Light-cured resin based on vegetable oil and itaconic acid and preparation method and application of light-cured resin

A light-curing resin, itaconic acid technology, applied in the chemical modification of fatty acid, fatty acid production, coating, etc., can solve the problems of mechanical properties and repair effect not meeting actual use requirements, complicated synthesis process, etc., to improve reusability. High efficiency, simple process flow, high functional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

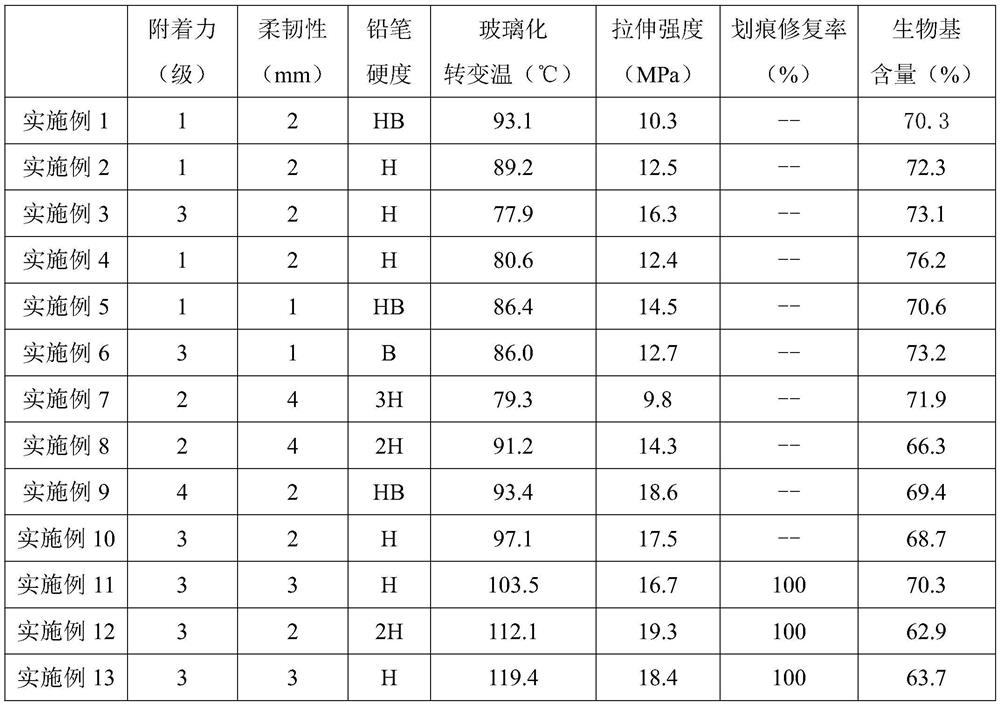

Examples

preparation example Construction

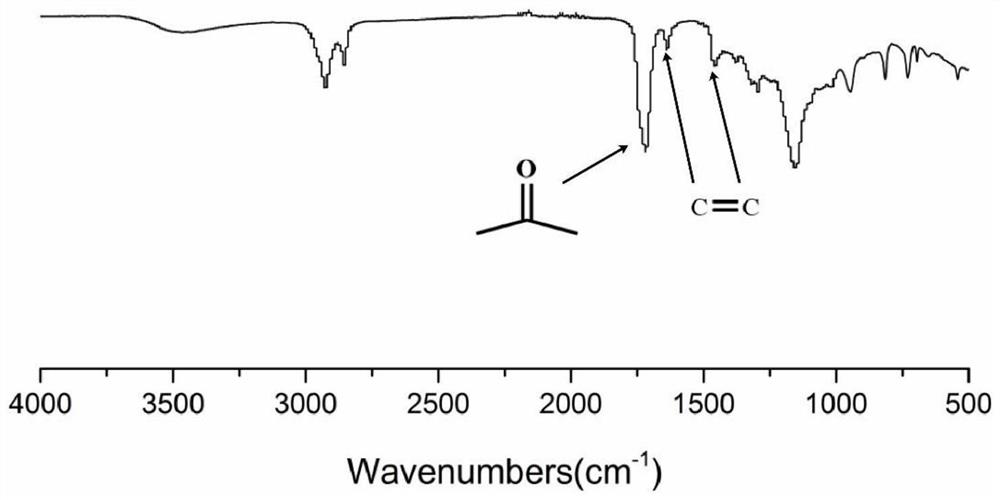

[0023] A method for preparing a photocurable resin based on vegetable oil and itaconic acid, the preparation steps are: (1) taking itaconic acid, glycidyl methacrylate, catalyst and polymerization inhibitor in a reaction vessel, the described The molar ratio of itaconic acid to glycidyl methacrylate is 1:1-1.1, the amount of polymerization inhibitor is 0.3-1% of the total mass, the amount of catalyst is 0.5%-1% of the total mass, stir well and preheat to Dissolve the solid, heat to 90-130°C and react for 1-4 hours; remove unreacted small molecules by distillation under reduced pressure to obtain the purified unsaturated itaconate half-ester precursor; (2) according to the carboxyl and epoxy groups The functional group ratio is 0.9-1.3:1, continue to add epoxidized vegetable oil into the reaction vessel, stir and heat up to 110-130°C, react for 2-5 hours, and obtain epoxidized vegetable oil-based epoxy acrylate prepolymer; ( 3) Add vinyl monomer, photoinitiator Darocur 1173 and...

Embodiment 1

[0029] (1) Add metered portions of itaconic acid and glycidyl methacrylate (the molar ratio of itaconic acid to glycidyl methacrylate is 1:1), and catalyst triphenylphosphine (amount of 0.3% of the total mass of itaconic acid and glycidyl methacrylate) and inhibitor hydroquinone (consumption is 0.5% of the total mass of itaconic acid and glycidyl methacrylate) in a reaction vessel, stir well Preheat until the solid dissolves, heat to 90°C for 4 hours; distill under reduced pressure to obtain a purified unsaturated itaconate half ester precursor;

[0030] (2) Continue to add epoxidized cottonseed oil (the molar ratio of the epoxy group on the unsaturated itaconate half ester precursor to the epoxidized cottonseed oil is 1:1) in the reactor, stir and heat up to 110 ℃, reacted for 5h, and obtained epoxidized cottonseed oil-based epoxy acrylate prepolymer;

[0031] (3) Add methyl acrylate monomer diluent to the epoxidized cottonseed oil-based epoxy acrylate prepolymer synthesized...

Embodiment 2

[0033] (1) Add metered portions of itaconic acid and glycidyl methacrylate (the molar ratio of itaconic acid to glycidyl methacrylate is 1:1.05), and catalyst triphenylphosphine (amount of 0.3% of the total mass of itaconic acid and glycidyl methacrylate) and inhibitor hydroquinone (consumption is 1% of the total mass of itaconic acid and glycidyl methacrylate) in a reaction vessel, stir well Preheating until the solid dissolves, heating to 100°C for 3 hours; distillation under reduced pressure to obtain a purified unsaturated itaconate half ester precursor;

[0034] (2) Continue to add epoxidized rubber seed oil to the reactor (the molar ratio of the epoxy group on the unsaturated itaconate half ester precursor to the epoxidized rubber seed oil is 1:1.1), stir and heat up to 120°C and react for 3 hours to obtain an epoxy acrylate prepolymer based on epoxidized rubber seed oil;

[0035] (3) Add hydroxypropyl acrylate monomer diluent to the epoxidized rubber seed oil-based epo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com