A kind of waterproof acrylic coating for zipper and preparation method thereof

A kind of technology of acrylic acid and acrylic acid prepolymerization, applied in the direction of coating, etc., can solve the problems of coating stretchability, poor toughness, zipper not washable, affecting clothing texture, etc., to improve crosslinking stability, mechanical strength, etc. Improved performance and good stretchability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

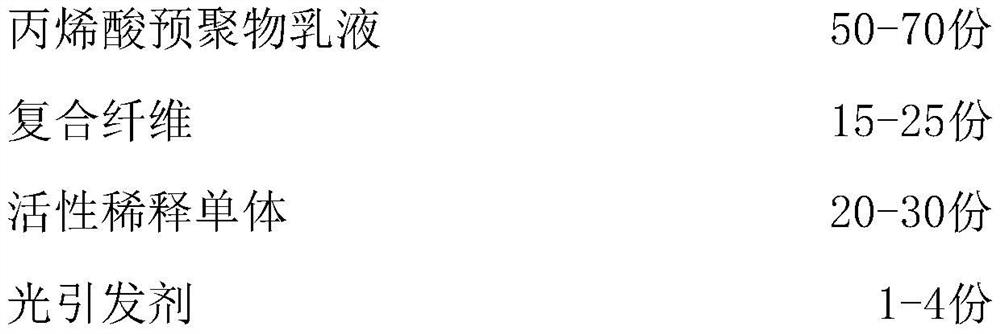

[0033]A waterproof acrylic paint for zipper, including the following raw materials by weight:

[0034]

[0035]Wherein, the composite fiber is composed of nano-cellulose filaments and a polyacrylamide layer covering the nano-cellulose filaments;

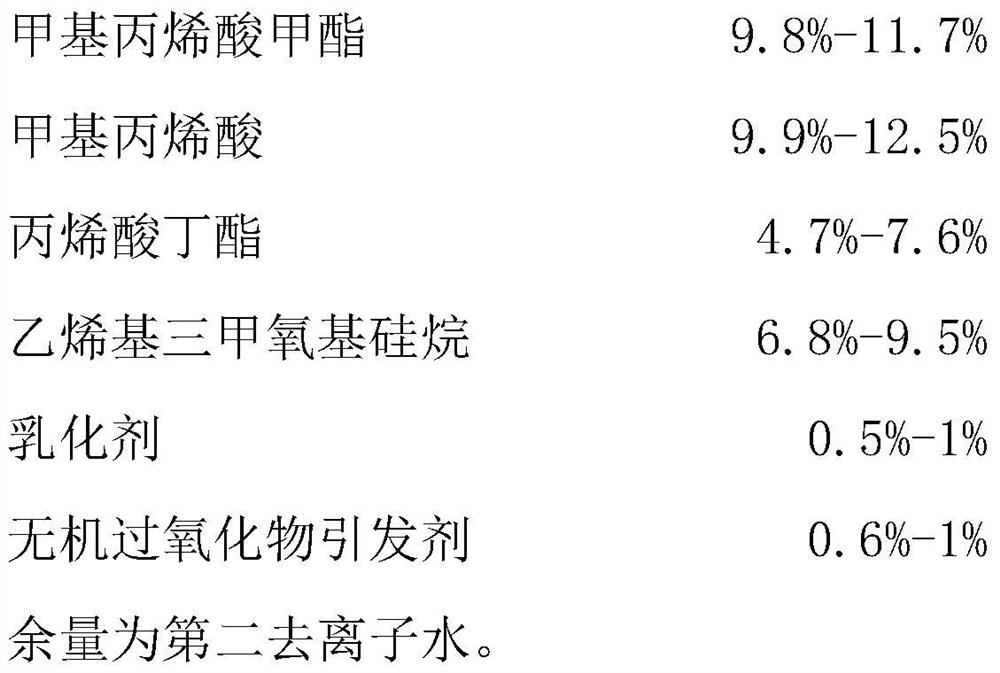

[0036]Wherein, each part by weight of the acrylic prepolymer emulsion is prepared from the following raw materials in weight percentage:

[0037]

[0038]Wherein, the emulsifier is composed of sodium dodecylbenzene sulfonate, sodium lauryl sulfate and sorbitan oleate in a weight ratio of 2:2:1.

[0039]Among them, the inorganic peroxide initiator is composed of ammonium persulfate and potassium persulfate in a weight ratio of 1:1.

[0040]Wherein, the preparation method of the acrylic prepolymer emulsion includes the following steps: weighing methyl methacrylate, methacrylic acid, butyl acrylate, vinyl trimethoxysilane, emulsifier, inorganic peroxide Initiator and deionized water. Add methyl methacrylate, methacrylic acid, butyl acrylate, vinyl trimethoxysilan...

Embodiment 2

[0048]A waterproof acrylic paint for zipper, including the following raw materials by weight:

[0049]

[0050]

[0051]Wherein, the composite fiber is composed of nano-cellulose filaments and a polyacrylamide layer covering the nano-cellulose filaments;

[0052]Wherein, each part by weight of the acrylic prepolymer emulsion is prepared from the following raw materials in weight percentage:

[0053]

[0054]Wherein, the emulsifier is composed of sodium dodecyl benzene sulfonate, sodium lauryl sulfate and sorbitan oleate in a weight ratio of 1:1:1.

[0055]Among them, the inorganic peroxide initiator is composed of ammonium persulfate and potassium persulfate in a weight ratio of 1:2.

[0056]Wherein, the preparation method of the acrylic prepolymer emulsion includes the following steps: weighing methyl methacrylate, methacrylic acid, butyl acrylate, vinyl trimethoxysilane, emulsifier, inorganic peroxide Initiator and deionized water. Add methyl methacrylate, methacrylic acid, butyl acrylate, vinyl trimetho...

Embodiment 3

[0064]A waterproof acrylic paint for zipper, including the following raw materials by weight:

[0065]

[0066]Wherein, the composite fiber is composed of nano-cellulose filaments and a polyacrylamide layer covering the nano-cellulose filaments;

[0067]Wherein, each part by weight of the acrylic prepolymer emulsion is prepared from the following raw materials in weight percentage:

[0068]

[0069]

[0070]Wherein, the emulsifier is composed of sodium dodecyl benzene sulfonate, sodium lauryl sulfate and sorbitan oleate in a weight ratio of 3:3:1.

[0071]Among them, the inorganic peroxide initiator is composed of ammonium persulfate and potassium persulfate in a weight ratio of 2:1.

[0072]Wherein, the preparation method of the acrylic prepolymer emulsion includes the following steps: weighing methyl methacrylate, methacrylic acid, butyl acrylate, vinyl trimethoxysilane, emulsifier, inorganic peroxide Initiator and deionized water. Add methyl methacrylate, methacrylic acid, butyl acrylate, vinyl trimetho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com