125 DEG C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for photovoltaic cable and preparation method thereof

A polyolefin cable material, photovoltaic cable technology, applied in circuits, electrical components, plastic/resin/wax insulators, etc. The effect of simple operation and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

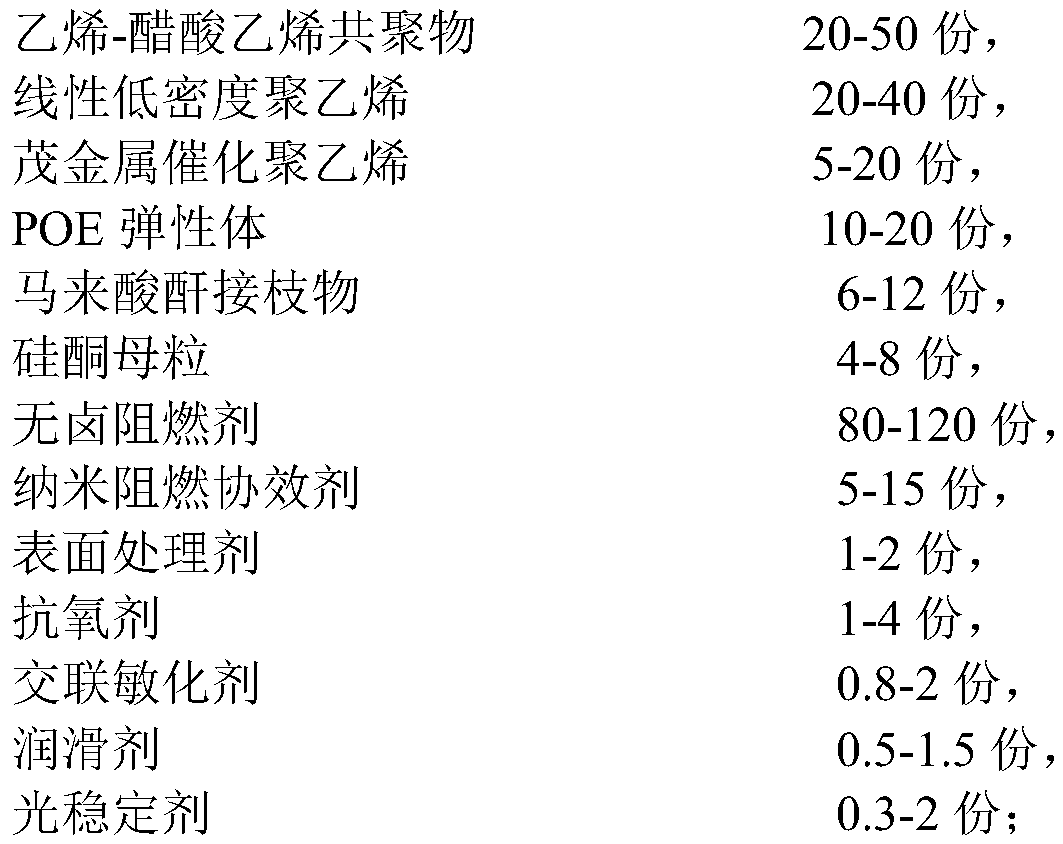

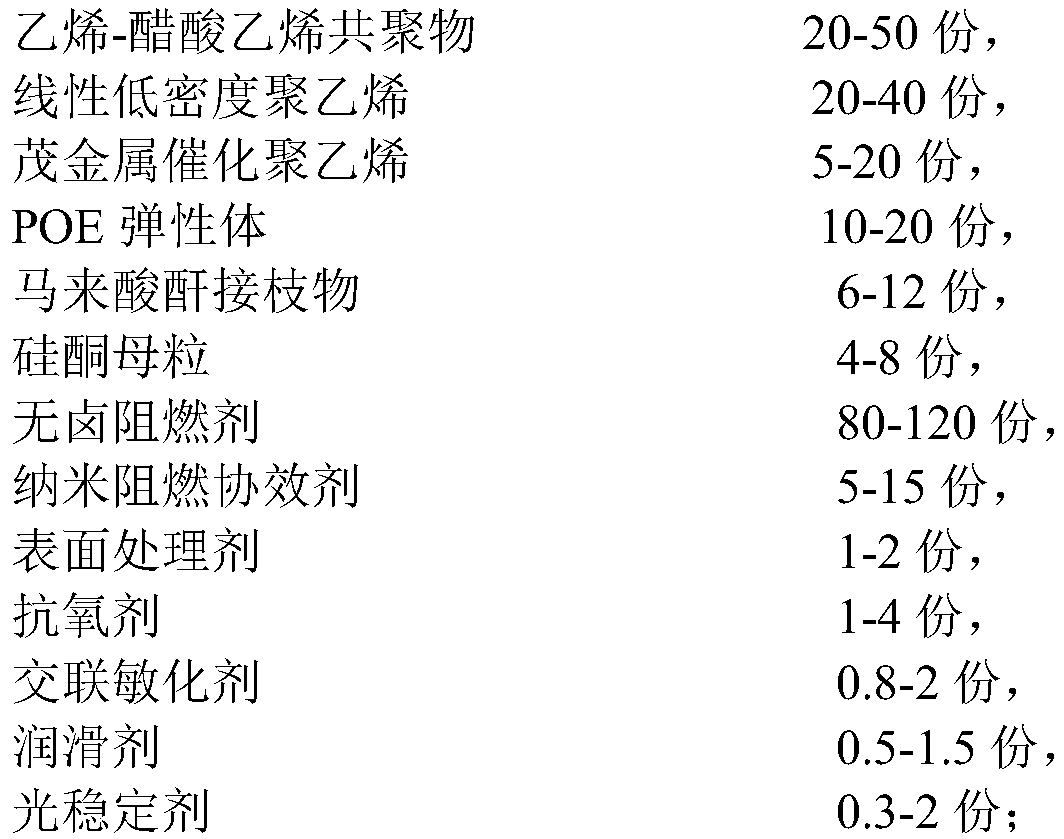

[0030] Example 1: A 125°C radiation cross-linked halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The material formula is as follows: 30 parts of ethylene-vinyl acetate copolymer, 30 parts of linear low-density polyethylene, metallocene-catalyzed 10 parts of ethylene, 20 parts of POE elastomer, 10 parts of maleic anhydride graft, 5 parts of silicone masterbatch, 80 parts of aluminum hydroxide, 20 parts of modified magnesium hydroxide, 10 parts of nano-montmorillonite, surface treatment agent 1.0 part, 2.0 parts of antioxidant, 1.2 parts of cross-linking sensitizer, 1.0 part of lubricant, 0.8 part of light stabilizer, the parts are parts by weight.

[0031] The preparation method of above-mentioned photovoltaic cable material and finished cable is as follows:

[0032] Step 1: Spray the surface treatment agent evenly on the aluminum hydroxide flame retardant, then mix in a high-speed mixer at a speed of 500±50rpm for 300-360s; after mixing, add mod...

Embodiment 2

[0038] Example 2: A 125°C irradiation cross-linked halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The material formula is as follows: 45 parts of ethylene-vinyl acetate copolymer, 20 parts of linear low-density polyethylene, metallocene 12 parts of ethylene, 15 parts of POE elastomer, 8 parts of maleic anhydride graft, 5 parts of silicone masterbatch, 80 parts of aluminum hydroxide, 20 parts of modified magnesium hydroxide, 10 parts of nano-montmorillonite, surface treatment agent 1.0 parts, 2.0 parts of antioxidant, 1.2 parts of cross-linking sensitizer, 1.0 parts of lubricant, 0.8 parts of light stabilizer.

[0039] The preparation method of the above-mentioned photovoltaic cable material and finished cable is the same as that in Example 1.

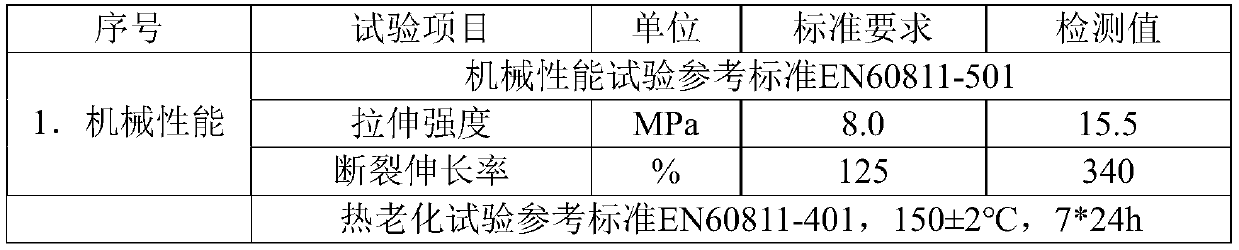

[0040] The main performance index of the material obtained in embodiment 2 is as follows:

[0041]

Embodiment 3

[0042] Example 3: A 125°C irradiation crosslinking type halogen-free flame-retardant polyolefin cable material for photovoltaic cables. The material formula is as follows: 45 parts of ethylene-vinyl acetate copolymer, 20 parts of linear low-density polyethylene, metallocene 12 parts of ethylene, 15 parts of POE elastomer, 8 parts of maleic anhydride graft, 5 parts of silicone masterbatch, 90 parts of aluminum hydroxide, 30 parts of modified magnesium hydroxide, 10 parts of nano-montmorillonite, surface treatment agent 1.0 parts, 2.0 parts of antioxidant, 1.2 parts of cross-linking sensitizer, 1.0 parts of lubricant, 0.8 parts of light stabilizer.

[0043] The preparation method of the above-mentioned photovoltaic cable material and finished cable is the same as that in Example 1.

[0044] Embodiment 3 gained material key performance index is as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com