Patents

Literature

59results about How to "Excellent tensile modulus" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

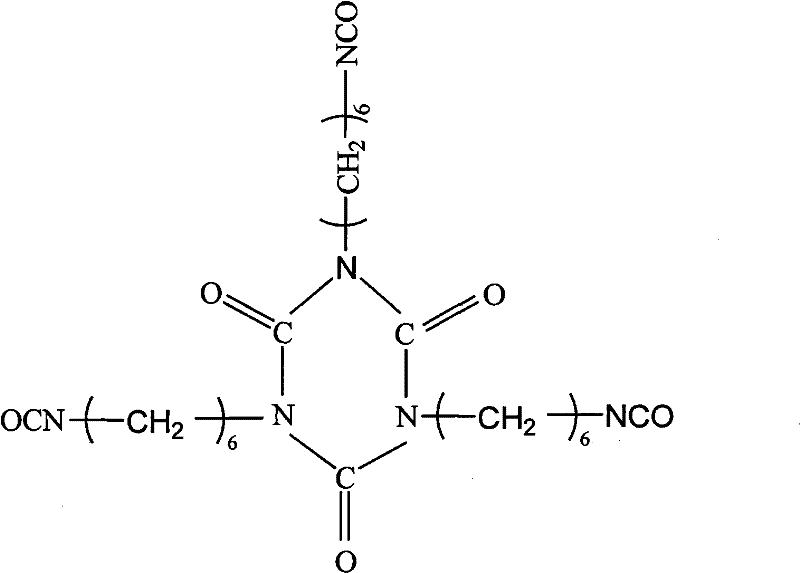

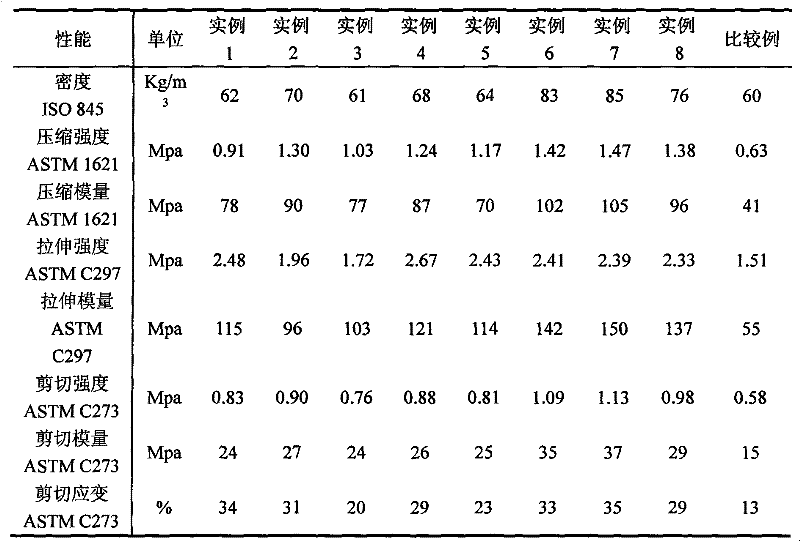

Improved crosslinked polyvinyl chloride structural foam and preparation method thereof

ActiveCN101580573ASimple manufacturing process controlWide operating range of parametersFoaming agentPolyvinyl chloride

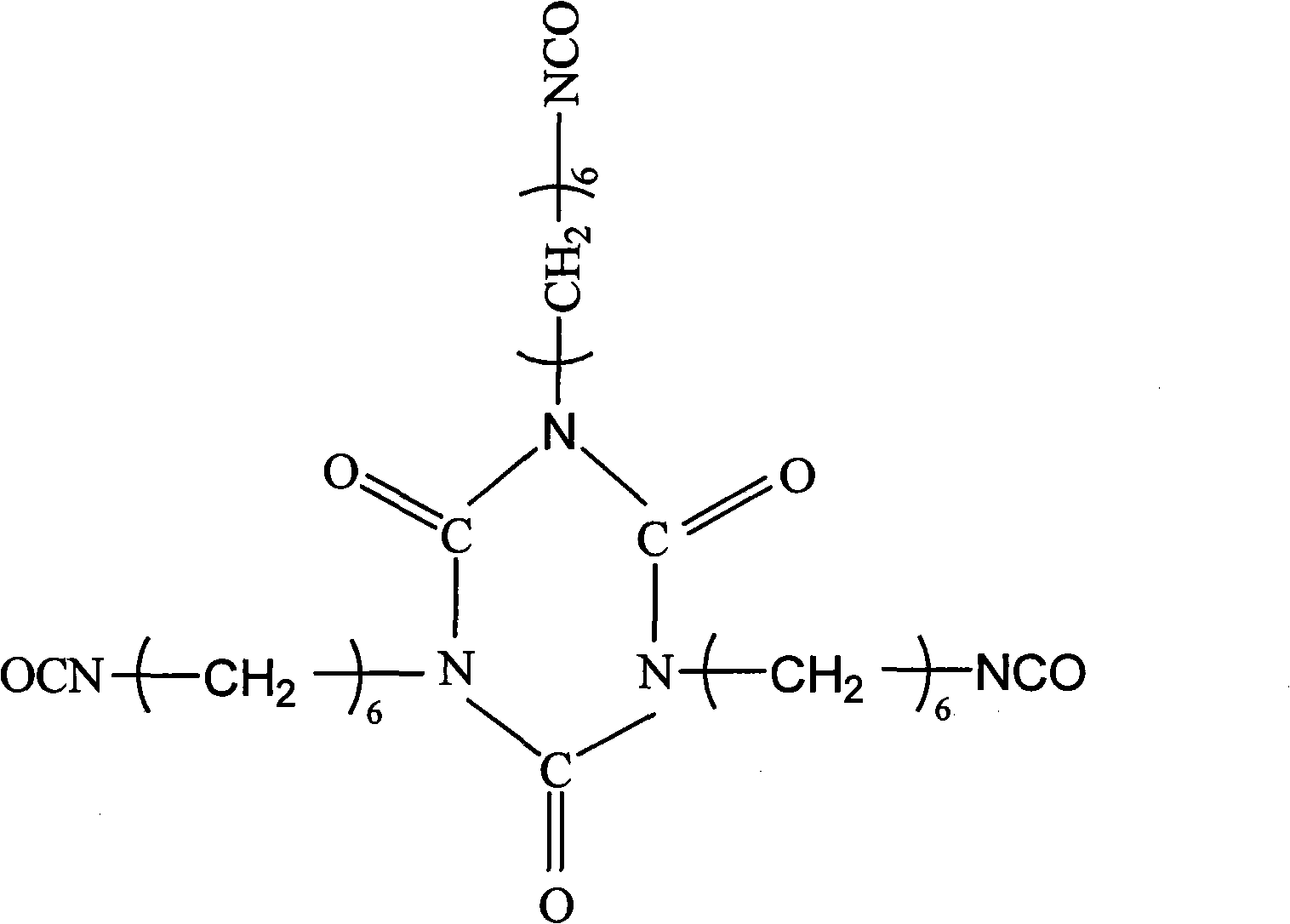

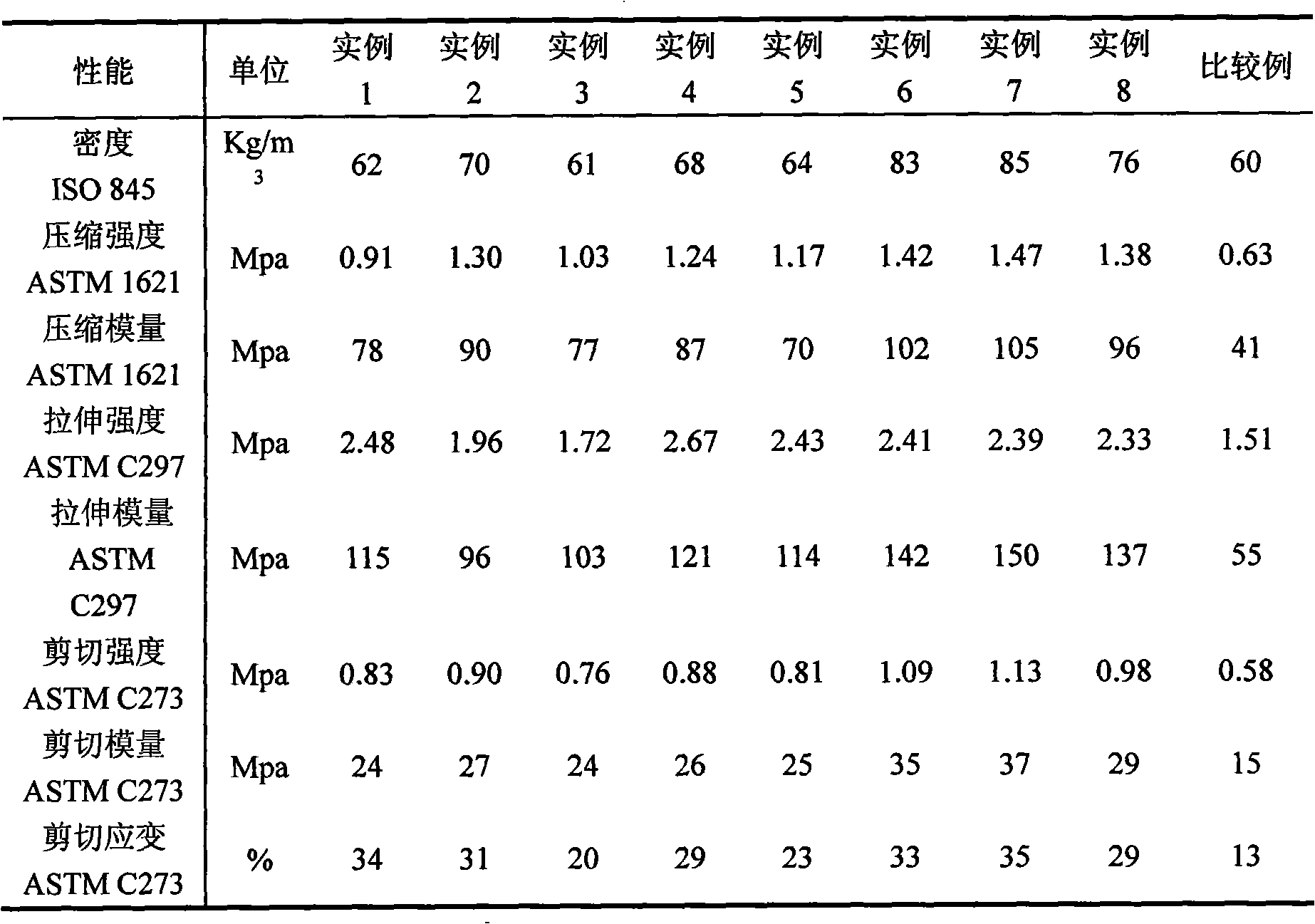

The invention relates to improved crosslinked polyvinyl chloride structural foam and a preparation method thereof. The foam is prepared from the following materials in portion by weight: 100 portions of polyvinyl chloride resin, 30 to 120 portions of isocyanate, 0.05 to 10 portions of epoxy components, 1 to 12 portions of foaming agent, 0.5 to 10 portions of triazine compound, and 1 to 30 portions of acid anhydride. The preparation method thereof comprises the following steps: (1) mixing the raw materials evenly to obtain a pasty mixture; (2) pouring the pasty mixture obtained in step (1) into a die, and fully decomposing the foaming agent to obtain a semi-foaming die pressing block; (3) cooling the semi-foaming die pressing block to room temperature; (4) placing the semi-foaming die pressing block obtained in step (3) into hot bath or steam to carry out swelling; and (5) cooling a swelled semi-finished product obtained in step (4) to room temperature, and then adopting hot water spray or curing post treatment in the steam to fully react the isocyanate so as to obtain cured block or plate crosslinked polyvinyl chloride structural foam. The foam has fine and even holes, and has good mechanical property and temperature resistance.

Owner:CHANGZHOU TIANSHENG NEW MATERIALS

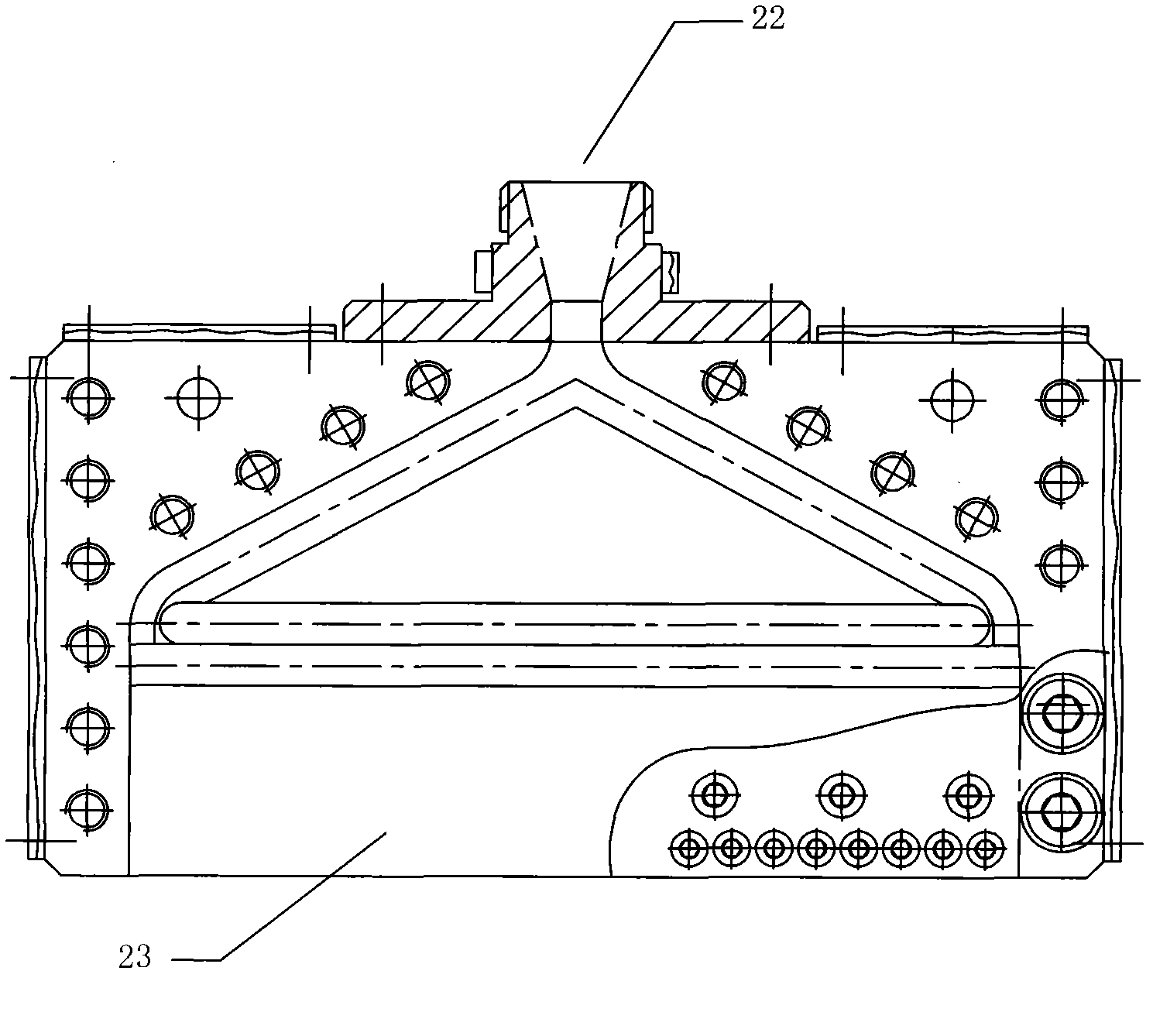

Preparation device of ultra-high molecular weight polyethylene sheets and preparation method thereof

InactiveCN102320137AHigh degree of automationIncrease productivityFlat articlesElastic modulusEngineering

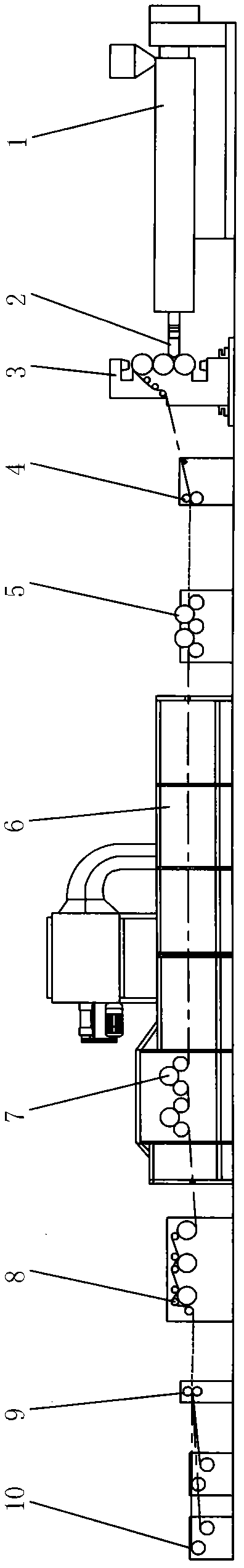

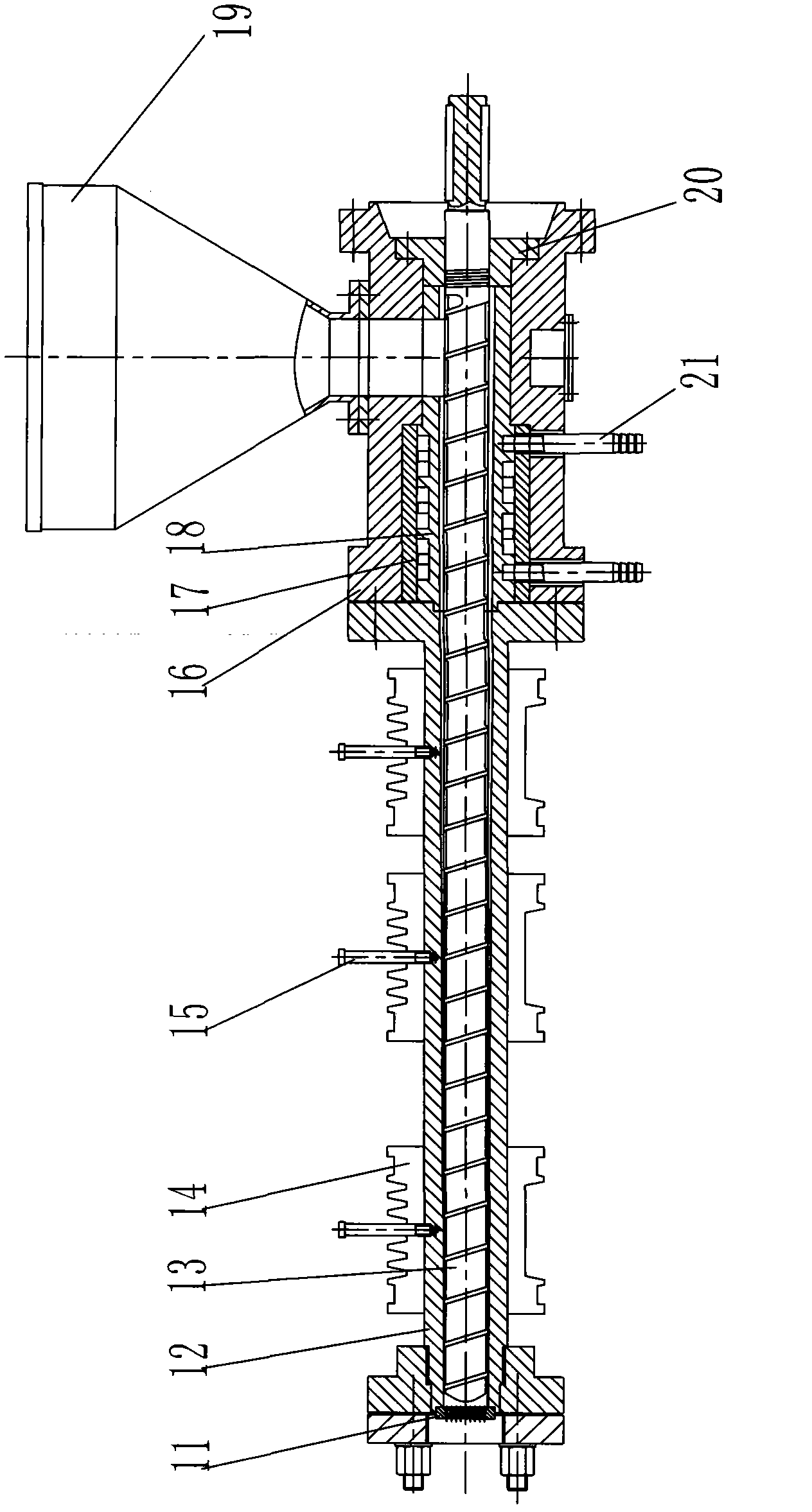

The invention discloses a preparation device of ultra-high molecular weight polyethylene sheets and a preparation method thereof, and the preparation device comprises an extruding machine, a plate die and a stretching device, wherein the stretching device comprises a heating device and a main stretching machine, and an auxiliary stretching machine is further mounted in the heating device; and a calendaring machine, a first traction machine and a conveyor are mounted between the plate die and the heating device. The preparation method comprises the following steps: (a) preparing materials; (b) extruding the materials; (c) shaping; (d) calendaring; (e) performing traction and conveying; and (f) stretching. By adopting the preparation device and the preparation method, the high-strength high-modulus ultra-high molecular weight polyethylene sheets which are in the width of 300-1200mm, the thickness of 1-10mm, the tensile strength of 200-400MPa and the elastic modulus of 8-16GPa can be produced, and the preparation device and the preparation method have the characteristics of high production efficiency and high degree of automation and further have broad application prospects.

Owner:辽宁鑫宝通新材料科技有限公司 +1

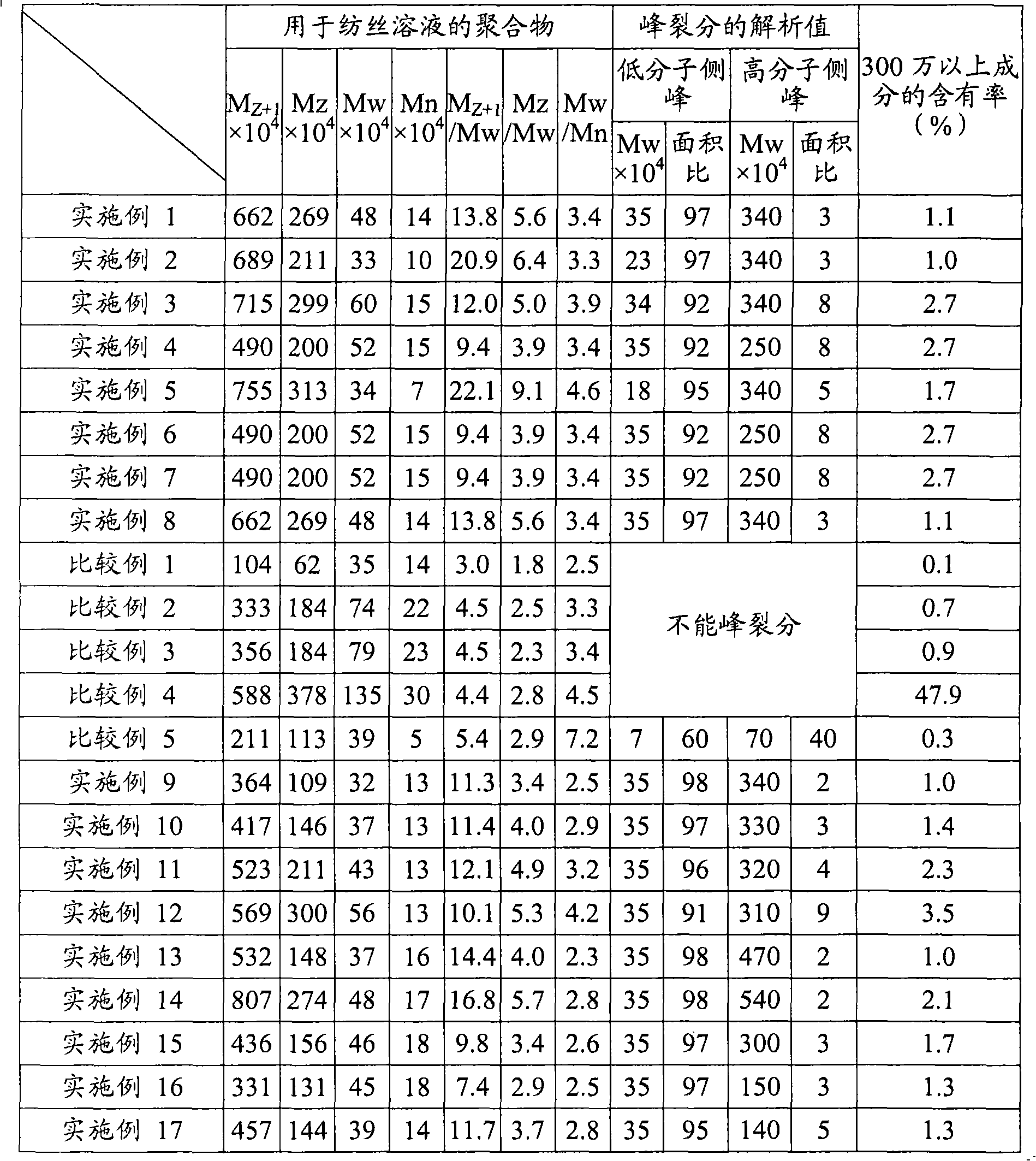

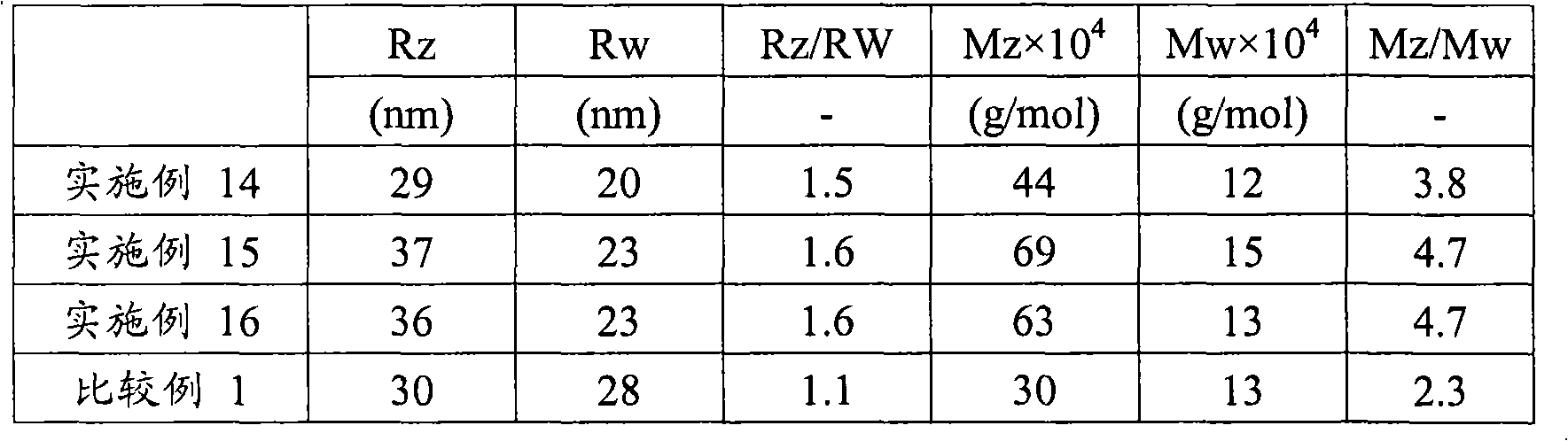

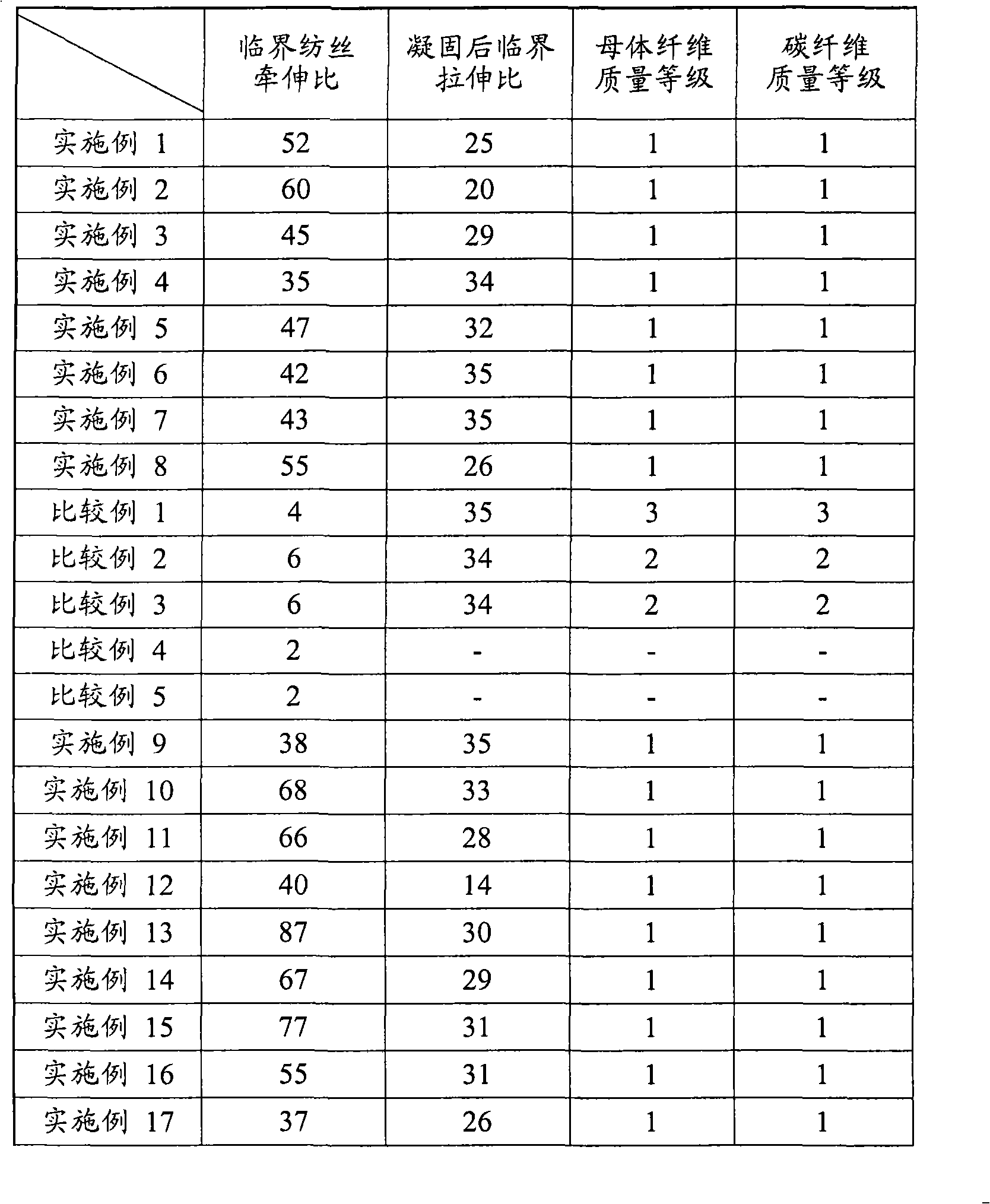

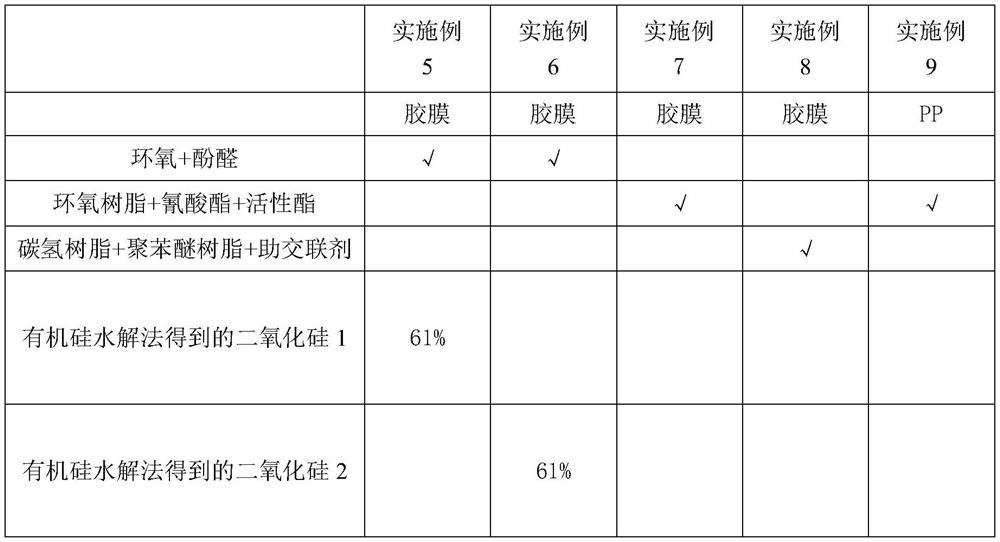

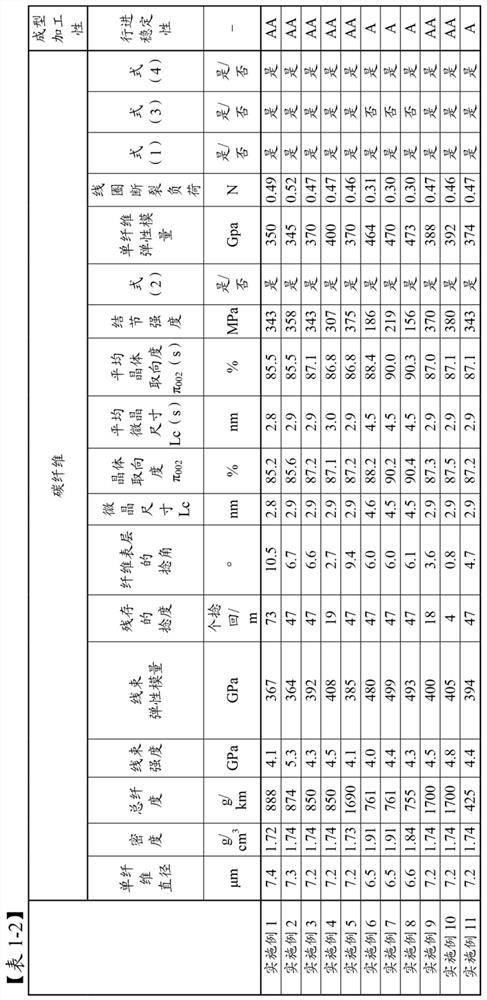

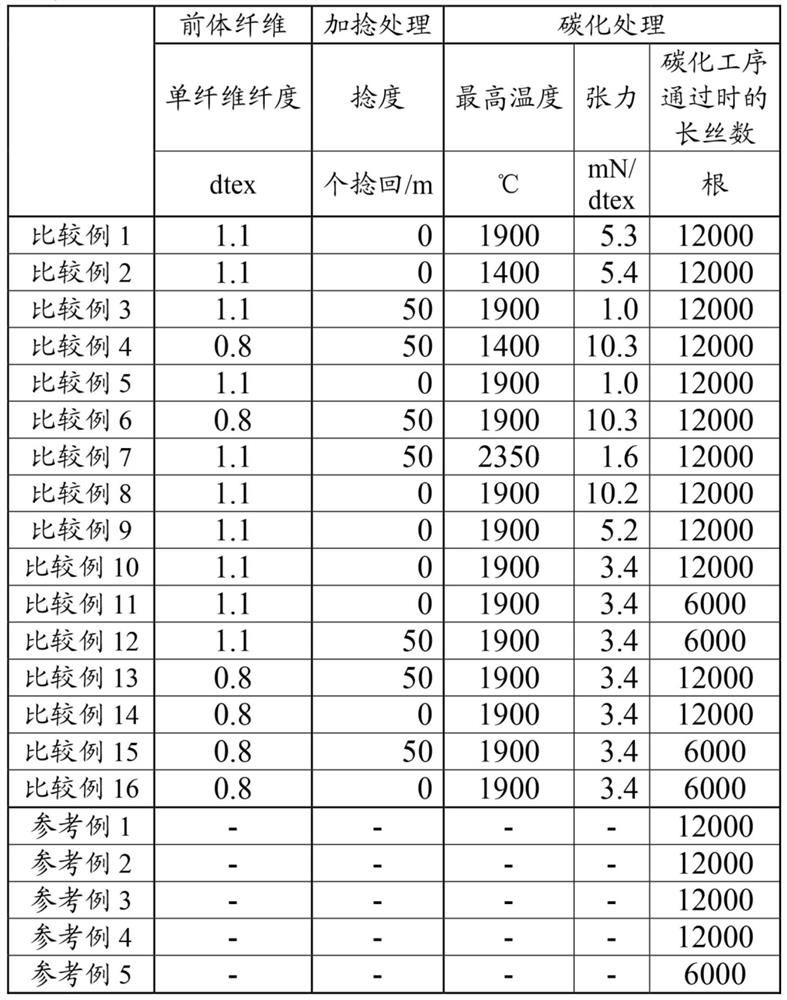

Polyacrylonitrile polymer, process for production of the polymer, process for production of precursor fiber for carbon fiber, carbon fiber, and process for production of the carbon fiber

InactiveCN101553511AIncrease spinning draft ratioQuality improvementMonocomponent synthetic polymer artificial filamentThin material handlingPolymer scienceCarbon fibers

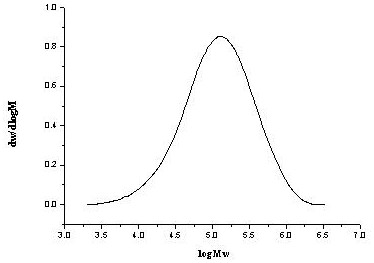

The invention relates to a polyacrylonitrile-based polymer, containing a polymer of which main component is acrylonitrile, which satisfies at least one kind requirement selected from the following [a] to [d]. [a] Z-average molecular weight (Mz) determined by gel-permeation chromatograph is 800,000 to 6,000,000 and degree of polydispersity (Mz / Mw) (Mw denotes weight average molecular weight) is 3.0 to 10.0. [b] Z+1-average molecular weight (Mz+1) determined by GPC method is 3,000,000 to 10,000,000 and degree of polydispersity (Mz+1 / Mw) is 6.0 to 25.0. [c] Mzm determined by gel-permeation chromatograph[space]multi-angle laserlight scattering photometry is 400,000 to 1,000,000 and degree of polydispersity (Mzm / Mwm) is 3.0 to 10.0. [d] Z-average radius of gyration (Rz) determined by gel-permeation chromatograph[space]multi-angle laserlight scattering photometry is 25 to 45 nm and its ratio to weight average radius of gyration (Rz / Rw) is 1.3 to 2.5.

Owner:TORAY IND INC

Polyacrylonitrile-based graphite fiber and preparation method thereof

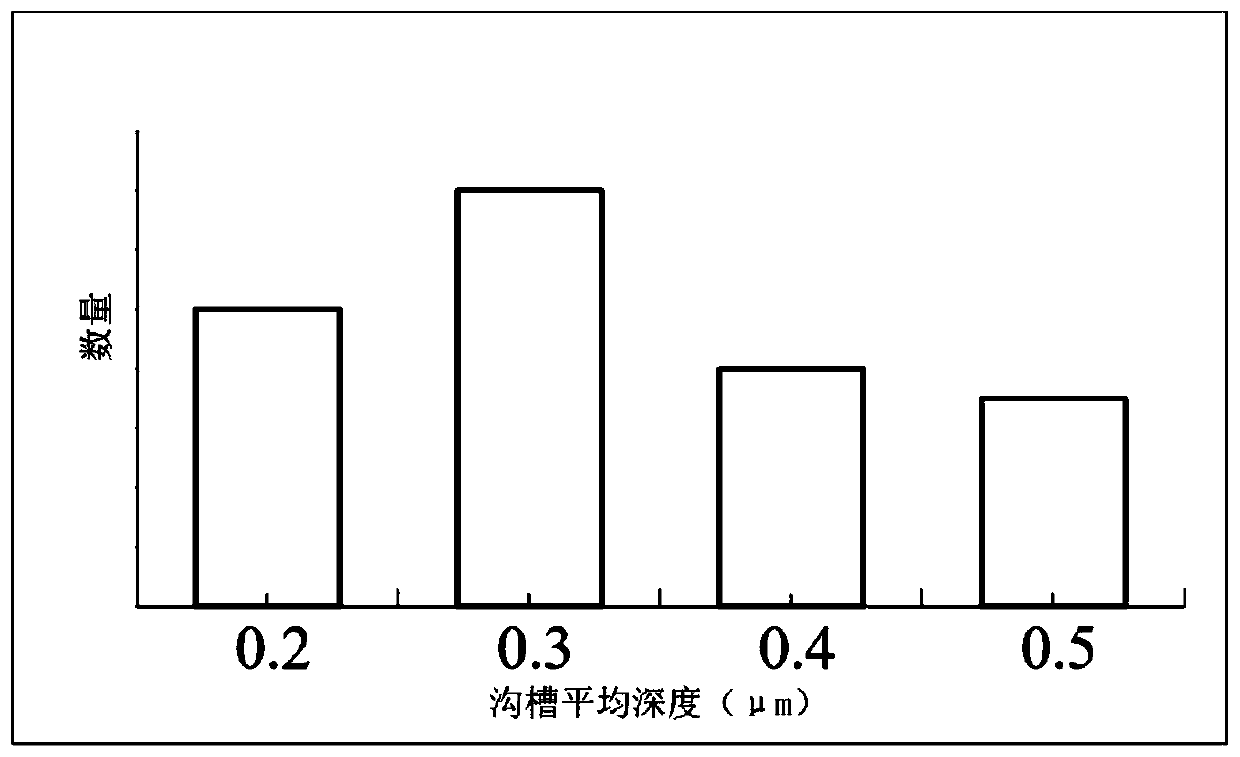

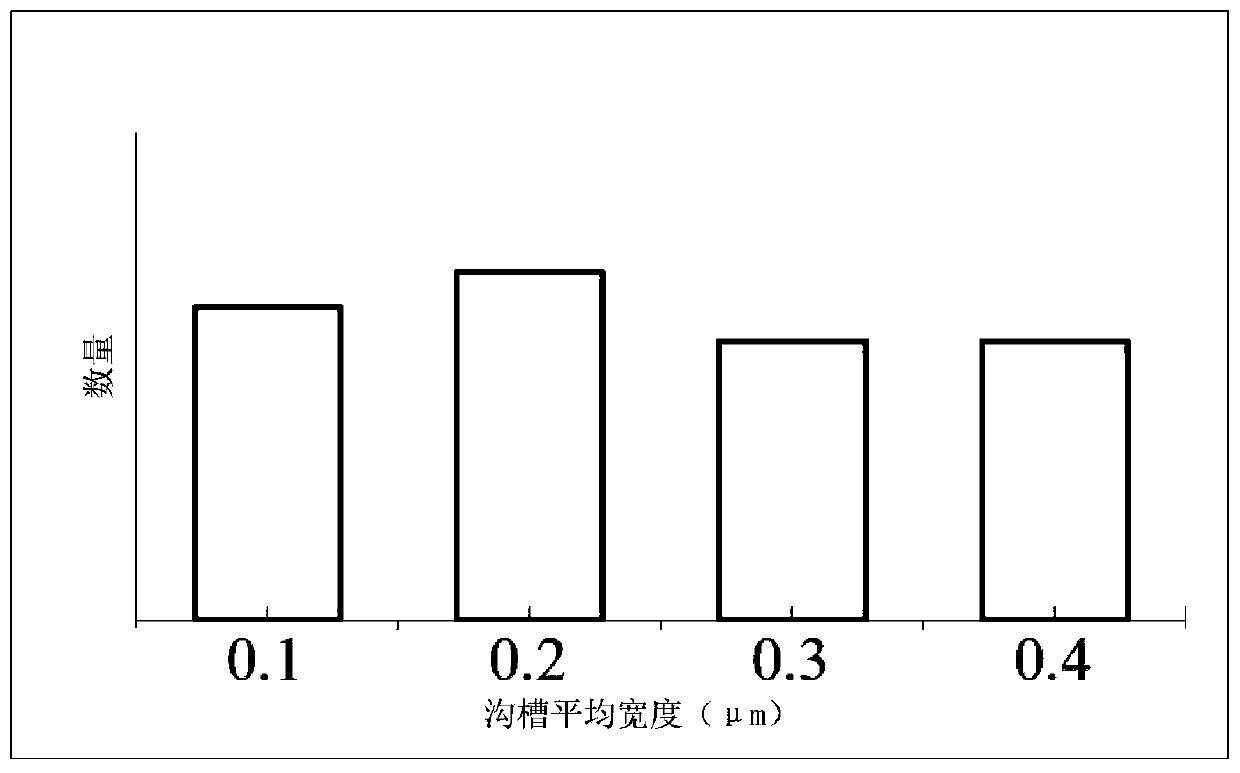

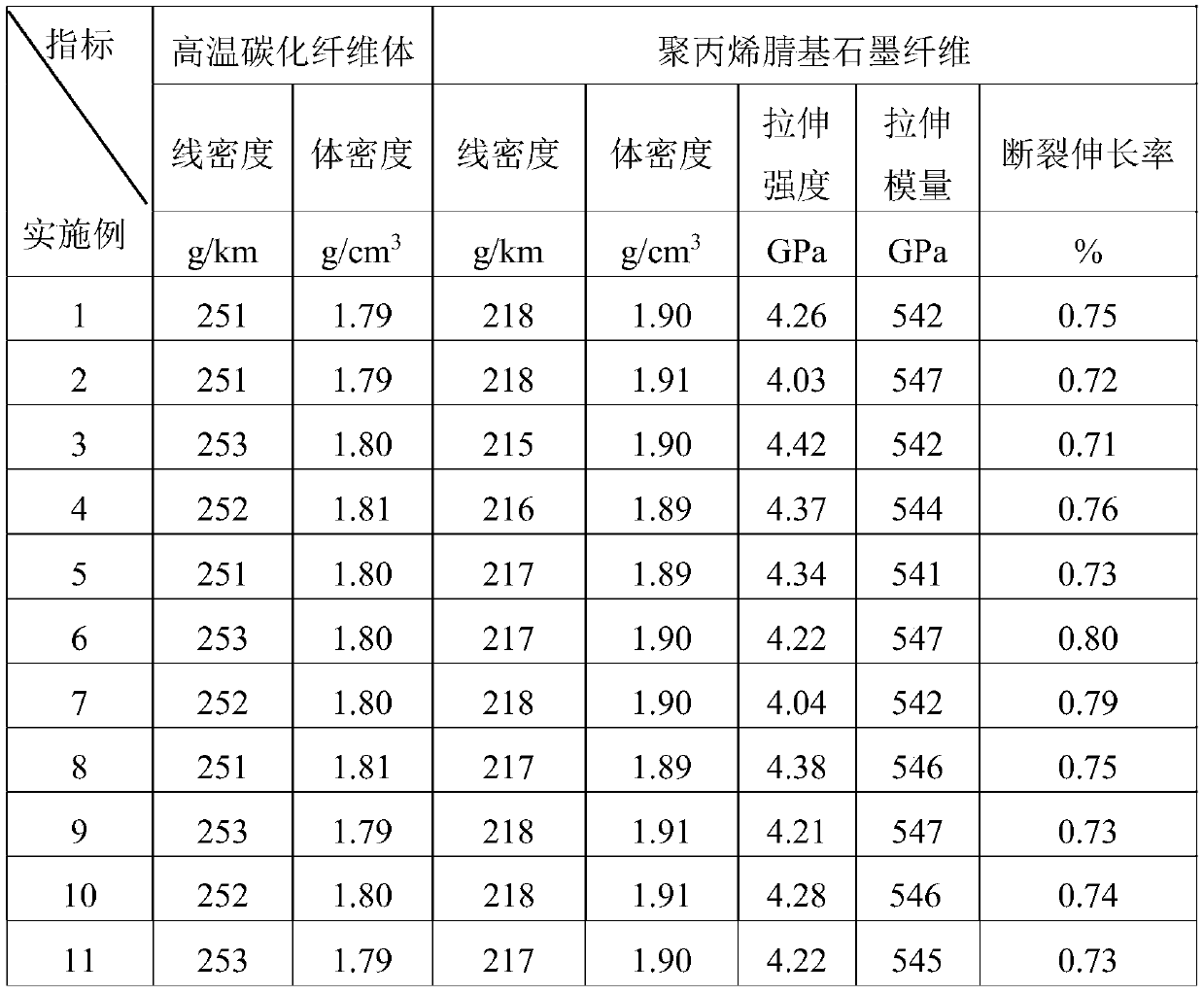

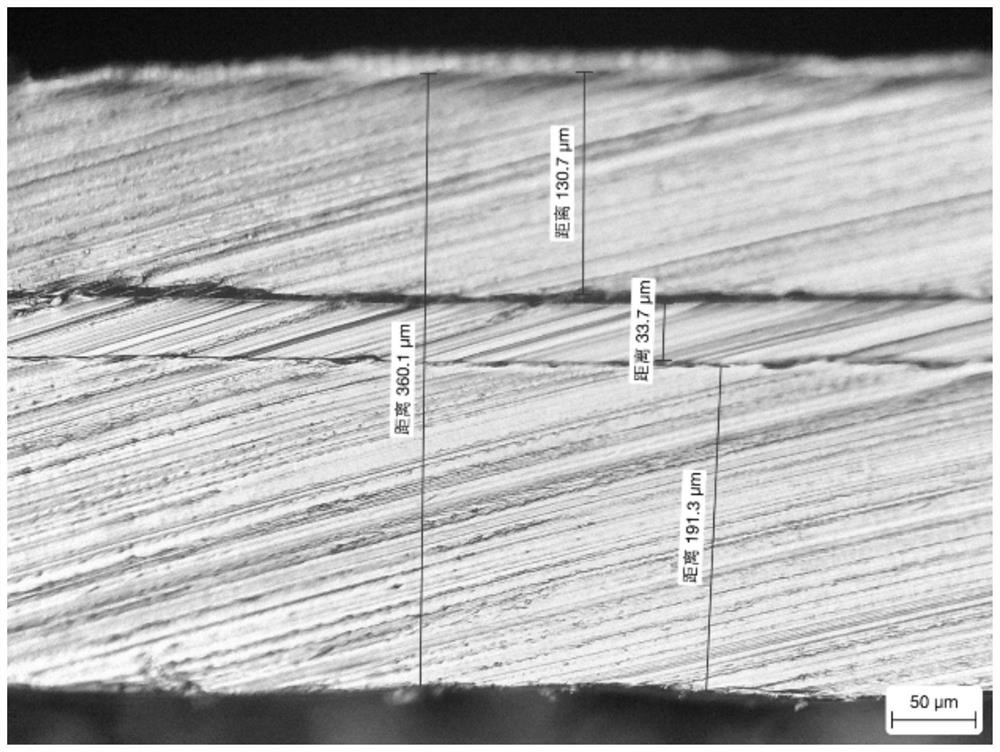

ActiveCN110067044AHigh tensile strengthImprove conductivityFibre chemical featuresGroove widthCarbonization

The invention discloses a polyacrylonitrile-based graphite fiber and a preparation method thereof. According to a main technical scheme, the polyacrylonitrile-based graphite fiber has the tension strength of 4.01-4.46GPa, a tension modus of 541-547PGa and a bulk density of 1.89-1.91g / cm<3>; and the linear density of a 6K polyacrylonitrile-based graphite fiber is 215-218g / km. The preparation methodof the polyacrylonitrile-based graphite fiber comprises the following step: carrying out pre-oxidation, low-temperature carbonization, high-temperature carbonization, graphitization and aftertreatment on protofilaments in sequence, so as to obtain the polyacrylonitrile-based graphite fiber, wherein the protofilaments are polyacrylonitrile fibers; the diameter of a single protofilament is 9-11mu m; the average groove depth of the protofilaments s 0.2-0.5mu m, the average groove width of the protofilaments is 0.1-0.4mu m, and the average surface roughness Ra of the protofilaments is 0.0182-0.0201mu m. The invention mainly aims to prepare the polyacrylonitrile-based graphite fiber which has an excellent mechanical property index such as strength and modi.

Owner:山西钢科碳材料有限公司

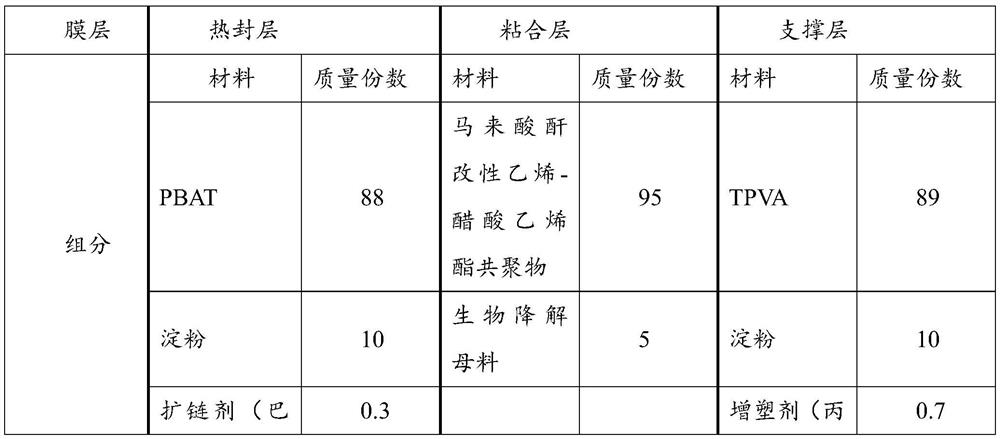

Composite film, preparation method thereof and plastic film product

PendingCN112677598AHigh strengthImprove toughnessSynthetic resin layered productsLaminationPolymer scienceComposite film

The invention discloses a composite film, a preparation method thereof and a plastic film product. The composite film comprises a heat sealing layer, a bonding layer and a supporting layer which are sequentially stacked, wherein based on the mass of the heat sealing layer, the heat sealing layer is prepared from a heat sealing layer raw material comprising 48-100 parts by mass of PBAT, 0-30 parts by mass of a filler, 0-20 parts by mass of a biodegradable material and 0-2 parts by mass of a processing aid, the bonding layer is prepared from a bonding layer raw material comprising bonding resin, the bonding resin is copolyester containing an active group, and the active group is a carboxyl or anhydride group; wherein the supporting layer is prepared from the following raw materials in parts by mass: 68-100 parts of thermoplastic modified polyvinyl alcohol, 0-20 parts of filler, 0-10 parts of biodegradable material and 0-2 parts of processing aid. The composite film provided by the invention has good mechanical properties, layers are not easy to separate, and the composite film has good application prospects.

Owner:佛山(华南)新材料研究院

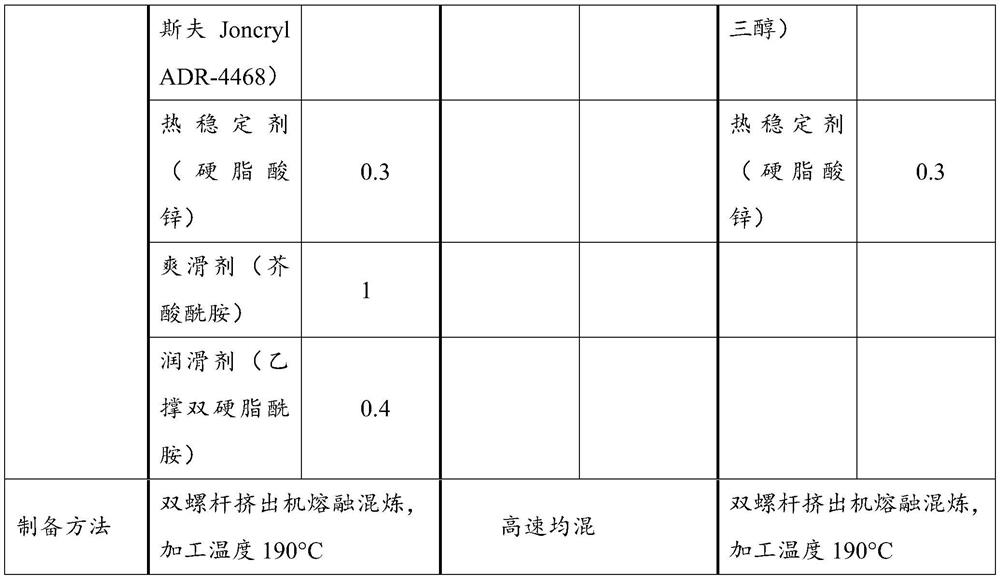

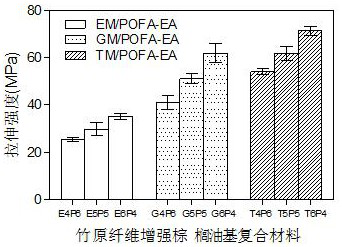

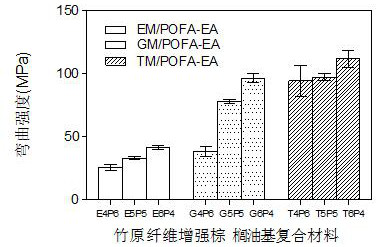

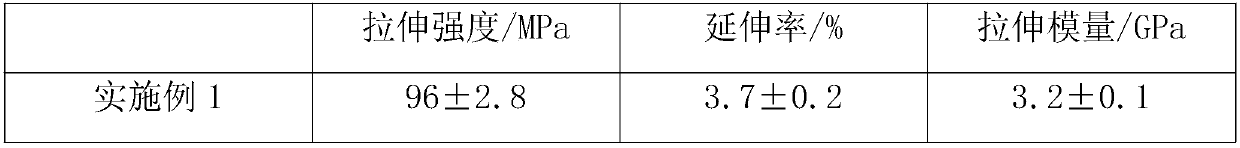

Natural bamboo fiber reinforced composite material based on natural polyphenol cross-linked palm oil-based resin and preparation method of natural bamboo fiber reinforced composite material

The invention belongs to the technical field of resin composite materials, and particularly relates to a natural bamboo fiber reinforced composite material based on natural polyphenol cross-linked palm oil-based resin and a preparation method of the natural bamboo fiber reinforced composite material. The environment-friendly palm oil-based resin is prepared by blending a natural polyphenol cross-linking agent and palm oil fatty acid acrylamide ethyl ester, and natural bamboo fibers, the palm oil-based resin and an initiator are subjected to hot press molding to obtain the natural bamboo fiberreinforced palm oil-based resin composite material. The natural bamboo fiber reinforced palm oil-based resin composite material prepared by the invention is environment-friendly and has good tensile strength, tensile modulus, bending strength and bending modulus.

Owner:FUJIAN AGRI & FORESTRY UNIV

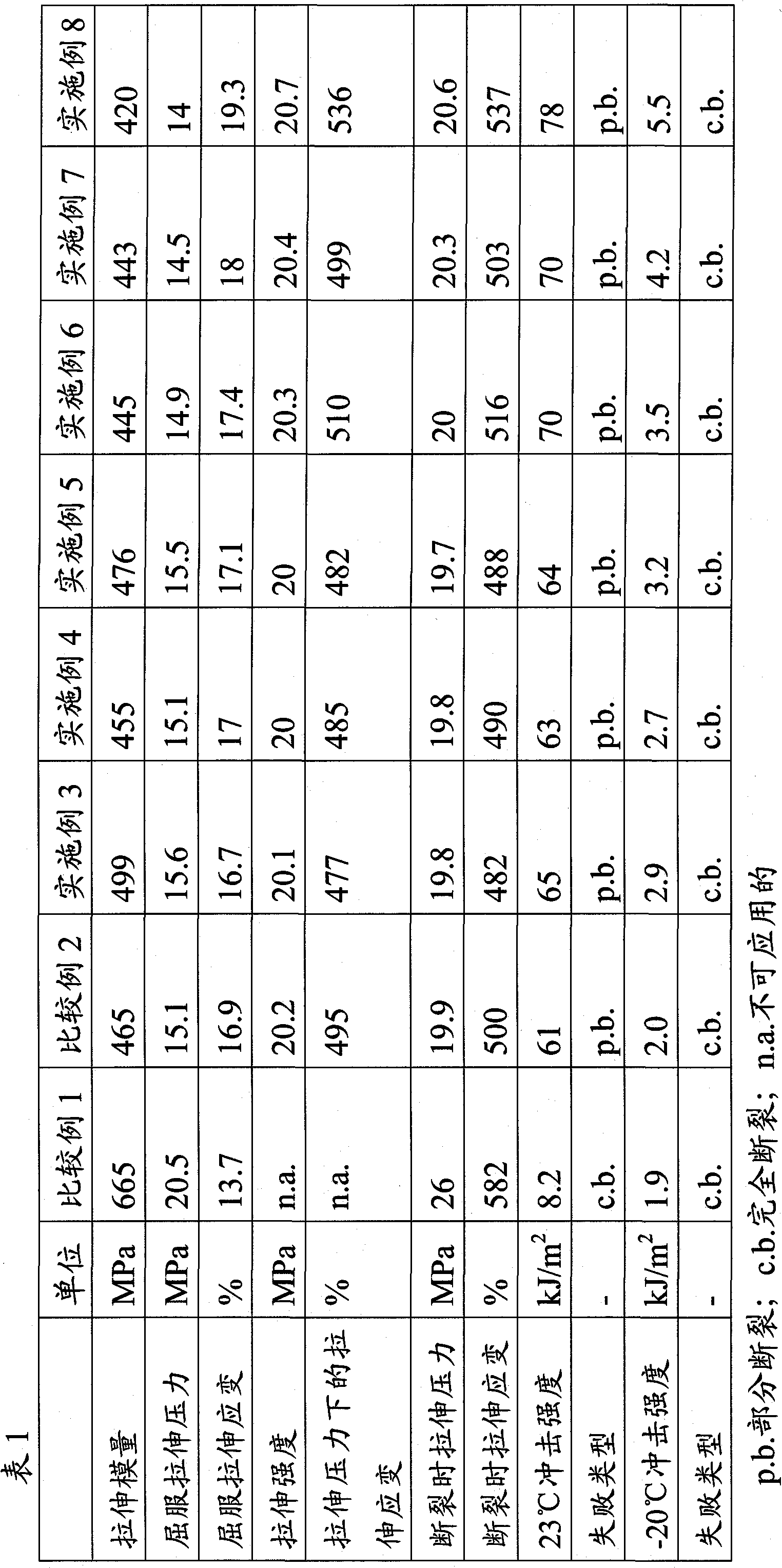

Flexible polypropylene with high impact strength

The present invention is directed to a first polypropylene composition comprising a propylene copolymer as matrix phase (A) comprising a homo / random / block copolymer consisting of a) a propylene homopolymer (A1); b) a propylene random copolymer (A2); and c) an ethylene-propylene rubber (EPR) (A3) and a polyolefin (B) dispersed in the matrix phase (A), which comprises hydrolysable silicon-containing groups. The present invention is furthermore directed to a second polypropylene composition comprising a matrix phase (A) comprising a propylene homo- or copolymer with an impact strength at + 23 DEG C of at least 40.0 kJ / m<2> in a Charpy notched test according to ISO 179-1eA:2000 and a polyolefin (B) dispersed in the matrix phase (A), which comprises hydrolysable silicon-containing groups. The invention is furthermore directed to a production process for the polypropylene compositions and an article made thereof.

Owner:ボレアリステクノロジーオイ

Preparation method and application of high-molecular-weight transparent polyesters

PendingCN112142962AImprove mechanical propertiesImprove thermal performanceCoatingsFuranPolymer science

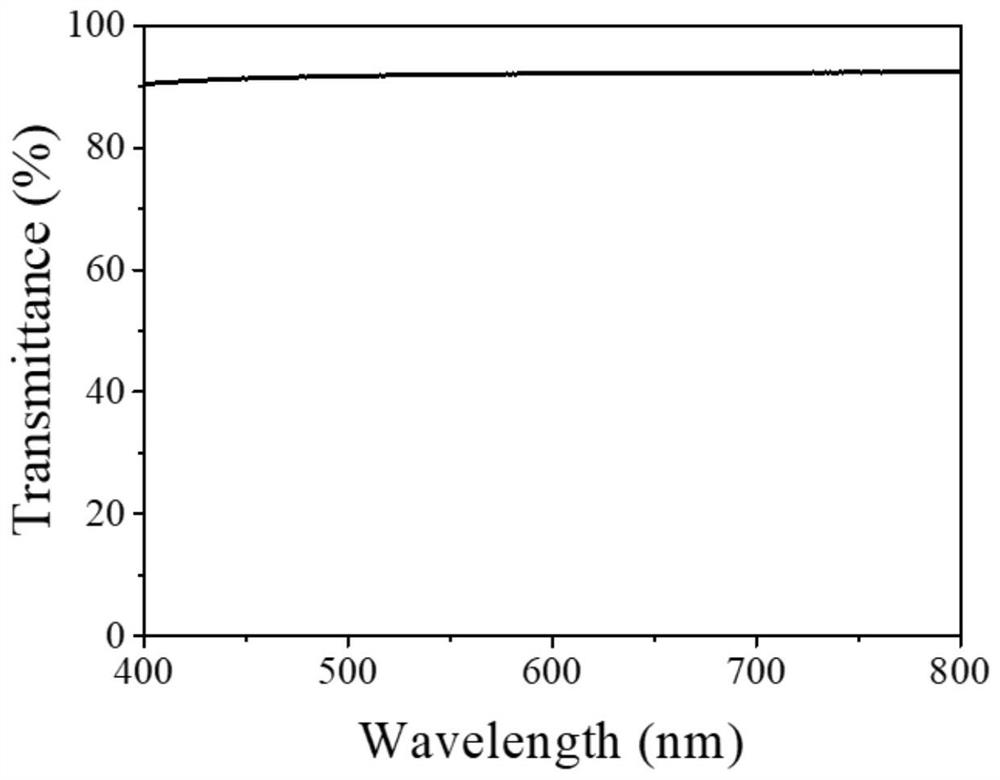

The invention discloses a preparation method and application of novel high-molecular-weight transparent polyesters, and belongs to the field of polyester synthesis. Terephthalic acid or isophthalic acid, 2,5-furandicarboxylic acid and dihydric alcohol or other dihydroxy compounds are used as raw materials, and a series of novel polyesters with high molecular weight are synthesized by adopting a melt polymerization method. The method provided by the invention has the advantages of small catalyst usage amount, efficient reaction and high transparency of the obtained polyesters, and the synthesized polyester has the characteristics of high molecular weight, wide molecular weight distribution, good thermal properties, excellent mechanical properties and the like, and is easy for hot processingtreatment in the next step. The transparent high-molecular-weight polyester prepared by the preparation method can be used as a main component for processing a bottle-grade polyester material, and can also be used as a substrate raw material of a transparent conductive polyester film material.

Owner:WUHAN UNIV OF SCI & TECH

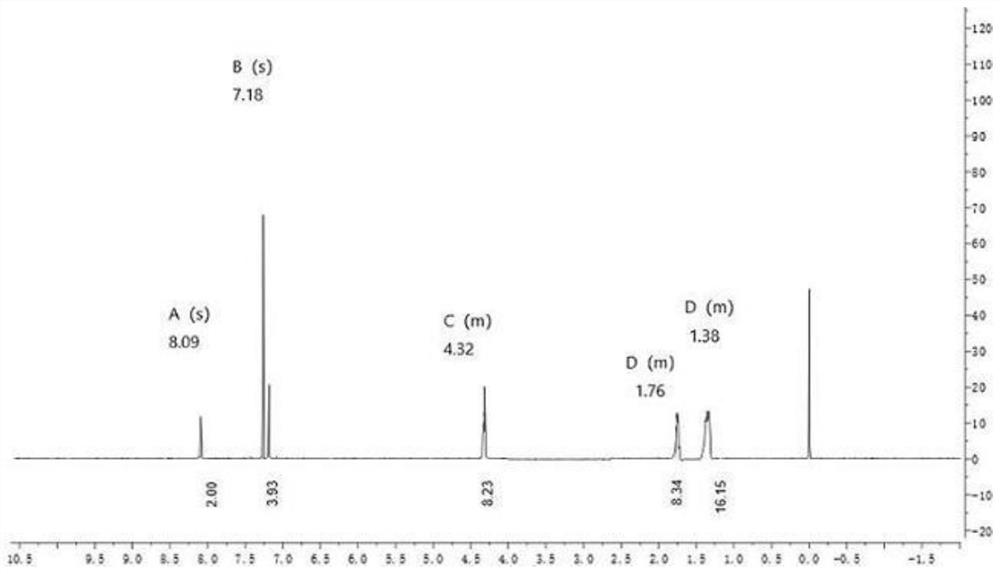

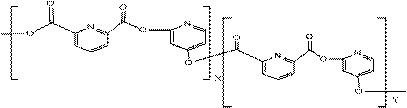

Synthesis method and application of biodegradable high-molecular-weight polyester

PendingCN112142963AImprove mechanical propertiesImprove thermal performanceSuture equipmentsCoatingsPolyesterPropanol

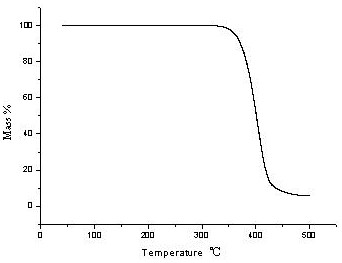

The invention discloses a synthesis method and application of biodegradable high-molecular-weight polyester, and belongs to the field of polyester synthesis. 2, 6-pyridine dicarboxylic acid and a dihydroxyl compound are used as raw materials, and a series of novel biodegradable high-molecular-weight polyesters are synthesized by adopting a melt polymerization method. The synthesis method comprisesthe following steps: under the protection of N2, stirring the raw materials at 160-185 DEG C under the action of a catalyst to react for 4.0-5.0 hours, heating to 200-220 DEG C, reacting for 2.0-3.5hours in a 5-15 KPa environment, and vacuumizing for 2.0-3.0 hours to obtain a polymer crude product; cooling the crude product, adding chloroform, dissolving, filtering, and adding ethanol or propanol and other low-carbon alcohols into the filtrate until no precipitate is generated; centrifugally filtering, washing the obtained precipitate with ethanol to remove impurities, and carrying out vacuum drying at 50-60 DEG C for 3.0-4.0 hours to obtain the required high-molecular-weight polyester. The weight-average molecular weight Mw value of the obtained polyester is 210,000 280,000 Da, and themolecular weight distribution Mw / Mn value is as wide as 3.0-4.9. The high-molecular-weight polyester prepared by the invention can be used as a main component of a medical material surgical suture andcan also be used as a flexible and foldable curved display panel base material.

Owner:WUHAN UNIV OF SCI & TECH

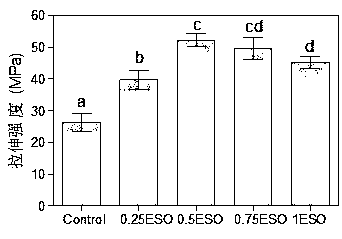

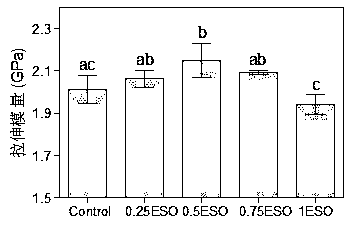

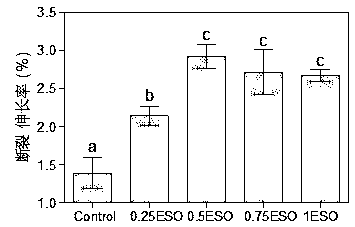

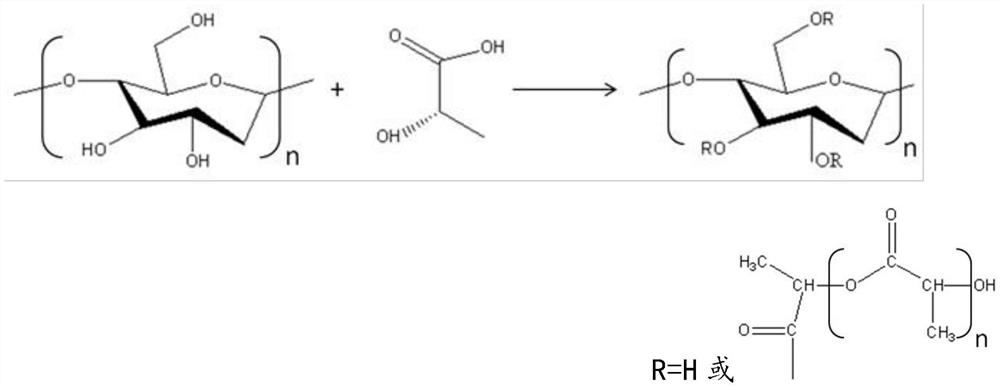

Reactive compatibilized bamboo fiber/polylactic acid composite material and preparation method thereof

The invention belongs to the technical field of fiber-reinforced resin composite materials and particularly relates to a reactive compatibilized bamboo fiber / polylactic acid composite material and a preparation method thereof. The preparation method comprises the following steps: coating bamboo fibers by adopting a vegetable oil prepolymer, uniformly mixing the obtained bamboo fibers and a polylactic acid resin, mixing by a twin screw mixer to induce a vegetable oil prepolymer reaction so as to obtain a reactive compatibilized bamboo fiber / polylactic acid mixture, and performing hot press molding on the mixture in a mold, so as to obtain the environmental-friendly and biodegradable bamboo fiber / / polylactic acid composite material. The prepared composite material has excellent tensile strength, tensile modulus and elongation at break.

Owner:FUJIAN AGRI & FORESTRY UNIV

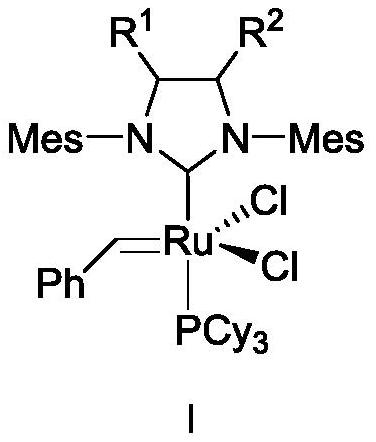

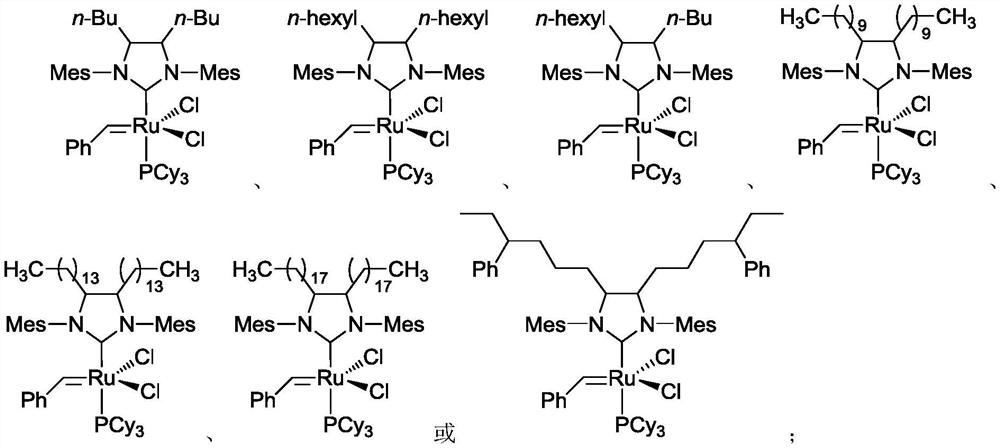

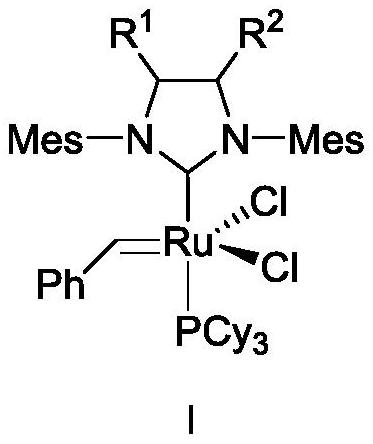

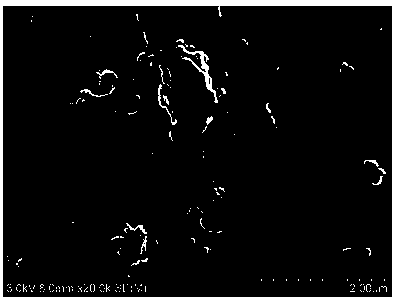

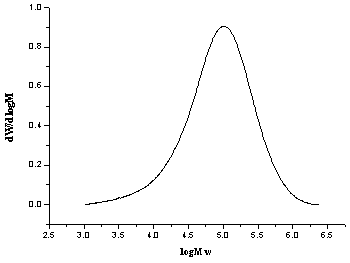

Composition, resin material, and method for producing same

ActiveCN112661884AEasy to useLong storage periodBulk chemical productionPolymer sciencePtru catalyst

The invention discloses a composition, a resin material and a preparation method thereof. The invention particularly discloses a composition which comprises the following components in parts by weight: 60-100 parts of dicyclopentadiene and 0.01-35 parts of a catalyst composition, wherein the catalyst composition comprises a ruthenium carbene compound as shown in a formula I or a salt thereof, and chlorinated paraffin, the chlorine content of the chlorinated paraffin is 5%-65%, and the chlorine content is the percentage of the mass of chlorine atoms in the mass of the chlorinated paraffin. The composition disclosed by the invention can be stored for a long time, the resin material prepared from the composition has good mechanical properties such as tensile strength, tensile modulus and elongation at break, and in addition, the preparation process of the resin material is simple and is suitable for industrial continuous production.

Owner:SHANGHAI ZHONGHUA TECH CO LTD

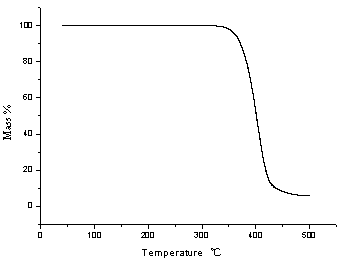

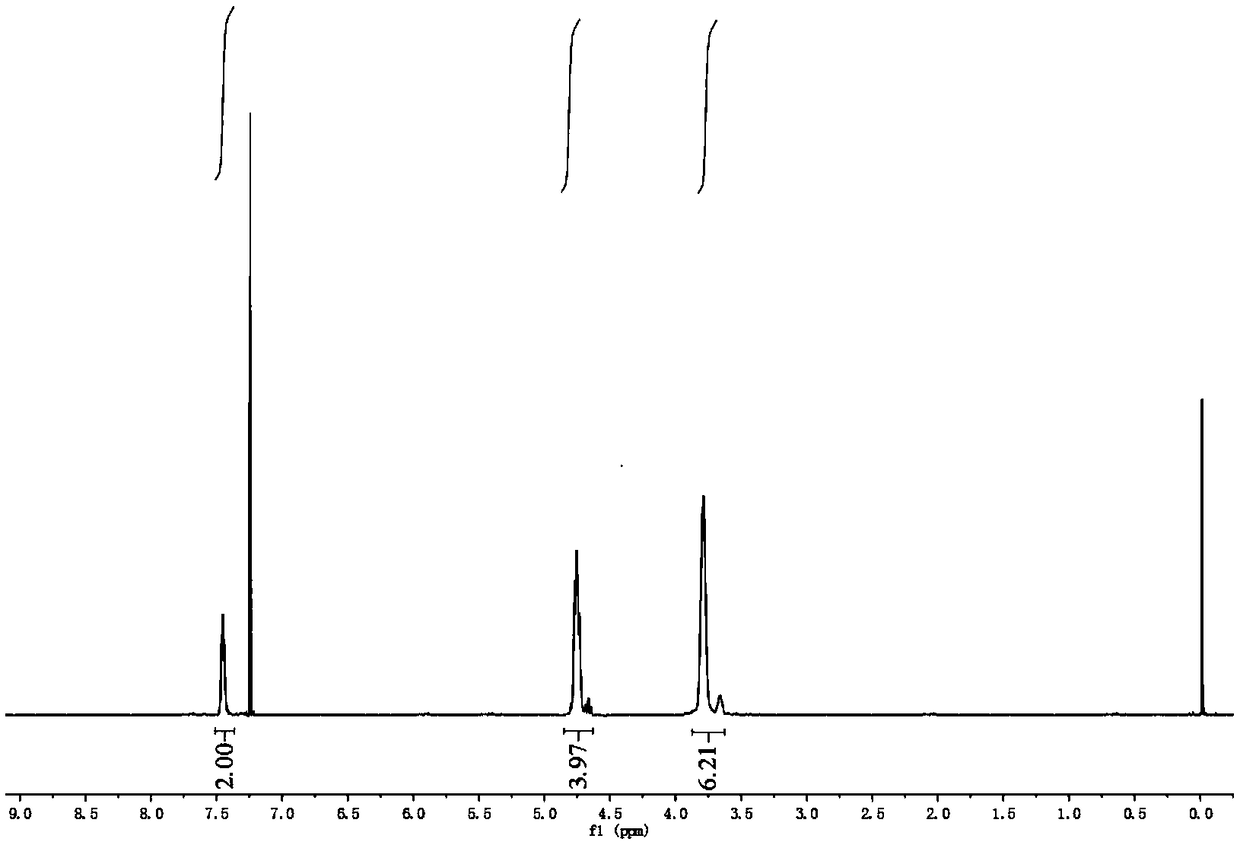

Preparation method of polyimide/sisal cellulose micro-crystalline shape memory composite material

The invention discloses a preparation method of a polyimide / sisal cellulose micro-crystalline shape memory composite material. The preparation method comprises the following steps: putting sisal cellulose micro-crystalline into a baking oven and drying at the temperature of 100 DEG C for 2 to 4 hours to obtain dried sisal cellulose micro-crystalline; then mixing the dried sisal cellulose micro-crystalline with ODA, ODPA and NMP, adding a mixture into a three-neck boiling flask, stirring and reacting at 25 DEG C in the atmosphere of nitrogen for 24 hours to obtain a viscous PPA solution containing the sisal cellulose micro-crystalline; carrying out ultrasonic dispersion for 30 minutes and uniformly smearing the PPA solution containing the sisal cellulose micro-crystalline on a horizontal mold, and then putting the mold into the baking oven for carrying out thermal amination reaction; after the reaction is ended, naturally cooling the baking oven to a room temperature, taking out the mold and separating a film, namely the polyimide / sisal cellulose micro-crystalline composite material. The method disclosed by the invention is simple in operation and easy for large-scale popularizationand application; in addition, the prepared polyimide / sisal cellulose micro-crystalline composite material has the advantages of excellent tensile modulus and heat resistance and certain shape memoryproperties.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

Polyester based on full biomass monomer, preparation method and application

The invention discloses polyester based on a full biomass monomer, a preparation method and an application, and belongs to the field of polyester synthesis. Polyester takes 2,5-dimethoxy dimethyl terephthalate with a cyclic rigid group, and isosorbitol as raw materials, obtaining an ester exchange product through a catalytical ester exchange reaction, obtaining a polyester crude product through acatalytical polycondensation reaction, and performing solvent extraction, precipitant precipitation, filtration and drying to form target polyester. Synthesized polyester has the characteristics of high molecular weight, high heat performance, good mechanical properties and the like, and the characteristic of easy degradation in a natural soil environment as biobased polylactic acid. Polyester based on the full biomass monomer is mainly applied to preparing a bottle level polyester material.

Owner:GUANGDONG YUESHENGRI PLASTIC SCI & TECH CO LTD

Para-type wholly aromatic copolyamide drawn fiber and production method therefor

ActiveCN104350190AExcellent tensile modulusHigh tensile strengthMonocomponent copolyamides artificial filamentWet spinning methodsFiberPolyamide

Provided is a para-type wholly aromatic copolyamide drawn fiber of which the tensile modulus of elasticity is 630 cN / dtex or higher. The drawn fiber is obtained by carrying out high-tension thermal drawing of a para-type wholly aromatic copolyamide fiber raw material within a specified tension and temperature range.

Owner:TEIJIN LTD

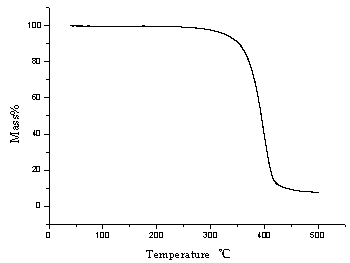

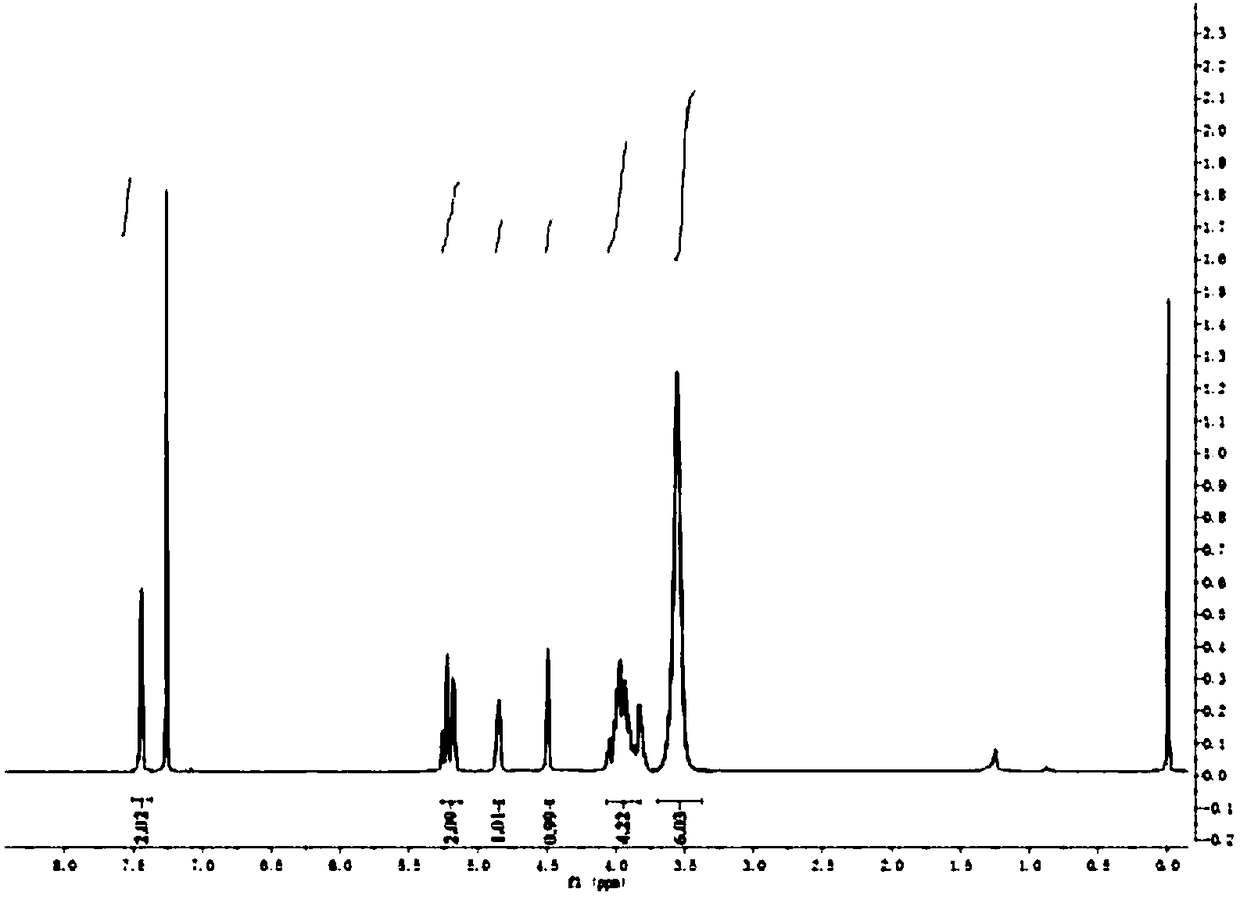

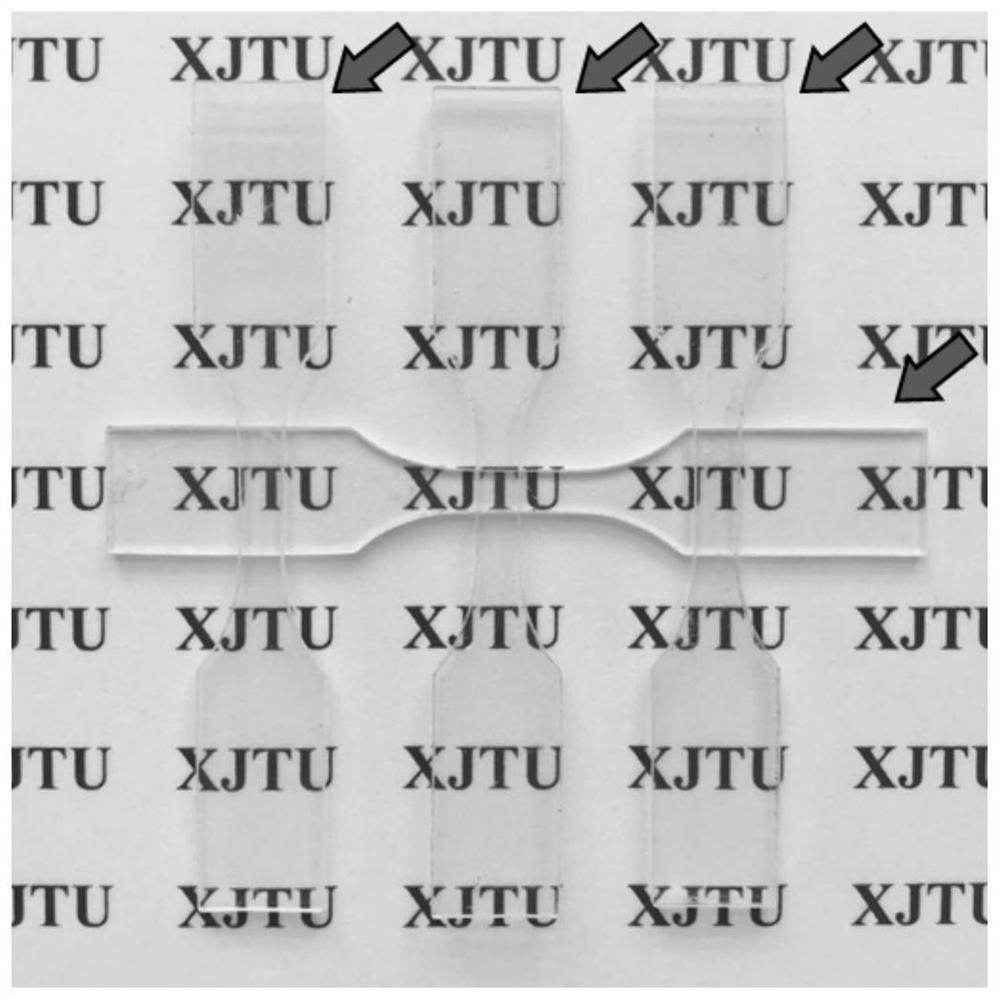

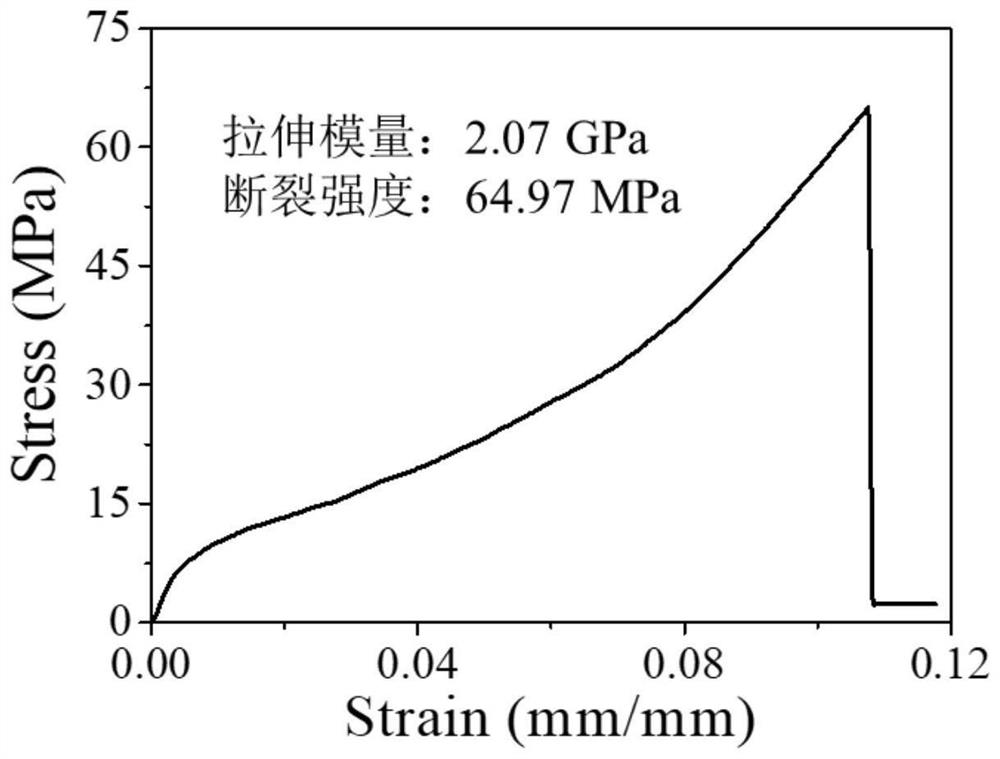

Methods for synthesizing, recycling and reprocessing recyclable shape memory thermosetting resin

The invention discloses methods for synthesizing, recycling and reprocessing recyclable shape memory polythiourethane thermosetting resin. The polythiourethane thermosetting resin is mainly prepared from mercaptan and isocyanate as main raw materials, and the recycling reprocessing is realized by utilizing the dynamics of thiocarbamate bonds in the polythiourethane thermosetting resin. The synthesis method comprises the following steps: uniformly mixing mercaptan, isocyanate and a catalyst according to a certain molar ratio, and conducting reacting at room temperature for 1-3 hours to obtain the high-strength colorless transparent shape memory polythiourethane thermosetting resin. The recycling and reprocessing method comprises the following steps: putting the prepared polythiourethane material into chloroform, adding excessive mercaptan to dissolve the material to form a transparent and uniform solution, then adding isocyanate for reaction to form a gel, and conducting crushing, drying and hot-pressing to realize recycling and reprocessing of the material, or subjecting the prepared polythionocarbamate material to crushing and hot pressing, so as to achieve material recycling andreprocessing.

Owner:XI AN JIAOTONG UNIV

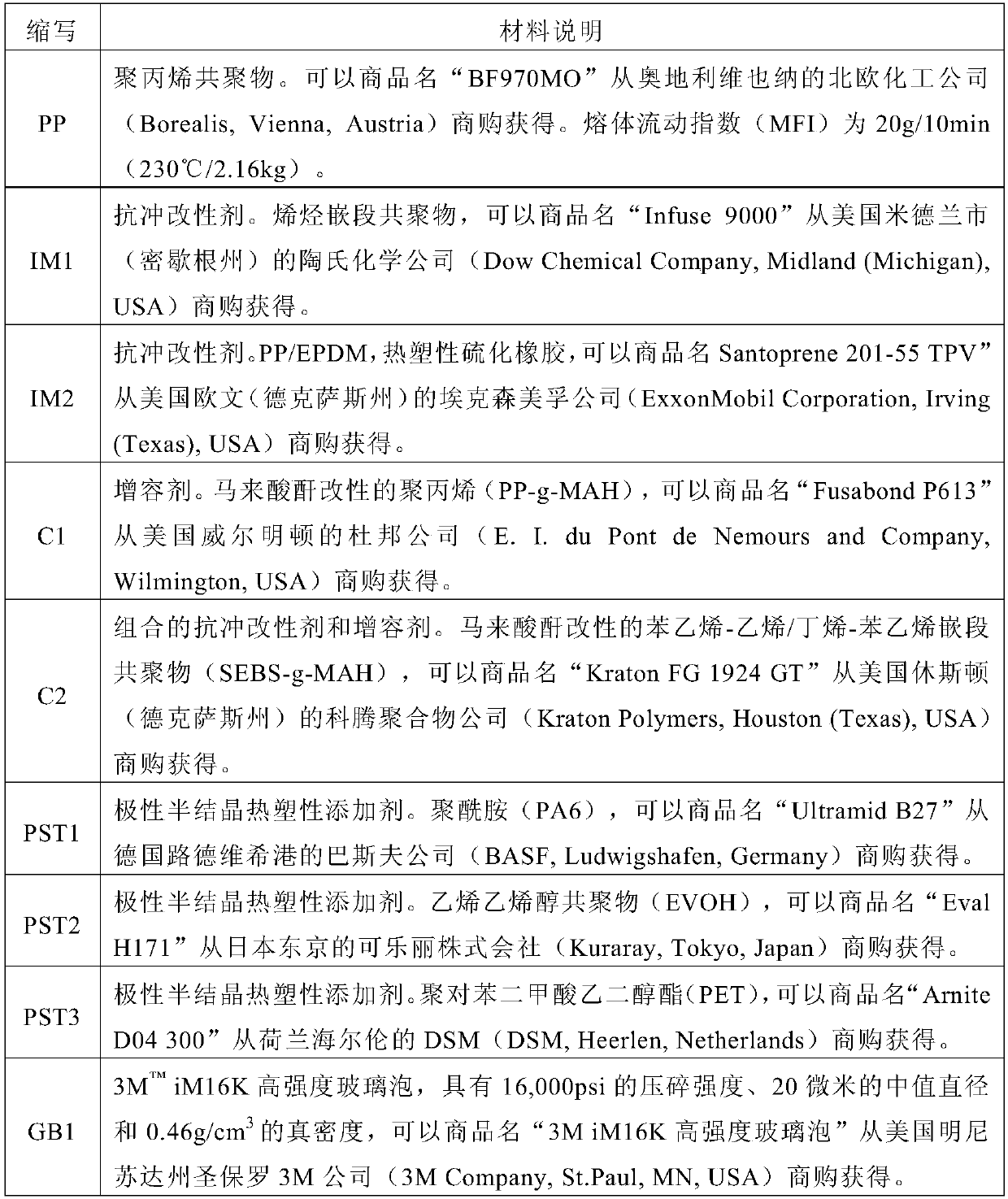

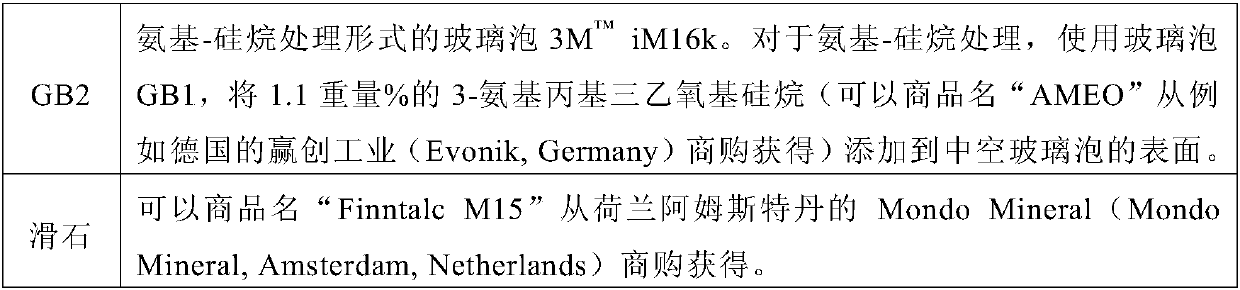

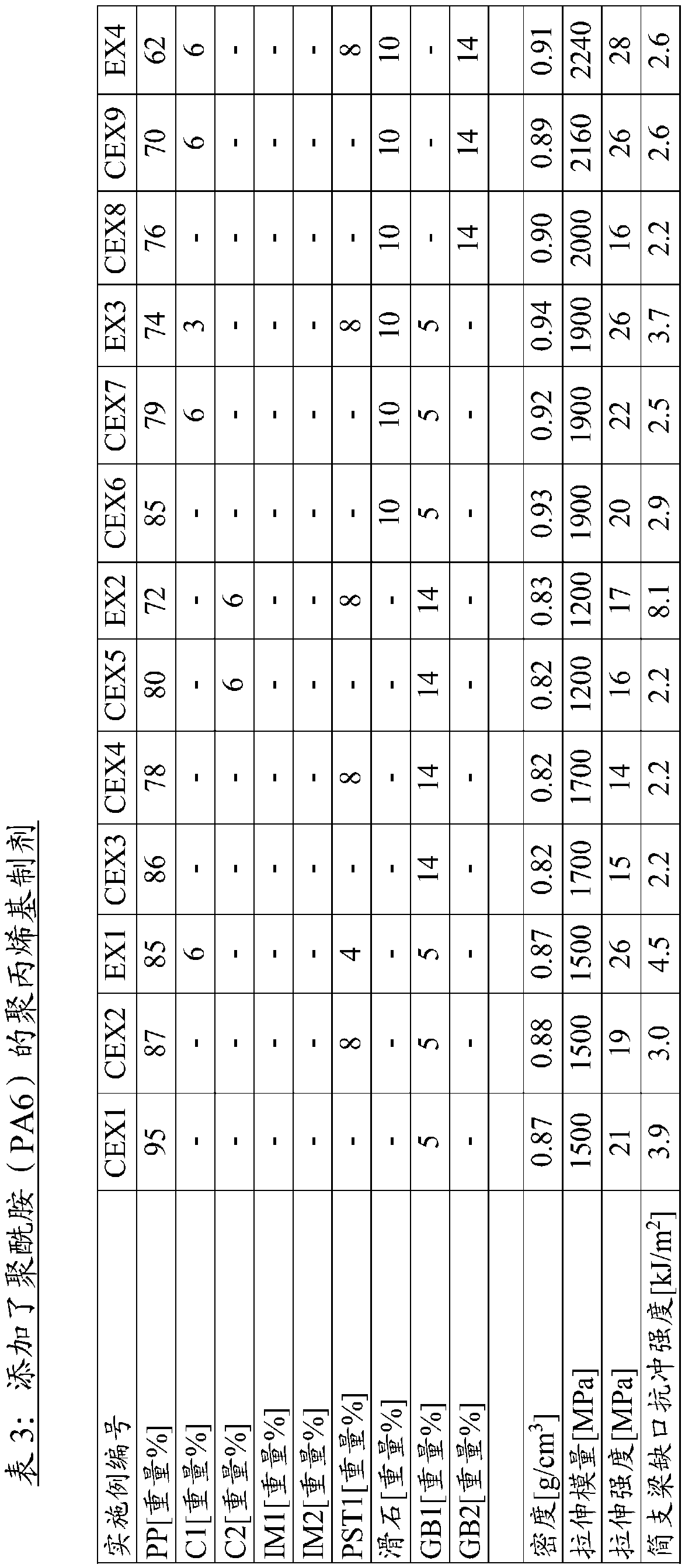

Polyolefin composition comprising hollow glass microspheres

The invention relates to a composition that includes a polyolefin, hollow glass microspheres, a polar semicrystalline thermoplastic additive, and at least one of an impact modifier or a compatibilizer. Articles made from the composition, a method of making such an article by melt processing the composition, and the use of the composition are also disclosed.

Owner:3M INNOVATIVE PROPERTIES CO

PE (poly ethylene) protection film material for automobile and preparation method thereof

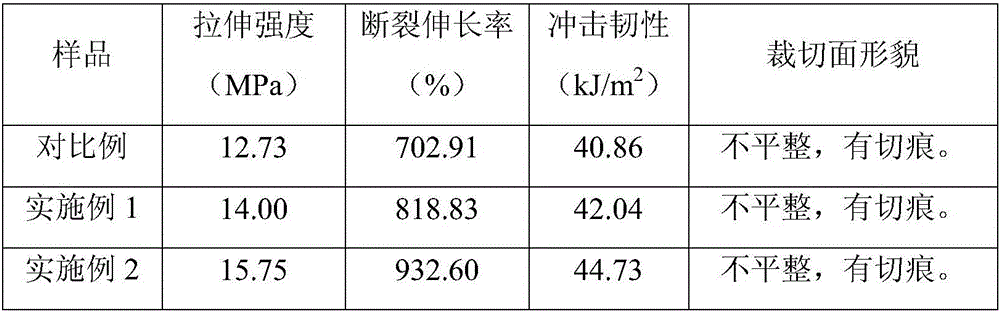

The invention relates to a PE protective film material for automobiles and a preparation method thereof. According to parts by mass, the components include: 100 parts of polyethylene PE, 10-30 parts of filler, and 1-5 parts of plasticizer. The preparation method includes: (1) weighing each raw material in proportion, melt extruding and granulating; (2) putting PE pellets into a twin-screw extruder, melting and mixing at 160-170°C, and stretching to form a film , and then apply the cross-linked acrylic resin adhesive to one side of the PE protective film, then pass the protective film through the air heating channel, and finally rewind and cut it. The invention significantly improves the tensile strength, reduces the toughness to a certain extent, further eliminates the phenomenon of burrs on the edge of the film caused by the uneven cutting surface, and effectively reduces the manufacturing cost of PE protective film products for automobiles, and has good application prospects.

Owner:宁波卓胜新材料有限公司

High-performance starch-based carbon fiber and preparation method thereof

InactiveCN107502998AHigh tensile strengthExcellent tensile modulusOrganic chemistryConjugated synthetic polymer artificial filamentsCarbon fibersParaffin oils

The invention discloses a high-performance starch-based carbon fiber and a preparation method thereof. The starch-based carbon fiber is prepared from the following raw materials in parts by weight: 50-80 parts of starch, 5-10 parts of paraffin, 1-3 parts of dehydration catalyst, cross-linking 3-8 parts of agent, 0.01-0.03 parts of biological enzyme, 10-20 parts of polyacrylonitrile, 5-10 parts of vinyl silicone oil; by introducing silicon atoms into starch-based carbon fibers, a small amount of carbon-silicon bonds are formed, so that starch-based Adjacent carbon atoms in carbon fibers are bonded by silicon atoms, which increases the force between carbon atoms, significantly improves the tensile strength and tensile modulus of starch-based carbon fibers, and is conducive to starch-based carbon fibers replacing polyacrylonitrile ( PAN)-based carbon fiber, pitch-based carbon fiber and viscose-based carbon fiber are popularized and applied in more fields.

Owner:DEYANG LIJIU YUNZHI KNOWLEDGE PROPERTY OPERATIONS CO LTD

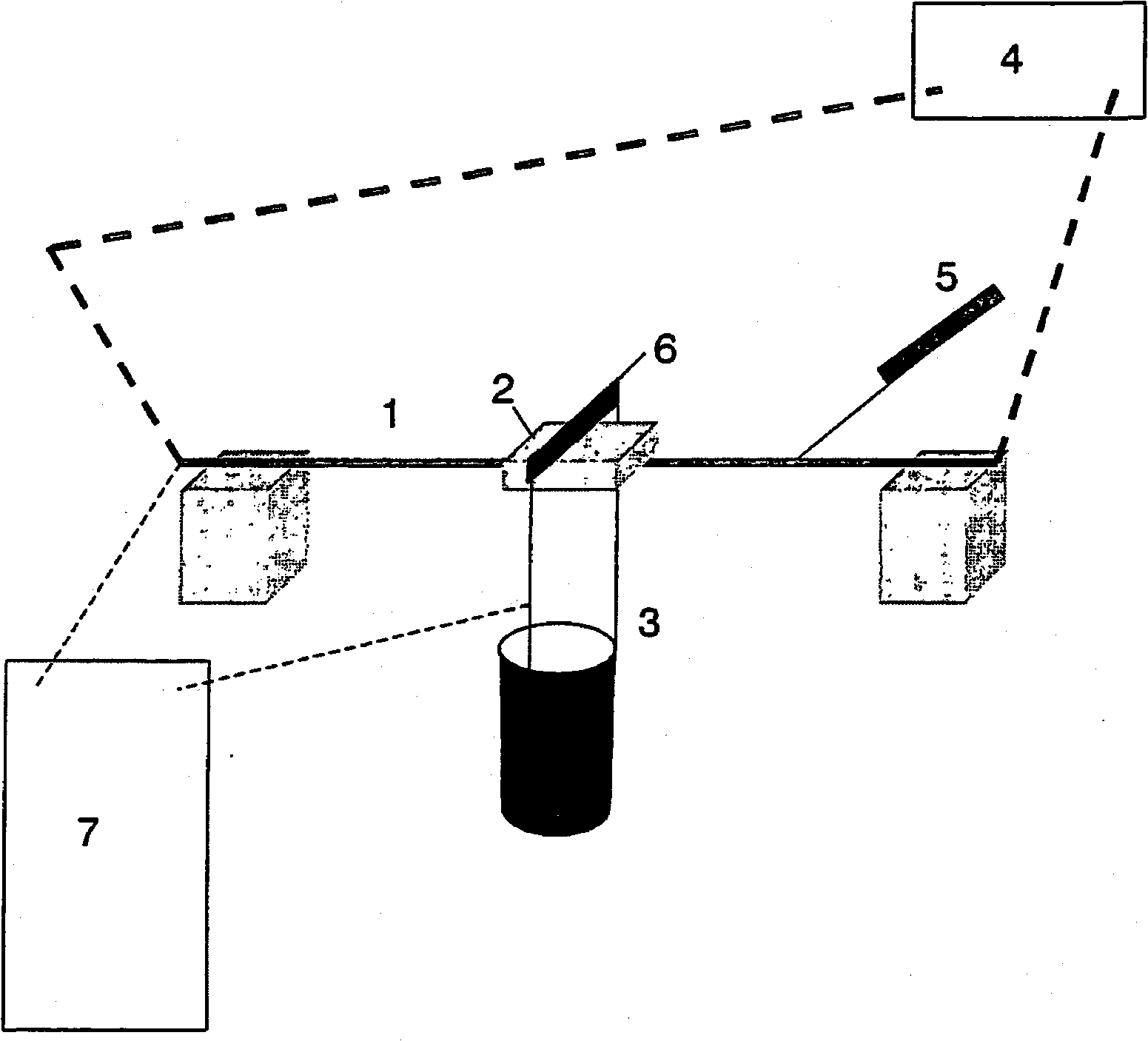

Method and device for producing a fiber composite material

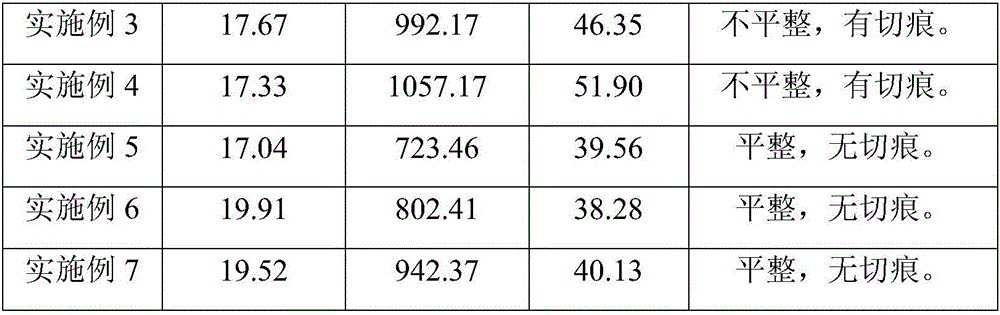

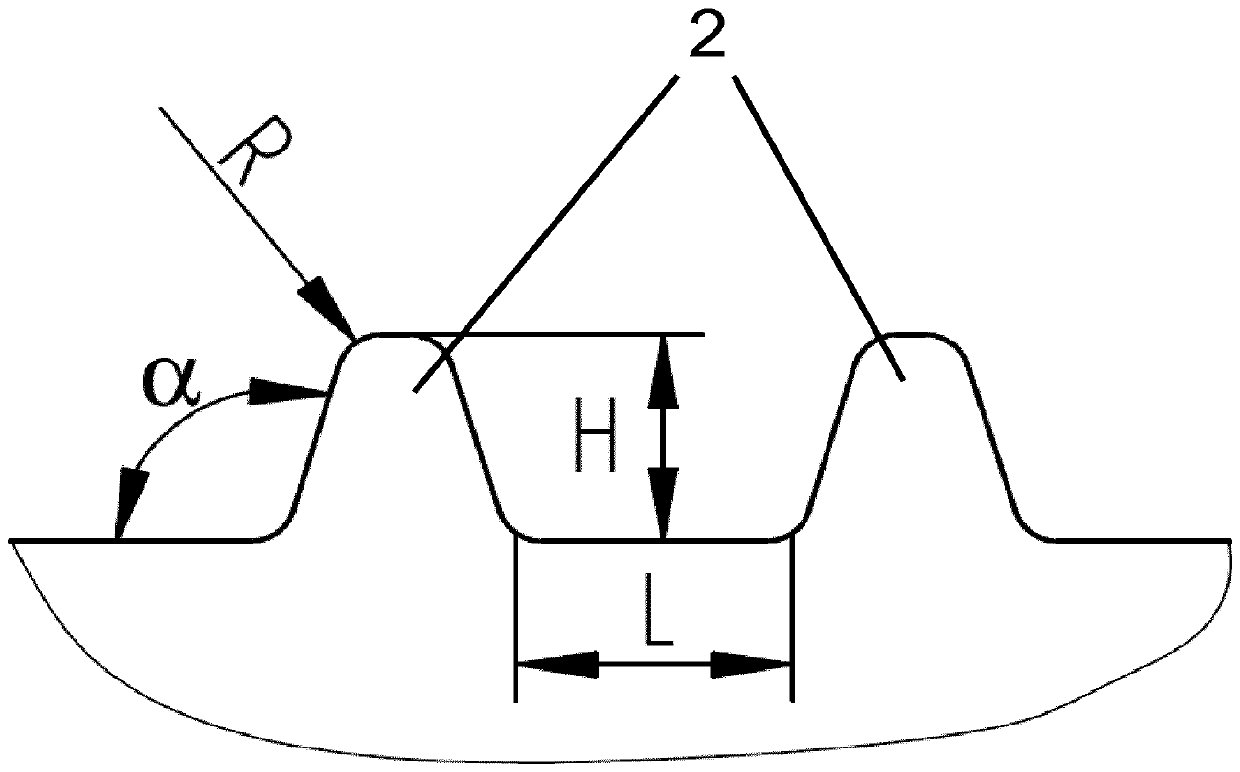

The invention relates to a method for producing a fiber composite material, comprising the following steps: a) a fiber bundle is guided over at least one deflection rod (1), which has radially peripheral rounded elevations (2), and said fiber bundle is thereby expanded; b) the expanded fiber bundle is subsequently drawn into an impregnation chamber; c) a melt is applied onto the expanded fiber bundle; d) the fiber bundle impregnated with melt is pulled through a draw-off nozzle at the tool end. The invention is characterized that a very good impregnation quality is achieved by said method anda corresponding device.

Owner:EVONIK OPERATIONS GMBH

Resin composition and application thereof

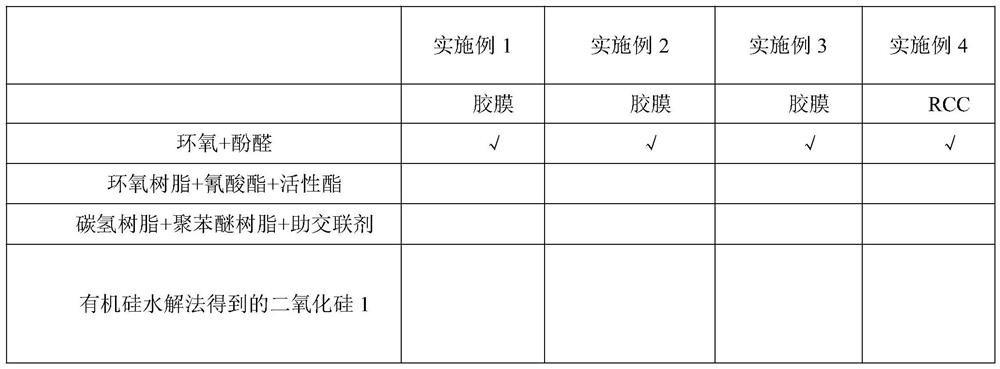

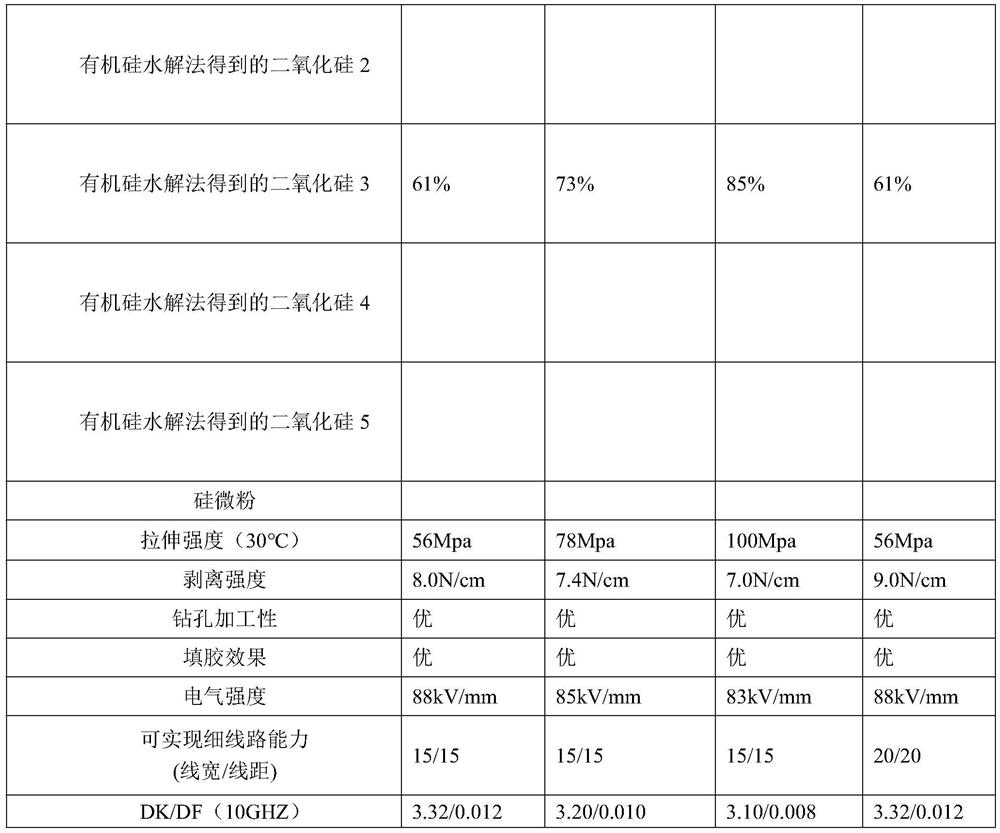

ActiveCN113604182AImprove particle size uniformityImprove uniformityMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceCopper foil

The invention provides a resin composition and an application thereof. The resin composition comprises the following components in percentage by weight: 15-39% of crosslinkable and curable resin and 61-85% of filler; and the filler is silicon dioxide prepared by an organic silicon hydrolysis method, the average particle size D50 of the silicon dioxide is 0.1-3 microns, the ratio of D100 to D10 is less than or equal to 2.5, and the purity of the silicon dioxide is greater than 99.9%. According to the resin composition disclosed by the invention, a prepared adhesive film and a resin-coated copper foil have relatively high tensile strength and peel strength, relatively good drilling processability, controllable flowability, good adhesive filling capability and relatively high electrical strength, can realize finer circuit processing capability, and are a printed circuit board material capable of being applied to a multi-layer laminated board, particularly a printed circuit board material of a multilayer laminated board with fine lines.

Owner:GUANGDONG SHENGYI SCI TECH

Glass fiber reinforced plastic for fishing rod and preparation method thereof

The invention provides glass fiber reinforced plastic for a fishing rod and a preparation method thereof, and relates to the technical field of glass reinforced products, and the glass fiber reinforced plastic is prepared from the following raw materials in parts by weight: 8 to 10 parts of glass fiber, 3 to 5 parts of nano-kaolin, 5 to 7 parts of white carbon black, 3 to 6 parts of carbon black,5 to 10 parts of gamma-glycidoxypropyltrimethoxysilane, 10 to 15 parts of polyimide resin, 3 to 5 parts of dopamine, 5 to 7 parts of nano-boron nitride, 6 to 9 parts of polylactic acid, 14 to 21 partsof polycarbonate, 1 to 1.5 parts of polyaluminosiloxane, 1 to 2 parts of nickel aluminide, 1 to 3 parts of chromium carbide, 15 to 17 parts of ABS resin, 4 to 6 parts of sulfur, 1 to 3 parts of nanotitanium dioxide, 4 to 6 parts of polyethylene wax, 5 to 7 parts of zinc stearate, 8 to 10 parts of a solubilizing agent and 2 to 3 parts of an initiator. The preparation method of the glass fiber reinforced plastic includes three steps. The glass fiber reinforced plastic for the fishing rod has the advantages of corrosion resistance, weather resistance, toughness, scratch resistance and flame retardancy. The glass fiber reinforced plastic has higher rigidity and bending strength, is not easy to break during use, and has long service life.

Owner:班戈设备系统(苏州)有限公司

High molecular weight polyester based on biomass as monomer, preparation method and use thereof

The present invention discloses a high molecular weight polyester based on biomass as a monomer, a preparation method and a use thereof, and belongs to the field of polyester synthesis. A monomer of 2,5-dimethoxyterephthalate dimethyl ester and diol, and a catalyst are heated to 120 DEG C-180 DEG C under a protection of nitrogen for atmospheric pressure transesterification for 2 h-4 h to obtain atransesterification product; the transesterification product is heated to 220 DEG C to 250 DEG C under a high vacuum of less than 20 Pa for a polycondensation reaction for 2 h-4 h to obtain a polyester crude product; and finally, solvent extraction, precipitant precipitation, filtration, and drying are carried out to obtain the target product: high molecular weight polyester. The polyester obtained by the method has a weight-average molecular weight (Mw) value of 110,000-150,000 Da, and a molecular weight distribution Mw / Mn value of 1.7-2.2. The synthesized polyester has a high molecular weight, a high heat performance, good mechanical properties and other characteristics. The prepared high molecular weight polyester based on the biomass can be used as a main component of bottle-level polyester material processing and can also be used as a component raw material for preparation of other polyester processing materials.

Owner:临沂斯科瑞聚氨酯材料有限公司

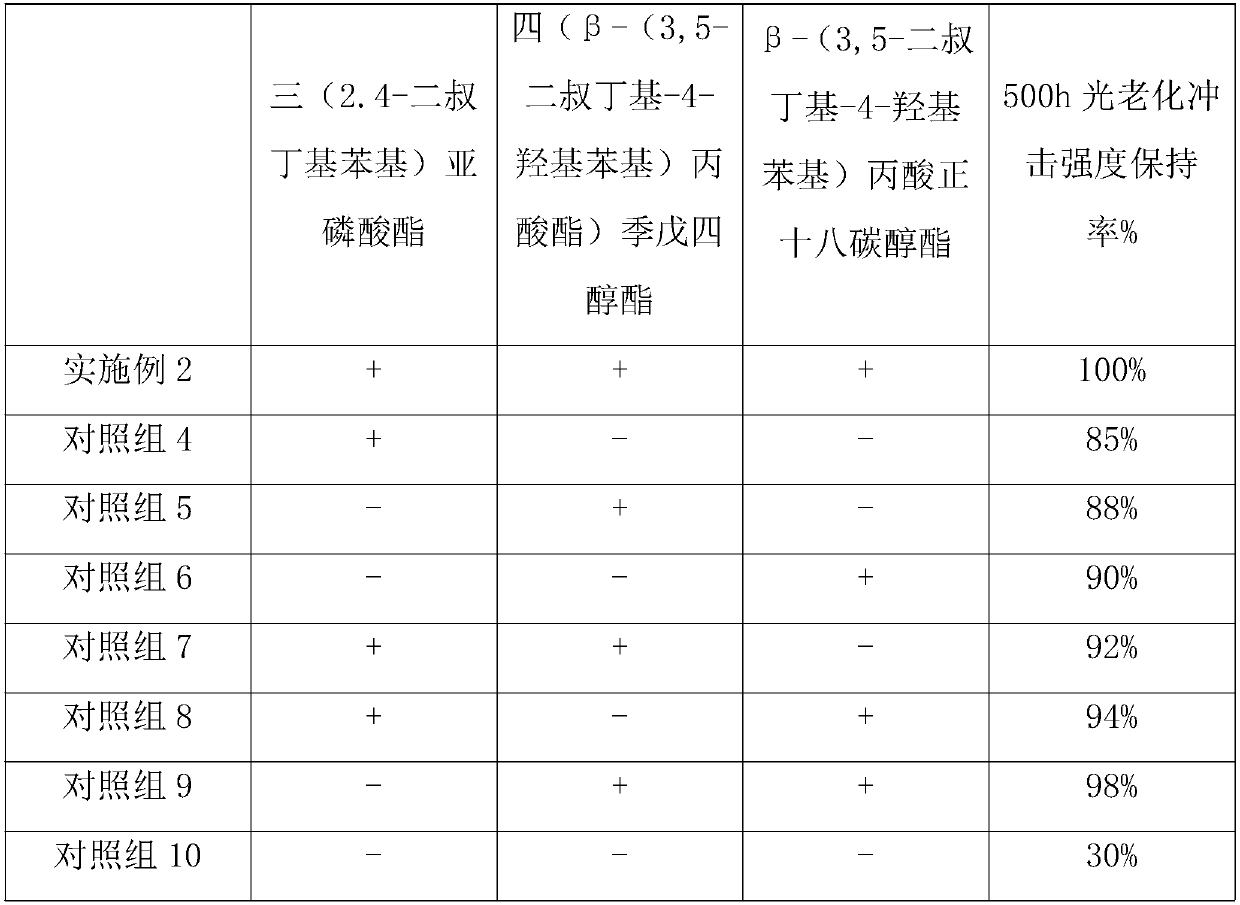

Inhaul cable sheath and preparation method thereof

InactiveCN107603035AReduce volatilityImprove antioxidant capacityFlexible shaftsZinc compoundsCarbon fibers

The invention relates to the technical field of inhaul cables, in particular to an inhaul cable sheath and a preparation method thereof. A sheath component is a section of half tube body which is provided with a draw pin and a mortise at two joint parts respectively. The inhaul cable sheath is characterized in that the sheath component is prepared from the following raw materials in parts by mass:10 to 20 parts of modified rubber, 6 to 12 parts of cyclodextrin, 5 to 8 parts of antioxidant, 3.6 to 6.4 parts of anti-ultraviolet agent, 1.2 to 3.6 parts of magnesium borate whisker, 1.2 to 3.6 parts of carbon nanofibres, 6 to 12 parts of vaseline, 2.4 to 4.8 parts of tourmaline particles, 1.6 to 3.2 parts of silicon carbide, 0.8 to 2.4 parts of diethylene glycol dibenzoate, 1.2 to 3 parts of nano titanium dioxide, 0.8 to 1.6 parts of calcium / zinc compound stabilizer, 1.2 to 5 parts of rare earth and 2.4 to 6 parts of flaky additives. The inhaul cable sheath disclosed by the invention has the advantages of good tensile strength, elongation and tensile modulus due to the use of the modified rubber; in addition, the proportion of raw materials is reasonable and the production cost is low.

Owner:JIANGYIN JIANGSHI AUTO PARTS

Polyether polyamide resin composition

A polyether polyamide resin composition which contains 15-200 parts by mass of a filler with respect to 100 parts by mass of a polyether polyamide resin in which diamine constituting units are derived from a specific polyether diamine compound and xylylenediamine and dicarboxylic acid constituting units are derived from an α,ω-linear aliphatic dicarboxylic acid having 4-20 carbon atoms.

Owner:MITSUBISHI GAS CHEM CO INC

Processing technology of environment-friendly degradable packaging shell

The invention discloses a processing technology of an environment-friendly degradable packaging shell, and the environment-friendly degradable packaging shell comprises the following raw materials inparts by weight: 30-60 parts of modified kenaf fibers, 20-40 parts of thermosetting polylactic acid, 1-3 parts of maleic anhydride and 3-8 parts of glycerol triacetate. The preparation method comprises the following steps: preparing the modified kenaf fibers: reacting kenaf fiber with sodium hypochlorite for delignification, reacting with potassium hydroxide for removing hemicellulose, adding NaClO2, 2, 2, 6, 6-tetramethylpiperidine oxide and a sodium hypochlorite solution for oxidation, carrying out ultrasonic treatment on an obtained product and lactic acid to enable lactic acid in a water-based medium to react with hydroxyl on the surface of the fiber at high temperature and high pressure, polymerizing lactic acid and replacing hydrogen atoms on hydroxyl, so that cellulose is changed from hydrophilicity to hydrophobicity; therefore, the tensile modulus of the degradable packaging shell is increased, the tensile strength is improved, the elongation at break is better, and the impactstrength is effectively improved.

Owner:安徽天路新材料股份有限公司

Spun Yarn Comprising Carbon Staple Fibers and Method of Preparing the Same

ActiveUS20180057970A1Excellent tensile modulusImprove surface resistanceFibre mixingCombing machinesYarnFiber

Disclosed herein is spun yarn and a method of preparing the same. The spun yarn includes carbon staple fibers including about 97 wt % or more of carbon, and thermoplastic resin fibers. The spun yarn includes carbon staple fibers prepared from scrap generated during manufacture of carbon fiber-reinforced plastic products, and can have good mechanical properties and conductivity.

Owner:LOTTE CHEM CORP

Starch-based carbon fiber and preparation method thereof

InactiveCN107502999AFewer oxygen-containing groupsAvoid damageOrganic chemistryConjugated synthetic polymer artificial filamentsCross-linkFiber

The invention discloses a starch-based carbon fiber and a preparation method thereof. The method comprises sequentially performing starch degradation, isomerization, dehydration, cross-linking polymerization, spinning, first pre-oxidation, second pre-oxidation and carbonization, not only Minimize the oxygen-containing groups in the starch molecules, and use the step-by-step pre-oxidation method to reduce the damage of the gas to the fiber structure and reduce the porosity in the fiber, so as to ensure that the prepared starch-based carbon fiber has tensile strength and good tensile modulus.

Owner:DEYANG LIJIU YUNZHI KNOWLEDGE PROPERTY OPERATIONS CO LTD

Para-type wholly aromatic copolyamide drawn fiber and method for producing the same

ActiveUS20150087800A1Excellent tensile modulusHigh tensile strengthMonocomponent copolyamides artificial filamentWet spinning methodsFiberPolyamide

Provided is a para-type wholly aromatic copolyamide drawn fiber having a tensile elastic modulus of 630 cN / dtex or more. The fiber is obtained by subjecting a para-type wholly aromatic copolyamide raw material fiber to high-tension hot drawing under a tension and at a temperature within specific ranges.

Owner:TEIJIN LTD

Improved crosslinked polyvinyl chloride structural foam and preparation method thereof

ActiveCN101580573BSimple manufacturing process controlWide operating range of parametersFoaming agentPolyvinyl chloride

Owner:CHANGZHOU TIANSHENG NEW MATERIALS CO LTD

Carbon fiber and method for producing same

ActiveCN112368432AExcellent tensile modulusExcellent formabilityMonocomponent synthetic polymer artificial filamentPolymer scienceFiber bundle

The present invention addresses the problem of providing a carbon fiber for a carbon fiber reinforced composite material which is not easily damaged during a molding process and exhibits an excellentelastic modulus. The carbon fiber has a strand elastic modulus of at least 360 GPa, a strand strength of at least 3.5 GPa, and a single fiber diameter of at least 6.0 [mu]m, and satisfies one or moreof the requirements below. (A) When one end is a fixed end and the other end is a free end that can rotate about the axis of a fiber bundle, the remaining twist number is at least 2 turns / m. (B) The total fineness, which is the product of the single fiber fineness (g / km) as a carbon fiber and the number of filaments (counts), is at least 740 g / km. In addition, the single fiber elastic modulus Es (Gpa) and the loop breaking load A (N) of the carbon fiber satisfy the relationship of expression (1). (1): A>=-0.0017*Es+1.02. Furthermore, the single fiber diameter of the carbon fiber is at least 6.0 [mu]m, the relationship between the strand elastic modulus E (GPa) of the carbon fiber and the knot strength B (MPa) of the carbon fiber as evaluated at a heating loss rate of 0.15% or less at 450 DEG C satisfies expression (2), and the twist number of the carbon fiber is 20-80 turns / m. (2): B>= 6.7*109*E-2.85.

Owner:TORAY IND INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com