Nano-montmorillonite and PET mixture forming system

A nano-montmorillonite and compound technology, which is applied in the field of polymer blend screw-type compound molding system, can solve the problems of complex process, extensive supporting equipment, high cost, etc., achieve uniform color, low manufacturing cost, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

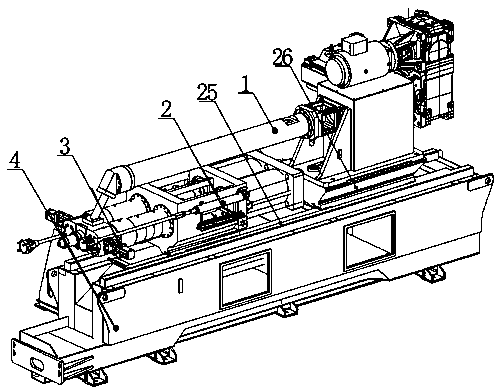

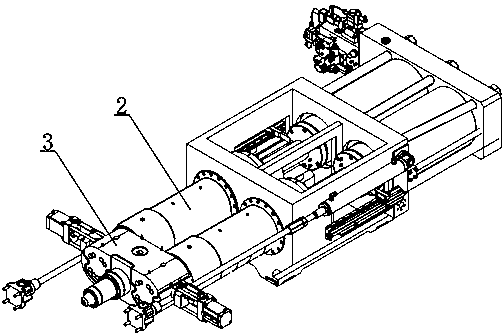

[0031] Such as figure 1 Shown, a kind of nanometer montmorillonite and PET mixture forming system, it is mainly made of frame 4, mixing extrusion device 1, alternate feeding device 3 and two injection devices 2, described mixing extrusion device 1 And two injection devices 2 are located on the frame 4.

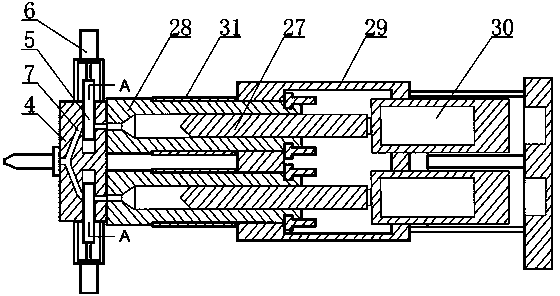

[0032] Such as figure 2 , 3 , 4, the alternate feeding control device 3 is mainly composed of a valve body 4, two columnar spools 5, and two oil cylinders 6, and the valve body 4 is provided with two A material injection channel 7 connected to the discharge end, and two feed channels 8 are also arranged in the valve body 4, and one end of the two feed channels 8 communicates with the discharge end of the mixing extrusion device 1 at the same time, and the other One end is respectively connected with two injection channels 7, and two columnar spools 5 for mixing materials are respectively arranged in the valve body 4, and are located at the junction of the feed channel 8 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com