Sapium sebiferum oil-based hyperbranched polyester plasticizer and preparation method thereof

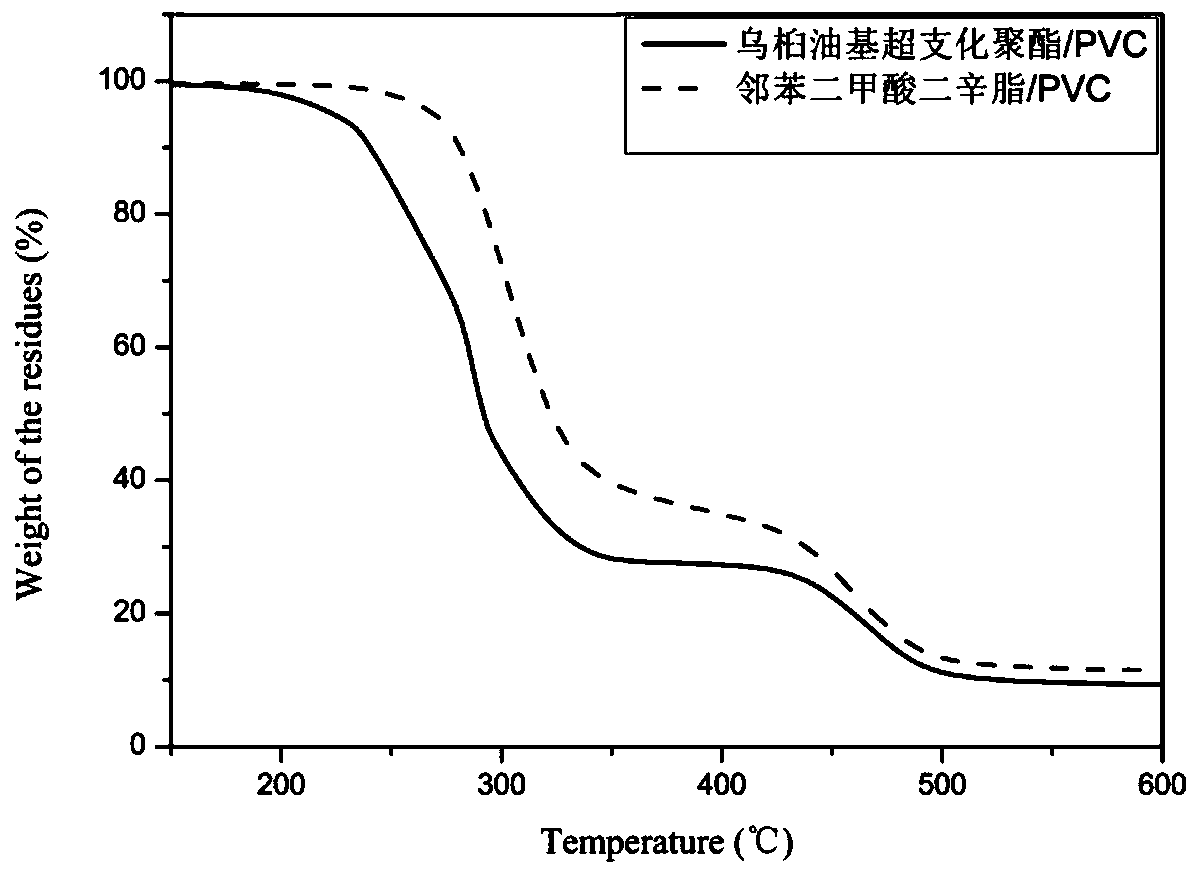

A hyperbranched polyester and hyperbranched polymer technology, applied in the field of tallow oil-based hyperbranched polyester plasticizer and its preparation, can solve the problems of poor compatibility, single performance, small molecular weight, etc. The effect of stable quality and increasing bio-based content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1, weigh 100g Chinese tallow tree oil, 10g 85% formic acid solution, 50g n-butanol, 4g deionized water and 0.3g 85% phosphoric acid solution catalyst and add it to a 250mL reactor, then add 30% hydrogen peroxide dropwise under vigorous stirring The solution was 45g, the rate of addition was 30ml / h, and then the reaction temperature was kept at 50°C for 3.5h. After the reaction, the crude product was left to stand and separated, and the oil phase was washed with 2% sodium bicarbonate solution and deionized water until neutral, and then dehydrated by distillation under reduced pressure at 80° C. to obtain tallow tree oil polyol.

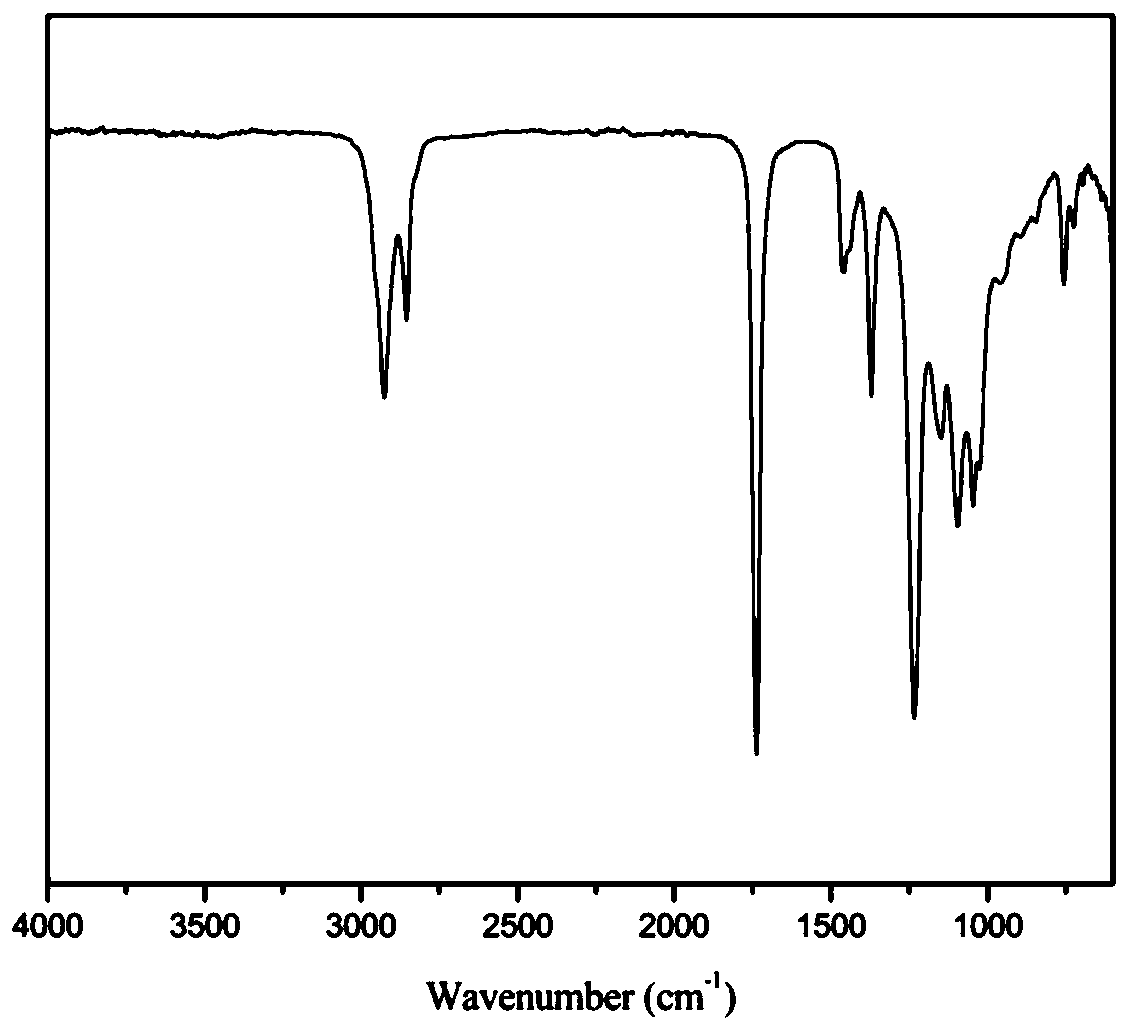

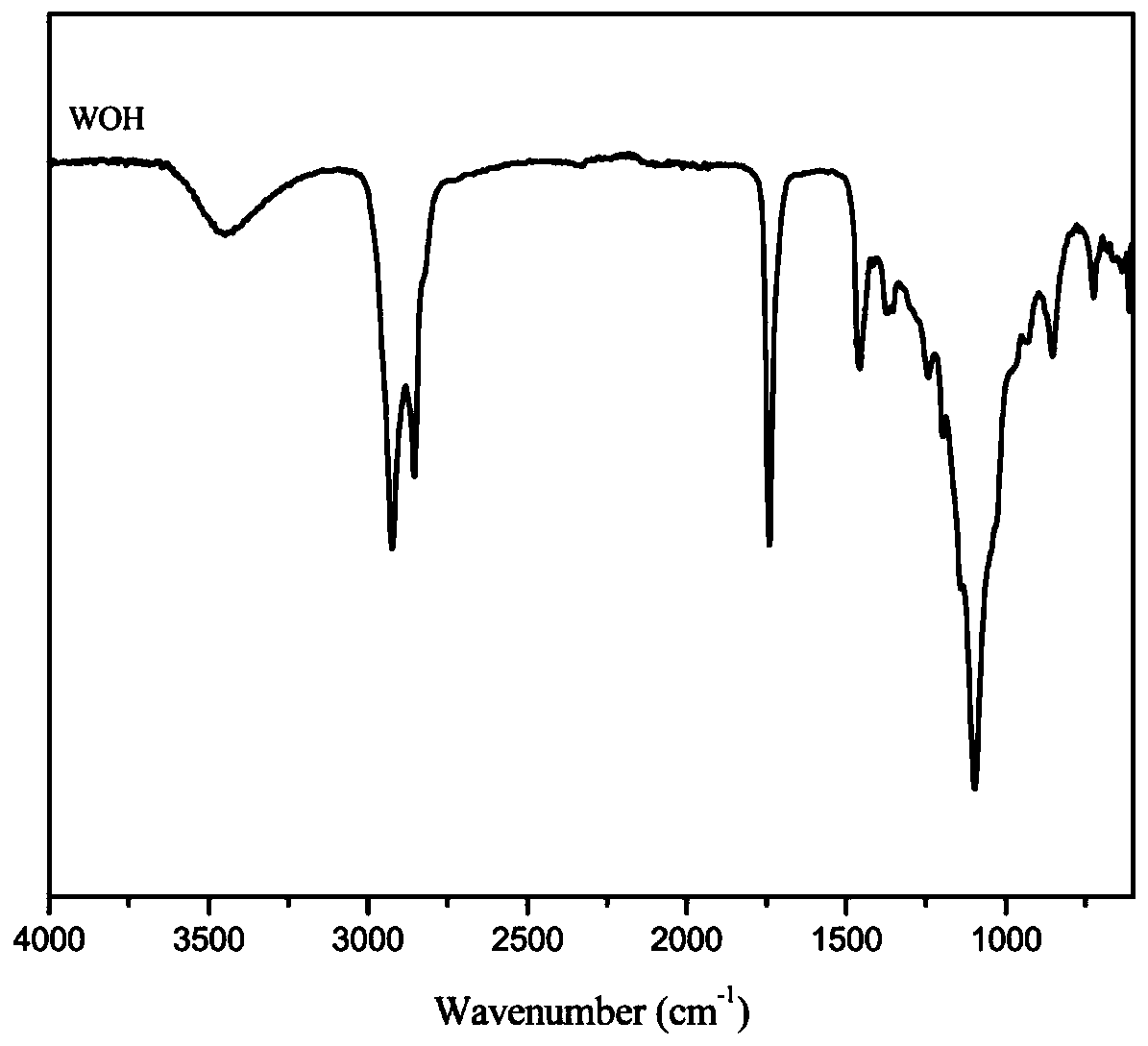

[0038] Step 2, weigh 30g tallow oil polyol, 0.2g boron tetrafluoride, nitrogen protection, stir and heat to 75°C, add 25g glycidol dropwise at a rate of 30ml / h, then heat the mixture to 100°C for 3h, Vacuum distillation gives tallow oil-based hyperbranched polymer (WOH).

[0039] Step 3: Weigh 20g of WOH and 23g of acetic anhydride into a ...

Embodiment 2

[0041] Step 1, take by weighing 100g Chinese tallow tree oil, 20g acetic acid solution, 30g ethanol, 3g deionized water and 0.3g 85% phosphoric acid solution catalyst and add in 250mL reactor, then drip 45g of 30% hydrogen peroxide solution under vigorous stirring condition, The dropping rate was 15ml / h, and then the reaction temperature was kept at 30°C for 6h. After the reaction, the crude product was left to stand and separated, and the oil phase was washed with 2% sodium bicarbonate solution and deionized water until neutral, and then dehydrated by distillation under reduced pressure at 80° C. to obtain tallow tree oil polyol.

[0042] Step 2, weigh 30g tallow oil polyol, dissolve 0.2g boron tetrafluoride in dimethyl sulfoxide under nitrogen protection, stir and heat to 75°C, add 18g ethylene glycol diglycidyl ether dropwise at a rate of 40ml / h , and then the mixture was heated to 100 ° C for 4 h, and the intermediate product WOH was obtained by distillation under reduced ...

Embodiment 3

[0045] Step 1, weigh 100g tallow tree oil, 10g 85% formic acid solution, 50g n-butanol, 4g deionized water and 0.3g 85% phosphoric acid solution catalyst and add it to a 250mL reactor, then add 70% hydrogen peroxide dropwise under vigorous stirring The solution was 30g, the rate of addition was 50ml / h, and then the reaction temperature was kept at 50°C for 3.5h. After the reaction, the crude product was left to stand and separated, and the oil phase was washed with 5% sodium bicarbonate solution and deionized water to neutrality, and then dehydrated by distillation under reduced pressure at 80° C. to obtain tallow tree oil polyol.

[0046] Step 2: Weigh 30g of tallow tree oil polyol, 0.2g of sodium methoxide, under nitrogen protection, stir and heat to 75°C, add 30g of glycidol dropwise at a rate of 30ml / h, then heat the mixture to 100°C for 5h, depressurize Distillation affords the intermediate WOH.

[0047] Step 3: Weigh 20g of WOH and 20g of maleic anhydride into a three-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com