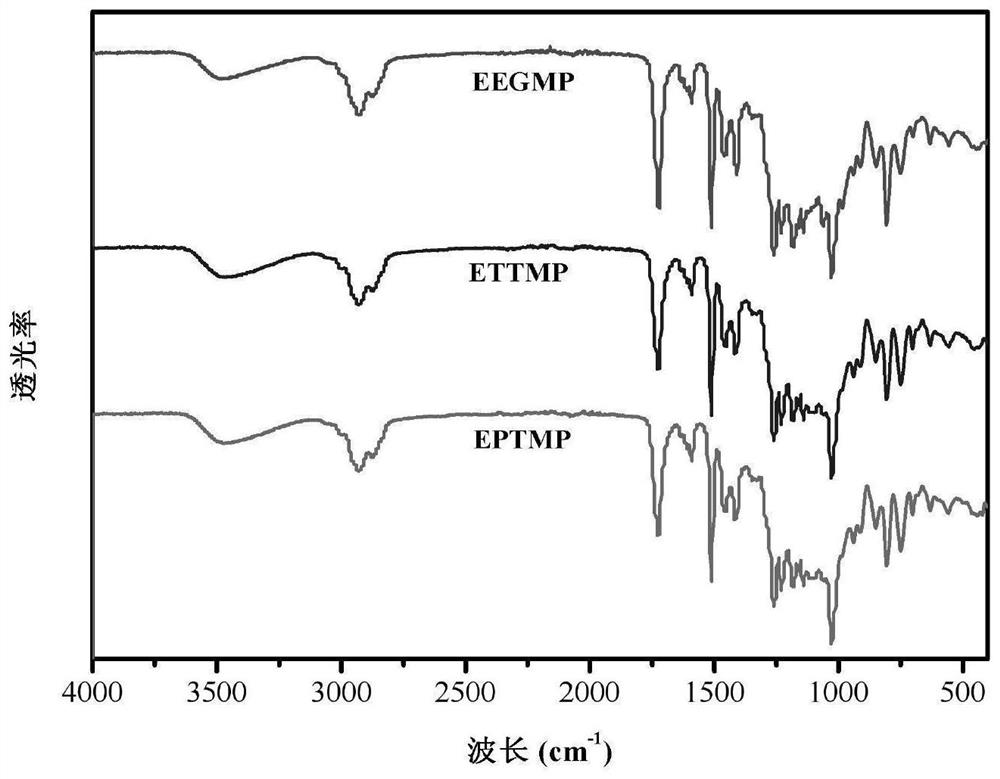

[0032] A preparation method of a bio-based self-healing flame-retardant material with high dielectric properties and its products are mainly divided into three steps: first, the bio-based compound eugenol is used as the main raw material, and the bio-based polyester is synthesized by "click chemistry" Monomer: Add 2-4mol eugenol and 1mol polymercapto ester into a quartz glass cup with a sealed cover and magnetic stirring, use ultraviolet light as the reaction light source, heat up to 30-60°C, add catalyst, the amount of catalyst is 1% of the total mass 2-5%, after reacting for 6-12 hours, the bio-based polyester monomer is obtained after natural cooling.

[0033] The polyhydric mercapto ester is any one of bis(3-mercaptopropionate) ethylene glycol, trimethylolpropane tris(3-mercaptopropionate) and tetrakis(3-mercaptopropionate) pentaerythritol ester. All were purchased from Shanghai Macklin Biochemical Technology Co., Ltd.

[0034] The catalyst is photoinitiator-184 or photoi...

Embodiment 1

[0045] Add 2 mol eugenol and 1 mol bis(3-mercaptopropionate) ethylene glycol ester into a quartz glass cup with a sealed cover and magnetic stirring, use ultraviolet light as the reaction light source, heat up to 30°C, add photoinitiator-184, The amount of the catalyst used was 2% of the total mass. After reacting for 12 hours, the eugenol-based polyester monomer (EU-EGMP) was obtained after natural cooling. Under a nitrogen gas atmosphere, add 1mol EU-EGMP and 6mol epichlorohydrin to a three-necked flask equipped with a reflux condenser, magnetic stirring and a thermometer, raise the temperature to 120°C, add 0.01mol benzyltriethylammonium chloride, and condense Reflux reaction for 30 minutes, after cooling down to 40°C, add 2mol sodium hydroxide and 2mol calcium oxide, keep at 40°C and continue to react for 2 hours, after the reaction is completed, the reaction product is filtered, the filtrate is distilled under reduced pressure to recover excess epichlorohydrin, and the sol...

Embodiment 2

[0047] Add 3mol eugenol and 1mol trimethylolpropane tris(3-mercaptopropionate) into a quartz glass cup with a sealed cover and magnetic stirring, use ultraviolet light as the reaction light source, heat up to 40°C, add photoinitiator- 184, the amount of catalyst used was 3% of the total mass, and after reacting for 10 hours, eugenol-based polyester monomer (EU-TTMP) was prepared after natural cooling. Under a nitrogen gas atmosphere, add 1 mol of eugenyl polyester and 8 mol of epichlorohydrin to a three-necked flask equipped with a reflux condenser, magnetic stirring and a thermometer, raise the temperature to 110°C, and add 0.05 mol of tetradecyl trimethyl Ammonium chloride, condensed and refluxed for 3 hours, cooled to 50°C, added 3mol sodium hydroxide and 3mol anhydrous sodium sulfate, kept at 50°C and continued to react for 3 hours, after the reaction was completed, the reaction product was filtered, and the filtrate was recovered by vacuum distillation Epoxidized eugenol-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com