Reactive compatibilized bamboo fiber/polylactic acid composite material and preparation method thereof

A technology of reactive compatibilization and composite materials, applied in the field of fiber reinforced resin composite materials, can solve the problems of high energy consumption and increased material preparation cost, and achieve the effect of excellent tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

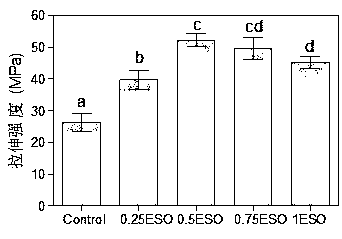

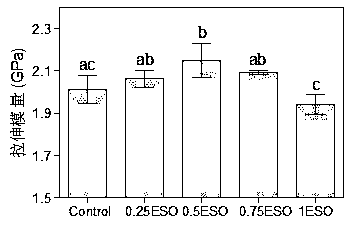

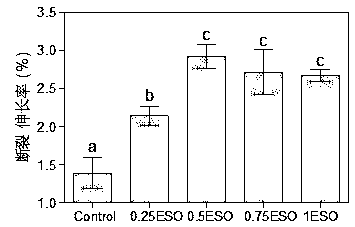

[0022] Reactive compatibilized bamboo fiber / PLA composite material: prepared from vegetable oil prepolymer, bamboo fiber and polylactic acid at a mass ratio of 0.25:20:79.75.

[0023] The preparation process of the vegetable oil prepolymer is as follows: 0.5 g of epoxy soybean oil and 0.01 g of cationic initiator boron trifluoride ethylamine complex are dissolved in 20 g of acetone and magnetically stirred for 5 minutes to form a vegetable oil prepolymer mixture; The mass ratio of cationic initiator and epoxidized soybean oil in the polymer is 0.02:1.

[0024] The preparation method of the composite material: spray the vegetable oil prepolymer on the surface of 40g of bamboo fiber and place it in an oven to dry for 4h at 80°C to remove acetone; mix the dried bamboo fiber coated with the vegetable oil prepolymer with 159.5g of polylactic acid After stirring evenly, add it to the feeding port of the twin-screw kneader, so that the mixture passes through the twin-screw kneader at...

Embodiment 2

[0026] Reactive compatibilized bamboo fiber / PLA composite material: It is prepared from vegetable oil prepolymer, bamboo fiber and polylactic acid at a mass ratio of 0.5:20:79.5.

[0027] The preparation process of the vegetable oil prepolymer is as follows: 1.0 g of epoxy soybean oil and 0.02 g of cationic initiator boron trifluoride ethylamine complex are dissolved in 20 g of acetone and magnetically stirred for 5 minutes to form a vegetable oil prepolymer mixture; The mass ratio of cationic initiator and epoxidized soybean oil in the polymer is 0.02:1.

[0028] The preparation method of the composite material: spray the vegetable oil prepolymer on the surface of 40g of bamboo fiber and place it in an oven to dry at 80°C for 4h to remove acetone; mix and stir the dried bamboo fiber coated with the vegetable oil prepolymer and 159g of polylactic acid After uniformity, it is added to the feed port of the twin-screw mixer, so that the mixture passes through the twin-screw mixer...

Embodiment 3

[0030] Reactive compatibilized bamboo fiber / PLA composite material: It is prepared from vegetable oil prepolymer, bamboo fiber and polylactic acid at a mass ratio of 0.75:20:79.25.

[0031] The preparation process of the vegetable oil prepolymer is as follows: 1.5 g of epoxy soybean oil and 0.03 g of cationic initiator boron trifluoride ethylamine complex are dissolved in 20 g of acetone and magnetically stirred for 5 minutes to form a vegetable oil prepolymer mixture; The mass ratio of cationic initiator and epoxidized soybean oil in the polymer is 0.02:1.

[0032]The preparation method of the composite material: spray the vegetable oil prepolymer on the surface of 40g of bamboo fiber and place it in an oven to dry at 80°C for 4h to remove acetone; mix the dried bamboo fiber coated with the vegetable oil prepolymer with 158.5g of polylactic acid After stirring evenly, add it to the feeding port of the twin-screw mixer, so that the mixture passes through the twin-screw mixer a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com