Regenerative low-smoke halogen-free cable material and preparation method thereof

A cable material and cable technology, which is applied in the direction of circuit, electrical components, electronic waste recycling, etc., can solve the problems of waste of resources, environmental pollution of solid waste, etc., and achieve the effects of reducing pollution, improving resource utilization, and reducing equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

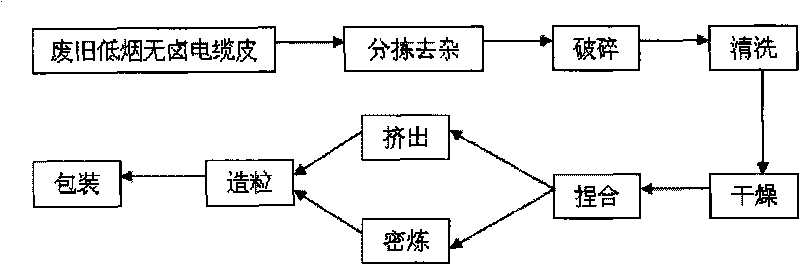

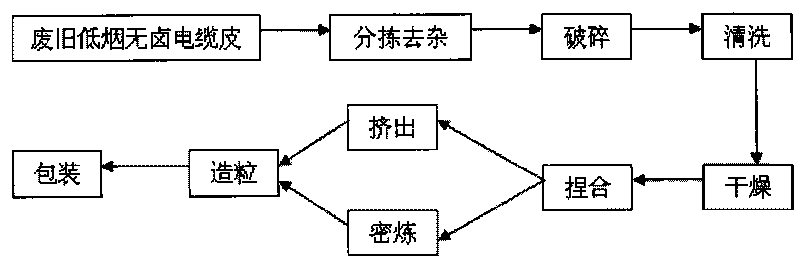

Image

Examples

Embodiment 1

[0023] A method for preparing a recycled low-smoke and halogen-free cable material, comprising the following steps:

[0024] (1) Take waste low-smoke and halogen-free cable sheaths, sort and remove impurities such as wire cores and non-low-smoke and halogen-free cable sheaths. Among them, the density of waste low-smoke halogen-free cable sheath is 1.48g / cm 3 ;

[0025] (2) Use a crusher to crush the sorted waste low-smoke and halogen-free cable sheaths. The maximum size of the crushed material is 10mm×10mm×10mm, and the smallest size is almost powdery. The smaller the size of the crushed material, the better. Considering the difficulty of operation and production cost, it is best not to be larger than 10mm×10mm×10mm.

[0026] (3) Centrifugally wash the scrap in step (2) with water to mainly remove impurities such as dust and silt in the scrap.

[0027] (4) Dry the scraps after cleaning. Drying can be natural drying, dryer drying or vacuum dryer drying, etc., to ensure that ...

Embodiment 2

[0033] A method for preparing a recycled low-smoke and halogen-free cable material, comprising the following steps:

[0034] (1) Take waste low-smoke and halogen-free cable sheaths, sort and remove impurities such as wire cores and non-low-smoke and halogen-free cable sheaths. Among them, the density of waste low-smoke halogen-free cable sheath is 1.45g / cm 3 ;

[0035] (2) Use a crusher to crush the sorted waste low-smoke and halogen-free cable sheaths. The maximum size of the crushed material is 10mm×10mm×10mm, and the smallest size is almost powdery. The smaller the size of the crushed material, the better. Considering the difficulty of operation and production cost, it is best not to be larger than 10mm×10mm×10mm.

[0036] (3) Centrifugally wash the scrap in step (2) with water to mainly remove impurities such as dust and silt in the scrap.

[0037] (4) Naturally dry the cleaned scrap to ensure that the moisture content in the scrap is not more than 0.3% (by weight).

...

Embodiment 3

[0043] A method for preparing a recycled low-smoke and halogen-free cable material, comprising the following steps:

[0044] (1) Take waste low-smoke and halogen-free cable sheaths, sort and remove impurities such as wire cores and non-low-smoke and halogen-free cable sheaths. Among them, the density of waste low-smoke halogen-free cable sheath is 1.46g / cm 3

[0045] (2) Use a crusher to crush the sorted waste low-smoke and halogen-free cable sheaths. The maximum size of the crushed material is 10mm×10mm×10mm, and the smallest size is almost powdery. The smaller the size of the crushed material, the better. Considering the difficulty of operation and production cost, it is best not to be larger than 10mm×10mm×10mm.

[0046] (3) Centrifugally wash the scrap in step (2) with water to mainly remove impurities such as dust and silt in the scrap.

[0047] (4) Carry out dryer drying to the crushed material after cleaning, ensure that the moisture content in the crushed material is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com