Moisture permeable porous film

A porous and moisture-permeable technology, applied in the field of thin films, can solve problems such as insufficiency and achieve good anti-adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

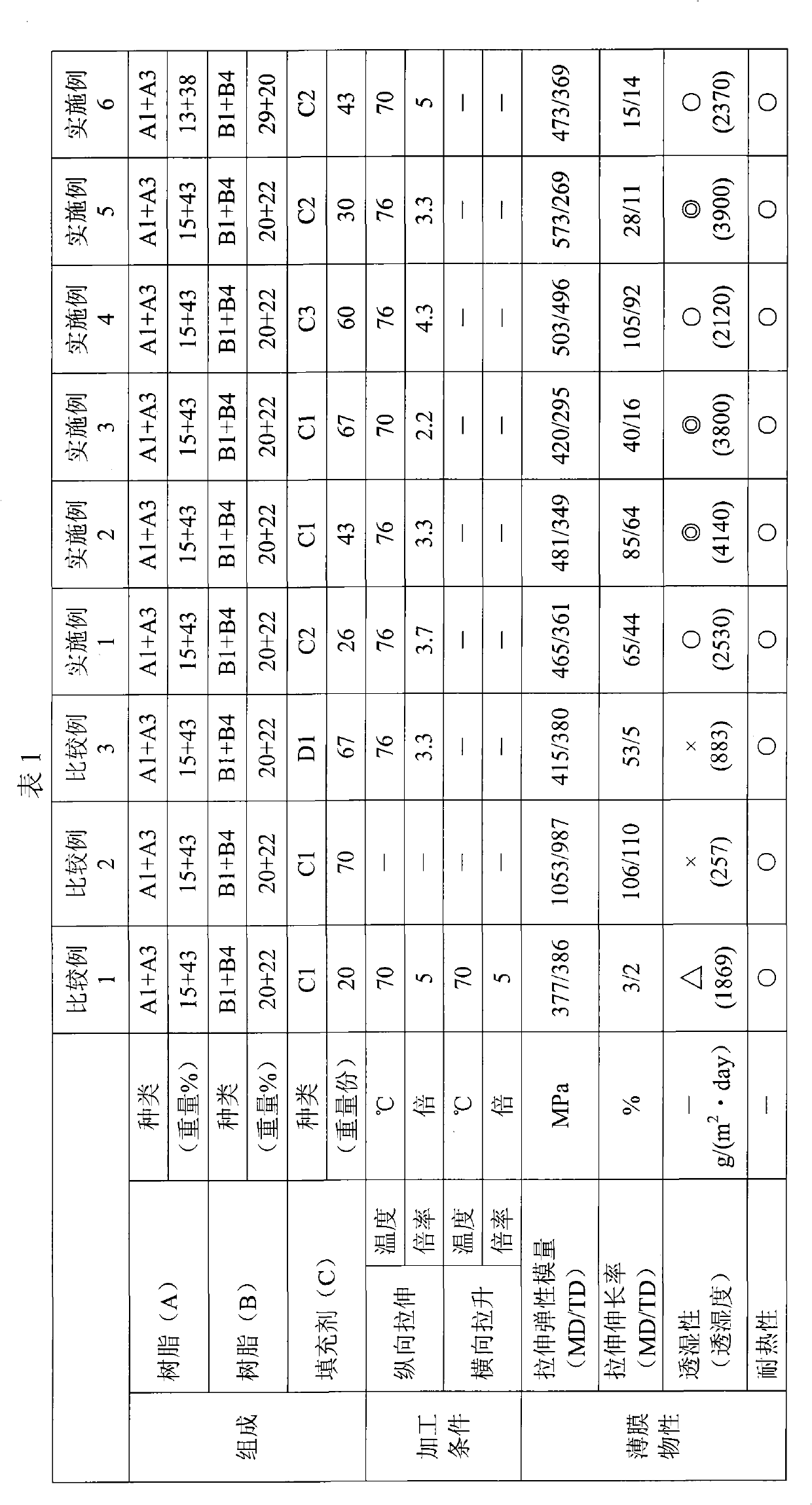

[0098] Polylactic acid resin (A1) 15 weight parts, polylactic acid resin (A3) 43 weight parts, polyethylene terephthalate adipate (B1) 20 weight parts, block copolymer plasticizer (B4) 22 Parts by weight, a mixture of 26 parts by weight of filler (C2), added to a vacuum twin-screw extruder with a screw diameter of 44mm and a screw temperature of 180°C, melted and kneaded while vacuuming, and after uniform mixing, the composition was obtained of pellets. The obtained pellets were vacuum-dried at 60° C. for 12 hours in a rotary vacuum drying oven.

[0099] The dried pellets were added to a single-screw extruder with a coil temperature of 180°C, and a film was produced by blowing the film as follows. From the spiral annular die head with a diameter of 250mm, a gap of 1.3mm, and a temperature of 160°C, a film bubble with an inflation ratio of 2.4 is extruded upward. After being cut into two pieces, it is wound up with a winder to obtain a film made by the blown film method.

[...

Embodiment 2

[0102] As shown in Table 1, the composition and manufacturing conditions of the film were changed, and the method of Example 1 was used to obtain a film with a thickness of 10 μm. The physical properties of the obtained films are listed in Table 1.

Embodiment 3

[0104] As shown in Table 1, the composition and manufacturing conditions of the film were changed, and the method of Example 1 was used to obtain a film with a thickness of 33 μm. The physical properties of the obtained films are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com