A kind of vinyl ester resin coating, superhydrophobic coating and its preparation method and application

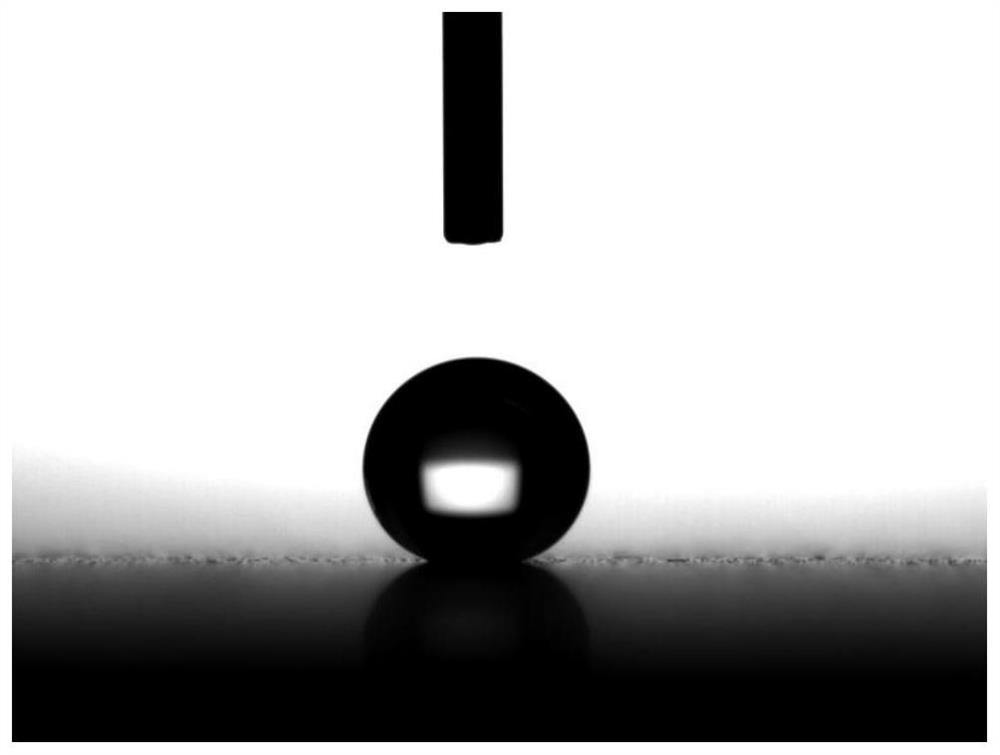

A vinyl ester resin and super-hydrophobic technology, applied in epoxy resin coatings, coatings, etc., can solve the problems of poor durability of hydrophobic effect, difficulty in wide use, poor adhesion and wear resistance of super-hydrophobic coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

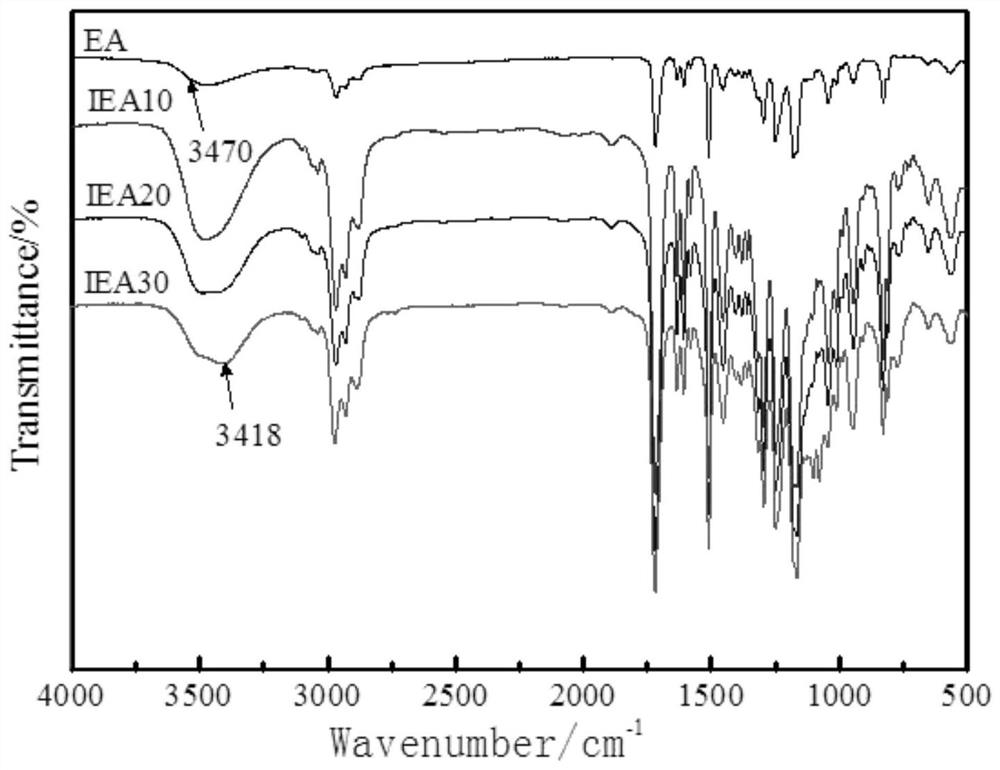

[0031] In the present invention, the preparation of the vinyl ester resin coating includes 30 to 55 parts by weight of the modified vinyl ester resin, preferably 35 to 45 parts. In the present invention, the modified vinyl ester resin is modified by a vinyl ester resin is obtained by a silicone coupling agent; a method of preparing a modified vinyl ester resin, preferably comprising the steps of:

[0032] The vinyl ester resin, the active diluent, and the silane coupling agent were mixed at 70 to 80 ° C for 2 to 5 hours, resulting in a modified vinyl ester resin.

[0033] The present invention is not particularly limited for the source of the vinyl ester resin, and can be prepared by a commercially available goods well known to those skilled in the art or by methods well known to those skilled in the art. In an embodiment of the invention, the method of preparing the vinyl ester resin preferably comprises the steps of:

[0034] The epoxy resin, methacrylic acid, and catalyst were ...

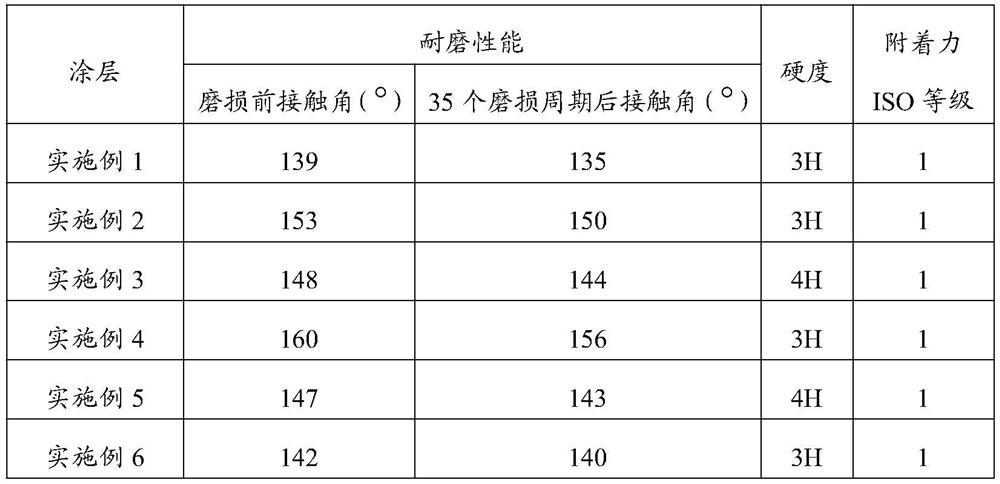

Embodiment 1

[0051] (1) Preparation of vinyl ester resin

[0052] The epoxy resin 128, methacrylic acid (the molar ratio of epoxy resin 128 and the methacrylic acid is 1.02: 1) and a catalyst (specifically N, N-dimethylbenzylamine, the amount of epoxy resin 128 and A 0.5% of the total mass of the primary acrylic acid) mixed, the reaction was carried out under 105 ° C, and the acid value was measured every 0.5h. When the acid value drops below 5 mgKOH / g, the reaction is stopped, naturally cooling to 70 ° C, hot out The vinyl ester resin is obtained and stored in light.

[0053] (2) Preparation of modified vinyl ester resins

[0054] To the vinyl resin is added with methacrylate (35% of the amount of vinyl resin mass) and a isocyanate triethoxysilane (10% of the amount of vinyl resin), The reactive vinyl ester resin was obtained at 75 ° C for 3 h.

[0055] (3) Preparation of vinyl ester resin coating

[0056] 15 g of the modified vinyl acrylate resin and 18 g of methacrylate resin were mixed a...

Embodiment 2

[0060] The superhydrophobic coating is prepared according to the method of Example 1, and the extent of the silane coupling agent is 20% of the mass of the vinyl resin in the process of preparing the modified vinyl ester resin in step (2).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com