Plant fiber reinforced bio-based thermosetting resin composite

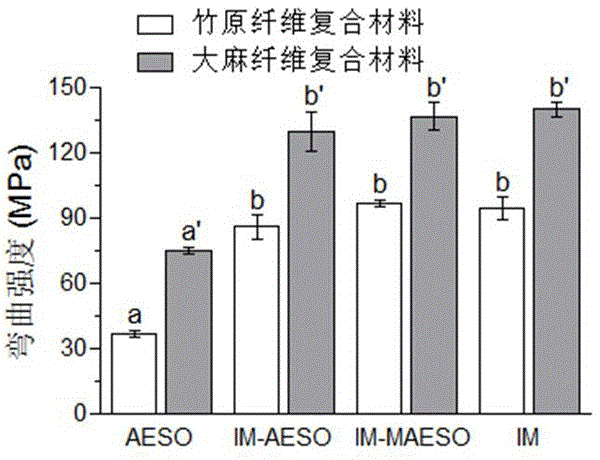

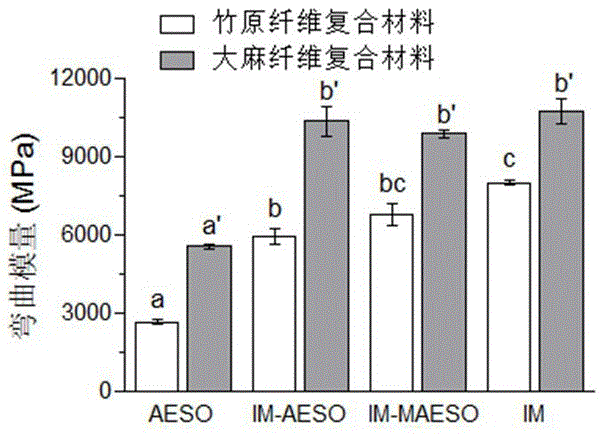

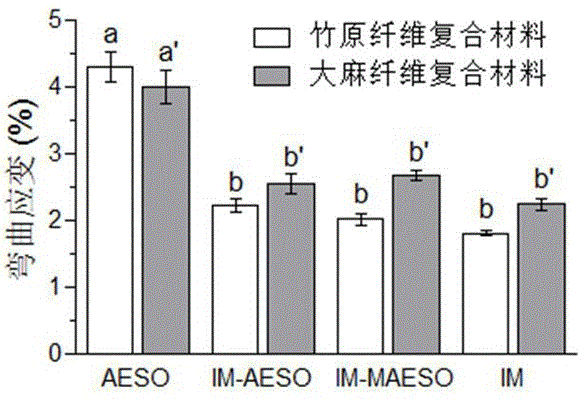

A technology of resin composite material and plant fiber is applied in the field of plant fiber reinforced bio-based thermosetting resin composite material and its preparation, which can solve the problems of high price and environmental pollution, and achieve the improvement of flexural strength and flexural modulus, flexural strength and flexural strength. The effect of increasing modulus and good flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Raw materials: bamboo fiber (average length 22.81mm, average width 150μm), purchased from Fujian Haibosi Chemical Technology Co., Ltd.; acrylate epoxy soybean oil (AESO) (model: F03; viscosity (23°C): 8000~20000cps; Acid value: ≤12mgKOH / g), purchased from Jiangsu Litian Technology Co., Ltd.; isosorbide, methacrylic anhydride (MAA) and tert-butyl peroxybenzoate (TBPB) were purchased from Sigma Aldrich (Shanghai) trade co., LTD.

[0043] The preparation method of bamboo fiber reinforced bio-based thermosetting resin composite material comprises the following steps:

[0044] (1) Synthesis process of isosorbide methacrylate (IM): put isosorbide in a round bottom flask, then add MAA and 4-dimethylaminopyridine, wherein the molar ratio of MAA to isosorbide is 3 : 1, the consumption of 4-dimethylaminopyridine is 5% of the amount of isosorbide substance; The flask is placed in an ultrasonic water bath, magnetically stirred at 500 turns / min, 60°C for 12h, and the ultrasonic pow...

Embodiment 2

[0049] Raw materials: bamboo fiber (average length 22.81mm, average width 150μm), purchased from Fujian Haibosi Chemical Technology Co., Ltd.; acrylate epoxy soybean oil (AESO) (model: F03; viscosity (23°C): 8000~20000cps; Acid value: ≤12mgKOH / g), purchased from Jiangsu Litian Technology Co., Ltd.; isosorbide, methacrylic anhydride (MAA) and tert-butyl peroxybenzoate (TBPB) were purchased from Sigma Aldrich (Shanghai) trade co., LTD.

[0050] The preparation method of bamboo fiber reinforced modified bio-based thermosetting resin composite material comprises the following steps:

[0051] (1) Synthesis process of modified bio-based thermosetting resin: put isosorbide in a round bottom flask, then add MAA and 4-dimethylaminopyridine, wherein the molar ratio of MAA to isosorbide is 3:1,4 - The amount of dimethylaminopyridine is 5% of the amount of isosorbide; the flask is placed in an ultrasonic water bath, magnetically stirred at 500 rpm, 60°C for 12 hours, and the ultrasonic p...

Embodiment 3

[0055] Raw materials: hemp fiber (average length 22.81mm, average width 150μm), purchased from Fujian Haibosi Chemical Technology Co., Ltd.; acrylate epoxy soybean oil (AESO) (model: F03; viscosity (23°C): 8000~20000cps; Acid value: ≤12mgKOH / g), purchased from Jiangsu Litian Technology Co., Ltd.; isosorbide, methacrylic anhydride (MAA) and tert-butyl peroxybenzoate (TBPB) were purchased from Sigma Aldrich (Shanghai) trade co., LTD.

[0056] The preparation method of the hemp fiber reinforced bio-based thermosetting resin composite material comprises the following steps:

[0057] (1) Synthesis process of isosorbide methacrylate (IM): put isosorbide in a round bottom flask, then add MAA and 4-dimethylaminopyridine, wherein the molar ratio of MAA to isosorbide is 3 : 1, the consumption of 4-dimethylaminopyridine is 5% of the amount of isosorbide substance; The flask is placed in an ultrasonic water bath, magnetically stirred at 500 turns / min, 60°C for 12h, and the ultrasonic pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com