Natural bamboo fiber reinforced composite material based on natural polyphenol cross-linked palm oil-based resin and preparation method of natural bamboo fiber reinforced composite material

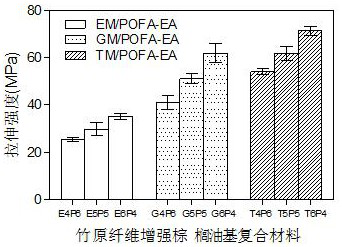

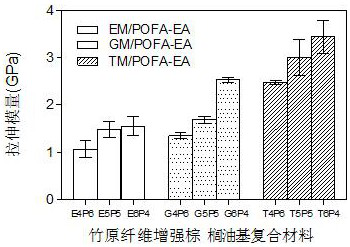

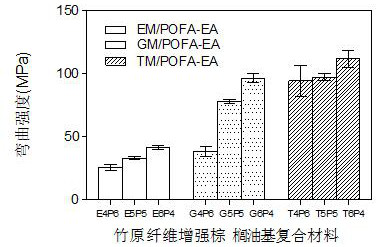

A technology of reinforced composite materials and natural polyphenols, applied in the field of resin composite materials, can solve the problems of low activity, environmental pollution, high viscosity, etc., and achieve the effect of good tensile strength, low price and large output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Eugenyl methacrylate cross-linked palm oil-based resin for bamboo fiber-reinforced composites:

[0038] The synthesis process of eugenol methacrylate: a certain amount of liquid eugenol is placed in a round bottom flask, then methacrylic anhydride and 4-dimethylaminopyridine are added, wherein the molar ratio of methacrylic anhydride to eugenol The dosage of 4-dimethylaminopyridine is 5% (molar ratio) of methacrylic anhydride; the flask is placed in an ultrasonic water bath, magnetically stirred at 500r / min, reacted at 60°C for 12h, and the ultrasonic power is 80W; the reaction products were subjected to saturated NaHCO 3 solution, 0.5mol / L NaOH solution, and distilled water were repeatedly purified several times, and in MgSO4 Under the condition of drying for 24 hours, eugenyl methacrylate was obtained.

[0039] The synthesis process of palm oil fatty acid acrylamide ethyl ester: 150g palm oil and 150mL THF are placed in a three-necked flask; then add 115g N -Hydroxy...

Embodiment 2

[0044] Eugenyl methacrylate cross-linked palm oil-based resin for bamboo fiber-reinforced composites:

[0045] The synthesis process of eugenol methacrylate: a certain amount of liquid eugenol is placed in a round bottom flask, then methacrylic anhydride and 4-dimethylaminopyridine are added, wherein the molar ratio of methacrylic anhydride to eugenol The dosage of 4-dimethylaminopyridine is 3:1, 5% (molar ratio) of methacrylic anhydride; the flask is placed in an ultrasonic water bath, magnetically stirred at 500 r / min, reacted at 60°C for 12h, and the ultrasonic power It is 80W; the reaction products are subjected to saturated NaHCO 3 solution, 0.5mol / L NaOH solution, and distilled water were repeatedly purified several times, and in MgSO 4 Under the condition of drying for 24 hours, eugenyl methacrylate was obtained.

[0046] The synthesis process of palm oil fatty acid acrylamide ethyl ester: 150g palm oil and 150mL THF are placed in a three-necked flask; then add 115g ...

Embodiment 3

[0051] Eugenyl methacrylate cross-linked palm oil-based resin for bamboo fiber-reinforced composites:

[0052] The synthesis process of eugenol methacrylate: a certain amount of liquid eugenol is placed in a round bottom flask, then methacrylic anhydride and 4-dimethylaminopyridine are added, wherein the molar ratio of methacrylic anhydride to eugenol The dosage of 4-dimethylaminopyridine is 3:1, 5% (molar ratio) of methacrylic anhydride; the flask is placed in an ultrasonic water bath, magnetically stirred at 500 r / min, reacted at 60°C for 12h, and the ultrasonic power It is 80W; the reaction products are subjected to saturated NaHCO 3 solution, 0.5mol / L NaOH solution, and distilled water were repeatedly purified several times, and in MgSO 4 Under the condition of drying for 24 hours, eugenyl methacrylate was obtained.

[0053] The synthesis process of palm oil fatty acid acrylamide ethyl ester: 150g palm oil and 150mL THF are placed in a three-necked flask; then add 115g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com