A kind of photocurable resin based on epoxy vegetable oil and gallic acid and its preparation method and application

A light-curing resin and epoxy vegetable oil technology, which is applied in the preparation of organic compounds, carboxylic anhydrides, and carboxylic esters, can solve problems such as high viscosity, slow curing speed, poor mechanical and thermal properties, and achieve low viscosity. , fast curing speed, excellent thermodynamic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

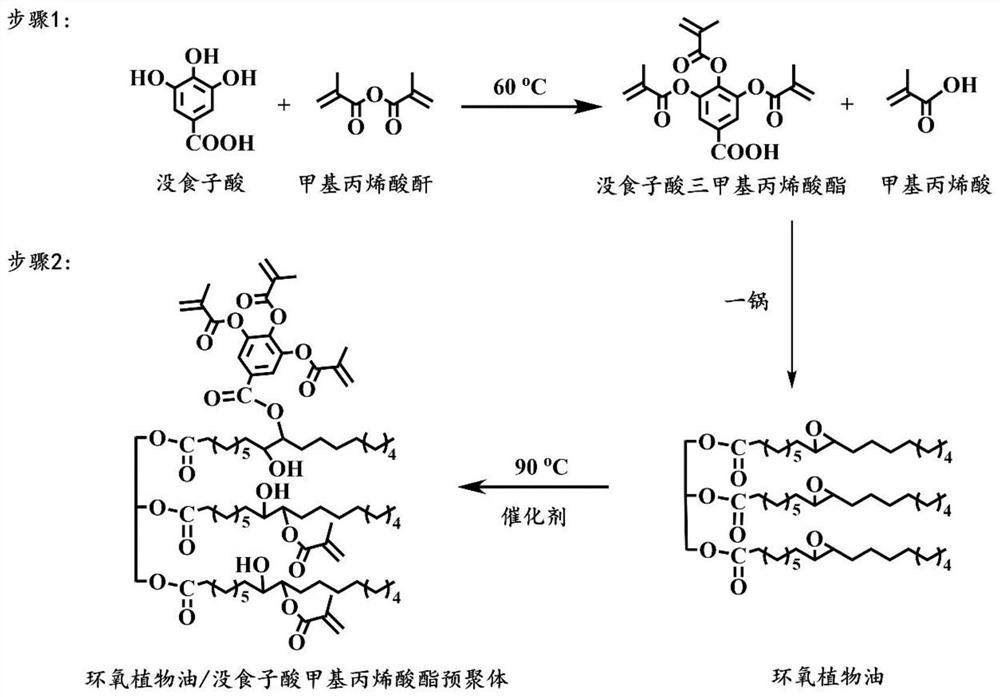

[0025] A light-curable resin based on epoxy vegetable oil and gallic acid and its preparation method and application, characterized in that the preparation steps are: (1) adding gallic acid and acrylic anhydride compounds in a reactor, gallic acid and acrylic anhydride compounds The molar ratio is 1:(2~5), the amount of polymerization inhibitor is 0.1~5% of the total weight of raw materials, after stirring evenly, it is heated to 50~150°C for 1~8h to obtain gallic acid triacrylate compound and acrylic acid The mixed intermediate of compound; (2) epoxy vegetable oil is joined in the reactor of last step, carry out epoxy ring-opening reaction with gained mixed intermediate, wherein the mol ratio of epoxy group and carboxyl group is (0.5~1.5) : 1, the amount of catalyst is 0.1% to 5% of the total weight of raw materials, the amount of polymerization inhibitor is 0.1% to 5% of the total weight of raw materials, 50 to 150 ° C for 1 to 6 hours to obtain a new type of bio-based epoxy ...

Embodiment 1

[0039] (1) Add gallic acid and methacrylic anhydride in the reactor, the molar ratio of gallic acid and methacrylic anhydride is 1:3.0, the amount of inhibitor hydroquinone is 0.5% of the total weight of raw materials, after stirring Heating to 60°C for 4 hours to obtain a gallic acid trimethacrylate / methacrylic acid mixed intermediate;

[0040] (2) Epoxy soybean oil is added to the gallic acid trimethacrylate / methacrylic acid mixed intermediate obtained in the previous step to carry out epoxy ring-opening reaction, wherein the molar ratio of epoxy group and carboxyl group is 1.3:1 , the amount of catalyst triphenylphosphine is 1% of the total weight of raw materials, the amount of hydroquinone as a polymerization inhibitor is 0.5% of the total weight of raw materials, react at 90 ° C for 4 hours, and obtain a bio-based epoxy acrylate prepolymer;

[0041] (3) Diluted monomer hydroxyethyl methacrylate and photoinitiator 2,4,6-trimethylbenzoyl diphenoxyphos were added to the bio...

Embodiment 2

[0043] (1) Add gallic acid and methacrylic anhydride in the reactor, the molar ratio of gallic acid and methacrylic anhydride is 1:3.0, the amount of inhibitor hydroquinone is 0.5% of the total weight of raw materials, after stirring Heating to 60°C for 4 hours to obtain a gallic acid trimethacrylate / methacrylic acid mixed intermediate;

[0044] (2) Epoxy cottonseed oil is added to the gallic acid trimethacrylate / methacrylic acid mixed intermediate obtained in the previous step to carry out epoxy ring-opening reaction, wherein the mol ratio of epoxy group and carboxyl group is 1.3:1 , the amount of catalyst triphenylphosphine is 1% of the total weight of raw materials, the amount of hydroquinone as a polymerization inhibitor is 0.5% of the total weight of raw materials, react at 90 ° C for 4 hours, and obtain a bio-based epoxy acrylate prepolymer;

[0045] (3) Diluted monomer hydroxyethyl methacrylate and photoinitiator 2,4,6-trimethylbenzoyl diphenoxyphos were added to the bi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com