Vegetable oil-based polyol, preparation method thereof, thermocuring vegetable oil-based polyurethane, and preparation method and application of thermocuring vegetable oil-based polyurethane

A vegetable oil-based, polyol-based technology, applied in polyurea/polyurethane coatings, polyurea/polyurethane adhesives, applications, etc., can solve problems such as adverse environmental effects and complicated preparation methods, and achieve improved mechanical properties and cross-linking density High, improve the effect of tensile strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

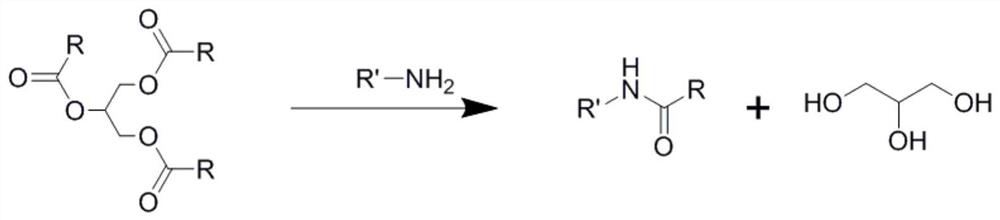

Method used

Image

Examples

Embodiment 1

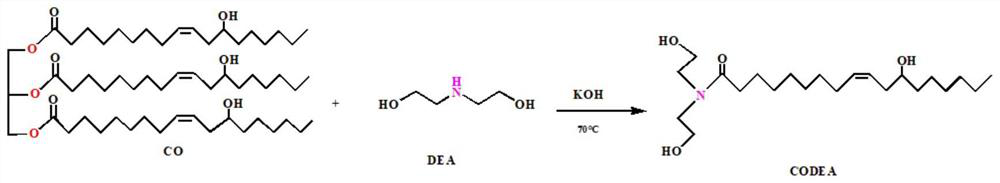

[0043] The preparation process of the castor oil-based polyol of the present embodiment is as follows:

[0044] (1) Put 152.5 g of diethanolamine (DEA) and 6.8 g of catalyst potassium hydroxide into a 1000 mL round bottom flask, stir mechanically, and heat up to 70° C. until the catalyst dissolves. Then slowly add 466.5g castor oil (CO) (the consumption mol ratio of ester bond in castor oil and diethanolamine is 1:1), add in 0.5h, then keep the temperature unchanged, react 2 hours, every 0.5 The acid value of the reactant was measured after 1 hour, and the reaction end point was reached when the acid value was less than 5 mg KOH / g. Then 300 g of ethyl acetate was added to the round-bottomed flask, the solution was then transferred to a separatory funnel, washed 3 times with saturated brine, and the organic phase was rotary evaporated at 45°C to remove the solvent to obtain light yellow and transparent aminolyzed castor oil (CODEA ). The reaction scheme of this step is as fol...

Embodiment 2

[0051] The preparation process of the castor oil-based polyol of the present embodiment is as follows:

[0052] (1) Put 152.5 g of diethanolamine and 6.8 g of catalyst potassium hydroxide into a 1000 mL round-bottomed flask, stir mechanically, and heat up to 70° C. until the catalyst is dissolved. Then slowly add 466.5g castor oil and finish adding in 0.5h, then keep the temperature unchanged, react for 2 hours, measure the acid value of the reactant every 0.5 hours, and reach the reaction end point when the acid value is less than 5mg KOH / g. Then, 300 g of ethyl acetate was added to the round-bottomed flask, and the solution was transferred to a separatory funnel, washed three times with saturated brine, and the organic phase was rotary evaporated at 45°C to remove the solvent to obtain light yellow and transparent aminolyzed castor oil.

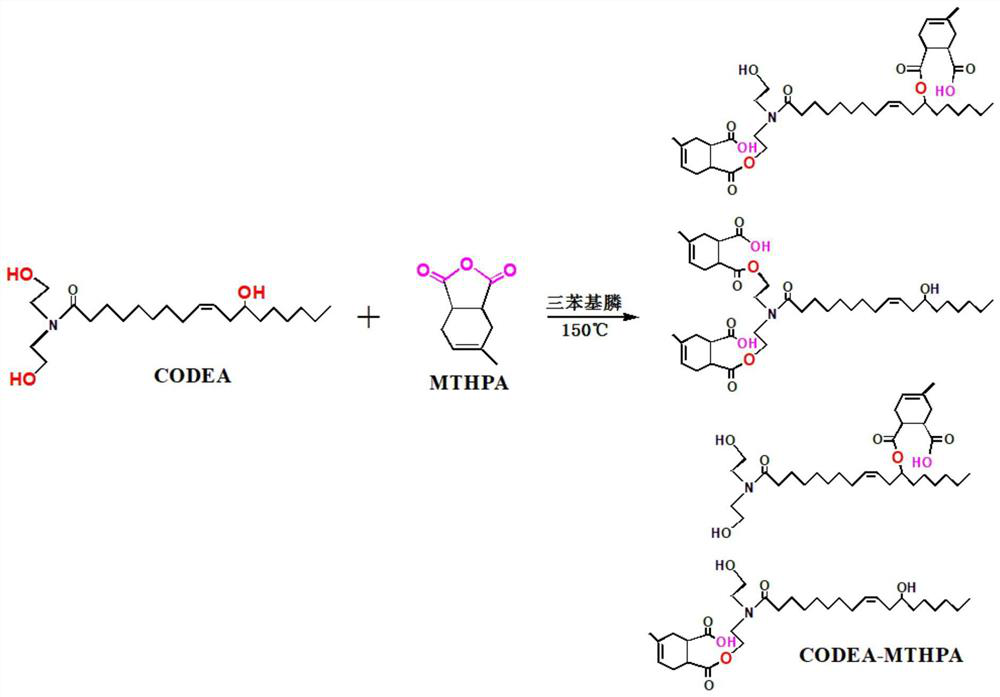

[0053] (2) in another 1000mL round bottom flask, add 200g aminolysis castor oil, 144g methyltetrahydrophthalic anhydride, 1g catalyst trip...

Embodiment 3

[0056] The preparation process of the castor oil-based polyol of the present embodiment is as follows:

[0057] (1) Put 152.5 g of diethanolamine and 6.8 g of catalyst potassium hydroxide into a 1000 mL round-bottomed flask, stir mechanically, and heat up to 70° C. until the catalyst is dissolved. Then slowly add 466.5g castor oil and finish adding in 0.5h, then keep the temperature unchanged, react for 2 hours, measure the acid value of the reactant every 0.5 hours, and reach the reaction end point when the acid value is less than 5mg KOH / g. Then, 300 g of ethyl acetate was added to the round-bottomed flask, and the solution was transferred to a separatory funnel, washed three times with saturated brine, and the organic phase was rotary evaporated at 45° C. to remove the solvent to obtain light yellow and transparent aminolyzed castor oil.

[0058] (2) in another 1000mL round bottom flask, add 200g aminolysis castor oil, 144g methyltetrahydrophthalic anhydride, 1g catalyst tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com